Hammer drill lubrication is necessary to maintain good performance of the tool. That is, it is needed quite often. After all, the parts in the gearbox are in constant contact with each other. Plus, dust constantly gets inside. In this article we will describe how to use lubricant correctly.

Current rotary hammers are divided into several classes. Many of them are designed for chiselling only, some are suitable for drilling, and some models can drill into a variety of materials. There are also hammer drills that combine all of the above functions at once. When working with each of these tools, a colossal amount of dust is released, which clogs the device. That is why periodic cleaning and lubrication of the tool is necessary. This will extend the life of the hammer drill and will not lead to its breakdown. There are two types of lubricant:

For drills; drill tips; for the gearbox.

Liquid oil from the manufacturer (Makita, Bosch) is often used to lubricate the gearbox. How this is done is usually described in the special manual for the device. It also specifies the timing and frequency of lubrication. The tool body has special holes and hatches into which oil is poured. Afterwards they are hermetically sealed. In this way, the oil properly fills the gearbox housing and the parts are evenly lubricated.

Lubricant for the rotary hammer gearbox - how to choose it?

As a rule, the instructions for each device specify the necessary lubricant. For example, a special lubricant P-08361 is produced for Makita devices. For Bosch there are other compositions. Branded lubricants have the necessary water resistance and prevent the formation of corrosion. In the same case, when there is no information in the instructions, you can use some other means. But you should ask your sales consultant whether they are suitable specifically for the hammer drill.

One of the most common products is diesel engine oil. Graphite lubricant, which is often used for open worm gears, is also considered good. Litol 24 can be called popular, but it also causes additional heating and braking. And it doesn’t last long, unlike branded oils. Not recommended for battery-powered devices.

How to lubricate a hammer drill and what is needed for this? Typically, many users have a question: how often should a hammer drill be lubricated? After all, the intensity of use is different for everyone. Some people use a hammer drill once a year, while others constantly use it for various jobs. Professionals advise looking at the magnitude of the loads, as well as the recommendations in the instructions. In this case, be sure to consider whether the warranty period has passed.

The second question that users have is how to do it themselves? For example, the warranty period has expired or you just want to do work at home. Modern devices have a special compartment where oil is poured. As a rule, the instructions indicate exactly where this hole is located. There should also be a disassembly diagram. The amount of oil that is needed is placed there (this is indicated in the instructions). However, before doing this, you need to flush the crankcase with machine oil or kerosene. In the case where there is no special hole and the device needs to be disassembled, you can additionally blow it out.

Only after washing and purging do they begin lubrication. There is no need to lubricate the transmission clutch and other areas that do not need oil. In addition to the gearbox, if necessary, you can lubricate the drill and other replaceable attachments. Litol is suitable for this. In the case when the device has an open cartridge, the oil seal can also be lubricated. It is only important to apply a small amount of oil to these areas. This can be done before each installation of the nozzle. After removing it, be sure to wipe the shank from dust.

Litol or grease for hammer drills can be purchased at any construction supermarket. You can also find branded oils there.

Video on the topic: Which oil is suitable for a jackhammer?

A little helper for big things. "Kedr" K56503

Changing MOTUL oil in the BOSCH GSH 5 CE Professional bump stop

Source

Jackhammer with hexagon 28.6mm Makita HM1317CB

After selecting the impact force, you need to carry out preparatory manipulations with the jackhammer. Jackhammers of different power differ in design.

Please note that any decent manufacturer of professional jackhammers makes handles with anti-vibration dampers that protect your joints from injuries and occupational diseases.

If an anti-vibration handle is not included in the design, we recommend not using this technique. Otherwise you will be dealing with cheap production.

