A rotary hammer is one of the heavy-duty household tools. The impact reciprocating mechanism is a separate discussion; in our material we will look at an equally important unit: the gearbox.

It works hard in any mode: drilling, perforation drilling, impact mode. Maintenance and lubrication of the rotary hammer gearbox is a mandatory procedure and is performed regularly using high-quality consumables.

Moreover, this is not just anti-friction oil; each manufacturer of power tools includes certain characteristics in the composition, they must correspond to operating conditions.

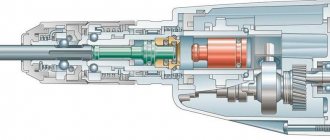

How does the gearbox (transmission mechanism) of a hammer drill work?

To understand the importance of selecting consumables, let’s consider the structure of this loaded unit.

The mechanism can be made in two versions:

- The hammer drill gearbox is separate, the reciprocating mechanism is separate. The piston group has its own lubricant; the gears of the transmission unit do not come into contact with it.

- The hammer drill is implemented using a ratchet design. In this case, the gearbox and impact mechanism are one whole. Accordingly, they have the same lubricant.

The transmission unit itself consists of a pair of gears (with a standard layout). A planetary layout is possible, in which case there will be more gears. The teeth can be straight or oblique (if the mechanism is designed for heavy loads).

Using a gearbox, the gear ratio is changed:

- the rotary hammer spindle shaft rotates at a lower speed relative to the motor rotor;

- Accordingly, the torque on the chuck increases in proportion to the decrease in speed.

In this way, two problems are solved: mechanical traction increases and speed decreases, for better control of drilling.

Why do you need to lubricate the transmission unit?

No matter how strong the metal of the gears is, the friction of the teeth against each other inevitably leads to wear.

In addition, in the absence of anti-friction lubricant, the gears become very hot during operation, and the so-called “tempering” of the hardened steel occurs - the metal loses its hardness. After this, rapid wear and even breakage of the teeth occurs.

In addition to standard loads (when gears engage during rotation), the teeth can move in the longitudinal, axial plane. This happens when the hammer drill is designed using a ratchet design.

The small gear, together with the movable shaft, moves back and forth relative to the large one. Accordingly, the lubricant should ensure unhindered sliding.

In addition, the gearbox shafts rest on bearings. If they are not sealed (with their own lubricant embedded), the same composition is used (all mechanics in one housing).

There are many greases that are used both on cars and “heavy” mechanisms, and in household (professional) electrical appliances. However, a conscientious user of an electrical appliance tries not to use universal compounds.

So, how to lubricate the gearbox to minimize its wear?

You must understand that power tools are sold ready to use. This means that the transmission unit of a new rotary hammer contains the right amount of oil, and it is “correct”.

Tool owners also know about the need to constantly lubricate the shanks of the working attachments. Grease for these purposes is almost always included in the tool kit.

Important, as an example!

The lubricant for the Makita rotary hammer gearbox, and the composition of the same brand marked “for drills,” are fundamentally different from each other. Consumables for the gearbox are marked with the generally accepted designation in the form of two gears.

However, not all manufacturers generously equip their tools with lubricants. Sooner or later, the owner has a question: what lubricant to use for a hammer drill?

Since universal lubricants (for example, Litol-24) are not always suitable for these tasks, it makes sense to look for trademarks of power tool manufacturers.

For example, lubricant for the Bosch rotary hammer gearbox is also suitable for other models. Elementary logic: if mechanical components operate under similar conditions, then the lubrication requirements are the same.

Just one point needs to be taken into account: the hammer drill mechanism must be exactly the same as that of the Bosch tool for which this lubricant is intended.

Installation of electric brushes

Remove dirt from the grooves of the brush holder and install the brushes in place, securing them with the latches.

Now is the time to check the performance of the hammer drill. Connect the plug of the hammer drill to the socket, turn on the hammer briefly in the “drilling” mode. Once you are sure the tool is working, turn it off. Set the mode switch to the “impact” position. Do not insert the tool. Check the functionality of the hammer drill in this position. At the same time, you checked the operation of the mode switch.

