Why won't the walk-behind tractor start?

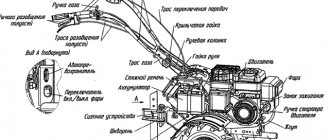

Malfunctions in this dilemma can be very different and relate to different walk-behind tractor systems. First, you need to check the availability of all the necessary spare parts and devices, especially if the walk-behind tractor is new or, on the contrary, has not been used for a long time. Before starting, carefully check all fasteners, connections and cables and their movement. Make sure there is oil in the crankcase and there is sufficient fuel level in the tank. Do not start the walk-behind tractor if the movement of the cables is difficult; this may indicate twisting of the harness threads.

After a winter holiday, the most common reasons for the failure to start a walk-behind tractor are oxidized contacts, damaged wiring insulation, and deterioration of fuel and oil during inactivity.

Also, common reasons that the walk-behind tractor does not start well include:

- Breakdown and/or clogging of the carburetor and its components;

- Malfunctions in the ignition system (a common failure);

- Low level of lubrication or its complete absence in the gearbox;

- Tasks in the operation of the cylinder.

Why does the walk-behind tractor stall when the air damper is open?

The carburetor air damper, in other words “choke”, is necessary for normal engine starting and its further stable operation. If the damper is not adjusted correctly, for example, when it is not completely closed, the engine may not start at all.

One of the common reasons for the incorrect operation of the power unit is air leaks. The reason for this may be depressurization of the carburetor. Check the spark plugs, tighten them if necessary, tighten the connecting bolts. If this does not help, replace the gaskets.

The engine will stall even with the air damper open. You can adjust it until it moves normally, without shifting or snagging.

This is interesting: the gears on the Agro walk-behind tractor do not engage.

No spark on walk-behind tractor

This malfunction is directly related to a breakdown of the ignition system. Failures in the ignition system include malfunctions of the magneto, generator, wiring, cap and spark plug. If the spark is lost or it is weak, the reason is solely in the cap and spark plugs. First, remove the spark plug and assess its condition. If necessary, wipe off the soot from it and fry it over the fire (if you cannot immediately change it to a new one).

Reinstall the spark plug and try to start the walk-behind tractor again. If there is still no spark, check the contact of the cap with the central electrode of the spark plug. The gap between the cap and the electrode is checked with a special probe and should be 0.8 mm.

A few words about how to avoid similar situations. First, always follow the instructions given in the instruction manual correctly. If you stick to them, your walk-behind tractor will last even longer.

Also, in order to avoid problems with starting a walk-behind tractor, it is important to know what motor cycle a given model has (which is also indicated in the annotation). For example, walk-behind tractors from the company Neva (MB-1 and MB-2, which in most cases are equipped with a Subaru engine), Zubr, Salyut, Agro, Cascade are equipped with a four-stroke engine. And the Mole company’s walk-behind tractors have a two-stroke engine. The value of this information for owners is that it shows how to properly refuel equipment. For models with a 2-stroke engine, it is necessary to prepare a special combustible mixture, for which gasoline and oil are mixed in a certain proportion. For walk-behind tractors with a 4-stroke engine, oil and gasoline are poured separately. But don’t forget to also look at their quality!

You should also always keep in mind the correct procedure for starting your walk-behind tractor. For example, for a walk-behind tractor from the Krot company or any other unit with an internal combustion engine, the start-up is carried out in the following sequence:

- Open the gasoline supply tap.

- Set the fuel choke lever in the Start mode (Choke).

- With the ignition off, the engine is run through the kick starter a couple of times.

- Start the walk-behind tractor and switch the fuel choke lever to the Run position.

With diesel engines of the Neva, Zubr, Salyut, Cascade or Agro walk-behind tractors, the situation is slightly more difficult. First you need to bleed the air from the fuel system. To do this, you need to open the fuel supply valve, unscrew the fuel hose connections until fuel appears, tighten the connections and blow out the injectors. If, after these manipulations, the walk-behind tractor does not start or does start, but thick snow-white smoke comes out of the muffler, it is necessary to urgently change the oil.