What kind of oil to pour into a jackhammer

Interskol M-30/2000B two thousand W reviews

7 reviews for the product Interskol M-30/2000B jackhammer two thousand W

Write a review

Review

And it is difficult to add oil, and after draining the factory lubricant, add oil. Here is a link, maybe it will save someone from the rapid failure of the hammer. https://www.interskol.ru/forum/comments.php?DiscussionID=3534&page=1#Item_0

Review

By the way, for those who are interested, here’s what I managed to find out. And I see that I already wrote the misconception that it’s not sixty, but 25-30 engine hours.

To prevent dust from entering and oil from leaking, this power tool has a sealed barrel design. For this reason }myth the jackhammer is used over a long period of time without the need to change or add oil. After initial commissioning, add oil every twenty-five hours of operation. 1. To add oil, turn on the machine so that the oil runs for a certain time and does not warm up. 2. Turn off the power tool and do not remove the power cord from the outlet. 3. Unscrew the oil reservoir cap (10) using a special key.

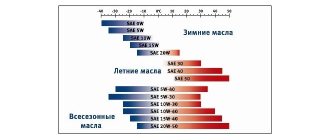

4. Fill in oil in a volume of thirty g. Use special oil “Mobil Delvac MX” with a viscosity of SAE 15W-40. Non-semi-synthetic, non-synthetic motor oils with an index corresponding to 15W-40 are used.

ctln.ru

What is a jackhammer, how does it work?

The device is a percussion tool designed to break and split rock sediment, concrete structures, asphalt, etc. The hammer is controlled manually by the operator; the direction of impact, frequency and duration of impact on the surface being treated are regulated. Since the force is transmitted to the working element (pike, blade, chisel, etc.) from the striker driven by an external energy source, the device belongs to the mechanized class of tools. The drive may be

The number of beats varies from 15 to 45 Hz. (i.e. 15–45 working movements of the striker per second).

In addition to manual jackhammers, there are machine tools that use a similar operating principle. They are used in the development of rocks in mines and open pits. The inventor of the machines is considered to be the French engineer Germain Sommeye (late 50s of the 19th century).

Mobile jackhammer in a mine tunnel

Bumper device

Despite the variety of types, their principle of operation is no different. The working part is a chisel, a peak or a slotting blade. This is, as a rule, a hexagon made of high-strength steel, pointed at the end. It is activated by a firing pin, which receives an impulse from the drive mechanism. The firing pin and piston are installed in the sleeve. Between them there is an air space, which, compressing, pushes the firing pin towards the peak. This design is necessary so that the destructive force does not have a direct application to the drive mechanism. Otherwise, shocks of 30–50 kJ. would quickly destroy the engine rod. During the reverse stroke of the piston, a reduced air pressure is formed inside the liner, which “pulls” the firing pin into its original position and the cycle repeats again. Regardless of the design solution of the drive, the mechanical part of the bump stop remains unchanged.

Jackhammer: purpose, characteristics, use

Dismantling work is of great importance in the construction industry. The main hand tool for performing them is a sledgehammer. For large-scale work, an automated mechanism is used, represented by a Girey crane. There is an intermediate version of a mechanized device suitable for dismantling work of various sizes. This is a jackhammer.

Several parameters are used to classify the devices under consideration.

Based on performance, jackhammers are differentiated into three types.

- Lightweight options are designed for household work. They are capable of crushing plaster, tiles, etc., which makes them suitable for home renovation. The weight of such mini jackhammers is 5-6 kg.

- Medium power devices are suitable for asphalt, so they are used for some construction work. Weight from 6 to 10 kg provides the possibility of long-term horizontal holding.

- In industry and during the construction of buildings, high-power jackhammers weighing 15-30 kg are used.

However, mass is an indirect indicator of performance. There is a classification close to the above, based on other, more significant parameters. It also includes four types.

- The first includes jackhammers with impact energy up to 30 J and frequency up to 45 Hz. They are suitable for medium-strength materials such as asphalt, brick, clay, and work in confined spaces.

- The second type is represented by options with an impact energy of 40 J and a frequency of 34 Hz, used in general construction work.