All that remains is to check the placement of the speed control button, make sure the contact connections are secure, and you can begin installing the cover.

Installing the cover

The cover is secured with three M×4 self-tapping screws of different lengths.

Connect the hammer drill to the 220Β network and check in all modes. The Makita 2450 or 2470 rotary hammer is assembled and working properly!

A professional, as he is also called, must take care of the tools he uses in the activities of his company. For this reason, the operating time of the equipment directly depends. Power tools require high-quality lubrication. This will protect components and mechanisms from wear. With all this, the work will be significantly more effective.

Read also: How to weld a water pipe using electric welding

Therefore, lubrication for a hammer drill is very important. It must be selected in accordance with the features of the equipment model. For each brand, a lubricant with certain technical features is developed. The different additives included in the composition provide very different properties of similar products. Therefore, it must be selected in accordance with the operating criteria of the hammer drill.

More than 150 years have passed since the removal of all additional parts since, back in 1851, a manual hammer drill . It was made for the needs of the mining industry and did not have the variety of modes that modern models currently have. But even then he significantly improved the work of workers. It is not without reason that this type of instrument has become widespread among craftsmen of various specializations.

Since then, the instrument has undergone significant design changes. One thing remains constant. the need for proper care. The device of the hammer drill is quite complex. Some of its parts can wear out quickly.

To prevent this from happening, lubricant

for a hammer drill it must have a number of properties. With the development of the presented power tool, its additional materials were also improved. To understand how to choose a lubricant, you need to consider the design features of the equipment.

You will prefer an electric mechanism, which is also called pneumatic, that is capable of producing the required effect on the material. The hammer drill has 2 main features. They are related to motor power and impact force.

The more than just the indicator in Watts and Joules, the stronger the instrument. Electrical and pneumatic types of equipment have different designs. Therefore, what kind of lubricant is used for each type of hammer drill will depend on the operating mechanism of their devices.

The electric type of tool consists of a coil, a core and a drill. These are the elements that need lubrication. The pneumatic mechanism has a cylinder and piston, a drill and a striker. They significantly influence the weight of the hammer drill.

Lubricant for rotary hammers from Makita, Hitachi and a huge number of other manufacturers performs the functions required of it. First, it flows around the necessary parts of the mechanism, preventing friction of their surfaces against each other. With all this, their wear is correspondingly reduced.

Such substances have additional additives that prevent corrosion. The second most important feature is the washing function. During operation of the equipment, small particles of material and dust will naturally enter the tool. They settle on the mechanism and lead to its wear.

Lubrication

collects this dirt and debris and keeps it in suspension. When a lot of contaminants accumulate here, the substance needs to be changed. There are mineral, synthetic and semi-synthetic lubricants. The cheapest substances are made based on oil. These are mineral varieties. They quickly lose their characteristics and require frequent replacement.

Synthetic lubricants are expensive, but the quality of this brand is the highest. They do not need to be changed frequently; they provide very good protection of the mechanism from wear.

Medium-priced semi-synthetic oils. They have better properties than mineral varieties. And they are not quite as good as synthetic materials.

Types of lubricants for gearboxes

Liquid lubricant

Similar to regular car motor oil. It is used in hammer drills with a hermetically sealed gear housing. The rotating shafts in such devices are sealed with oil seals, with the help of which the oil is retained inside.

Lubrication is carried out through special holes, which are then tightly closed. The system is very effective because gears and other elements subject to friction are evenly coated with an antifriction compound.

In addition, the working fluid acts as a heat sink and helps cool the gearbox by coming into contact with the walls of the housing. However, there is a drawback: when heated, the pressure in the sealed gearbox housing increases.

Since there is no breather (like in a car engine crankcase), loss of lubricant squeezed out through the seals is possible.

