Chainsaw malfunctions Friendship

Question: Chainsaw Druzhba 2. The primary defect is startup, 3-4 puffs and then it stalls, gasoline drips from the air filter mesh, the spark plug is flooded.

What can be done? Answer: Remove the carburetor, unscrew 6 screws. The diaphragm is fine, but there is a lot of dirt, grains of sand, and specks in the working chamber - remove the valve.

Specks on the rubber valve. Wash with a brush, spray with foam cleaner (acetone) and wipe until shiny. We put the valve in place, make sure it is tight by blowing with your mouth. We check the tightness by connecting the fuel hose.

We blow out the carburetor with a pump or compressor. We collect. We start the saw, check at speed, idle speed and transient modes (during a sharp release and a sharp increase in gas.

If necessary, adjust the quality of the mixture with a screw, idle speed with a screw on the trigger. The saw should work.

Question: Can anyone tell me how to adjust the clutch of the saw at the start of engagement?

Answer: This adjustment on the Druzhba 2 chainsaw is made in cases where the clutch comes together at idle engine speed (the saw chain moves along the bar).

The clutch will slip, most often due to the loss of elastic properties of its rings as a result of their overheating during prolonged slipping at high speeds.

The restoration of the elastic properties of the rings is carried out by cold hardening, straightening along their outer diameter on a mandrel, the diameter of which is 10-15 mm less than the inner diameter of the ring.

Straightening is done with a sharp hammer head across the ring, evenly along the entire perimeter. Make a smaller stretch at the ends of the rings.

As a result of straightening, the gap in the ring lock is significantly reduced. The lateral spread of the ends of the ring in the lock is eliminated by bending it by hand.

Question: A Druzhba 4M chainsaw with an interesting sign of operation is being repaired. When working approximately 10-15 minutes. It stalls and the spark disappears completely.

After cooling (about 20-30 minutes) 10-15 minutes. works fine, and again from the beginning. There is a problem with the ignition, the question is - is there any pattern that the ignition can work like this, or could it be anything, it’s better to change the whole thing?

Answer: This electronic ignition appears to be overheating. It's worth trying to change the magneto. You can't fit into the magneto anyway - everything is flooded with something.

They say it's difficult to fix.

Question: I used a Druzhba 4M chainsaw with electronic ignition, it worked perfectly, last year it stopped starting, I changed the magneto and capacitor - it didn’t help.

I took it apart and dried the magneto on a sunny day, it suffered, there was no spark. I changed the coil and contacts, cleaned it - well, everything is fine.

Then I found the reason - poor contact of the capacitor with the coil wire, corrected it, a spark appeared. I pour about 2 ml of gasoline under the spark plug. syringe, but no cotton. does not light up - the spark seems normal.

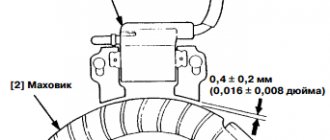

True, I installed the ignition. so tell me - right or wrong: set the TDC, set the gap in the contacts to 0.25, turn the crankshaft clockwise so that the piston moves 4.2 mm from TDC.

As I understand it, the ignition moment, the contacts begin to open - so did you do it right or not? But realistically, what is the gap in the contacts?

And also on the new contact group the contacts do not match, i.e. that the hat is to the hat, although I looked at the old one, they also don’t quite match, but the truth is a little more even. Could this affect the ignition?

Answer: The advance moment is only always before TDC. Apparently you did a very late ignition. Not reaching 2-4 mm from TDC.

Small errors in the gap in the contacts and advance do not critically affect the start. As far as I understand, the size of the gap affects the power of the spark.

Don’t be overly burdened with it, but still strive for a regular one. But there are factors that affect the gap. This is basically play in the crankshaft bearing.

If the backlash is huge, then the gap in the contacts can vary, which leads to unstable operation. A more important parameter is ignition timing.

But even here you can make a mistake of 1 mm along the piston stroke, it’s not scary. But it is no longer desirable. It can be properly adjusted only with the help of a strobe using pre-applied marks on the flywheel.

Question: Tell me, how does someone stop the crankshaft of the Friendship 2 chainsaw to loosen the clutch or flywheel nuts?

Answer: On the clutch side, use a screwdriver in the disc hole and catch on some edge.

On the flywheel side, I secured it with my original flat key from a spare parts kit, on the air duct side, it locks it very well in one of the positions, you just need to make sure that the key is at the very base of the flywheel blades.

Then I tightened the nut not too tightly with the original puller under it and hit it through the rod into the end of the shaft with a hammer.

Question: How to properly adjust the tension of the saw chain on the Druzhba 4 saw?

Answer: This adjustment is made after installing a new saw chain on the bar, as well as during operation with a chainsaw, since the saw chain (especially a new one) stretches during operation and its tension weakens.

Adjust the chain tension in the following sequence: Loosen the fastening of the tire to the gearbox by unscrewing the nut.

By rotating the tensioner screw, tighten the saw chain so that when the lower branch of the chain is pulled away from the bar in its middle part, the edge of the connecting link of the chain is at a distance of 5-10 mm from the edge of the bar.

The tensioned chain should move along the bar by hand. A new saw chain on a new bar that has not been broken in may not move by hand. This is not a defect.

After a short run-in of the sawing apparatus at medium speed (3-5 minutes), the mobility of the saw chain on the bar will be restored. Tighten the tensioner nut.

Question: Tell me, what are the parameters of the crankshaft nut on the clutch side of the chainsaw?

Answer: M14x1 height 4mm. the same nut secures the chain drive sprocket.

Question: Tell me about the contact chainsaw Friendship 4 Electron.

The problem is this: it starts the first or second time, it idles normally, the power seems to be normal, but you start sawing, and as soon as you turn the saw away from you, it stalls, it’s exhausted, maybe someone knows the reason?

Answer: what if the saw is running without load and “turned up” will it also stall? According to the theory, the engine stalls if there is nothing to burn or ignite.

Moreover, usually, when the ignition system fails, the engine stalls “sharply,” and when the power system fails, it convulses, but does not stall immediately.

So you need to inspect the ignition and power system. Ignition is easier - check the spark in the “wrapped” position of the saw.

Question: I have been using the Druzhba 2 saw since 1974.

It broke down a lot in different ways, but now the problem is the following - I put in a new spark plug, it starts fine, but as soon as I burn 2 tanks of gasoline (I make the mixture 20/1) and the spark disappears, the spark plug is all wet with carbon deposits, I heat the spark plug - it starts, but it works not for long. the situation repeats itself, I put in a new one again, again 2-3 tanks and that’s it.

Moreover, whenever I unscrew the spark plug it is always wet, tell me what is the reason and how to fix it?

Answer: Reduce the gap in the spark plug to 0.5 mm, if the ignition is contact - clean and adjust the breaker.

