What needs to be lubricated on a hammer drill?

Typically, maintenance of power tools is performed in the fall or spring, when a long vacation begins for the device or its preparation for the next season. To diagnose a power tool correctly, you must first figure out which parts on the hammer drill need to be lubricated. Structurally, a hammer drill is a complex device consisting of a number of the following elements:

- Body - the basis of the tool, inside which all the component parts are located

- An electric motor is the main unit that drives the tool’s executive element—the chuck. Motors in rotary hammers have a horizontal and vertical arrangement

- The piston system is an integral part of the gearbox, which is responsible for generating impact actions

- Chuck - has a special mechanism with quick fixation of working attachments

- A gearbox is a mechanism that transmits rotational movements from the electric motor shaft to the tool chuck. The design of the gearbox has a “drunk bearing”, which creates shock movements transmitted to the piston system

- A safety mechanism in the form of a clutch that limits the rotation of the chuck when the working attachment is jammed, thereby preventing overheating of the motor

- Working attachments are auxiliary elements that are installed in the design of the tool chuck

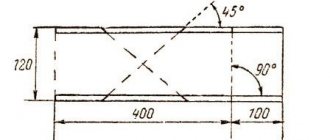

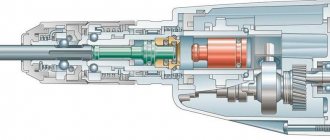

To imagine what a hammer drill consists of, below is a diagram of the structure of a power tool.

Knowing the design of the tool in question, you can figure out which parts of the hammer drill need lubrication. First of all, the rotary hammer requires lubrication of the gear unit, the main purpose of which is to regulate the rotation speed of the working nozzle fixed in the actuator (chuck). When the tool is operating, the gears experience high mechanical loads, which increases friction. Lack of lubricants leads to accelerated gear wear.

To increase the service life of the mechanism in question, you will need to regularly not only add lubricant to the gearbox design, but also first remove the remnants of old lubricants. Not many people know why obsolete hammer drill lubricant is removed. It must be removed in order to clean the metal particles and dust that are formed during the friction of the gears. If you do not clean out the old lubricant and apply new lubricants on top of it, then the effectiveness of such diagnostics will be zero.

This is interesting!

During the production process of gears, an increase in metal dust occurs, which negatively affects the operation of parts, since it increases the friction force, which means increased heating and accelerated wear.

The gearbox or transmission mechanism in the hammer drill is lubricated from the factory, but the lubricant must be changed every year with daily use of the unit. In addition to the gearbox, the tool also requires lubrication: the chuck and the seat of the installed attachment - the drill (tail part). From the factory, the cartridge (its internal part) is not lubricated, so the owner of the tool needs to worry about this if there is a desire to use the unit for a long time. In addition to the inside of the hammer drill chuck, the shank of the installed attachments also needs lubrication.

The design of the unit also includes plain bearings. They are also subject to heavy loads, so to increase their service life, when carrying out diagnostic procedures, it is necessary to add lubricants to the bearing structure.

This is interesting!

Few people know, but to improve the performance of the tool, another unit of the tool also needs lubrication - the commutator unit.

How to properly lubricate a hammer drill

Lubrication of the hammer drill plays an important role among other procedures associated with the periodic maintenance of this tool. This preventive measure should be carried out after the time specified in the instructions for use. Timely replacement of lubricant reduces friction in the device components, slows down the wear of parts, thereby extending its service life. It should be borne in mind that the old lubricant must be removed when adding a new one. Hammer drill lubricant is produced by different manufacturers. At the same time, various types are intended for its individual nodes.

What parts in a hammer drill need lubrication?

In order to properly maintain a rotary hammer, you need to know which parts to lubricate and how often. This mechanism has a rather complex structure. It consists of the following main components:

housings with vibration protection; an electric motor having a vertical or horizontal arrangement; piston system; cartridge; a gearbox made in the form of a housing (crankcase), inside of which worm, bevel, and cylindrical gears are located; a safety clutch designed to stop the rotation (if the nozzle gets jammed during operation) of the chuck; working attachment (drill, blades, chisels, crowns or peaks).

The schematic structure of the hammer drill is shown in the photograph below.

A gearbox is a unit responsible for regulating the speed of the working nozzle. Its closed design is designed to protect the parts located inside from dust, dirt and possible mechanical damage. During operation of the tool, the gears experience significant loads, and the friction between them increases significantly. This leads to an increase in their wear rate.

We recommend: Types and sizes of profiles for drywall - how to install

As a rule, for various models of tools, the gearbox comes lubricated from the factory. But during operation, the metal of the parts is destroyed. As a result, metal dust is formed, which, when mixed with lubricant, leads to an increase in friction force (therefore, to accelerated wear). Timely replacement of the lubricant helps slow down the destruction process.

