How does the engine for the Salyut walk-behind tractor work?

Auto mechanic, specializes in agricultural equipment

Today, there are a large number of different models of special equipment that are used for soil cultivation in agriculture. Here devices of the salute model are often distinguished. This equipment is in great demand among agronomists, but a distinctive feature of walk-behind tractors is the short service life of their engine.

Due to the fact that the build quality is not the best, it is necessary to select models that are equipped with an improved power plant from a more famous manufacturer. In this case, you need to familiarize yourself with the Briggs Stratton engine, and also find out which models can replace it, and how to change the oil in the engine of a salute brand walk-behind tractor.

Before purchasing this walk-behind tractor, you need to decide on the model.

Advantages of the HONDA 190 engine

Honda engines for walk-behind tractors, the price of which is quite affordable, are durable and have a reserve of more than 3000 operating hours.

The gear reducer is considered the main advantage of the walk-behind tractor

The Salyut walk-behind tractor with a Honda 190 engine has the following advantages:

- economical fuel consumption;

- low level of noise and vibration during operation;

- ease of operation;

- quick start;

- compliance with environmental requirements;

- low maintenance requirements;

- products are certified.

Engines for the Salyut walk-behind tractor

Before considering in detail the procedure for changing the oil for the Salyut 5 walk-behind tractor, you need to familiarize yourself with the models of power plants that are mounted on these devices. Let's take a closer look at all the currently used options:

Among such a number of power plants, it is quite difficult to choose the most suitable option for yourself. That is why all units must be considered in detail and in full.

In this video you will learn about the engines in salute walk-behind tractors:

Important! When choosing a unit for your special equipment, you need to take into account the operating features, since any of the motors has more positive qualities in any direction.

Briggs Stratton

Quite often, engines of this brand are installed for the Salyut walk-behind tractor. Let's look at the main distinguishing features of these power plants:

Also, these devices are characterized by low oil consumption, and also low cost. At the same time, large investments in repairs and maintenance during operation are not required.

Important! If a power unit from this manufacturer is installed, it is recommended to regularly check the oil level, since if it is insufficient, the engine may have a shorter service life.

Honda

These power structures are widespread throughout Russia. Let's look at the main distinguishing features of these devices:

All these qualities distinguish engines from the manufacturer Honda. However, despite the quality, the cost of the units is quite high when compared with other similar options for units for Salyut walk-behind tractors.

Important! The engine is characterized by high speeds, which makes it quite voracious in comparison with other manufacturers of units for similar special equipment.

Subaru

Another power plant that is very popular among owners of special equipment. These models have absorbed all the positive qualities from other manufacturers. Due to the many models released, it is recommended to first compare all the characteristics, since after installing the Subaru engine, the walk-behind tractor may change significantly. Here it should be understood that the devices have a fairly high cost, but the service life is also higher. Additionally, it should be noted that both gasoline and diesel can be used as fuel here. This point should be taken into account when purchasing.

Important! Subaru engine units have high power and are operated at high speeds, which is why high fuel and oil consumption may be periodically observed in comparison with other power plants.

Lifan

These motors for walk-behind tractors appeared relatively recently, but are already very popular among gardeners and commercial organizations involved in agriculture. Let's consider the main characteristic features of these motors:

Also, these installations are not highly voracious during frequent use (the engines do not consume large amounts of fuel or oil, compared to other similar models from other manufacturers).

Important! Despite the large list of qualities of such power plants, the models appeared on the Russian market relatively recently, which is why they are not widely used. Also, during operation, it is necessary to monitor the condition of the spark plugs; there are often cases when they are flooded.

Another manufacturer of power plants for Salyut brand walk-behind tractors. These units are in great demand. They are characterized by the following distinctive features:

Despite the large number of positive aspects, when operating these motors you can also encounter some disadvantages. The most pronounced disadvantage is the high cost of spare parts (in order for the engine to last a long time, consumables need to be changed quite often). In addition, it is necessary to use high-quality oil, which in some cases has to be topped up, since if there is a shortage of it, the engine life is reduced.

It is worth noting that not all brands of motor units for Salyut walk-behind tractors were considered here; there are also other manufacturers of power plants, however, their characteristics and performance are somewhat worse than those of the models mentioned here.

Features of the gearbox design

This structural element includes many individual parts. Here we need to consider some of the nuances of the design of this working unit, namely:

In this video you will learn about the gearbox of the walk-behind tractor: Also, the oil seal in the gearbox of the Salyut walk-behind tractor must be replaced in a timely manner, since this element is responsible for the tightness of the entire structural component. If this device fails, oil gradually disappears, which is extremely important for the operation of the entire mechanism.