After a long period of inactivity, the diesel engine should be started according to the following algorithm:

- Open the petrol tap.

- Check for presence of lubricant.

- Turn on the ignition.

- Turn the throttle slightly, no more than halfway.

We also suggest that you familiarize yourself with how to properly start a walk-behind tractor:

Repair of components and mechanisms

Starting a diesel walk-behind tractor after purchase can be difficult. The fact is that air gets into the fuel supply system. If cranking for a long time (with the starter) does not allow it to start, then the air plugs should be released. To do this, open the diesel supply valve and unscrew all connections along the fuel channels. The final point of purging is the nozzles.

In order for an internal combustion engine to start, a number of requirements must be met. Let's list them in order:

- Preparing the fuel mixture.

- Fuel supply to the cylinder.

- Ignition of the mixture.

- Exhaust gas release.

Fulfillment of the above conditions guarantees the start of any motor.

Difficulties during startup indicate a malfunction of components and mechanisms. The success of the repair depends on the correct diagnosis. If defects are found, they repair the diesel walk-behind tractor. Maintenance and minor repairs can be done on your own. You will need a set of keys, locksmith tools and skillful hands.

At the stage of preparing the fuel mixture, the following incidents are possible:

- the air filter does not allow air to pass through;

- the hole in the tank lid is clogged;

- the fuel supply path is clogged;

- The carburetor broke down.

After a series of unsuccessful starts, it is useful to unscrew the spark plug. The working part can be filled with fuel. Dry the part. Next, pump the cylinder through the hole. We twist the candle and start it again.

If the spark plug is dry, it means that fuel is not entering the combustion chamber. Let's perform a series of steps to restore the supply system:

- drain old gasoline;

- rinse the tank;

- clean the filter from dirt;

- blow out the fuel supply hose;

- blow out the carburetor jets;

- fill the tank with clean gasoline;

- open the faucet;

- clean the breathing channel in the lid.

How do walk-behind tractors start?

As you know, walk-behind tractors are either gasoline or diesel. Starting occurs in a different way. Therefore, the reasons why the Neva walk-behind tractor does not start may differ significantly.

Before starting the walk-behind tractor after purchase or after winter, you must check the presence of each part and their condition, the condition of the contacts and wires. You also need to change the oil and add fuel.

In most cases, the unit may not start after winter. You must keep in mind that storage in a cool and damp room does not go without any traces. You will encounter problems such as:

- Oxidation of contacts; v

- Clogged jets;

- Damage to insulation on wires;

- Damage to fuel and oil.

Be sure to check the oil level before starting. If it is not enough, the piston group may completely fail.

Starting a gasoline and diesel unit

The equipment is equipped with gasoline or diesel engines. Starting a diesel walk-behind tractor

and a gasoline device has differences. For this reason, it is necessary to analyze the factors due to which the unit does not start for each specific type of engine.

Before purchasing a walk-behind tractor

, preparing special equipment. It is necessary to make sure that absolutely all elements are present and to make sure that the mechanisms are securely fastened.

Mechanisms often refuse to work after winter. A long break becomes a prerequisite for the occurrence of problems in the walk-behind tractor systems. Storing in a cool and humid area will cause the following problems:

- oxidation of contacts;

- violation of wiring insulation;

- watering of fuel and oil;

- clogged carburetor jets.

Before launching a new walk-behind tractor

They control absolutely all connections, clutch cable, reverse and gas. Do not turn on the device if there are clamps or twisting of the harness threads.

During the first start-up, be sure to check the oil level in the crankcase. Lack of lubrication will damage the piston group. The crankshaft spins up to 1400 revolutions per minute at idle. It only takes a couple of seconds to create a scuff mark on the cylinder plane.