It should also be taken into account that often cheap models are lubricated rather poorly or with material of dubious quality. It is recommended to re-coat them immediately after purchase.

In addition to the transmission mechanism, the cartridge and the seat of the inserted replacement nozzle should be treated with lubricant. The first one is delivered dry. Only the area in direct contact with the shank of the nozzle is coated with it: in this place, strong friction occurs during operation of the tool. If it is not reduced, this leads to increased wear of the cartridge, even to the point of severe damage. Also, the tail part of the nozzle quickly wears out and can be deformed under the influence of impact forces during strong heating, which is caused by friction.

How often should you lubricate the tool?

The nozzle shanks should be lubricated at each installation, after wiping off any dust or other contaminants . If the work is carried out intensively, then you need to visually monitor the degree of lubrication of the seat of the nozzle used.

The hammer drill works with different intensity for different users: some use it every day, while others use it only occasionally. Therefore, there is no clear answer about the regularity of applying or replacing lubricant. To determine the need to change the lubricant in general, you need to focus on the following:

intensity of tool use; recommendations set out on this issue in the instructions for the hammer drill; warranty period.

The most complete recommendations from manufacturers regarding lubrication of tool components are contained in the operating instructions. Parts not listed there do not need lubrication.

Features of selecting lubricant for gearbox, drill, chuck

A lubricant is a substance designed to reduce the friction force between parts interacting with each other. Of course, some friction remains, and during use of the tool, the contacting structural elements continue to wear out. But in the presence of lubrication, the process slows down significantly compared to dry friction.

Lubricants are synthetic, mineral and semi-synthetic. The second type is made from oil. It quickly loses its performance characteristics and needs to be changed more often.

The main parameter of lubricant products is the degree of its viscosity. Manufacturers of rotary hammers, in their operating instructions, recommend using a lubricant with a certain value for this characteristic to care for their tools.

Each brand of lubricant has its own technical characteristics that should be taken into account when choosing. To lubricate the gears, chuck, and nozzle shank, only types of compounds suitable for processing these parts are used.

Thus, the material used to reduce friction in the gearbox is not used to lubricate drills.

To lubricate the hammer drill transmission mechanism, it is recommended to use gear oil. It is poured through a special hole in the housing in the amount required by the instructions. At the same time, it covers interacting parts, filling the crankcase. Hammer drill oil should be of liquid consistency.

Gear oil SX75W90 GL4 1L

The transmission mechanism is also lubricated with special plastic compounds. But you need to take into account that not all equipment is able to work normally when using substances with such a consistency. If the gear parts are (partially or completely) plastic, then it is possible to use silicone lubricant, for example: 220-R Silicone DBC or HVS-100 Silicone #3 from Huskey.

Silicone grease 220-R Silicone DBC

To reduce friction between the tail parts of the nozzles and the cartridges, you need to use compounds of a thick consistency, which indicate that they are intended directly for drills. If there are none, then you can use a graphite analogue. But it removes heat worse than a special composition. Thick varieties of silicone lubricants are also used for cartridges.

Lubricant can be used both branded (from manufacturers of hammer drills, for example, Hitachi, Metabo, AEG, Bosch, Bosch, Interskol, Zubr), and from companies involved in the production of lubricants (Xado, Ravenol, Shell and others). The most popular companies with a popular range of products are presented in the table below.

| Company manufacturer | Suitable range | Purpose of the lubricant |

| Bosch | 3605430008, 1615430012 | hammer oils |

| 1615430005 | gear oil | |

| 1615430010, 1615430009 | for nozzle shanks | |

| 1615437512, 1615430014, 1615437511, 1615430015, 1615437509, 1615430019, 1615430016 | hammer drill lubricants in various packaging | |

| Makita | 181573-3 | for the Boers |

| 042024-0A | SDS+ tool gearboxes | |

| 183477-5, 042005-4A | SDS+ devices | |

| P-08361 | tool reducers SDS MAX | |

| Lubcon | Thermoplex ALN 250 EP | gear lube |

| Thermoplex ALN 1002 | for rotary hammers | |

| Turmogrease NM 4602/0 | universal composition | |

| Nanotek | MetalPlak Electra | processing of tail parts of nozzles |

| Metabo | 631800000 | lubrication of drills |

| Bison | Bison expert 60 | processing of nozzle shanks |

| Bison expert 125 | ||

| Bison ZSB | ||

| Interskol | v9000327 and v9001698 | lubrication of drills |

| PRORAB | 0125 | plastic composition intended for processing the tail parts of nozzles |

| Kress | 98035301 | lubrication of drills |

| different manufacturers | Litol-24, Litol-24 LUX | for lubrication of transmission mechanism and equipment |

Bosch and Makita gear oils are most popular among consumers.