Important! Despite its design feature, this element is not a complex mechanism and, if necessary, anyone can cope with its overhaul or repair independently.

Modifications

Lifan 168F-2

The cheapest configuration with a connecting shaft size of 19 or 20 mm. The manufacturer's price is 9,100 rubles.

For more details about the operation of the Lifan 168F-2 engine, watch the video:

Lifan 168F-2 7A

Motor variant equipped with a lighting coil capable of powering consumers up to 90 W. This allows it to be used on a variety of equipment that require lighting devices: motorized towing vehicles, light swamp vehicles, and so on. Price – 11,600 rubles. The shaft landing diameter is 20 mm.

Lifan 168F-2 ignition circuit

The power unit has a conical shaft output; it differs from the base model only in the conical groove of the crankshaft toe, which ensures a more accurate and tight fit of the pulleys. Price – 9500 rubles.

Lifan 168F-2L

This engine has a built-in reduction gearbox with a landing diameter of the output shaft of 22 mm and costs 12,100 rubles.

Motor Lifan168F-2R

The motor is also equipped with a reduction gear, but with an automatic centrifugal clutch, and the landing size of the secondary shaft of the gearbox is 20 mm. Engine cost: 14,900 rubles.

Lifan 168F-2R 7A

As is clear from the markings, this version of the engine, in addition to a reduction gearbox with an automatic clutch mechanism, has a seven-amp light coil, which increases its price to 16,500 rubles.

Lifan 168FD-2R 7A

The most expensive version of the engine, priced at 21,500 rubles, is distinguished not only by the diameter of the gearbox output shaft increased to 22 mm, but also by the presence of an electric starter. However, the rectifier required to charge the battery is not included in the delivery package.

Types and purposes

The reducer of the Salute walk-behind tractor in its structural integrity contains such elements as a boot, an oil seal, gears, bearings and a number of other elements. However, in this case it is necessary to understand the purpose of this mechanism and its varieties:

The drive mechanism itself serves to receive torque from the engine, and then transmit it to the axle, while evenly distributing the load on each wheel. Also, these products can be divided into angular, worm and step-down, depending on their purpose.

Important! Regardless of what type of mechanism is installed, it is mandatory that the gearbox seal be replaced during maintenance, and the oil in the gearbox of a Salyut 100 walk-behind tractor or on any other device is also changed.

Gearbox for walk-behind tractor Salyut 5

Auto mechanic, specializes in agricultural equipment

Modern special equipment includes a lot of different components. There are main power parts, as well as auxiliary mechanisms and body devices. Each individual element is responsible for its work, which is why a full-fledged device performs the task assigned to it. Almost every modern equipment has in its design an element such as a gearbox. This mechanism has the purpose of uniformly converting and transmitting torque. In this case, it is necessary to consider in detail the gearbox of the Salyut brand walk-behind tractor.

What and how much oil to fill

Many ignorant owners of special equipment are interested in the question of what kind of oil is poured into this part. Let's take a closer look at the criteria for choosing this component:

Do not pour oil into the gearbox. As a rule, gear oil is used for special equipment, which provides the best performance indicators for such mechanisms. This consumable must be filled into the gearbox in accordance with the level. The amount of liquid for each individual node is different.

Important! The oil in the gearbox of the Salyut walk-behind tractor, or, as it is also called, a walk-behind cultivator, must be kept at a level, but not allowed to reach its maximum, otherwise there is a possibility of depressurization of the device and fluid leakage.

Changing the oil in a walk-behind tractor

You can change this consumable in the Salyut 5 walk-behind tractor yourself; you don’t have to contact specialists for this. Let's take a closer look at how this procedure is performed:

After the maintenance has been carried out, it is necessary to run in for some time without loading the unit so that all parts can get used to the new lubricant.

Important! If flushing is used, then it is necessary to let the device work for some time (usually about an hour) so that all stuck-on impurities are removed.

Replacing oil seals

If maintenance is performed, then this element will also have to be replaced. Let us consider in detail how this procedure is performed:

- first of all, you need to remove the cutters from the device;

- Next, you need to unscrew the holding bolts;

- after this, the corresponding cover is removed;

- the old structural element is removed;

- a new oil seal is placed in its place;

- sealant must be applied on top.

After this, the lid is closed, the bolts are screwed in, and the removed cutters are installed in place.

It is worth noting that this procedure is recommended to be carried out in conjunction with replacing the fluid, which is carried out once every 100 hours of using special equipment.

How much to pour the mixture

The amount of liquid that is poured into the mechanism directly depends on a number of factors, namely:

Taking into account all these nuances, you can choose the optimal value at which the device will work best. As a rule, about two liters of transmission fluid are poured into this part of the walk-behind tractor. To determine the reliable amount of this component, you can take a wire 70 centimeters long, and then bend it and insert it into the mechanism. As a result, at least 30 centimeters should be smeared on it (this is considered the norm). If the indicator is less, then you need to add fluid.