Reasons for the Malfunction of the Friendship Saw Stalls When Starting

Chainsaw malfunctions Friendship

Question: Chainsaw Friendship

2. Primary disadvantage. start, 3-4 puffs and stalled, gasoline drips from the air filter mesh, the spark plug is flooded. What do they do?

Answer: Remove the carburetor, unscrew 6 screws. The diaphragm is fine, unfortunately, there is a lot of dirt, grains of sand, and specks in the working chamber. remove the valve.

Specks on the rubber valve. Wash with a brush, spray with foam cleaner (acetone) and wipe until shiny. We place the valve in the area and make sure it is tight by blowing with your mouth. check the density by connecting the fuel hose.

We blow out the carburetor with a pump or compressor. We collect. We start the saw, check at speed, idle speed and transient modes (during a sharp release and a sharp increase in gas.

As necessary, we adjust the quality of the consistency with a screw, and the idle speed with a screw on the trigger. Saw

must work.

Question: Can anyone give me a hint on how to adjust the saw clutch at the start of engagement?

Answer: This adjustment on the Druzhba 4.5 chainsaw is done when the clutch comes together at idle speed of the engine ( saw chain

moves along the bus).

The clutch will “slip” in most cases due to the loss of elastic parameters of its rings during their overheating during long-term slipping at high speeds.

Restoring the elastic parameters of the rings is done by cold hardening, straightening along their outer diameter on a mandrel, the diameter of which is 10-15 mm smaller than the inner diameter of the ring.

Straightening is done with a sharp hammer head across the ring, moderately along the entire perimeter. At the ends of the rings, make the smallest stretch.

And therefore, when straightening, the gap in the ring lock is significantly miniaturized. The lateral spread of the ends of the ring in the lock is eliminated by manual bending.

Question: A Druzhba 4M chainsaw with an interesting feature of operation is being repaired. During operation approximately 10-15 minutes. stalls, the spark is completely lost.

After cooling (approximately 20-30 minutes) 10-15 minutes. works fine, and starting again from . Problem with ignition, question. Is there some kind of pattern that can work like this in the ignition, or perhaps anything, it’s better to change it completely?

READ How to Disassemble a Circular Saw

Answer: This electric ignition appears to be overheating. It's worth trying to change the magneto. In any case, you can’t fit into the magneto. our client is left with something there.

It's hard to fix, they say.

Question: I was using a Druzhba 4M chainsaw with electric ignition, it worked perfectly, which stopped starting last year, I changed the magneto and capacitor. didn't help.

I took it apart and dried the magneto on a sunny day, it suffered, there was no spark left. I changed the coil and contacts and cleaned them. and what remains for our client to do is unclear.

Later I found the reason. Bad contact of the capacitor with the coil wire, corrected it, a spark appeared. I pour about 2 ml of gasoline under the spark plug. syringe, but no cotton. does not light up. The spark seems normal.

True, I installed the ignition. say so. true or false: set the TDC, set the gap in the contacts to 0.25, turned the crankshaft clockwise so that the piston moved 4.2.7 mm from TDC.

The chainsaw stalls when you press the gas

Stalls

chainsaw

when

pressing the gas.

The Partner 370 chainsaw began to stall with

the slightest pressure on the handle.

The chainsaw does not start or does not start well. Reason and how to fix it.

Why won't the chainsaw start? Cause

.How to eliminate.

This is, as I understand it, the ignition moment, the contacts begin to open. so did you do it right or not? But realistically, what is the gap in the contacts?

And also on the new contact group the contacts do not match, i.e. that the hat is to the hat, although I looked at the old one, they also don’t quite match, but the truth is a little more even. Could this affect the ignition?

Answer: Moment of advance. it is only always up to TDC. Apparently you did a very late ignition. Not reaching 2-4 mm from TDC.

Small errors in the gap in the contacts and advance do not critically affect the start. As far as I understand, the size of the gap affects the power of the spark.

READ Husqvarna 142 Carburetor Tuning

Don’t be overly burdened with it, but still strive for a regular one. But there are factors that affect the gap. This is basically play in the crankshaft bearing.

If the backlash is huge, then the gap in the contacts can vary, which leads to unstable operation. A more important parameter is ignition timing.

But even here you can make a mistake of 1 mm along the piston stroke, it’s not scary. But it is no longer desirable. It can be properly adjusted only with the help of a strobe using pre-applied marks on the flywheel.

Question: Tell me, how does someone stop the crankshaft of the Friendship 2 chainsaw to loosen the clutch or flywheel nuts?

Answer: From the clutch side. a screwdriver into the hole of the disk, and catch on some edge.

From the flywheel side. I secured it with my own flat key from a spare parts kit, on the side of the air duct, it locks it very well in one of the positions, you just need to make sure that the key is at the very base of the flywheel blades.

Then I tightened the nut not too tightly with the original puller under it and hit it through the rod into the end of the shaft with a hammer.

Question: How to properly adjust the tension of the saw chain on the Druzhba 4 saw?

Answer: This adjustment is made after installing a new saw chain on the bar, as well as during operation with a chainsaw, since the saw chain

(especially a new one) stretches out during operation and its tension weakens.

Adjust the chain tension in the following sequence: Loosen the fastening of the tire to the gearbox by unscrewing the nut.

By rotating the tensioner screw, tighten the saw chain so that when the lower branch of the chain is pulled away from the bar in its middle part, the edge of the connecting link of the chain is at a distance of 5-10 mm from the edge of the bar.

The tensioned chain should move along the bar by hand. A new saw chain on a new bar that has not been broken in may not move by hand. This is not a defect.

READ Petrol mower stalls at high speed Cause

After a short run-in of the sawing apparatus at medium speed (3-5 minutes), the mobility of the saw chain

the tire will be rebuilt. Tighten the tensioner nut.

Question: Tell me, what are the parameters of the crankshaft nut on the clutch side of the chainsaw?

Answer: M14x1 height 4mm. the same nut secures the chain drive sprocket.

Question: Tell me about the contact chainsaw Friendship 4 Electron.

The problem is this: it starts the first or second time, it idles normally, the power seems to be normal, but you start sawing, and as soon as you turn the saw away from you. stalls, is tortured, maybe someone knows the reason?

Answer: what if the saw is running without load and “turned up” will it also stall? According to the theory, the engine stalls if there is nothing to burn or ignite.

Moreover, usually, when the ignition system fails, the engine stalls “sharply,” and when the power system fails, it convulses, but does not stall immediately.

So you need to inspect the ignition and power system. It's easier with ignition. Check for spark in the “wrapped” position of the saw.

Question: I am using a saw

Friendship 2 since 1974.