Bosch grease 3605430008

When using a tool whose quality is confirmed by a special certificate, you should use only lubricants of brands specified by the manufacturer of the device. The use of other materials will result in loss of the possibility of warranty repairs and maintenance of the hammer drill.

Some may have a question: is litol suitable for lubricating a hammer drill? It is due to the fact that this lubricant, in terms of its characteristics, is inferior to specially developed compounds from well-known companies. Litol can be used, but it will need to be changed more often. The best lubricant option is the composition specified by the manufacturer. There will be no problems when using it, incl. with warranty service.

How to properly lubricate parts: algorithm of actions

Lubricating the drill tail and chuck with your own hands is very easy. It is enough to do the following:

Wipe the cartridge and the tail part of the drill with a rag to remove any contaminants on their surface (old grease, dust); Apply a suitable composition to the shank of the nozzle or add directly to the mounting socket.

You should constantly monitor the presence of lubricant, adding it if necessary. Neglecting this recommendation will lead to overheating of the drill and increased wear of the chuck. In this case, the shank may flatten or tear off from the working part of the nozzle.

If the tool is equipped with an open chuck, then after disassembling and cleaning it, you should lubricate the seals.

Regarding gearbox lubrication, things are a little more complicated. Most modern models are equipped with containers. After opening the lid, pour oil into them or add another suitable lubricant. The location of the required hole is often indicated in the instructions. It also contains a diagram for removing the cover. The whole process goes like this:

We recommend: How to make a snow shovel with your own hands?

remove the lid; drain the remnants of the old lubricant; blow out (for example, using a compressor) or flush the crankcase with gasoline; fill in new oil in the amount regulated by the operating instructions so that its level does not exceed the existing control mark; put the cap in place, closing the hole.

If the tool is under warranty, then only the recommended oil should be used. When there is no special hole to fill it in, you will need to disassemble the hammer drill. If warranty service is valid, it is recommended to contact the service center specialists about this.

Sequence of lubrication of the gearbox with disassembly of the hammer drill

If the warranty period for the hammer drill has expired, then you can do all the work of lubricating the gearbox yourself. You will need the following tools and materials:

locksmith set (screwdrivers with different bits, hex keys, pliers, etc.); clean rags; petrol; appropriate type of lubricant according to the instructions.

Lubricate the hammer drill gearbox by performing the necessary actions according to the following algorithm:

study the operating instructions for the device model used; clean the housing from dust, as well as from other existing contaminants; then proceed to disassemble the cartridge: using a screwdriver, remove the rubber and locking rings (as shown in the photographs below);

Rubber ring

Retaining ring

remove the cartridge casing; remove the pressure ring; remove the spring, as well as the balls;

remove the mode switch (this is done in different ways for different models); Having unscrewed the screws with a screwdriver or hexagon, disassemble the rear part of the housing to disconnect the brushes from the commutator;

disassemble the front part of the case: unscrew the screws that tighten it longitudinally;

remove the gearbox together with the electric motor shaft;

wash the removed parts and the device body from the inside to remove old grease using a rag soaked in gasoline; wipe them with a dry cloth and let them dry; lubricate the gearbox completely, as shown in the photographs below;

Lubricated elements of the transmission mechanism

Fully coated gearbox

assemble the hammer drill.

A preliminary study of the instructions is necessary not only to learn how to use the tool correctly, but also to familiarize yourself with the diagram of its disassembly and assembly.

Additional recommendations

When carrying out independent lubrication of the transmission unit, you need to take into account these recommendations.

You need to remember the exact location of the parts and fasteners to be removed so that everything is installed in its place during assembly and no unnecessary spare parts are left behind. The tool should be disassembled to lubricate the gearbox only when it has completely cooled down after work. It is not necessary to apply the compound to non-lubricated structural elements. The best option is to use branded lubricant compositions designed specifically for the brand of equipment used. It is advisable to inspect the disassembled gearbox for defects in gears (wear, missing teeth, cracks) and other elements - this will help to replace parts in time and avoid big problems in the future.

Taking photographs of the entire process of disassembling the rotary hammer will help to reassemble it correctly.

Modern rotary hammers are quite easy to maintain. Lubrication of their working units does not take much time. The main thing in this case is to use the composition recommended in the instructions or suitable for its intended purpose (or universal). During complete disassembly of equipment, you need to work as carefully and carefully as possible in order to obtain a high-quality result. You should also observe safety precautions when lubricating a tool that is disconnected from the power supply.