Old oil can cause the engine to not run. At the same time, the walk-behind tractor emits white exhaust gases. This begs for an absolute oil change.

It should be taken into account that the mini-tractor does not start easily if there is not enough oil. Keep an eye on this setting before

How to start a carburetor and diesel walk-behind tractor. In some modifications, protection is determined by a low level. The device blocks startup and the unit freezes.

It should be remembered that any type of engine requires a specific brand of gasoline. For a two-stroke engine, fuel is prepared separately. The fuel mixture consists of fuel and oil. The number of ingredients is kept in strict balance.

Why won't the Neva walk-behind tractor start?

Neva walk-behind tractors are distinguished by their reliability and durability, but, like no matter what kind of equipment, nasty moments happen from time to time in the form of breakdowns. The Neva walk-behind tractor may not start for various reasons, which we will try to understand in this article.

READ What kind of oil is poured into the Neva Motoblock

Spring is the beginning of the season for gardening and gardening. It was during this period that it became clear that something was wrong with the walk-behind tractor. It is necessary to immediately find out the cause of the breakdown and remove it as quickly as possible.

Neva walk-behind tractors come in various models, such as MB1, MB2, and others. They all differ in engines, motors and design. Before you begin to determine the cause of the breakdown, carefully study the instruction manual.

Breakdowns, their causes and solutions

There may be several circumstances why the walk-behind tractor does not start:

- The wire broke;

- Insufficient fuel level;

- Fuel is not absorbed;

- Spark plug problems.

If you plan to find the cause of the breakdown and remove it without the help of others, then follow this sequence of work:

- Check the wire from the power button to the spark plug;

- You need to remove the spark plug. The contact can be cleaned with sandpaper and at the same time check the distance between the contacts;

- Screw the candle into place;

- Blow out the fuel supply system;

- If necessary, clean the fuel filter. It may be clogged, which makes it difficult to supply fuel to the combustion chamber.

A few more methods to bring your walk-behind tractor to life:

- If the starter cord just comes out easily, the reason may lie in a cylinder seal that has worn out, or in a gasket between the carburetor and the filter that is installed incorrectly.

- If the unit starts up, but immediately stalls, the reason may be poor patency of the sump tank. Check the faucet and clean it. There may also be water in the fuel, so the fuel needs to be changed one hundred percent.

- If you hear popping noises and flames coming out of the muffler, you need to check the flywheel key. It may be damaged or deformed. It needs to be changed.

- If you see that the walk-behind tractor switches off at times accompanied by popping noises, you should check the spark plug. If it is wet, replace it with a new one or clean it. To do this, you need to wash it, think about it and calcinate it.

Always choose only high-quality fuel and oil for your own equipment. Otherwise, you may encounter problems, even to the point where the car simply breaks down. Finding a replacement for a damaged part for a Neva walk-behind tractor is not a problem, but it will already cost certain foreign exchange costs.

Ignition system

Why won't the engine of the Neva walk-behind tractor start? Due to a malfunction in the ignition system. The prerequisite may be a magneto, cap, spark plug or high-voltage wire. You need to look at every detail. If there is dirt or moisture, this may be the main reason for the problem. Everything needs to be cleaned and dried.

Another reason is lack of spark. This is due to the disgusting contact between the cap and the central electrode of the spark plug. A spark plug can also be a reason for a weak spark. Check the gap and condition of the electrodes. It is necessary to remove all fumes from all parts and the insulator.

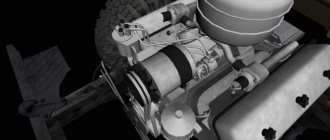

The piston system can also fail. It is necessary to check the condition of each component part. There is a lot of load here, and the rubbing surfaces get very hot.

Check the intake and exhaust valves to ensure they are seated tightly. The last path to diagnosis is the muffler. Combustion products are deposited on the walls of this part. To avoid engine stalling, it is necessary to clean the muffler channels from time to time.