It broke down a lot in different ways, but now the problem is the following. I put a new spark plug in, it starts up fine, but as soon as I burn out 2 tanks of gasoline (I make the mixture 20/1) and the spark disappears, the spark plug is all wet with carbon deposits, I heat the spark plug and it starts up, but doesn’t work for long. the situation repeats itself, I put in a new one again, again 2-3 tanks and that’s it.

Moreover, whenever I unscrew the spark plug it is always wet, tell me what is the reason and how to fix it?

Source

Recommendations for the operation and maintenance of the Druzhba chainsaw

The Druzhba chainsaw is designed for felling forests and sawing logs. Thanks to its convenient design, the technical characteristics of even models from the 60s remain acceptable for many consumers.

To keep the saw in working condition, preventive maintenance of all components must be carried out regularly, and adjustments must be carried out at least once a year.

Device

The main parts of the chainsaw are as follows:

- engine;

- sawing apparatus;

- frame with handles;

- gas tank

The engine is a single-cylinder two-stroke carburetor. Cooled by air flow created by a centrifugal fan. The engine and sawing apparatus are independent units, connected into 1 unit with flange fasteners and secured with a clamp.

When the fuel tap is opened, fuel enters the diaphragm carburetor, which ensures uninterrupted supply to the engine at any angle of inclination and strong vibration. The design of the chainsaw does not allow the engine to stop if the chain gets jammed in the barrel while cutting wood.

The handles are located high, which provides the following capabilities:

- do not bend over while working and get tired less;

- work in deep snow conditions;

- increase user safety.

Characteristics

Over the 60 years of production, the design of the Druzhba chainsaw and its characteristics have changed insignificantly.

The general parameters are:

- weight when fully equipped - 12.5 kg;

- dimensions - 865x460x500 mm;

- saw bar length - 450 mm;

- The fuel tank capacity is designed for 1.5 liters of fuel liquid;

- spark plug - any with a diameter of 17 mm.

The main difference between the modifications is power. It is indicated by the number in horsepower at the end of the model names.

Friendship 2

The technical characteristics of this model are as follows:

- engine power - 2.2 kW;

- saw starting type - manual;

- lack of a rotary gearbox.

What makes Druzhba 2 different from the first model is the presence of a device for braking the chain, which made it safer: the tool cannot accidentally injure the worker or the people around him. The material from which the case is made is reliable and can withstand any temperature changes.

Friendship 4

This model received a gold medal at the World Technology Exhibition in Brussels in 1958.

The technical characteristics of the chainsaw are as follows:

- power - 2.94 kW;

- engine oil tank volume - 150 ml;

- total shaft rotation speed - 5000-5400 rpm;

A gas-powered saw can cut through a trunk with a diameter of up to 50 cm in 1 minute.

Friendship 4M electron

The Druzhba 4M electron chainsaw is distinguished by the fact that this model is equipped with an electronic non-contact ignition system, which significantly increases the reliability of the engine.

The technical characteristics of 4M are as follows:

- power - 3 kW;

- fuel consumption - 720 g/kW h;

- the distance between the spark plug electrodes is within 0.6-0.7 mm.

The inner walls of the aluminum cylinder liner are plated with chrome to increase wear resistance. The model is equipped with rubber shock absorbers that reduce the transmission of engine vibration to the handles. The Druzhba-4M model uses a KMP-100U carburetor, and with the Druzhba 4A modification, the use of forced chain lubrication began due to the installation of an oil pump. This made it possible to significantly increase the service life of the chain and guide bar.

Model range of chainsaws Druzhba

The advantages of the Druzhba chainsaw, in addition to those mentioned above, are that it cuts smoothly and accurately, is highly productive and all the parts are in a durable case. Its disadvantages include significant weight - more than 12 kg with dimensions of 86.546x50 cm and a cable starter.

The main difference between modifications of the Friendship chainsaw is engine power:

- Friendship 2 has a power of 2 kilowatts, manual start and, unlike the 1st model, an element for chain braking.

- Druzhba 4, which received “gold” at the World Technology Exhibition in Brussels in 1958, has almost one kilowatt more power, sawing effortlessly, with shaft revolutions of more than five thousand, a half-meter log in one minute.

- Friendship 4M-electron, having a non-contact electronic ignition system, uses the engine resource with greater efficiency, with almost the same power - 3 kW. The cylinder's chrome coating adds wear resistance, and rubber gaskets reduce overall vibration. In modification 4A, an oil pump is installed for forced lubrication of the chain.

Like any other technical device, the Druzhba 4 chainsaw requires constant carburetor adjustment, attention, regular care and preventive maintenance. At least once a year it is necessary to fine-tune the Druzhba 4 carburetor, including its adjustment.

Advantages and disadvantages

The advantages of the Friendship saw are:

- long service life;

- simple device - you can quickly access any node without much difficulty;

- smooth and precise cutting;

- high performance;

- maneuverability;

- All parts are reliably protected by a durable casing.

The successful design of the Druzhba 4 chainsaw engine made it possible to use it in the production of walk-behind tractors, lawn mowers, and also to develop on its basis the SD-60 engine for driving stationary installations - generators, pumps.

The disadvantages of a chainsaw include the following:

- heavy weight;

- removable rope starter.

Operation, maintenance and repair

To ensure trouble-free operation of the saw, it must be adjusted periodically. The operating instructions supplied with the equipment describe the features of setting up the model. Incorrect configuration will lead to unbalanced operation of the nodes.

How to adjust the carburetor

Failures occur when not enough or too much fuel is supplied, as well as if the proportions when mixing fuel with air are violated.

Carburetor adjustment is carried out as follows:

- The fuel regulating screw is first turned all the way, and then back (counterclockwise) 1.5-2 turns.

- Start the engine, warm it up for 1-2 minutes and turn the T screw in one direction or another to ensure its stable operation at maximum speed. The chain should not move along the bar at idle speed.

- Check and, if necessary, seal the connection between the carburetor and the cylinder.

It is easier to adjust the carburetor using a tachometer, but at home, in most cases, engine operation is adjusted by ear. When both the quantitative and qualitative fuel supply is normal, the engine does not overheat, does not choke, runs smoothly, without sharp sounds. When adjusting, turn the screws slowly, without jerking.

How to set the ignition

Stable operation of the engine is ensured by correctly adjusted ignition - the Druzhba 4 chainsaw in this case will consume a minimum amount of fuel. The saw is ignited thanks to a magneto using a spark plug and a special wire.

To monitor the quality of the spark for igniting the chainsaw, place the spark plug on the cylinder body and pull the starter. If the spark plug is in working condition, a spark will jump between the electrodes. A weak spark will not ignite the fuel; such a spark plug must be replaced.

It is better to replace the contact ignition of a chainsaw with an electronic one. This will eliminate constant problems with its regulation. It is necessary to ensure that the ignition coil mounting screws do not loosen.