- The third type includes models with impact energy up to 45 J and frequency up to 20 Hz. They are used for work with vertical impacts on durable materials.

- The fourth type is represented by hammers with an impact energy of more than 50 J and a frequency of up to 24 Hz. Such devices are used for high-strength materials.

Based on the power source, there are four types of jackhammers.

- Pneumatic devices are the most common type. The power source for them is a compressor. The principle of operation is based on the pressure of compressed air molecules on the chisel. This equipment is suitable for destroying any structures made of brick and concrete. For household options, a power of 5 J is required, and in industrial models this parameter ranges from 10 to 100 J. This is enough to destroy asphalt, stone, concrete, etc.

- Electric hammers are powered from the mains. The principle of their operation is to drive the striker through the rotational element of the electric motor. Performance parameters are up to 1700 W of power, 45 J of impact energy and 2000 beats per minute of frequency. Thus, these types of jackhammers have high impact power, but are not suitable for cutting and drilling materials.

- Gasoline devices are driven by an internal combustion engine, which does not have valves and a shaft. With low power, the main advantage of these options is autonomy, that is, the ability to be used anywhere. This is due to the absence of the need to connect to an energy source. The duration of operation is determined only by the amount of fuel. In addition, jackhammers of this type are considered safer in comparison with analogues. However, they have a high noise level. These models are used in the mining industry for the destruction of concrete, asphalt, and frozen soil.

- Hydraulic hammers use different power sources. They are usually used in emergency rescue operations.

READ Stihl Chainsaw Floods Spark Plug Won't Start

Pneumatic hammers are also divided into two types based on their operating principle.

- Volumetric devices are driven by rapidly expanding air in the chamber.

- The operation of turbine options is ensured by the energy generated by the rotation of the turbine.

The simplest classification of jackhammers based on a set of basic parameters differentiates them into professional and household.

Concrete breakers are distinguished by their large size, weight and productivity. These devices are designed for vertical and inclined work with concrete slabs, rocks, asphalt pavement, and frozen soils. Rotary hammers are usually more compact than jackhammers or similar in size, they are distinguished by greater accuracy and the ability to perform the functions of a drill and screwdriver with adjustable speed and reverse. This versatility makes them much better suited for household work. Thus, the operating instructions for PE-2520M indicate the possibility of its use as both a jackhammer and a drill.

How to use the device, safety precautions

Working with a jackhammer has a number of features associated with the impact of negative factors on the operator.

- increased vibration during operation;

- increased level of dust in the chiselling area;

- high noise intensity, hazardous to health;

- an abundance of small particles of solid material flying at high speed from under the bit.

- It is prohibited to carry out work without the use of personal safety equipment - earplugs or headphones, a respirator, safety glasses, as well as to work without gloves and a protective suit made of thick fabric.

- It is prohibited to use a jackhammer that is known to be faulty. Before turning on, it is necessary to check the fastening of the chisel and the tightness of the bolts on the housing.

- During operation, following the safety rules, it is necessary to hold the bump stop only by the standard handles. It is unacceptable to work with one hand.

- If there is an additional holder, use it for its intended purpose. The body position must be stable.

- It is prohibited to entrust the instrument to minor children and to leave it turned on unattended. It is unacceptable to point the tip of the chisel towards other people.

- After completing work, do not touch the metal part of the housing with bare hands. This may cause severe burns.

- It is unacceptable to use the tool for purposes other than its intended purpose, such as a crowbar or a shovel when the drive is turned off.

- The maximum operating period of a jackhammer is limited to 6 hours. Resumption of work is permissible only after a 1-hour break.

- When using the tool in the cold season outdoors, the lubricant needs to be warmed up. To do this, you need to turn on the device, and for 2-3 minutes. warm up at idle speed.

When working with a chipper, protective equipment is required.

Therefore, safety requirements include the following points:

Following these simple rules will protect the user from injury and the bump stop from premature wear.