Important! If maintenance is performed, it is necessary to fill the liquid to the level, otherwise rapid wear of a part such as the gearbox will be observed.

Characteristics

| Engine power (hp) | 6,5 |

| engine's type | 4 stroke |

| Engine | Lifan |

| Engine capacity (cm3) | 195 |

| Fuel | Gasoline AI-92 |

| Fuel tank volume (l.) | 3,6 |

| Processing width (cm) | from 30 to 88 |

| Processing depth (cm) | up to 25 |

| Number of speeds (forward) | 2 |

| Number of speeds (reverse) | 1 |

| Transmission | Mechanical |

| Clutch | Belt |

| Engine cooling | Air |

| Packaging dimensions (mm) | 1510x620x1335 |

| Weight (kg) | 76 |

Equipment:

Operating instructions for Ugra NMB-1N17

Ugra NMB-1N17 goes on sale with instructions for use. According to this document, it is unacceptable to load the walk-behind tractor at full power in first gear without attached attachments. Otherwise, the speed limit of 3 km/h in this gear will be exceeded and the device may fail.

Speed optimization

| Broadcast | Speed km/h | Soil and attachments |

| 1 | up to 3.61 | Work on heavy soils, potato planter, trailer with load, adapter. |

| 2 | up to 5.88 | Work on light soils, cultivators on heavy soils |

| 3 | until 8.52 | Cultivators on light soils, driving with a trailer on roads |

| back | up to 2.28 | Rotary mower, snow blower. |

In the first days of operation, it is recommended to operate the engine at 2/3 power; it is allowed to operate at full speed for no more than 30 minutes. After 30 hours of operation, the break-in period can be considered completed, and the walk-behind tractor can be loaded at 100%.

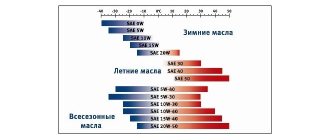

For the gearbox, you should use oil that meets the requirements of TSn-10 GOST 23652-79 or another that meets SAE: 80 - 85W API: GL3...GL4.

The oil change on the Ugra NMB-1N17 walk-behind tractor is performed after break-in, that is, 30 hours of operation after the first start. During scheduled maintenance, the oil level is checked and topped up to normal. The oil is changed after 100 hours, then the pattern is repeated.

Ugra NMB-1N17 walk-behind tractor with Lifan 170F 7.0 hp engine:

Repairs and malfunctions

Despite the fact that walk-behind tractors of the Salyut model range are reliable, in some cases malfunctions occur in the gearboxes. Let's look at the main problems you may encounter and how to deal with them:

Other malfunctions may also occur related to the breakdown of bearings or gears, as well as anthers; here it is necessary to immediately replace worn parts.

Important! If the device is non-separable, then if there is a serious malfunction, you will have to buy a new one, which is why, in order not to encounter unnecessary costs, the oil fluid on such elements is replaced more often.

Currently, special equipment includes many high-quality structural elements. However, even despite this, it can be subject to breakdowns. Often the failure of components is associated with a lack of lubrication, which has an extremely detrimental effect on the metal. That is why, in order to avoid unnecessary waste of funds, it is recommended to carry out maintenance in a timely manner. In this case, the working apparatus will perform all the duties assigned to it for a long time.

Device, spare parts and components.

SPARE PARTS FOR TRACTORS

ADJUSTMENTS OF MTZ TRACTORS ___________________

DIESEL ENGINE PARTS ___________________

MTZ SPARE PARTS CATALOG ___________________

TECHNICAL CHARACTERISTICS OF TRACTORS ___________________

SPECIAL EQUIPMENT BASED ON MTZ AND ATTACHMENTS ___________________

AGRICULTURAL MACHINERY AND EQUIPMENT ___________________

Advantages of the NMB-1N17 model

- massive weight improves the passage of virgin soils;

- the equipment has two power take-off shafts;

- 4 working speeds (including reverse gear);

- gear reducer;

- steel gear housing;

- no belts (no need to replace);

- easy silent start;

- high stability during operation;

- minimal damage to plants in the adjacent row to the one being treated;

- the walk-behind tractor operates taking into account the connection of a wide range of attachments (including equipment from others);

- The clutch material is cermet discs;

- high traction force;

- ability to transport loads weighing up to 500 kg when using a trailer;

- comfortable, non-slip handle, adjustable to the operator's height.

Ugra NMB-1N17 with the appropriate additional equipment can easily cope with the role of a snow remover, lawn mower, segment cultivator, and feed crusher.