Source: Tehnika.expert

1

Lubricant for hammer drills - why is it needed?

Lubricant for rotary hammer drills, its gearbox and other elements is not much different from any other lubricant in its external characteristics. This is an oily, viscous substance, the purpose of which is to reduce the coefficient of friction of the moving structural parts of the drill. It is very important to understand that the presence of lubricant can only reduce the wear of mechanisms, and not completely eliminate it. Over time, the lubricant becomes quite saturated with dust released during crushing and drilling, which changes the viscosity of the lubricant. As a result, the level of wear increases even more if the old lubricant is not updated in a timely manner.

Lubricant, like any oily, viscous substance, helps reduce wear on mechanisms

One of the main parameters when choosing a lubricant is its viscosity. High-quality products have high prices, but saving here is not recommended. The hammer drill itself belongs to the category of quite expensive devices, so it is necessary to take care of its condition so that it fully works out the funds invested in it.

We recommend

Do-it-yourself drill sharpenerWhen you can drillDo-it-yourself power supply for an 18V screwdriver - how to extend the life of the tool

Why do you need to apply lubricant?

A rotary hammer is a mechanism that contains many moving parts that are subject to heavy loads. To understand why a hammer drill needs lubrication, let’s look at the purpose of lubricants. Lubricants are added to the design of the unit for the following purposes:

- Reduce friction. By reducing friction, the service life of parts increases, so it is necessary to lubricate almost all moving components and mechanisms, except for the internal part of the electric motor (rotor or armature rotating inside the stator)

- Increase heat dissipation or increase heat dissipation. When parts rub, they heat up, which lubricants are designed to combat.

- Protection of the mechanism from the penetration of dust and moisture from the outside, as well as retention of metal dust and particles that form during friction

The presence of lubricant not only reduces friction of parts, but also increases the efficiency of mechanisms. It is the frequency of maintenance that determines how long a hammer drill can last.

This is interesting!

The cartridge and the tail of the nozzles need lubrication, which is done to reduce friction and also to reduce heat. Indeed, during the operation of the nozzle, the cartridge clamps come into contact with the tail part, which quickly heat up.

Lubricating the rotary hammer inside, how often should it be lubricated?

Most often it is necessary to lubricate the shanks of the attachments installed in the tool chuck. Moreover, these can be not only drills, but also other attachments - a lance, a chisel, a spatula. Before applying lubricant to the tail end of the tool, it will need to be wiped down initially to prevent small particles from getting into the inside of the tool chuck.

If you work with a hammer drill for a long time, then you need to lubricate the attachments every 3-4 hours of operation, which also depends on the type of work performed. Once a month you need to lubricate the cartridge structure. If you have to work with the unit every day for 10-12 hours, then you can lubricate the cartridge more often (once a week).

Depending on the frequency of use of the tool, the timing of the need for preventive measures differs. For example, if you use the device once a week or a month, then it makes no sense to disassemble it every year to add lubricant to the gearbox. With such rare use, lubricants can be added once every three years. If you use the device every day, then it is advisable to lubricate the gearbox and bearings at least once a year.

When answering the question of how often you need to lubricate a hammer drill, you should take into account the following factors:

- How often are power tools used?

- Read the instructions and find out how often the manufacturer recommends lubricating

- Warranty periods

Full recommendations on how often you need to apply lubricant for the hammer drill are indicated in the instructions. In any case, there is no need to add lubricants in the midst of construction work. You should wait until the end of the work or the arrival of cold weather, when the tool is used less often, and set aside one day for preventive maintenance.

Useful tips

Owners of drills and hammer drills often wonder about the frequency of lubrication. Determining the time frame is problematic, but on average, the optimal period for changing the oil is considered to be a period of 12 months if the tool is operated at medium intensity.

Lubrication of many modern devices has been greatly simplified thanks to the introduction of a number of useful improvements. For example, popular brands often make special holes in the equipment into which a lubricant is simply poured , and there is no need for its disassembly and subsequent reassembly.

Typically, such systems are designed very competently - in addition to holes for filling oil, there are also outlets through which spoiled lubricant is drained.

There are special marks on the surface of the device that directly indicate how much lubricant is needed to maintain the functional operation of the power tool.

The only thing that is required in this case is to blow out the hole as intensively as possible before use. To do this, you can use a compressor and then flush the hole with gasoline.

Lack of lubricant often becomes the main cause of serious malfunctions of the hammer drill. In crushing mode, the lubricant is wasted in a significant amount, and if there is too little lubricant on the gearbox or drill, this often causes overheating of the entire device.

At the same time, there is no need to be zealous - if too much oily composition is applied, the rotation speed of the drill will be reduced, and this will also worsen the performance of the tool as a whole. In addition, excess lubricant will end up on working surfaces that are difficult to clean.