Often, when using a pneumatic jackhammer, some users increase the pressure of the compressor supplying compressed air to the tool. They proceed from the simple reasoning that the greater the pressure on the piston, the greater the impact force. This is true. But, unfortunately, for a very short time.

The compression level must correspond to the set nominal pressure of the unit

All rating parameters of the hammer are indicated taking into account the nominal pressure - this is, as a rule, 0.5–0.6 MPa. (or 5–6 atm.). When the pressure increases to 7–8 atmospheres, the load on the piston increases sharply (by 40–60%), and this leads to a halving of the service life of the parts. Therefore, the conclusion is simple - instead of “squeezing” unusual power out of a hammer, it is better to choose a tool with increased impact strength.

During operation of an electric jackhammer, sparks occur on the electric motor commutator. This must be remembered when performing work near combustible and flammable materials. In such a situation, it is safer to use pneumatically driven devices.

Catalog

The jackhammer is designed to destroy concrete and brick foundations, loosen hard and frozen soil, and asphalt concrete pavements. Also designed for punching grooves, holes and niches in concrete and masonry.

READ How to cut 10 cm polystyrene foam

| Name of parameters | Meaning |

| Single impact energy; J(kgf.m) | 25 |

| engine's type | Asynchronous three-phase with squirrel-cage rotor |

| Power | 1.05 kW |

| Voltage | 220 volt 50 hz |

| Beat frequency; s-1(bpm) | 19,5 |

| Weight (without cable and working tools) | 21 kg |

The main purpose of a jackhammer is to destroy foundations (concrete, brick). Can be used for loosening soil (frozen, hard) and asphalt concrete surfaces. Can be used for punching grooves and niches as well as holes in concrete and masonry.

| Name of MO-2 parameters | Meaning |

| Single impact energy; J | 39 |

| Compressed air pressure is nominal; (Pa) | 6105 |

| Free air flow; (l/sec) | 22 |

| Hammer weight without tools; (kg) | 8.5 |

| Beat frequency; s-1(bpm) | 22.5 |

Frequently asked questions about jackhammers

What is the difference between a jackhammer and a hammer drill?

A jackhammer differs from a hammer drill in its larger size and weight, power and increased capabilities. Unlike a hammer drill, a jackhammer is capable of destroying several tons of concrete or other materials per day, and also shows a higher rate of work.

What kind of oil should I put in a jackhammer?

Each manufacturer specifies a brand of oil that is suitable for its jackhammers. When purchasing a Dnipro-M jackhammer you will receive oil for the gearbox and shank included.

How to lubricate a jackhammer?

Before inserting the nozzle into the chuck, it is necessary to lubricate its shank with lubricant. This will provide a good level of glide during operation and reduce heat levels.

Review of Dnipro-M demolition hammers

Our brand's assortment includes several models of jackhammers that are suitable for performing work of varying complexity.

SH-160

In size, this model is no larger than a hammer drill, but has excellent technical characteristics. Weighing only 5.5 kg, the tool is capable of destroying up to 5 tons of concrete daily. The SH-160 jackhammer can easily handle concrete, brick and stone.

You will find it convenient to work with this model not only due to its compact size and light weight, but also to the presence of AVT technology, which significantly reduces vibration levels. The handle of the tool is rubberized and allows you to hold it securely in any working conditions. The SH-160 also has a tool position adjustment function that allows you to change it in a few seconds.

The number of blows when working with the model reaches 3600 per minute, which ensures the required pace of work. The nozzle is firmly held in the SDS-max chuck even with the most intensive use.

SH-210AV

The SH-210AV is great for breaking down even the toughest materials. It easily copes with the task of dismantling foundations, monolithic structures, and asphalt pavement. The 2100 W motor and 65 J impact force can destroy 7 tons of concrete per day. You can work comfortably throughout the working day thanks to AVT technology, which reduces vibration during operation.