Grease

It is much more widespread due to ease of use. It has a thick consistency and good adhesion. It is applied to the gearbox parts in the disassembled state of the latter.

In this case, it is enough to simply control the amount of lubricant. When cold, the lubricant is thick enough to adhere firmly to the mechanisms. After assembly, complete sealing of the gearbox is not required; high-quality gaskets and sealing bushings on the shafts are sufficient.

During operation of the hammer drill, when the gearbox heats up, the viscosity of the lubricant decreases and it spreads evenly over the surface of the parts. After cooling, the lubricant thickens again and is fixed on the gears.

How to lubricate a Makita hammer drill

To properly lubricate a Makita hammer drill, you must first gain access to them - disassemble the tool body. The units that always need to be processed are the gearbox and the chuck. The cartridge is first cleaned of old grease and particles. Apply new lubricant according to the instructions. Before use, it is necessary to lubricate the drill shank to reduce friction and extend the life of the mechanism.

Lubrication of the hammer drill is important because it prevents particles and dust from entering the working parts of the tool. Before using the drill, the grooves are treated with a special lubricant, which prevents contamination and dusting of the unit components.

Properties of gear lubricants

The standard characteristics of thick oils for general use are not suitable for a rotary hammer gearbox. Only compositions for automobile CV joints have similar parameters.

Some properties are generally unique, since the gearbox mechanism does not simply operate under large variable loads. When the impact mechanism operates, the lubricant is spontaneously squeezed out of the contact zone.

Composition requirements

- Adhesion must be so high that an oil film remains between the parts under any load.

- A high level of water resistance is required - rotary hammers can operate in conditions of high humidity. When cooling, a reduced pressure occurs in the gearbox housing, atmospheric air along with liquid vapor is sucked inside.

- If water gets in, an emulsion should not form.

- Since the gearbox gets very hot during operation, the lubricant thins out due to temperature. In this case, the basic properties should be restored after cooling. The heated composition should also not lose its basic antifriction parameters.

- Requires high dropping point. Otherwise, the rotating gear, under the influence of centrifugal forces, will throw lubricant from the surface of the teeth.

- Fine cement (stone) dust gets into the gearbox housing. The composition of the lubricant is selected in such a way that abrasive particles are bound and removed from the zone of intense friction. When using good oil, the dirt is always on the walls of the gearbox, and not inside the gears.

- Since the gear housing is made of aluminum alloys and the gears and bearings are made of alloy steel, the anti-corrosion properties should be equally suitable for both metals.

The same properties (with the exception of dropping point and adhesion indicators) must be present in liquid compositions. In a sealed gearbox housing, lubricant adhesion is not required: liquid oil constantly washes all parts of the mechanism during operation.

Which manufacturers produce gear lubricant?

General purpose brands such as Castrol, Xado, Ravenol, Shell, etc. Of course, these products do not have approval from the hammer drill manufacturer. But the description must contain information that this is a lubricant for a power tool gearbox. All you have to do is choose the right consistency. Information about this is in the technical documentation of the tool.

- Specialized brands: Bosch, Makita, Lubcon, AEG. This is a better choice, but you should be more careful when purchasing. The documentation for the lubricant may contain a list of specific models of the hammer drill manufacturer. Compatibility with tools from different brands is determined by consistency and similar characteristics.

- An interesting product: semi-liquid lubricant for gearboxes “ULTRA”. This is a compromise between consistency and liquid oils.

The lubricant easily turns into a liquid state with slight heating, and at the same time has excellent adhesion. Therefore, this product can be used in both crankcase and non-sealed gearboxes.

How to lubricate a hammer drill

Different types of lubricants are used to lubricate the gearbox and the drill chuck.

Gearbox lubricant

A special lubricant is used here, which should be called gear lubricant. It can be under the brands under which the perfs themselves are produced - Makita, Bosch, AEG, etc. But it can also be produced by a company that deals specifically with this type of product, for example, Ravenol, Shell, Xado, etc.