To learn how to properly lubricate a rotary hammer, watch the following video.

How to lubricate the hammer drill gearbox and chuck correctly

Lubrication for the rotary hammer gearbox begins with the fact that you first need to disassemble the power tool to get to the device itself. You can start lubricating the gearbox immediately after the warranty period ends. To disassemble the device body, you will need to take the following tools and materials:

- Screwdriver Set

- Clean woven materials to remove old grease

- Gasoline or solvent

- Lubricant

When all the tools and materials are ready for work, you can begin to lubricate the hammer drill gearbox. Along with the gearbox, the tool chuck is also lubricated, since in order to remove the transmission mechanism, you will need to start the dismantling process from the actuator.

The sequence of lubricating the gearbox with disassembling the hammer drill is as follows:

- First, the body of the power tool must be cleaned of dust. This is necessary in order to prevent contaminants from entering the device.

- Prevention should begin with disassembling the cartridge. Using a screwdriver, remove the rubber and then the retaining ring (under the rubber).

- After this, remove the cartridge cover

- The pressure ring is removed

- The spring is removed along with the balls. The fixing part of the gearbox in the cartridge is disconnected, so we proceed to dismantling the transmission mechanism

- The tool body is disassembled. First, remove the rear part, which will allow you to disconnect the brush assembly from the electric motor commutator.

- After this, the front cover is removed

- The gearbox of the power tool is dismantled along with the shaft. To do this, the mode switch must be switched to the “jackhammer” mode. After this, the mode switch is removed, and then the gear unit is carefully removed

When the gearbox is removed from the body of the tool in question, we proceed to changing the lubricant, which is quite possible to do at home.

- You need to pour gasoline into a bowl-type container, then lower the mechanism and start washing it

- After thoroughly washing out the old grease, you need to wipe the device and let it dry. When washing with your own hands, you need to pay attention to the condition of the node. The presence of defects is unacceptable, therefore, if they are detected, you will need to either make a replacement or buy a new gearbox for the rotary hammer

- Using a lubricant (exclusively new), you should thoroughly lubricate the mechanism

- It is better to apply an exhaustive amount of lubricant than not enough.

- After this, you can begin assembling the mechanism

When installing a part, you need to follow the assembly sequence, which is the opposite of disassembly. This also requires lubricating the bearing units and internal parts of the cartridge after assembly. Subsequently, to lubricate the cartridge, it should not be disassembled, since the lubricant can be applied inside the hole into which the working attachments are installed.

This is interesting!

The design of the hammer drill is thought out in such a way that the device in question can be lubricated with your own hands. Lubricant for the hammer drill is applied only after the obsolete lubricant has been completely removed from the mechanism.

Lubricant for rotary hammer gearbox

Rotary hammer and its internal structure

A hammer drill is a tool that is familiar to almost everyone who has ever done home renovations.

Outwardly, it is very similar to a drill and the functions are the same, the production of holes. The difference between the tools is that a drill cuts into a hole using the sharpened edge of the drill, removing chips, while a hammer drill punches holes, as if with a chisel. Therefore, the power of a hammer drill is indicated in joules and is called impact energy. The tool is chosen based on this indicator, as well as on the power of the engine, if it is electric. To get a blow, you need an impulse that is created by an electric or pneumatic motor.

To properly use and maintain this tool, you need to at least superficially know its structure from the inside. Of course, many manufacturers have now mastered the production of this tool, but its general design has remained unchanged, with the exception of some modifications, since 1932, when the first power tool appeared. By the way, the first was a pneumatic hammer drill, which was invented specifically for work in mines in 1851.

Internal design of the hammer drill

The tool, as shown in the figure, consists of an electric motor (if it is electric), a gearbox, which, together with a safety clutch, regulates the speed and impulse, an impact mechanism and a quick-release chuck of the SDS max or Plus system. The gearbox contains gears, which must be lubricated for good trouble-free operation. The set of bearings in the impact device also need lubrication.

The remaining devices that are located in the hammer drill are called additional. This is an operating mode switch, a mechanism for fixing the power button, reverse, as well as devices such as anti-vibration, dust removal during operation, fixing the depth of work, adapters for the chuck and others - they may or may not be present. This depends on the model and manufacturer.

We recommend: Screwdriver bits - how to choose the right ones and which ones are better

Rotary hammer maintenance

Like every tool, a hammer drill needs proper care.

The tool is not cheap, therefore, timely maintenance will allow your tool to last for many years. Moreover, a hammer drill requires this more often than any other tool. Remember under what conditions this tool works. Dust, vibration, the nozzle bites into concrete or brick with a reciprocating motion.