Basic malfunctions and their elimination

If you know why the tool malfunctions, you can repair it yourself at home.

When the Druzhba 4 chainsaw engine starts and stalls, the reasons may be as follows:

- There is not enough fuel in the gas tank. It is necessary to add the mixture according to the instructions supplied with the instrument.

- The spark plug was splashed with fuel. This prevents a spark from forming. The candle must be removed, dried, and heated on a gas burner.

- Poor contact between spark plugs and wire. This occurs due to the increased gap (more than 0.5 mm) between the tip of the spark plug and the wire. The spark plugs must be cleaned of carbon deposits with a wire brush and blown with air. They need to be changed periodically.

If engine malfunctions occur at idle, repairing the Druzhba 4 chainsaw comes down to the following:

- replacing the fuel mixture with reducing the amount of oil;

- cleaning the air filter and muffler (due to its clogging, the engine runs but does not develop speed);

- checking the fuel line and replacing the tube if necessary.

If the cutting speed has decreased and the tire is “driving”, pay attention to the sharpness of the saw teeth. A well-sharpened chain is more important than a strong engine. It is best to take it to a master for sharpening or use a machine with a rotary sharpening disk. The bevel of the Friendship saw blade on the bottom edge is 45°, and on the side edge - 60°. The height of the limiting protrusions relative to the chain teeth should be the same and checked after 3-4 sharpenings of the chain.

It is recommended to place the chain in liquid lubricant for some time, preferably heated.

The reasons why the Friendship saw does not start may be the following:

- The fuel mixture does not comply with the repair and operating instructions for the model.

- Manufacturing defects. Repairs are carried out in a warranty workshop.

When assembling, even if the parts fit tightly, you should not use force, for example, hitting them with a hammer. By replacing worn elements, you can restore the functionality of the chainsaw or extend its life.

Homemade Chainsaw Ignition

Electric ignition unit for chainsaw

Despite the widespread distribution of chainsaws imported from other countries, the population, especially in rural areas, still uses many Russian “Druzhba” and “Ural” devices. Both saws have a common drawback that I also had to deal with. fragility of the electric ignition unit . This problem is not new. see article by P. Ivanov “Repairing the ignition unit of a chainsaw” in “Radio”, 2003, No. 2, p. 45. Nowadays it is not difficult to buy a block, but it is expensive and does not last long. I decided to start developing my own design, which I bring to your attention.

Unlike the one mentioned above, the ignition unit does not contain remote elements and fits entirely into the original dimensions of the factory unit. The board of the old unit must be removed.

The block diagram is shown in Fig. 1. Generator coil L1, ignition coil (high-voltage transformer) T1, capacitor C1, induction ignition pulse sensor L2 and a duralumin base were used from an old ignition unit . Other elements. newly introduced.

Rice. 1 Schematic diagram of the device

When the flywheel rotates, the generator coil L1 generates an alternating current, which, after rectification by the diode bridge VD1-VD4, charges the capacitor C1. At a certain position of the flywheel, a short pulse of positive polarity appears at the terminals of the sensor coil L2, which, passing through the diode VD5 and the current-limiting resistor R1, opens the thyristor VS1. Capacitor C1 is discharged through an open thyristor and the primary winding of the ignition coil T1. Its secondary winding forms a high voltage pulse, which is then supplied to the spark plug.

The amplitude limiter of the opening pulse is assembled on transistor VT1, resistor R2 and zener diode VD6. As long as the voltage on the control electrode of the trinistor VS1 does not exceed the stabilization voltage of the zener diode VD6, the transistor VT1 is closed and does not affect the control electrode circuit. When the zener diode VD6 opens, current begins to flow through it and resistor R2. A voltage appears across resistor R2, which slightly opens transistor VT1, which shunts the control electrode circuit of thyristor VS1. As a result, the pulse amplitude is limited to about 4 V at the zener diode indicated in the diagram. This voltage is enough to reliably open the thyristor.

In order for the described design to fit into the dimensions of the factory ignition unit , it is necessary to modify the thyristor. To reduce its length, the threaded shank was shortened (1-2 threads were left), the cathode and control leads were also shortened to a length of 4.5 mm. Before shortening the lead, it must be compressed in two places near the body using side cutters with blunt cutting edges. Then, above these places, the lead is bitten off and the cut is soldered with solder.

The terminal can be compressed no closer than 2 mm from the SCR body, otherwise the insulator will crack. This compression is necessary to increase the contact area between the internal conductor coming from the crystal and the external terminal of the SCR.

READ Chainsaw Partner 350 ignition gap

The unit is installed using rigid copper wire with a diameter of 0.4-0.45 mm in vinyl insulation. Diodes VD1. VD4 are assembled closely into a block and their terminals are soldered in such a way that AC terminals are obtained on one side of the block, and on the other. permanent. The transistor is secured with the screw that was used to secure the factory board. A petal is placed under the transistor, to which the leads connected to the body are soldered. Resistors, diode VD5 and zener diode VD6 are soldered to the terminals of transistor VT1 by surface mounting.

Capacitor C1 is placed in the same place, and the bridge VD1-VD4 is placed in the same compartment. Wires from coil L1 to the bridge. flexible, of the same cross-section. The wire going to the anode of the thyristor is soldered to its body. Before filling with the compound, the thyristor is held “suspended” on rigid wires in such a way that it does not protrude beyond the dimensions of the unit, and a gap of about 2 mm remains between the thyristor body and the duralumin base of the generator. After testing for functionality, the assembled unit is filled with epoxy compound, making sure that the parts of all elements close to the edges and the SCR housing are covered with a layer of compound. After the compound hardens, the thyristor is rigidly fixed to the base of the generator. The finished block is shown in Fig. 2.

Rice. 2 View of the finished block

When installing the unit in a chainsaw, it may be necessary to adjust the ignition timing. In practice, it was often necessary to set it earlier relative to the factory mark. If you plan to install the block in a Ural chainsaw, before assembly you need to remove part of the mounting protrusion from the back side of the base, painted in Fig. 3 in blue, flush with the base plane. Under the remaining parts of the protrusion, when installing the block in place, it is advisable to place gaskets made of heat-insulating material, such as asbestos cardboard, with a thickness of no more than 0.5 mm. With a greater thickness, the flywheel may interfere with the block parts. Gaskets are needed because the design of the Ural chainsaw provides for the installation of an electronic ignition unit directly on the wall of the engine crankcase, which becomes very hot during prolonged operation.

Ignition from a chainsaw to a motorcycle engine TULA (aka ANT) part 1.

Ignition

from

a chainsaw

to a TULA engine Review of the device. The video is not complete. The battery died while filming, so...

Ignition from a chainsaw for a Minsk cross motorcycle

Review of parts, their installation and testing of the motorcycle.