Some people use simple lithol or salidol for these purposes. But compared to special lubricating products, they dry out faster and do not eliminate friction as much as they should.

Lubricant for drills

Everything is exactly the same here. Special lubricants for this purpose are called “for drills”. And they are also usually produced by the same companies that make hammer drills.

In the absence of special lubricant, you can use graphite. But it does not remove heat from the shank so well, and this is important, since sometimes during prolonged operation the shank becomes flattened, which makes it difficult to remove later.

How to properly lubricate the gearbox

Having decided on the choice of brand, we proceed to routine maintenance. Liquid oils are drained from the gearbox in the same way as in a car. If the waste looks too dirty and is saturated with abrasive inclusions, the gearbox should be washed with a special compound.

You can also disassemble the housing and perform a thorough cleaning. Then careful assembly is carried out (if necessary, replacing the gaskets), and the new composition is poured through the standard holes.

Step-by-step video instructions for lubricating the rotary hammer gearbox

The amount of oil is indicated in the documentation. If it is absent, you can measure the volume of drained waste. True, natural losses should be taken into account.

With consistency compositions it is somewhat simpler. The gearbox is clearly disassembled, the components can be removed (be careful not to lose the springs and retaining rings).

Then the metal parts and gear housing are thoroughly cleaned and rinsed. Kerosene is usually used (aggressive detergents can damage sealing bushings and gaskets).

Lubricant is applied to the assembled gearbox (without cover). It must completely cover all gears and moving parts of the mechanism. The layer thickness is no more than 5 mm, the internal cavities are completely filled.

However, you should not work according to the principle: “you can’t spoil porridge with oil.” Excess lubricant will complicate the operation of the mechanism and will definitely come out, damaging the gasket or oil seal along the way.

The illustration shows how not to lubricate the gearbox.

This is not the way to lubricate the gearbox!

The frequency of replacements does not depend on calendar days, but on the number of engine hours. Information about this is in the documentation for the tool. It should be remembered that “station wagons” like Litol last less.

Assembly procedure for the Makita 2450 rotary hammer

Impact mechanism assembly

How to assemble the impact mechanism of a Makita rotary hammer? The impact mechanism is assembled from two units: a barrel shaft with a spur gear and an intermediate shaft with a rolling bearing.

A). A spur gear, pos. 19, is put on the barrel, pos. 21, and pressed by a compression spring, pos. 18. To fix the spring, it is pressed with washer 30, pos. 17, and secured with retaining ring 28, pos. 16.

B). To assemble the striker, you need to put ring 9, pos. 25, on the striker shaft, tighten the rubber ring, pos. 26, and press it with the metal ring, pos. 27.

Now we move to the opposite side of the barrel, pos. 21. On the other hand, the inner surface of the barrel must be lubricated with grease and the assembled firing pin, pos. 24, must be inserted inside.

Intermediate shaft and piston assembly

Assembling the intermediate shaft assembly

To assemble the intermediate shaft, you need to put the rolling bearing pos. 41 on the shaft pos. 40 with the teeth to the shaft splines, and put the coupling pos. 39 on the shaft splines.

Translation of translational motion

On the opposite side of the shaft, a helical gear 26 pos. 42, a flat washer 8 pos. 45, a bearing 608zz pos. 46 and a retaining ring 8 pos. 47 are put on. The intermediate shaft is assembled.

Assembly of the gearbox assembly

The gearbox unit is mounted on the internal housing, pos. 49.

Inner housing

By the way, there are cases when the axles jump out of the internal aluminum housing. Both axles are pressed into the housing.

The assembled intermediate shaft is inserted into the housing, pos. 49, the rolling bearing arm of which must fit into the hole in the cylinder hinge.

In this case, the rolling bearing lever, pos. 41, of the intermediate shaft must fit into the cylinder hinge, pos. 32, and the lower bearing of the intermediate shaft into the seat in the housing. This procedure is usually performed by rocking the structure until the parts completely fall into the indicated places.

Read also: How to install electric heating in a private house