The jackhammer package includes a case made of impact-resistant plastic. The case has wheels that make it easy to move the tool. The package also includes: SDS HEX pick and chisel, additional handle, gearbox and shank oil.

The comfortable handle with an internal width of 134 mm allows you to hold the tool with both hands. The package also includes an additional handle that can be rotated 360 degrees, improving the quality of control of the jackhammer.

SH-220AV

The most powerful jackhammer model in the Dnipro-M range. It has become the choice of professionals who successfully use it to work with foundations, monolithic structures, stone and asphalt. With a power of 2200 W and an impact force of 65 J, you can destroy 10 tons of concrete per day. The service life of the model is increased thanks to the metal gear housing, which improves engine cooling and allows the tool to operate stably for a long time.

How to choose a quality one

In order for the jackhammer to serve for a long time and not break, it is necessary to make the right choice of model. The technical characteristics of the tool must correspond to the tasks facing it. Equipment that is too powerful and oversized consumes a large amount of electricity, requires maintenance in specialized workshops and expensive consumables. Insufficiently powerful - it will not cope with the given amount of work. Therefore, when choosing, you need to take into account all the details and nuances of the upcoming load on the tool. The following technical parameters are considered the main criteria that you need to pay attention to when choosing a breaker machine.

- Dimensions: length, width, height. The larger the linear dimensions of a mechanical hammer, the correspondingly greater the power and its resolution. However, indiscriminately chasing a “big and strong machine” is not always justified. In some situations (for example, during apartment renovations), it is more reasonable to use compact equipment that allows you to work in cramped circumstances.

When chiseling holes in concrete floors, a hammer with increased impact force is used

. On the one hand, the greater the weight of the tool, the greater the pressure it exerts on the surface being destroyed. But if you have to break a wall or ceiling elements, the load falls entirely on the user’s arms (and legs). In this case, it is better to give preference to lightweight models with high impact performance.

When performing work in a horizontal plane, the weight of the tool must be selected in accordance with the physical capabilities of the operator

Beat frequency. This is one of the main indicators that directly affects the performance of the tool. It can be measured in hertz (Hz) or revolutions per minute (rpm). The number of hertz shows the number of beats per second. Revolutions per minute indicate the frequency of translational movements of the rod within one minute.

The impact frequency and the energy value of a single impact are displayed in the hammer data sheet

The petrol drive of the jackhammer allows for work to be carried out in autonomous mode.

Noise-absorbing headphones protect your hearing from overload.

In addition to the listed parameters, it is sometimes useful to take into account additional technical characteristics.

Transport weight of the tool. This is the weight of the tool packed in a case along with consumables and spare parts.

Factory case for transporting the hammer

Oil for preparing gasoline mixtures intended for two-stroke engines.

Additional functions. These are devices that facilitate operation and contribute to greater work efficiency. These include a locking start button, an anti-vibration system and an idle shock limiter. The latter option significantly increases the service life of the hammer. In addition, on electrical mechanisms it is common practice to install a graphite brush wear indicator, notifying the user of the need to replace the electrodes.

Choice

First of all, it should be noted that jackhammers are primarily professional equipment. This is due to their lack of demand for domestic and economic purposes, as well as their high cost.

Consequently, the main factor in choosing a jackhammer is the purpose, that is, the volume and nature of the planned work. This determines the required parameters and functions of the device. In addition, it is not advisable to purchase such a device for one-time work.

There are several basic parameters for jackhammers.

- Weight determines the ability of the device to be supported by weight. Thus, models weighing up to 6 kg are relevant for high-altitude work or cramped conditions. Hammers up to 10 kg can be held horizontally when carrying out horizontal work on dismantling walls and making holes. With heavier hammers you can work vertically on foundations, soil, etc.

- The impact force is equivalent to the amount of material it breaks off. Thus, the effectiveness of the tool and the speed of work directly depend on this indicator. It can range from 2.8 to 63 J.