Ignition system malfunctions

The engine will not start if there is a malfunction in the ignition system. Why is this happening? Sources of failure may include the magneto, high voltage wire, cap and spark plug. An external inspection checks the cleanliness of the ignition system parts. Dirt and moisture cause high voltage breakdown to the housing. The absence of a spark occurs when the cap has poor contact with the central electrode of the spark plug.

A weak spark indicates poor spark plug performance. It is necessary to check the gap and condition of the electrodes. Check the gap with a feeler gauge. Typically it is 0.8 mm. If necessary, remove fumes from metal parts and insulators. It is recommended to replace the spark plug.

The condition of the piston group parts affects the readiness of the engine as a whole. They work in difficult conditions. Under load, the rubbing surfaces heat up. The cylinder, piston and rings are responsible for an important indicator - compression. A low compression ratio in the cylinder will indicate replacement of parts.

You should also check the intake and exhaust valves. They should fit snugly on the saddles. The muffler is the last point on the exhaust gas path. Combustion products are gradually deposited on the walls of the muffler, and the engine stalls. For normal passage of exhaust gases, the walls should be periodically cleaned of carbon deposits.

Experts advise following all manufacturer's recommendations. The unit must not be overloaded.

Compliance with all requirements will extend the life of the mechanisms.

Before starting work, the owner must read the operating instructions.

In this topic, we will analyze the malfunctions of walk-behind tractors and cultivators of all brands. Neva, Zubr, etc., and their elimination and repair. Most problems are typical for all types of walk-behind tractors, their engines and other components.

Differences between gasoline and diesel engines Neva

Neva walk-behind tractors are functional devices that have a lot of advantages. With their help, you can easily cultivate the land, get rid of weeds, plant and dig up plants, remove the harvest, and mow the grass. And this is not the entire list.

The units are equipped with either a diesel or internal combustion engine. The starting of different types of engines differs from each other, therefore, before answering the question of why the Neva walk-behind tractor does not start, it is necessary to find out all the intricacies of its operation.

Before turning on the equipment, you need to make sure that there are no visible mechanical damages, that the equipment is all assembled, that the wires have not come loose anywhere, and so on. Often engines do not start after winter. If you stored the walk-behind tractor in a wet and cool room, you will eventually be able to find the following breakdowns:

- Oxidation of wires;

- Oil watering;

- Violation of wire insulation;

- Clogged jets in the carburetor.

When you just purchased a walk-behind tractor, you cannot turn it on right away. You need to carefully check all the details: connections, clutch, gas and reverse cables. Moreover, you cannot turn it on if there is twisting of the strands of the harnesses.

Even if you are assured that the unit is completely ready for operation, first also check the oil level in the crankcase. If there is not enough of it or there is an excess, the engine may simply not start. If your equipment has been sitting for a long time, the oil may deteriorate, which will also cause problems in the operation of the engine. In this case, simply replace it with a new one.

Also keep in mind that each engine runs on different gasoline. A two-stroke engine requires a special mixture of gasoline and oil, and the ratio of ingredients must meet certain standards. Almost everything also depends on the properties of the fuel. Refuel only at reputable and proven gas stations.

The walk-behind tractor starts and stalls: causes of malfunction and mechanisms for eliminating them

Owners of either brand new or used motor cultivators are not insured against a situation where the walk-behind tractor starts but immediately stalls at idle.

It can be caused by a number of factors:

- problems in the ignition system:

- loose or broken electrical contacts;

- spark plug malfunction. They can be installed only after unscrewing and external inspection. If the candle:

- dry - the cause of the malfunction lies in the carburetor, where gasoline is not supplied. It may occur due to clogging of its filter or a separate jet;

- wet - the engine does not develop speed due to an excess of fuel;

- covered with soot - the fact of its failure, which may result in the failure of an ignition spark to form. Testing with electrodes will help you finally verify this;

- after replacing or cleaning the spark plug, the electronics are examined - the integrity of the connections and the wires themselves, which may need repair due to strong vibration;

- shortage or poor quality of fuel . Often the engine does not gain speed due to an incorrectly prepared fuel mixture or debris in the carburetor. In this case, the repair begins with removing it from the walk-behind tractor body and cleaning it from dirt particles. At the same time, they change the fuel, after draining the old one and washing the fuel tank and supply hoses.