As stated above, the internal parts of the gearbox need lubrication to prevent friction between them. At the same time, lubricating them once is not enough. Dust particles enter the oil through technological holes, and the oil itself becomes different, while the dust in it becomes like an abrasive, which helps to quickly wear out parts. Therefore, in order for the tool to remain in working condition longer, it must be periodically inspected and the lubricant changed.

Therefore, when purchasing equipment, you must carefully read the technical documentation, which must indicate which lubricant is preferable to use and how often to perform maintenance.

If the hammer drill was purchased through a dealer network or in a store that has the appropriate certificate, for the duration of the warranty you must use the lubricants specified in the documentation. You can also carry out maintenance at one of our network of service centers.

A technical inspection is necessary in cases where the tool suddenly smells of burnt rubber, unstable operation or short circuits, as well as the appearance of unusual sounds. This will be a reason to immediately contact a warranty workshop or inspect the equipment yourself.

At the end of the warranty period, you can choose to either continue to use this branded lubricant or buy cheaper analogues.

If you bought a tool made in China, which does not initially mean that it will break right away, depending on your luck, but it may not have a warranty from technical service centers either. Therefore, you immediately need to be prepared to maintain and select lubricants yourself.

Features of gearbox lubrication

Each tool has its own design differences that distinguish the tool of one company from the tool of a competitor company.

Therefore, before starting work, especially if you are doing it for the first time, be sure to prepare the operating instructions, lubricant and a sufficient amount of dry, clean rags.

First of all, after the instrument has cooled down well, you need to thoroughly remove dust from the instrument. Then we check the lubricant container and change the lubricant, filling it to the level indicated on it. There is no need to overdo it. By the way, the bearings and the cartridge, which is open, also need to be lubricated.

You can read how to disassemble the cartridge and lubricate it in another article; this process is not complicated.

It should be noted that the grease for drills and for the gearbox are completely different and are not interchangeable.

I would also like to note that disassembling and lubricating the gearbox in a hammer drill is not difficult. It will be difficult to assemble it later without loss. Therefore, you need to start work provided that you have some experience in such work.

If you had to disassemble the gearbox yourself, you need to lay them out in the order of disassembly on a clean workbench and remember the order of disassembly.

After disassembly, all parts should be carefully laid out on a flat surface.

Disassembly begins with the cartridge, then the housing is disassembled and the wires from the starter are disconnected and the brush holder is removed, and carefully.

Now let's move directly to the gearbox. The body itself is installed in a vertical position in a vice and is disassembled, carefully laying out the parts one by one. As a matter of course, next to it there should be a diagram from the device’s passport indicating all the details. Can be downloaded from the Internet.

When disassembling, you need to pay attention to the fact that not all parts need to be lubricated; some of them are not lubricated at all according to their design.

But still , all parts must be cleaned of dust. If the part cannot be cleaned, it must be replaced.

Sometimes breakdowns occur such as breakdown of the windings either in the armature or in the stator or quite frequent wear of the brushes. This mainly happens due to the same dust that gets inside, even if you use a special vacuum cleaner.

After disassembly, all parts of both the gearbox and the hammer drill itself must be washed. Use gasoline, kerosene or spindle oil. Then thoroughly wipe the parts and the body itself with a dry and clean cloth. After which everything should dry, there is no need to rush to collect it right away. Then you need to lubricate all lubricated parts and replace parts that have failed. There is no need to add extra oil. We assemble everything in reverse order.

How to lubricate the chuck and drill bit of a hammer drill

The simplest action is to lubricate the tail part of the attachments installed in the structure of the power tool. The principle of applying lubricant to the shank of the drill and other attachments is as follows:

- To begin with, the shank of the nozzle must be wiped, removing dirt from the recesses, if any.

- Apply a suitable lubricant to the drill tail. To lubricate the working element, add the substance directly to the seat

- In order for the lubricant to reach all parts of the cartridge, it must be added until it begins to release from the mounting hole. To press it in, it is better to use a syringe with a thin tube.

- The substance on the drill shank should be thoroughly spread over the entire shank

This is interesting!

The lubricant for the hammer drills and the chuck must be of the same type. If you neglect the recommendations for adding lubricant to the design of a hammer drill or drill, this will cause accelerated wear of the executive body and the working attachment.

At this point, the process of adding lubricants is considered complete, and it must be repeated as often as possible, which depends on the duration of operation of the unit.

How to lubricate the barrel perforator gearbox

The gearbox on a rotary hammer is the second largest component, the serviceability of which determines the effectiveness of the tool. Modern professional models of barrel perforators are equipped with special containers that are designed for adding lubricant. Special liquid oils are poured into these containers (crankcase), which envelop the transmission mechanism during operation.