- The impact frequency, reflecting their number per unit time, also determines the speed of work, but is inversely related to the previous parameter. That is, as the force of impacts increases, their frequency decreases. So, in light models this characteristic can be up to 3500, while in heavy ones. from 1100.

- Power determines the penetrating power of a jackhammer and the operating cycle time. It is 0.5.2 kW. For finishing work, 1.2 kW is sufficient. To destroy a concrete or brick wall, 1.6 kW is needed. The greatest power is required for dismantling road surfaces.

The given technical characteristics of jackhammers are largely determined by the type of drive. That is, one of the classifications is of great importance. To understand how to choose a model, you need to know the features of the types allocated to it.

Pneumatic devices, in comparison with electric and internal combustion engine hammers, due to their simpler design, are considered more reliable and durable at a significantly lower cost. In addition, they have the smallest weight, ranging from 1.5 to 16 kg. In addition, such hammers are very productive. Finally, these models are suitable for work in conditions of high humidity and near flammable substances. The main disadvantage is that it is connected to a power source in the form of a compressor, which will have to be purchased separately at a considerable price. Moreover, it is necessary to select this device based on the parameters of the hammer. The main characteristics are volume and working pressure. The compressor parameters determine the duration of operation.

Electric jackhammers are tied to a power source, just like pneumatic jackhammers. In contrast, such devices cannot be used near flammable substances due to the engine sparking during operation. They are also not suitable for high humidity conditions. Despite this, they are a very common type of jackhammer. This is due, first of all, to significantly greater efficiency in comparison with pneumatic jackhammers and models with internal combustion engines. In addition, they have the best environmental performance, the lowest level of vibration and noise. Despite the external energy source, it is not provided with additional equipment, provides unlimited operating time and ease of connection. Finally, with a more complex design, they are easy to maintain. In addition to the main parameters, engine power is of great importance for these hammer models. For domestic purposes, jackhammers of this type are most often used.

In addition, there are battery options that combine the above positive qualities of electric hammers with the autonomy of gasoline ones. However, they do not last for centuries, since the duration of operation is determined by the capacity of the battery, which requires further charging.

Models with internal combustion engines are the most mobile. At the same time, they are characterized by high noise levels and the presence of toxic emissions. In addition, instead of being tied to an energy source, they require a supply of fuel, the amount of which determines the duration of operation. Finally, ICE hammers are the most difficult to maintain: they require draining residual fuel, cleaning filters, etc.

In addition, the preferential working position of the jackhammer is of great importance.

Horizontal modifications are distinguished by their low weight and the presence of appropriate handles: holding the rear and controlling the front.

READ Modernization of the Ignition System of the Mole Cultivator

Vertical breakers are heavier and equipped with side handles.

Finally, the manufacturer plays a significant role when choosing. There are a number of brands known for high quality products. Manufacturers that produce the best jackhammers include Bosch, Sparky, AEG, Makita, DeWALT, Hitachi, Metabo, Milwaukee.

Types and design of a jackhammer

The most popular classification of jackhammers is by type. There are fenders with an electric motor, internal combustion engine, pneumatic and hydraulic tools.

Before we examine in detail the features of each type, let's talk about the general features of the entire category. The jackhammer device includes the following components:

- frame;

- equipment (chisel, lance, etc.);

- impact mechanism;

- chuck for fastening equipment;

- gearbox;

- pen;

- start button.

How does a jackhammer work? The energy that originates in the engine or supplied from the compressor pushes the firing pin. It transmits the movement of the pike, which acts on the material being destroyed.

Electrical

Electric jackhammers always include an electric motor, which draws voltage from the mains. Between the engine shaft and the piston there is a gearbox, which is responsible for transmitting force. The firing pin is driven by a piston mechanism.