- Another reason that the walk-behind tractor starts up and immediately stalls, related to gasoline, may be depressurization of the gas tank itself. Very often this is observed after a long period of inactivity (for example, after winter), when the walk-behind tractor has not been used for a long time and has been stored with gross violations. After repairing or replacing the entire fuel tank, the functionality of the device is usually restored;

- cool weather, which often causes diesel equipment to stall. Therefore, in early spring, experts advise turning on the walk-behind tractor only after pouring hot water into the radiator;

- gearbox malfunction. The fact that the cultivator does not develop speed and stalls at idle is indicated by a characteristic knocking noise from the gearbox, which occurs against the background of a lack of lubricant.

Why won't the Neva walk-behind tractor start?

Technological progress has not affected farming either. For everyone who works with the earth, an unlimited number of different equipment has appeared on sale, which significantly simplifies the work and protects human health.

Walk-behind tractors are universal machines that can handle any task from plowing the land to planting plants and harvesting crops. There are an unlimited number of types on sale, divided by manufacturers, price category, and type of motor.

In this article we will look at a situation where the Neva walk-behind tractor does not start for some reason. You can ultimately identify the cause of the breakdown and quickly fix it.

Units and mechanisms

Starting a new Neva walk-behind tractor can be very problematic. This is due to the fact that there is air in the system. If the starter fails to turn on, all air must be bled out.

To do this, you need to open the diesel fuel supply valve and unscrew all connections along the fuel channel to the nozzle.

To start a gasoline engine, you must perform the following steps:

- Prepare a mixture of fuel;

- Put fuel into the cylinder;

- Light the mixture;

- Release processed gases.

There may also be a problem with the spark plug. If it is quite wet, there is an excess of oil. It is necessary to dry the part, pump the cylinder through the hole and screw the spark plug into place. Then try to turn on the walk-behind tractor.

READ Do-It-Yourself Motoblock On Big Wheels

If the spark plug is 100% dry, it means fuel is not entering the ignition chamber. To return the feed system, you need to perform the following steps:

- Get rid of old gasoline;

- Clean the tank;

- Clean dirt from the filter;

- Clean and blow out the fuel supply hoses;

- Clean the jets in the carburetor;

- Fill with new gasoline;

- Open the tap;

- Clean the breathing channel in the lid.

Methods for repairing Neva walk-behind tractor engines

The problem can occur in either an old engine or a completely new one. However, don't despair. Even a non-professional will be able to find the cause and eliminate it.

Units and mechanisms

Launching a new Neva walk-behind tractor can be very problematic. This is due to the fact that there is air in the system. If the starter fails to turn on, you need to bleed out all the air.

To do this, you need to open the diesel fuel supply valve and unscrew all connections along the fuel channel to the nozzle.

To start an internal combustion engine, you need to do the following:

- prepare the fuel mixture;

- let fuel into the cylinder;

- light the mixture;

- release exhaust gases.

The problem could also be with the spark plug. If it is completely wet, there is too much oil. You need to dry the part, pump the cylinder through the hole and screw the spark plug into place. After that, try to turn on the walk-behind tractor.

If the spark plug is completely dry, then fuel is not entering the ignition chamber. To restore the feed system, you must perform the following steps:

- get rid of old gasoline;

- clean the tank;

- clean dirt from the filter;

- clean and blow out the fuel supply hoses;

- clean the jets in the carburetor;

- add new gasoline;

- open the tap;

- clean the breathing channel in the lid.