Rice. 3 Reverse side of the part

In the above block, instead of those indicated in the diagram, you can use diodes KD105G, KD209 with any letter index, as well as other suitable dimensions with a reverse voltage of at least 400 V and an average forward current of at least 0.3 A. We will replace the KS133A zener diode with KS 139, KS 147, KS 156 with letter indices A, B, G or their imported analogues, provided that the sum of the stabilization voltage of the zener diode VD6 and the voltage of the IBE transistor VT1 does not exceed the permissible voltage at the control terminal of the thyristor. SCR KU202N can be replaced with KU202M, KU205V, KU205G. Tri-nistors in a plastic case should not be used due to their insufficient resistance to overheating.

READ Cutting Logs Along with a Chainsaw

In conclusion, I will add that more than 20 blocks were assembled according to the description provided and they work for a long time and reliably. The unit I assembled and installed on my chainsaw 6 years ago has never failed.

Author: A. KARPOV, p. Imiskoye, Krasnoyarsk Territory

Readers' opinions

- Alexander / 01/14/2018. 15:53 Hello! I have SCRs constantly flying in this circuit. I change it every year. Can you tell me what could be the reason?

- Nikolay / 05.25.2017. 20:42 where to connect the wire on the magneto

- kuku / 08/10/2016. 17:05 I don’t know the Chinese ignition device First you need to check the spark This is not like checking on a spark plug This is nonsense You need to remove the “fishing rod” attached to the spark plug, expose the wire and first keep it at a distance of 3-4 mm from the ground Then move it away from the ground to - into the wire by 5-6 mm, and further, but gradually Note the length of the spark The length of the spark should be 61 mm corresponding to the mixture pressure in the cylinder of 6 atm. means 6 mm, slave pressure 7 atm. 7 mm If the spark is small and not long enough and weak, then move the magneto or coils to the right or left relative to the magnets, but by a very small amount - 0.5 mm. the spark will increase in length, which means in power. So notice this position. At the longest spark length, the ignition of the spark will be fast and confident. After completing the adjustment, put the fishing rod on the wire and on the spark plug and check. Success will be achieved! All the best, good luck!

- Igor / 04/10/2016. 15:51 I lost a spark on my Chinese saw, tell me what it could be

- rifat / 01/29/2016. 20:14 Quiet as in the forest Sometimes the ignition is often early. less often later. To adjust the rough ignition, I changed the resistance value R2 100 ohm to a larger value when the ignition is advanced, and a smaller value when retarded. Of course, you need a strobe light.

- Rifat / 11/20/2015. 15:32 Victor! dated March 2, 2015. You most likely have the ignition timing off. That is, the spark should advance ahead of TDC by 2.8.3.2 mm or 29 degrees before TDC. To do this, you need a strobe or a homemade device with a neon lamp, which connected to the coil on the high-voltage wire going to the candle. The number of turns is 30-40, the arced end is free, we hold the neon light bulb by one wire with our hands. True, it shines dimly but is visible only in the dark. We check the flash and advance from TDC with a strobe. I won’t explain, this is written about in many instructions and manuals.

- rifat / 04.11.2015. 19:23 Alexander! Look at my answer to Fedor!

- Rifat / 11/04/2015. 19:22 same name from o805 2013 Exactly, mixed up! You can easily figure it out on your own

- rifat / 04.11.2015. 19:19 Fyodor If there is a wire sticking out, it’s for emergency jamming. It goes to the button that on the fan body you can safely throw away. You can stop it anyway, but you can spoil the purchased item in no time by shorting it out.

- rifat / 04.11.2015. 19:02 I apologize, you should read the base is moving forward, clockwise, to the limit, and the advance is very early

- rifat / 04.11.2015. 18:49 Dear craftsmen! I have a question for you. I assembled the diagram presented above. The spark is exceptional, it appears with half a kick, quickly. But there is a problem with the ignition timing, the spark appears 8-10 mm before TDC. When I try, it even becomes scary to start. But moving the electronics unit itself back on the seat does not work, it’s just a limit, then you need to grind the aluminum base itself. Question: how to make the ignition timing later, how and what to add to the circuit, or change the value of which element thread I'm waiting for an answer

- Fedor / 04/19/2015. 12:21 I bought a new ignition , the wire is sticking out, why and where to connect it, it’s not clear I can’t find the answer, tell me the Ural saw Thank you.

- Victor / 03/02/2015. 16:11 The scheme doesn’t work at all. I didn’t take measurements, but the spark is such a color that you can use it instead of a headlight, but the fuel doesn’t want to ignite! The spark does not have enough current to ignite the gasoline.

- Alexander / 10/12/2014. 09:47 I bought a new ignition and some wire is sticking out, where to attach it. It's not on the old one!

- [email protected] / 05/08/2013. 08:07 In the photo, are the designations of coils L1 and L2 mixed up?

- Alexander / 03.23.2013. 14:59 I assembled the circuit and everything worked right away. They asked me to assemble another one, I assembled it, but no matter what you want, there is no spark. I tried changing parts on the first block - everything works, the second is useless. Maybe someone had problems, write.

- Vadik / 01/30/2013. 15:08 I assembled the circuit, spark-beast. The saw starts, but it works stupidly (the UOS is not working properly), it picks up speed poorly, has interruptions at medium and high speeds, and may stall. I think the circuit does not take into account the need for a thyristor blocking current

- Alexey / 01/12/2013. 19:57

- Alexander / 10.27.2012. 15:58 Help me figure out how to make a wiring from a transistor with resistors to a thyristor. Anyone can help. Write by email [email protected]

- Volodya / 04/23/2012. 06:27 If possible, send me a diagram for the ignition of the M/P Taiga, electronic. Email, Thank you!

READ How to Adjust the Carburetor on a Husqvarna Chainsaw

1

234Forward

You can leave your comment, opinion or question on the above material:

How much does a Druzhba chainsaw cost?

Chainsaw ZiD Druzhba 4 can be bought for 15 thousand rubles. The price of a used unit depends on its condition, the degree of wear of the main elements, the total service life, the presence or absence of all components, a passport and ranges from 1 to 7 thousand rubles. For example, a Druzhba-Altai chainsaw from the 90s, which differs from the basic one in an improved carburetor and saw system, can be purchased for 5 thousand rubles.

Spare parts are in demand. The most worn part - the sprocket - can be bought for 100-150 rubles, the starter - for 600-700 rubles, and the electronic ignition system - for 1 thousand rubles.

The design and principle of operation of the ignition system on a Druzhba chainsaw

For more than 30 years, until the end of the 1980s, Druzhba chainsaws were produced with contact ignition (mechanical breaker). The principle of generating electricity is the same as that of more modern electronic systems. A magnetic rotor mounted on the crankshaft rotates inside the coils. The primary winding of the coil consists of several turns of thick copper wire and produces a current of low voltage (V, Volt), but quite high strength (A, Ampere).