Electric chippers are a very popular tool that can often be found in everyday life. Its main advantages:

- the ability to quickly connect to the network;

- no need to purchase additional equipment (compressor);

- environmental friendliness;

- relatively little vibration.

Perhaps the only thing that brings discomfort during work is the cord. You have to be careful not to damage it during operation. You may also need an extension cord.

Gasoline

They have an internal combustion engine that converts gasoline into energy. These hammers are heavier and more powerful than electric ones. They are self-contained as they do not have a power cord. Gasoline jackhammers are very convenient to use where it is not possible to connect the tool to the network.

Among the disadvantages are the need to refuel the jackhammer and pour oil into it, and the presence of exhaust during operation.

Pneumatic

They use compressed air for work, which comes to them from the compressor. When compressed air enters the valves, pressure arises on one side and a rarefied environment on the other. This sets the firing pin in motion. These jackhammers do not have their own motor. Their weight rarely exceeds 15 kilograms. In addition to the parts listed above, pneumatic fenders also include:

- fitting - the air supply compressor tube is connected through it;

- starting spool;

- valve system;

- piston;

- muffler.

Pneumatic hammers are often used for professional purposes. This technique is capable of working in the most difficult conditions, as well as in high humidity. The main disadvantage of this type of tool is the need to purchase a compressor unit, which can be quite expensive.

Device

The main structural elements for any type of jackhammer are represented by a striker, a nozzle, a cartridge, etc.

Pneumatic piston models are designed according to piston systems based on the impact principle. The main structural elements are represented by a starting spool, a striker, a piston, a fitting for a compressor hose, a cup with a ring valve and a valve box, and a muffler. In addition, jackhammers include two springs, a shock absorber, a retaining ring, a handle, and a housing.

The named parts are combined into several units.

- The hammer, also called the trigger and air distribution mechanism, includes the firing pin and the barrel.

- The vibration protection of the handle is represented by a glass and sealing bushings.

- Anti-vibration protection from the chisel includes a manipulator and a spring-loaded bushing.

- The housing-handle includes a housing, an aerodynamic noise muffler and a trigger mechanism.

The impact system has two main functions: supply, dispersal and removal of air, converting its energy into work.

Electronic models are equipped with such specific components as an electric motor, a gearbox that serves to convert the rotation of the latter shaft into reciprocating movement, a crank mechanism with a piston that provides pressure in the cylinder acting on the firing pin.

Components specific to internal combustion engine jackhammers include the carburetor, fuel tank, starter, ignition system, and fuel pump. In addition, taking into account the increased vibration of these devices, the handle and control elements are separated from the body by a spring suspension.

READ Champion Chainsaw Oil

In addition, there is additional equipment for the hammer. It includes four subsequent devices. An automatic speed controller, called a soft start and an idle speed limiter, serves to extend the life of the motor by eliminating overloads and gradually accelerating. The principle of its operation is based on adjusting the speed in accordance with the load. The side handle increases ease of use, facilitating proper retention and distribution of effort. The impact frequency control increases the degree of control of the tool, providing the option of a demolition hammer for materials of different hardness. The button lock ensures that there is no need to constantly hold it during operation.

The principle of operation of jackhammers is to develop reciprocating movements of a striker located in the barrel, which is not kinematically connected with other parts. This is accomplished by different mechanisms depending on the type of hammer.

Thus, in piston pneumatic models, the air supplied by the hose from the compressor overcomes the resistance of the valve spring when acting on the handle. As a result, the valve moves, opening the opening of the impact mechanism. Alternately, a vacuum and excess pressure are created in the lower and upper parts of the cylinder due to the passage of compressed air between them by the valve system, generating reciprocating movements of the striker.

The operation of a pneumatic turbine hammer is based on the drive by the energy generated by the rotating air of the turbine wheel.

Gasoline hammers are also usually equipped with a pneumatic impact mechanism. The piston, changing the pressure in the cylinder, leads to the movement of the hammer piston with an attached tip.