Almost all power drives of chainsaw equipment produced in recent years are equipped with easy start and electronic ignition systems, decompressors and booster pumps. When asked why the chainsaw does not start with such rich equipment, service specialists do not give a definite answer.

Depending on the class and purpose, domestic and professional models are equipped with carburetor power units of a similar design, running on high-octane motor gasoline with a small admixture of motor oil for two-stroke engines.

The working volume of chainsaw engines varies from 26 to 60 cm3, power ranging from 1 to more than 6 hp. A characteristic feature of chainsaw drives is maximum compactness, convenient maintenance, and access to setting points. The standard service life of budget models is 1,500 hours, branded ones - more than 2,000.

Features of returning chainsaw scrap

It is not always possible to check a tool purchased in a store in operation, since even reputable trading organizations, citing the lack of conditions and fire regulations, reduce pre-sale preparation to a minimum.

- Each new model may differ in design from previous developments. Therefore, the owner of the tool begins to prepare for the first start by studying the instruction manual. The work is carried out in accordance with the manufacturer's recommendations.

- If the new tool has obvious damage, does not start or is not complete, it is advisable to return the chainsaw to the seller.

- The store is obliged to accept the defective product, exchange it for an identical model or return the money. Chainsaws that have obvious signs of disassembly or operational damage cannot be returned.

Defective new chainsaw, subject to exchange at the place of purchase within 14 days. After this time, the warranty comes into force, allowing you to fix the tool malfunction free of charge in a service center.

Limitations in independently finishing the warranty instrument

Even with an easy start system, new, untested equipment is relatively difficult to start. It is not recommended to disassemble the recoil starter before the end of the warranty service and repair period.

- For service departments, such a modification may be a reason to refuse free replacement of failed, more valuable equipment.

- If you independently eliminate minor deficiencies, such as “gasoline does not flow” or “the air intake is loose,” penalties are not applied.

- Practice shows that problems with starting budget chainsaws appear after 2-3 years of operation. In such a situation, the owner has to put up with additional repair costs or rely on his own plumbing skills.

Thanks to the higher quality of materials and factory assembly, branded models have an order of magnitude fewer problems with starting. However, the recommendations given in this article may be useful for owners of mid- and high-end chainsaws.

The information received will prompt you in the direction of solving the problem when the Chinese chainsaw does not start. Almost all Chinese chainsaw imports are developed on the basis of European models, so the design and operational differences are insignificant.

Owner reviews

Ivan Samoilov, 38 years old, Amur region

“My Chinese saw doesn’t start well; in general, we can say that it doesn’t start, because it immediately stalls. I start it up through rather complex manipulations, at full throttle it works and saws for some time. However, after a short time it begins to sneeze and stalls - it is impossible to work. I tinkered with it myself for a long time, and then took it to the workshop. It turned out the magneto came off - I never would have thought it was the fault of the carburetor.”

Ivan Vesnin, 33 years old, Solnechnogorsk district

“After winter I decided to take my chainsaw for a walk in the garden. Right away everything went well, I managed to start it up quite quickly, after warming up I even trimmed one apple tree, and then it began to stall. It will run for 8-10 minutes and then die. And not only under load, but also at idle. I was already scared - I decided that it was time to change the piston. And then I think: let me clean the breather. It worked for an hour - it saws perfectly, it picks up speed evenly and quickly, it starts at half a turn, I completely forgot what it means to stall. These are childhood diseases.”

Yakov Baulov, 59 years old, Siberian Federal District

“After a long period of inactivity (I didn’t approach it for the whole winter), the chainsaw began to stall at high speeds and when the gas was sharply applied. It seems to start gaining momentum, but when adding gas, at some point it stalls. It didn't start very well from the very beginning, but I adjusted the carburetor and it seemed to work out. In short, I searched for the fault for a very long time until I climbed into the gas tank and discovered that my chainsaw was not equipped with a fuel filter - there was simply the edge of the fuel line sticking out. This is a complete failure - how could such a unit be released from the factory. Now I fixed it - it started working normally, no longer stalls. Laughter and tears – where is this world coming to.”

Chainsaws are lightweight in design and reliable in operation.

Read also: You pump the jack and lower it

When handled correctly, breakdowns occur occasionally and are quickly eliminated if the owner knows where to find the cause.

And yet, the question of why the chainsaw won’t start cannot be answered with complete certainty. Such a tool in its own right is an ordinary two-stroke gasoline engine. For its normal operation, four conditions are needed: fuel, air, spark and lubrication.

The carburetor is responsible for producing the air-fuel mixture, the filter cleans the air from dust, the ignition unit and spark plug provide the spark, and the lubricant is found in gasoline.