The secondary winding consists of many turns of thin wire. In some ways it is a step-up transformer. Passing through it, the electric charge changes its characteristics. And the output voltage is 15-30,000 V at a scanty current (milliamps). This current is capable of producing a high-temperature spark (arc) between the electrodes across the gap, which can be observed on each spark plug.

The latest modification of this chainsaw with contact ignition, Druzhba 4A, was produced until the end of the 1980s. Afterwards it was replaced with Druzhba 4A Electron with contactless ignition, as indicated by the prefix in the model name.

Repair and operation of the ignition system of the Druzhba chainsaw

The operation of the Druzhba-4 chainsaw revealed a number of shortcomings. What is especially annoying is that it is almost impossible to start a hot engine.

The cause of this “illness” is a weak ignition system.

To increase the power of the spark on the spark plug, the ignition system must be redone. Such a modification can also be useful in the absence of a working magneto coil for the standard ignition system.

Interlayer insulation is required: after each layer of wire, a gasket is made of paper or varnished cloth. The beginning of the winding is soldered in place of the standard terminal to the core, and from the end of the winding a terminal is made with a mounting wire for connection to the ignition breaker. The coil is insulated on top (you can use insulating tape). The circuit of the capacitor connected in parallel with the breaker and the coil remains unchanged.

Next, conclusions are drawn using two mounting wires through a piece of rubber hose as a seal. To ensure reliable insulation of the wires, it is advisable to combine them into a common sheath of PVC tube.

A B-115 ignition coil with a remote resistor, which is attached to the side of the coil, is used as a step-up transformer. This type of coil is found in the ignition systems of Moskvich, Volga and other cars. The use of motorcycle ignition coils is undesirable: they do not provide sufficient spark power. The ignition coil is attached using a clamp to the chainsaw frame in any convenient place.

The wires coming from the engine “snail” are connected as follows: one, coming from the common connection point of the capacitor, breaker, coil output - to the “VK” terminal of the B-115 ignition coil; the second, coming from the ground and connected to the magneto mounting bolt - to the terminal of the B-115 ignition coil, which does not have a designation. It is advisable to choose wires of different colors.

Next, the ignition coil is connected with a high-voltage wire to the engine spark plug.

Adjusting the ignition timing gave very good results, all the “illnesses” of the chainsaw disappeared. For several years now, the redesigned ignition system has been working properly on the Druzhba-4 chainsaw.

In conclusion, we can say the following: the ignition coil slightly “spoils” the appearance of the saw, but it is better to have a saw that is reliable in operation than one that brings nothing but torment.

This ignition system can also be used on other types of engines, which was tested on moped engines of type D-5, D-6. The winding in this case contains 160 turns.

How to check the ignition of Friendship

If the internal combustion engine of a chainsaw fails, in addition to the fuel supply, first of all check for the presence of a spark on the spark plug:

- Remove the cap and unscrew the spark plug.

- The spark plug thread is shorted to ground (cylinder ribs), and the starter is pulled. Contact ignition produces a large blue spark. Electronic - small yellow, difficult to see in sunlight. But this is the norm for electronic systems.

- If there is no spark, replace the spark plug with a guaranteed good one and check again.

- If the problem is not in the spark plug, remove the cap from the spark plug wire and, when the starter jerks, check for the presence of a spark between the bare wire and the ground with a gap between them of 0.2-1 mm.

- If there is no spark at the output, check or change the spark plug wire.

DIY repair

When the above measures do not eliminate the problem, the reasons may be as follows. The electronic ignition unit has failed. All elements of this unit are sealed (filled with compound) and cannot be repaired. The entire unit needs to be replaced.

The cam (contact) ignition system of the Druzhba chainsaw is repairable. There are several reasons for its failure:

- The textolite insulator of the moving contact of the breaker was pierced to ground. Replaces with a working one without any options.

- The moving and fixed contacts of the breaker (cams) were burnt. Clean with a fine file or emery until the surfaces are smoothly adjacent to each other. They change when completely burned out.

- The capacitor is designed to protect contacts from burnout. It rarely fails and does not directly affect the formation of a spark. When diagnosing, it is simply ignored.

- Interturn short circuit, break in the secondary high-voltage turns of a coil with a thin wire.

Chainsaw repair Druzhba

All breakdowns of Friendship chainsaws can be divided into several main groups of faults:

- Something is wrong with the lubrication system.

- Some component of a 1-cylinder, two-stroke, carburetor engine, or even more than one, has failed.

- The ignition system does not work, not producing a spark or producing it with a force insufficient to ignite the fuel mixture.

- Failure of other parts of the chainsaw (saw blade, frame with handles or gas tank).

If you are not an electrical engineer or a person with experience in numerous successful repairs, then self-repairs must be carried out in accordance with the instructions.

For example, constant malfunctions of the engine, sporadic inability to start it, and so on, can be caused by the following reasons:

- Lack of gasoline in the gas tank. It is necessary to add fuel to the appropriate mark.

- The spark plug is flooded with gasoline, which prevents the formation of a spark of sufficient power. This candle must be dried and calcined on a gas stove or other burner. This also indicates that the carburetor is out of adjustment and there is an excess of gasoline. To eliminate this, it is necessary to close the corresponding output and operate the starter for some time.

- Poor contact between the spark plug and the corresponding wire due to the resulting gap of more than half a centimeter. The spark plug is cleaned of carbon deposits (the electrodes are cleaned with fine-grained sandpaper) and blown out from all sides.

- The air filter is clogged with dirt. To be cleaned or replaced.

- The fuel filter is clogged with all sorts of debris. Using a wire hook, you need to disconnect the filter from the hose, clean it and, after thoroughly drying, install it back.

Important! In order to ensure that the Druzhba gasoline-powered saw operates without interruption, all filters must be replaced at least 2-3 times a year and cleaned as needed, but at least once a month.

- The muffler is clogged with dirt. Its spark arrester becomes clogged, mainly due to poor quality or the wrong brand of oil, or if its content in the fuel mixture is high. To be cleaned and dried, including the fuel pipe.

- Carburetor membrane sticking. Full adjustment with disassembly and reassembly or replacement of the carburetor.

- Due to low speeds, any 2T oil can be used. But it is necessary to maintain a ratio of 15:1.

- If the gas-powered saw stops working when tilted away from you, then it is necessary to change the crankshaft seals, and possibly the entire central piston group.

- Manufacturing defects. Delivery to the collection point specified in the instructions is required if the warranty period has not expired.

Also, repairs must be made in the appropriate workshop if the tire “drives.” A correctly sharpened and seated chain is more important than the strength of the engine. As a preventive measure, it is recommended to lower the chain into a container filled with liquid lubricant in a warm state.