To fill oil, there is a special hole in the housing design (usually in the upper part of the tool), the location of which is indicated by the manufacturer. The principle of changing gearbox oil in such devices is much simpler, and is based on the following steps:

- The lid is removed, depending on the manufacturer

- Remains of old lubricant are removed

- The crankcase is being purged or flushed with gasoline.

- New oil is refilled in the amount recommended by the manufacturer

- The cover is installed in place, and you can continue to use the tool.

Only the recommended oil should be poured into such hammer drills. Another advantage of such hammer drills is that they do not require you to wait until the warranty period expires in order to disassemble the body and apply lubricant. However, there is also a drawback to such devices, which is manifested in the following factors:

- Expensive

- The need to regularly monitor the amount of lubricant and top up and replace it

- It is not possible to lubricate the plain bearings at the same time, since to access them you will need to disassemble the housing

How to process parts

We begin the impregnation procedure by rinsing and cleaning the device, and then wiping it dry. And only then do we apply a protective agent. Do not lubricate parts that do not require sliding. After all, it could damage him. In particular, the transition coupling does not require such attention.

In the case when the cartridge is open in the electric machine, then the oil seal can be repaired by the transmission. Just don’t apply too much ointment to these places. It is advisable to do this work before each assembly of the nozzle. After removing it, be sure to wipe off any dust from the shank.

Don't miss: How to remove a chuck from a drill (keyless and keyless)

How to lubricate a rotary hammer gearbox or what are the requirements for lubricants

Many tool owners ask whether it is possible to lubricate the rotary hammer gearbox with conventional lubricants, such as Solidol or Litol-24. To answer this question, let’s look at the requirements for lubricants for rotary hammer gearboxes.

- Adhesion - and its value must be so high that an oil film is created under any type of load

- Resistance to moisture - you have to work with a hammer drill not only in dry and warm rooms, so their use in places with high humidity or in the cold contributes to the formation of moisture. Hammer drill lubricant must provide resistance to moisture penetration

- When water gets inside the instrument, it should not form an emulsion - the moisture should be repelled

- During operation, rubbing parts heat up to high temperatures, which often leads to dilution of lubricants. This is normal for all types of lubricants; only gear substances should restore their properties when cooled

- When the gears rotate, the lubricant should not be scattered over the inner surface of the housing, otherwise after an hour of working with the tool, the transmission unit will need to be re-lubricated

- Prevents the penetration of dust and small particles into the tool gears

- Possess anti-corrosion properties suitable for metals such as aluminum and alloy steel

Based on the above requirements, we can conclude that Litol and Solidol are far from the best options for lubricating the rotary hammer gearbox. For this tool, it is better to buy special lubricants that meet all of the above requirements. It is these lubricants that not only help to increase the service life of the transmission unit, but are also capable of providing reliable protection of the mechanism for a long time.

We service the operation of the regulator

By its design, this is the most complex unit of the device and therefore requires special attention. Retouching the gearbox of the device is not difficult.

But it will be difficult to assemble a pre-disassembled unit yourself. In addition, if the power tool has a warranty, then it is easier to contact a special workshop, which is obliged to provide warranty service for the equipment.

If your impact machine is not covered by the warranty or the established requirements for the equipment have passed, or maybe the service center is far away, then you can lubricate the necessary elements yourself. At the same time, try to show concentration, accuracy, and you will also need:

- Set of locksmith tools. Using them, you can assemble and disassemble the impact machine regulator;

- Rag;

- The content itself is for carrying out lubricant products.

During disassembly, pay attention to all spare parts. Some of them do not have transmission content. Not all of them are processed. Therefore, there is no need for lubrication. When disassembling the parts, remember their order of arrangement.

In order to know how to lubricate the rotary hammer gearbox, try to use compounds similar to liquid oil. Fill a certain volume into the filler necks specially made for this purpose. This way, the regulator body will fill with oil and be safely sealed from the inside thanks to the caps installed on the holes and bolts.

During operation, all parts are coated evenly with this component. It must be remembered that after performing operations with an electric drill, you cannot disassemble the gearbox and immediately lubricate the hammer drill inside. After all, the still hot elements of the regulator, when cold lubricant gets on them, can lose their physical characteristics.

After its constituent parts have been removed from the body, they must be washed with gasoline or technical oil and wiped dry. Wash the outside of the regulator cover, wipe it and let it dry completely.

The most famous manufacturers of oil for lubricating this mechanism are the famous brands “Bosch” and “Makita”. For example, it is worth mentioning two types of popular products from the mentioned manufacturers, which are used in the assembly or repair of impact machines:

- anti-adhesive “Makita P-08361” 30 ml;

- ointment "Bosch 1615430005" 45 ml.