Ignition system

Why doesn’t the engine of the Neva walk-behind tractor start? Due to a malfunction in the ignition system. The cause may be the magneto, cap, spark plug or high voltage wire. Every detail must be inspected. If there is dirt or moisture present, this may be the root cause of the problem. Everything needs to be cleaned and dried.

Another reason is the lack of spark. This occurs due to poor contact between the cap and the central electrode of the spark plug. The spark plug can also be the cause of a weak spark. Check the gap and condition of the electrodes. It is necessary to remove all fumes from all parts and the insulator.

The piston system can also fail. It is necessary to check the condition of each component part. There is a huge load here, and the rubbing surfaces become very hot.

Check the intake and exhaust valves to ensure they are seated tightly. The last path to diagnosis is the muffler. Combustion products are deposited on the walls of this part. To avoid engine stalling, you need to periodically clean the muffler channels.

How to avoid breakdowns of the Neva walk-behind tractor?

Every peasant knows how expensive it is, no matter what kind of equipment, including the repair of parts. Naturally, if you have excess funds, you can afford to buy new components or even new equipment.

But still, you should adhere to the usual rules in order to extend the life of your own Neva walk-behind tractor. As mentioned above, before work, check all mechanical parts for defects.

Also read the annotation before the work, where it is written down what needs to be done and how. Storage plays an important role. Water may cause corrosion in various parts of the unit. Oil and fuel may simply deteriorate.

If you value your equipment, follow the storage rules, also promptly clean the equipment from dirt when working in the ground, as well as from the accumulation of soot on various parts. Don’t forget to check the oil and change it when it’s time. Then your Neva walk-behind tractor will serve for many years, delighting you with its amazing condition.

Adjustment of valves

Adjusting the valves is a fairly common procedure, for which you will need wrenches, screwdrivers and a feeler gauge. The process of adjusting the valves is needed to establish good and technically correct clearances between the valves of the walk-behind tractor engine. Adjusting valves using the example of the Neva MB-23 walk-behind tractor (the principle is the same for everyone)

The adjustment sequence is as follows:

- Remove the casing that covers the engine;

- Remove the valve box cover;

- Make adjustments (see below);

- Replace the valve box cover;

- Replace the casing.

The valves are located under the valve cover. The gap size can be checked with a feeler gauge. The intake valve clearance is 0.15 mm, and the exhaust valve clearance is 0.2 mm. The dipstick should fit under the valve with the correct gap size.

To adjust, the valve nuts are loosened, then a feeler gauge is inserted, after that the adjustment itself is made, and the valve nut is tightened.

First launch and testing of the Neva MB-2 walk-behind tractor

The first launch must be created following the following scheme:

- Make sure that the walk-behind tractor is in complete condition (the height of the control rod and handles must correspond to the user’s height);

- You can start the engine only in this case if the walk-behind tractor is placed on a level surface;

- Check the oil and fuel levels in the tank;

- Also check the threaded connections;

- Then you can start the engine by gently turning the ignition knob;

- The idle time (without load and movement) should be about 10 minutes, then you can move away and operate the walk-behind tractor.

The break-in period is the first 20 hours of operation of the walk-behind tractor, after which it is necessary to change the oil. During this period it is more important:

- Do not operate at full throttle;

- Work only on previously prepared soils (not virgin soil);

- For cultivation, use only the number of cutters that are included in the kit;

- The Neva MB-2 walk-behind tractor can only be loaded at ¾ power during the run-in period;

- Gear changes in the gearbox can only be created when the rotation of the drive pulley is completely stopped;

After the first 20 hours of operation after the first start, the engine oil should be changed.

Adjusting and tuning the Neva MB-2 carburetor

The functionality and durability of the walk-behind tractor engine depends on the measured operation of the carburetor. That is why its adjustment and tuning are of such fundamental importance. In addition, if the carburetor is incorrectly configured, a gasoline walk-behind tractor may experience increased fuel consumption

Adjusting the carburetor of the Neva MB-2 walk-behind tractor is done as follows:

- The full throttle and idle screw are turned out to the maximum.