How to adjust the ignition on Druzhba

The spark on the candle must flash strictly at a certain moment. On Druzhba - when the piston with a portion of the fuel-air mixture approaches the spark plug, not reaching 4 mm from TDC. Only with a precisely adjusted spark point will the engine operate normally. Deviations are called early or late ignition.

With small deviations in one direction or another, the engine will perform worse (lack of power, overheating, excessive fuel consumption, poor starting). With more significant ones it will not work at all. Can shoot into the exhaust system or carburetor.

Mechanical chainsaw breaker Friendship is simply regulated.

Before adjusting, you need to check - perhaps the fastening of the entire system platform has become loose and it has turned. It is checked by matching the factory marks (marks) on the metal base of the ignition and the engine crankcase. As a rule, they are stamped in the form of stripes on the upper right side of the ignition and should match. If there is a bias, it is corrected.

The maximum gap (at the peak of the divergence) between the cams (contacts) should be from 0.2 to 0.4 mm. Ideally 0.3 mm. Checked with a calibrated feeler gauge in the BDC piston position. This gap may increase beyond the permissible limit due to a decrease in the thickness of the contacts (burnout, grinding during cleaning). It is adjusted to 0.2-0.4 mm by turning the adjusting screw using the eccentric, with the pad of the entire breaker loosened.

But a spark occurs at the moment the contacts begin to connect, so its adjustment is more important than the maximum gap at BDC. When the piston does not reach TDC 4 mm, the breaker contacts should begin to diverge. This position is also adjusted by turning the screw using an eccentric. Most often this point is checked visually.

For more precise adjustment, you can use a 12 V indicator light with two wires powered by a battery.

The battery negative is connected to engine ground. One wire of the light bulb indicator is connected to the battery positive. The second wire of the indicator light is pressed against the body of the movable insulated contact. If the contacts are closed, the light shines.

Lightly turn the flywheel by hand. As soon as the contacts open, the light goes out. This is the moment the contacts begin to connect and a spark forms. The piston at this moment should be in a position that has not reached TDC 4 mm.

It is important not to confuse this with the position where TDC has passed by 4 mm.

How to set the ignition on a chainsaw

The ignition of the chainsaw should be adjusted periodically. This action involves setting the correct spark plug gap between the coil and the flywheel. The parameter depends on the chainsaw model. It is indicated in the operating instructions. The average value is 0.2-0.4 mm. Having the correct gap is important to ensure that the spark appears at the right moment, i.e. not earlier and not much later than the fuel supply.

Special templates will help you adjust the ignition on a chainsaw, but it is not always advisable to purchase them for one-time use. Therefore, they can be replaced with a homemade one. To make it, you need to cut a strip from a plastic bottle. The part of the container where there is no relief embossing is suitable. After this, you can install the ignition in the following sequence:

- Unscrew the ignition bolts a little to loosen them.

- Connect the magnets located on the flywheel to the ignition coil.

- Press the plastic plate between the flywheel and the reel, and then tighten the bolts back.

- Remove the strip.

- Turn the flywheel a full rotation several times in a row, making sure that it does not catch anywhere.

If the diagnostics revealed any malfunctions of the coil and it was not possible to adjust it, then the part must be replaced, since repair is impractical.

Remaking the ignition of the Druzhba chainsaw

Since the engines on the Druzhba 4A and Druzhba 4A Electron chainsaw models are absolutely identical, the interchangeability of contact and electronic ignition systems on all models is quite possible.

Moreover, it is sometimes possible to remake a failed coil of an old contact ignition and install it instead of a failed electronic version.

Reworking the contact ignition coil

The coil is removed and all the high-voltage secondary winding made of the thinnest wire that has become unusable is removed. The primary winding, consisting of several turns of powerful wire, almost never fails. She is left in place.

The main thing is not to damage the insulating layers of varnish during dismantling.

Instead of the removed winding, they use an external high-voltage coil (bobbin) from a motorcycle, a two-speed moped of the Soviet period, or a car. The coil is attached in any way in a convenient place. Restore the connection diagram to the same as it was with a stationary winding:

- from the primary winding of the coil to the + (plus) contact on the bobbin;

- from the contact - (minus) on the bobbin to ground (engine housing).

The disadvantage of this option is that an additional part will appear on the body of the Druzhba chainsaw.

The advantage is that high-voltage coils are easy to change and are available.

You can also find descriptions online of how to repair the electronic ignition system of Friendship, which is reasonably considered to be practically unrepairable. This option is also possible, but for this you need to be an experienced specialist in the field of electronics and electrical engineering.

The ignition device on the Druzhba chainsaw is described in the following video, which also provides recommendations for adjustment:

For residents of the USSR, Druzhba was the only chainsaw, always in short supply, but relatively affordable. (Ural was created on the basis of Druzhba as a more powerful option for the timber industry). Hundreds of thousands of Friendships have been issued over decades. Many of them, due to their good maintainability, are still in working order. And spare parts, including two types of ignition systems, can still be found at flea markets and even online at sites like Avito.

Do-It-Yourself Ignition of a Chainsaw

In some timber industry enterprises, and also on private farms, Ural-electron and Druzhba-4-electron chainsaws are still used, the engines of which are equipped with an electric ignition unit. This block is very simple in design, but unfortunately, just like other equipment, it sometimes burns out. Replace it with a new one. this is a precious pleasure, especially since at the moment the industry is producing a magneto of such a quality that it is enough for one hour of work, or a maximum of a week... Any radio amateur is fully capable of repairing this common rumor block himself.

Block diagram option 1 (recommended).

Block diagram option 3.2 (often used).

L1 – generator coil, d=0.063mm, W=11000 turns, R=3000 ohm; L2 – control coil, d=0.1mm, W=1200 turns, R=80 ohm; T1 – high-voltage transformer, d1=0, 28mm, W1=75 turns, R1=0.5 ohm, d 4=0.063mm, W2=6900 turns, R2=2000 ohm;E – electrical unit;C1 – capacitor 0.47 uF 630V;R1 – resistor 390 ohm 0 ,25 W;V1–V5 – diodes, correspond to KD 209;V6 – thyristor corresponds to KU 202

Before repairs, you need to find out what circuit the ignition unit is assembled according to. Option 1.