Don't miss: Hammer drills - how to choose

Such motor compounds are water-resistant and thereby protect the parts of the electric drill from moisture and rust. After lubricating all the parts, carefully reassemble the gearbox in reverse order. Do not forget that containing too much anti-adhesive products can negatively affect its performance.

After all, it can get very hot. The problem is not always with the oil. If you use the chiselling work for a long time, then its contents do not reach all the spare parts of the tool in the required quantity. The cause may also be clogged cooling holes of the impact machine. To do this, you need to clean the device from dust.

Expert opinion

Victor Budaev

Specialist

You should know it! For the current hammer drill with a complex gearbox, cream lubricant is suitable. Please also keep in mind that not all types of it can constantly work with compositions of this texture. Transmission material for the regulator is a must have for every owner of this tool. If the device is under warranty, then it is advisable to use the services of a service center.

Lubricants for gearbox, chuck, drill and brushes

Now let’s figure out how to lubricate a rotary hammer, and what substances are best used for power tools. Lubricants are different, but they have one main purpose - to reduce friction. It is impossible to completely eliminate friction, but it is necessary to reduce its value in order to extend the service life of the entire tool. As the load on the gearbox increases, the engine begins to suffer, which also begins to operate in overload mode.

Lubricants for hammer drills come in the following types: synthetic, mineral and semi-synthetic. Each type of oil has its own advantages and disadvantages, so we will look in detail at what is best to use to lubricate the hammer drill components. It is recommended to use special gear oil for the gearbox. This is the kind of oil that needs to be poured into a special hole, which is found on modern professional hammer drills.

If there is no special hole for filling liquid oil, as on pistol hammer drills, then special plastic or viscous compounds are used for them. However, it is important to take into account that plastic compositions are used exclusively for metal parts and assemblies. If the design of the tool has plastic parts, then it is better to use silicone fluids for lubrication.

For drills and tool chucks, thick consistencies are used, which have a special designation indicating that they are intended for drills. If it is impossible to find such substances, then it is recommended to use graphite compounds. You can also use silicone lubricants in a thick consistency, which are also used to lubricate cartridges and drill shanks.

To lubricate bearings, it is recommended to use lubricants such as Solidol or Litol-24. The difference between them is that Litol is able to withstand much higher temperatures than Solidol, so of these options it is definitely better to give preference to Litol.

To lubricate the manifold assembly, it is recommended to use silicone lubricant in liquid form. It lubricates the brush assembly, which reduces not only friction, but also improves contact. The result will be noticeable immediately, as sparking will decrease and the service life of the brushes will increase.

Which manufacturers produce lubricant for hammer drills?

To choose the right lubricant for a hammer drill, you will need to pay attention to models that have a note stating that the mixture is intended for the gearbox of a power tool. You can then choose the appropriate consistency based on cost. However, expensive lubricants are not always good, since in most cases buyers have to overpay just for the brand.

When choosing, you can give preference to lubricants from manufacturers such as Bosch, Makita, Lubcon and AEG. When purchasing substances from these manufacturers, you also need to consider one important factor - compatibility with specific models of power tools. It is worth noting another type of lubricant, ULTRA-0 - a semi-liquid substance that, when heated, turns into a liquid state. This type of lubricant is suitable for crankcase sealed and non-sealed gearboxes.

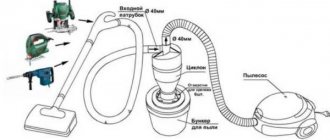

Similar types of lubricants can also be used for other types of power tools, for example, drills, screwdrivers, jigsaws. Not only the service life of the tool, but also its performance depends on the quality of the preventive maintenance carried out. Working with a device that regularly undergoes cleaning, lubrication and replacement of failed parts is not only pleasant, but also convenient, since the owner can always be sure that the unit will not let you down. Take care of your instrument as you would take care of yourself, and it will serve you faithfully, even regardless of who its manufacturer is - China or Europe.

Choosing a lubricant

In the process of processing a specific brand of electric drill, advice from the manufacturer of this equipment, which is indicated in the technical document with a specified service life, will help. He will definitely indicate the required type and replacement period for the selected model. A consultant in the store can give specific recommendations.

Don't miss: Choose a hammer drill for your home: types, parameters, power

Sometimes owners do not use branded contents for coating, but more inexpensive analogues. It can be lithol or grease. Although they do not harm the elements of the electric machine, they should be replaced much more often.

An inexpensive and universal retouching would be the oil used to fill diesel engines. For successful coating of devices, compounds are used, and its basis is graphite.

Useful and very interesting articles about sawing tools.