- Both screws are unscrewed 1-1.5 turns.

- Next comes starting and warming up the engine.

- The throttle control lever is placed in a position in which the engine will operate at low speed.

- Set low idle speed until the unit operates stable.

- The idle speed is set to maximum.

- An adjustment is made to the low idle speed.

- Steps 6 and 7 are performed until the engine runs smoothly (soundingly smoother) at idle speed.

For long-term and uninterrupted operation of the walk-behind tractor, you need to frequently diagnose the engine’s operation, monitor the frequency of oil changes, and also observe operating conditions and time intervals for scheduled maintenance.

Changing the engine oil

The manufacturer recommends using such well-known brands of motor oil for the walk-behind tractor as LUKOIL standard SAE 10W30 API SF/CC, also RAVENOL SAE 30 API CD/SF.

At temperatures above four degrees Celsius, using thickened types of oils (for example, 10W30 brand) will lead to increased consumption of this type of fuel, therefore in the cool season it is recommended to check the oil level in the engine more often, preventing its level from dropping below normal.

The oil change is carried out after the walk-behind tractor has recently been in operation, while the engine has not yet completely cooled down. It should be warm, but not hot. The remaining oil is drained from the tank one hundred percent, then new oil is added until the oil level reaches a special mark. The drain plug is then tightened tightly and wiped dry.

Operation and maintenance of Neva MB-2

Replacement of gearbox seals

Replacing the oil seals in the Neva MB-2 walk-behind tractor is done if an oil leak is detected.

A similar condition is unsafe because the walk-behind tractor gearbox may be left without oil, and this will lead to rapid wear of the unit.

The sequence for replacing oil seals is as follows:

- Remove the cutters from the shaft, cleaning the shaft and covers from dirt and oil residues.

- Unscrew the cover bolts, tap off the oil and debris, and remove the cover from the gearbox.

- The old oil seal is replaced with a new one and wiped dry.

- The cover is screwed into place (it is placed on sealant as needed) and secured with bolts.

READ What kind of oil for a four-stroke walk-behind tractor

Basic faults

Belt adjustment and dimensions

For the Neva MB-2 walk-behind tractor, an A-1180 drive belt is used. This model uses one belt that provides front movement.

In other modifications of the Neva MB-2 model, two drive belts are used. Reverse gearing is done in the gearbox itself.

Replacing the belt for MB-2 walk-behind tractors is done in the following sequence:

- The shield is removed, and then the pulley protective cover.

- The spring from the walk-behind tractor rod is removed to loosen the belt.

- The screws securing the bracket are turned.

- The bracket rotates to a position in which the limiting pins do not prevent the part from being removed from the pulley.

- They adjust the pulleys, and then install a new belt.

- Pull the belt onto the gear shaft pulley, and then onto the motor pulley.

- In reverse order, place other parts in their places.

Basic rules for setting the ignition

Checking and setting the ignition on the Neva MB-2 walk-behind tractor is carried out according to the following principle:

- The spark plug is turned inside out, the electrodes are wiped dry, then the carbon deposits are removed;

- The gap between the electrodes is measured and set;

- The spark plug body is fixed to the cylinder head;

- The crankshaft rotates up to 4 times (use a starter cord for scrolling);

- If the ignition is working properly, a white-blue spark should be struck. Its absence or yellowish color indicates a malfunction.

Next, you should check the condition of the flywheel and stator and the size of the gap between them (the norm is from 0.10 to 0.15 mm).

The gap is increased, if necessary, using a feeler gauge. As an auxiliary tool in the absence of a probe, you can use an A4 sheet folded into four times or a razor blade. If the clearance between the flywheel and the stator is normal, the ignition will work properly.

Motoblock MB-1: frequent breakdowns of the unit and their solutions

This walk-behind tractor can safely be called the first-born in Niva production. Naturally, by today it has been modernized in almost everything and has acquired a more modern design. With the help of such a unit, you can perfectly process the entire area in any weather. It will perform well both on flexible sandy soil and on hard ground. And the metal cylinder liner ensures its reliability and long service life.