It is necessary to measure the resistance of the generator coil L1 and the secondary winding of the transformer T1, the resistance of the control coil L2 and the primary winding of the transformer T1; it is not at all necessary to determine it, just check them for an open circuit. Then check the serviceability of the thyristor control circuit by measuring the resistance. We connect one probe to the sealed terminal going to resistor R1, the second to ground. In one direction, the resistance is equal to the sum of the resistances of the resistor and the direct junction of diode V5, approximately 2.4. 4 rooms In the other ∞. If all windings and the thyristor control circuit are in good condition, you need to make a drill, 1.5-3 mm in diameter, at the point of connection of the anode of the thyristor V6 with the capacitor C1 (point A), and by unsoldering the coils, check the diodes V1-V4 and the capacitor for serviceability C1. If one of the diodes is faulty, there is an option to solder it by surface mounting, having previously destroyed the old faulty diode by drilling. It is better to use a drill for this. If the passage of capacitor C1 is faulty, you need to remove it, insert a new one and solder the lead to the designated point, then fill it back with epoxy glue. If the thyristor malfunctions, I recommend changing the block circuit one hundred percent, having previously removed the old one, soldered it by surface mounting and filled it with epoxy glue.

READ Replacing the Rubber Tip on a Spark Plug in a Chainsaw

Additionally, if the resistance of the thyristor control circuit is more than normal, the contact of the circuit with ground may be broken, to restore it you need to: release the M3 bolt from the glue, unscrew it, clean the contact and tighten it again, but this is a new one (point B), how else it is called simply soldering the overhead conductor, connecting it to the magneto body. If the saw operates at high speeds intermittently, you need to replace transformer T1. If after several minutes of operation the spark is completely lost, this indicates a malfunction of thyristor V6, you need to change the circuit. Option 2. If the windings of the coils are working properly (the resistance of the generator coil with one terminal is possibly ≈ 1 kohm, this is normal). check whether the terminal of the capacitor soldered to the terminal of transformer T1 has broken off. If all parts of the circuit are in good working order, I recommend turning the generator coil over, aligning the output wires. If at least one book of a circuit element malfunctions, it is better to change the circuit completely, soldering it according to the circuit of option 1, winding a coil with 2 terminals. If there is no generator coil with 2 terminals, you can install it with one terminal, but with insulation. Simply drill out the tubular rivet with a Ø5.1 mm drill and insert a Ø 4mm PVC tube, and during assembly slip in fiberglass washers and a mounting tab for the second output.

When replacing parts, excellent results are obtained with 1N4007 diodes and KU709V/KU712V thyristors. By and large, there is an option to install a diode in parallel with the thyristor. this will slightly increase the energy and duration of the spark. To increase the values of these features even more, there is an option to replace the half-wave rectifier with a bridge rectifier; the above-mentioned diode is not needed at the same time.

Content

✅Ural chainsaw. assembly nuances that are not talked about

It is better to set the thyristor response level to 600-700 rpm.

this will provide a greater range of regulation of the ignition timing (as they say at the moment: torque) when changing speed, at the cost of a slight deterioration in starting. Under any circumstances, after changing the thyristor, or parts in the circuit of its control electrode, the installation of the SPD will often be disrupted, which, in the absence of a shield, will require an additional option on the engine. READ Do-it-yourself grinding with a grinder without dust

According to the regulation of UOZ. The control pulse generated by the control coil is bell-shaped. to a first approximation it is similar to a quadratic sine. So, with an increase in the speed of rotation of the flywheel, the scope of this pulse increases, and at a certain speed it turns out to be sufficient to start the thyristor, i.e. achieves trigger level (I like the term trigger level). Why, at this speed, the thyristor response level is in the zone of the top of the pulse. With the upcoming increase in the speed of rotation of the flywheel, the range of the control pulse continues to increase, although the level of operation of the thyristor remains unchanged. This leads to the fact that the control signal achieves the level of operation of the thyristor not at the top, but earlier. at the front. Those. As the range of the control pulse increases, the moment it is equal to the thyristor response level moves from the top along the front edge to the beginning. According to this movement, the ignition timing also changes. The typical value of this configuration when changing the flywheel rotation speed from the beginning of sparking to 5000 rpm is approximately 15 degrees, with careful adjustment you will get 19.20 degrees. This is the adjustment that is provided automatically. In addition to this, everyone can find the popular setting by rotating the base of the magneto in the mounting socket. this is in some way a zero setting: just compensation for the spread in the characteristics of the magneto parts to obtain a given ignition timing at one point (if I’m not mistaken, at the point of 5000 rpm)

Chainsaw engine recoil. Timing of early ignition on a chainsaw.

Borodach, May 1, 2006. 16:25, wrote:

what does this phrase mean: It is better to set the thyristor response level to 600-700 rpm. and how do you implement this and by what marks is there an option to set, in this case, the ignition moment with an ordinary strobe?

Regarding the level of operation of the thyristor, it has already been said. Getting it to the required speed is easy only on the switchboard, where the flywheel is rotated by an electric motor. But without it it is somewhat difficult: you need to manipulate the level (voltage) of the thyristor operation. Usually MB-1 is set to a minimum of 300.500 rpm, so you need to increase this level by 20.100% by inserting a resistor in the control coil circuit one by one, in this case the main thing. do not take away, i.e. do it step by step. Regarding the strobe, IMHO, it makes sense to do the initial installation of the magneto. And then a narrow adjustment is needed at rated speeds at rated load. optimal from time to time maybe shifted up to several degrees.

Borodach, May 5, 2006. 18:53, wrote:

READ Chainsaw Husqvarna 236 Starts and Stalls

How much will the ignition timing change from changing the polarity of the L1 coil and do you have a thyristor control circuit for MB-1 or maybe a better one.

Approximately 90 degrees. But the response threshold in this case decreases by a factor of 4. Traditional control circuit: the upper terminal L1 is connected to the anode of the diode, the cathode of which is connected to a resistive divider: the upper resistor (which is on the diode). in MB-1 it seems like it should be from 750 Ohm to 8.4.5 kOhm, the lower one (which is common). from 51 Ohm (recommended for the thyristor used in MB-1) to 510 Ohm. The divider output is connected to the control electrode of the thyristor. The upper resistor adjusts the thyristor response level. In terms of performance/simplicity ratio, it’s better, IMHO, so far we haven’t been able to come up with anything.

Chainsaw ignition (magneto, flywheel)

Borodach, May 5, 2006. 18:53, wrote:

I would like to rework the ignition, because I also don’t like the way it works!

Don't run into problems. For example, a system with a bridge is more sensitive to the uneven (unequal) magnetization of the flywheel magnets and the asymmetry of the magnetic gaps. This manifests itself as the engine not developing, as it is also called unstable operation. The risk of running into this common rumor increases over the life of the motor. With the use of a standard charging coil in this circuit, the unevenness of the voltage to which the capacitor is charged turns out to be more difficult than in the initial version, which leads to an increase in the load on the thyristor in the zone of 2000. 4000 rpm. By and large, instead of the MB-1 magneto, you can take the EM-7. It’s like there’s a bridge rectifier, and the spark is already 2.4 times longer. True, the highest voltage is somewhat much less, so with a perfectly splashed spark plug, the engine may not even start. That is, if you dare to redo it. For this purpose, it is better for you to find a faulty lighter, and not to hack a working one.

Source