The width of the cultivated strip of land reaches 90 cm. The reverse allows the walk-behind tractor to make turning movements, thereby increasing the maneuverability and mobility of the machine. In third gear, the unit reaches speeds of up to 9 km/h. In first gear, used for deep soil cultivation, such as cultivation, the speed is 1 km/h.

Motoblock Ugra NMB-1 N1 in action:

Technical side of the model

Model features

Specifications

Salute Motoblock has a 4-pin Lifan 168F-2B engine;

Easy to use, even a boy can do it.

What can you do in the garden using the Motoblock Salyut 100 unit

Looses and plows the ground without problems and quickly;

It is used both in the garden and in mountainous areas. Able to work on any soil, including virgin soil. Selects the depth and width that suits you.

Did you know? During Soviet times, this unit was produced not only in Russia. They assembled in Georgia and made tires in Yerevan. In Ukraine, then and now, in the same plant - Advis, walk-behind tractors are produced.

Advantages and disadvantages

Firstly, as said earlier, its size is very convenient to use. A plus will be a gear reduction, with which you can change the speed to a suitable one and there is also a belt drive.

It is important to know : original belts can hardly withstand a long time, so experienced walk-behind tractor users advise immediately replacing them with more durable ones.

A plus is also the control of the gearbox using the steering wheel. There is no need to bend and break your back; you can safely use it without causing problems to your spine.

The control levers now have a plastic handle, which is convenient, since previously the handles were made of metal and could pinch your hand.

The only drawback of the walk-behind tractor can be considered the belts, which, as we already know, should be replaced immediately.

Maintenance

Manufacturer's recommendations are important when using any tool, but it is extremely important to know how often and what kind of oil to fill.

It is advised to change the oil for the first time after the first 25 hours of operation, but this is only the first time. With further use, the oil can be changed at 90 - 100 hours of use of the unit.

Pour oil into a special hole - 1 liter. It is advisable to use oil - TM-5-18 (TAD-17-I).

Fill with oil with the engine off. Place in a horizontal position and use reverse on the lever. Use the dipstick and find out how much oil you need. Drain off the oil that has already been used.

What's the problem if it won't start?

First, before use, you need to check the unit for serviceability. You need to check the clutch, reverse and gas connections.

The most common reason why the walk-behind tractor does not turn on is stagnation. It was not used for a long time in winter and then oxidation of contacts or watering of fuel or oil could occur. Another reason could be a problem with the wire insulation.

Some people use weights with containers of sand or pebbles to help the unit in heavy ground.

Weights are used when plowing land or hilling plants. They are adapted to cultivators.

What types of lubricant should be used?

There are two types of lubricant for walk-behind tractors:

- For 4 stroke engine

- For 2 stroke engine

In the engine

The primary oil change in the internal combustion engine occurs after 28-32 hours of operation. The next replacement can be made no more than 2 times a year - in summer and winter, even if the unit has been standing for some time without operation. To begin the replacement process itself, you need to prepare special attributes - a funnel and a container for draining the waste liquid.

At the bottom of the engine there is a hole with a cap through which old oil can be drained. A drain container is placed in the same place, the locking cap is unscrewed, and the waste liquid is drained. It is necessary to wait some time for the residue to completely drain from the engine system. Then the plug is screwed into place and fresh oil .

READ How to Make a Crawler Motoblock with Your Own Hands

Its quantity should be identical to the drained amount. If it is not possible to take measurements, it is better to look at the technical data sheet of the unit, where the required number in grams is indicated. After new oil has been poured into the engine, it is necessary to check its level. To do this, just use a special probe.

It is worth noting that in some engines that are sensitive to oil fluids, for example, Subaru or Honda, it is assumed that they use oils of a certain class, that is, SE and higher, but not lower than the SG class.

This instruction is general for both two-stroke and four-stroke models. More specific information on how to replace the oil in a walk-behind tractor is best considered in the instructions for the specific unit.

Gearbox manufacturing process

First, the parameters of the power plant are calculated. The crankshaft speed can be found in the technical specifications. This is the first quantity required to perform the calculation. The value is not constant, with the addition of “gas” the number of revolutions increases. Basic value: idle speed +10% .

Next, the suspension axle revolutions are calculated . Knowing the size of the wheels, it will be possible to calculate the amount of run-out per revolution. The number of axis revolutions is calculated to ensure a comfortable speed - 3-5 km/h, which is the second value for design.

For example, idle speed +10% is 600 rpm. The required wheel axle speed for 3 km/h is 200 rpm. So, the gear ratio should be 3:1 . The rotation speed of the axis is reduced by three times in relation to the speed of the motor shaft, and the torque increases accordingly by three times. Gearbox types:

Source