At the moment, we will look at more frequent cases of breakdowns of this unit. Usually, all repair instructions can be found in the instruction manual, so if you still have it, you can safely use its instructions. But if this item is lost, then you can use our advice.

Do-it-yourself repair of the Neva MB-1 and MB-2 walk-behind tractor according to all instructions

The first Neva walk-behind tractors appeared back in the 80s. Today, they not only have not lost their popularity, but have even become even more in great demand.

Thanks to the constant modernization of models, Neva units amuse their customers with an affordable price, good wear resistance, the highest quality of all devices and a long service life. Among the huge number of models of this brand, we will talk about two more favorite ones: the MB-1 and MB-2 walk-behind tractors. We will find out not only their features, but also try to analyze the more common reasons for their breakdown.

Let's look at the most common malfunctions of the MB-1:

- In case of oil leakage along the output shaft, the first thing to do is remove the axle shaft cover and change the cuffs.

- What to do if the gearbox jams? In this situation, you need to disassemble the walk-behind tractor, where you need to change the broken chain.

- If there is no kinematic connection inside the gearbox, it means that the broken sprocket in the block needs to be replaced.

- Gear malfunction: they do not engage at all or do not shift. There can be several reasons for such a breakdown. 1st destroyed switching pin. 2nd thread of the shift knob is cut. In these cases, we simply replace the defective parts with new ones.

- Oil leakage on the shift shaft. The first thing we do is check the oil level in the gearbox. If an excess of it is found, then drain the excess, and if on the contrary, top up.

- Wear of the shaft seal edge. Everything is very simple here: we disassemble the gearbox and replace the worn cuff with a new one.

- The restoration of the overrunning clutch should be carried out as follows: remove the starter, take out the clutch, and grind off the grooves for the balls. It is necessary to pour a little oil inside to minimize friction between the clutch and shaft. We install everything back.

Malfunctions of Neva MB-2:

- The separation of the semi-axes is unrealistic. In this case, we check the drive adjustment. If it is incorrect, change the cable tension.

- Self-switching gears or lack of fixation. Such a problem can appear in 3 cases, or the switching adjustment system is broken. Then you need to loosen the screws that hold the board, engage one gear and tighten the screws back. Either the spring is broken or the board retainers are worn out. In this case, it is simply necessary to replace the broken parts. Or the fork cheek has worn out, then it is necessary to disassemble the gearbox and replace the broken part.

- If there is no kinematic connection inside the gearbox, then it is necessary to change the shift fork itself. Another possibility is that the welding of the gear to the block shaft has broken.

It is worth keeping in mind that before you repair the Neva walk-behind tractor yourself, you should carefully read the repair instructions that the manufacturer offers for you. If you don’t have such an annotation, then you should use the tips above. Of course, if you do not have special abilities to repair such equipment, then it is better to entrust the Neva MB walk-behind tractor to specialists. There are a huge number of service centers that will carry out a complete diagnosis of the equipment and be able to identify the exact cause of the malfunction.

Remember, in order for the walk-behind tractor to serve you for many, many years and not succumb to any malfunctions, it is necessary to do timely oil changes and adhere to all operating conditions.

Sources:

https://yargeo.com/motoblok-neva-mb-2-plavajut-oboroty/ https://sadovaja-tehnika.com/motobloki/ne-zavoditsya/ https://pro-motobloky.ru/motobloki/neva/ pochemu-ne-zavoditsya.html https://sadovij-pomoshnik.ru/motobloki/neva/pochemu-ne-zavoditsya-prichiny.html https://fermerinform.ru/remont-obsluzhivanie-motoblokov-neva-mb2/ https: //sadovij-pomoshnik.ru/motobloki/neva/remont-neva-mb-1-i-mb-2.html