The reasons why the chainsaw refuses to start must be found one by one, from the usual ones and moving on to more complex ones. Anyone who immediately rushes to disassemble the carburetor when the chainsaw has trouble starting when hot is taking a very big risk. It is better to repair and adjust this unit in a special workshop, and not on your knee.

When, some Russian auto industry chainsaws, if you set a goal, users did not go into the carburetor to configure the composition of the fuel consistency, they make the jets unregulated.

For trouble-free operation of the chainsaw, it is necessary to pay increased attention to fuel . If the fuel mixture is not prepared correctly, then even a reliable Husqvarna will not start. With all this, the owner will begin to find the cause of the malfunction in any way, alas, not in the fuel. To eliminate this factor, it is always necessary to prepare a fuel mixture from high-quality gasoline and the brand of oil indicated in the annotation.

It must be done in such quantity that it can be produced one hundred percent in 10-15 days . If you keep it in a canister for a month, the gasoline will lose its octane properties and problems with the service of the saw are guaranteed for you.

Read:

Chainsaw malfunctions often occur due to the spark plug being flooded with gasoline at the time of start-up. This problem can be solved by turning out and drying the spark plug (without calcination!) The excess fuel is drained through the spark plug hole, after that they take a 20-30 minute break, then put the spark plug in the area and repeat the start. A good owner always has new spark plugs in stock so that when troubleshooting, they can exclude this part from the list of suspects.

The lack of a spark is often caused not only by a spark plug failure , but also by poor contact between its tip and the high-voltage wire. If this connection does not cause suspicion when checked, but a spark does not occur when the starter is turned on, the electrical ignition unit will be at fault. Such a unit is not repaired, but replaced with a new one.

Don't forget that inspecting the spark plug provides important information. If it is dry, it means that no fuel is entering the cylinder and it is necessary to inspect the entire supply chain from the carburetor. Dark carbon deposits indicate an incorrect adjustment of the carburetor, which supplies too much fuel to the mixture, or an overflow of oil into gasoline.

If the chainsaw starts and stalls when you press the gas, this indicates a poor fuel supply. The reason for this is that the fuel filter or carburetor jet is clogged. Of course, the first unit should be checked and cleaned in a short time, but in the second case it is better to trust the specialists.

Disassembling and cleaning a chainsaw carburetor requires experience and accuracy . Therefore, it is usually taken up only by those owners who have already successfully performed this function more than once.

You should also pay attention to the air filter so as not to find the cause of malfunctions in the chainsaw in the wrong direction. If it is clogged with dust, then you cannot count on easy starting and smooth operation.

myth the valve smooths out the pressure in the gas tank over the course of fuel consumption. When it becomes clogged, a vacuum appears in the tank and fuel stops flowing into the carburetor. This disease is treated by cleaning the breather using an ordinary sewing needle.

It is not difficult to exclude breather from the list of suspects . For this purpose, it is necessary to disconnect the fuel hose from the carburetor and see if fuel flows out when using it. When gasoline flows in a working stream - the breather is clean, in which case fuel does not flow from the gas line or flows out very slowly, then the cause of the malfunction has been established.

Many owners of new Shtil chainsaws are frightened by the increase in idle speed after the first tanks of gasoline are used up. Experts consider this behavior of the saw to be normal and indicating that the running-in of the engine and carburetor is proceeding normally. Do not rush to contact the service center, but simply slightly reduce the engine speed with the carburetor idle screw.

If the power has dropped and the chainsaw stalls at idle , do not forget to check the muffler, which you prefer is clogged with tarry exhaust deposits. Cleaning the exhaust channel and muffler eliminates these difficulties.

What to do if your chain saw won't start

Good afternoon, dear readers and subscribers of my blog! At some inopportune moment, you may find that your chainsaw

won't start. But don’t rush to immediately take a repair tool; perhaps you can fix this breakdown yourself. I will tell you what to do in cases where the chainsaw does not start, and how to find the right solution to this problem.

Possible causes of problematic startup

In most cases this happens:

- unqualified tuning of the fuel system;

- ignition malfunctions;

- dirty air intake filters.

Most often, a chainsaw does not start when cold or starts poorly after long-term storage, refueling with substandard fuel, or the presence of a large gap in the spark plug electrodes.

In the private sector, the peak of operational failures occurs after winter and late autumn, after the completion of intensive work on harvesting and sawing fuel wood.

How to start a chainsaw correctly: instructions

Let's look at the main steps that need to be followed in order to properly start the Stihl chainsaw.

- Before starting, the chain brake must be activated. It is activated by pressing it forward (as shown in the photo).

- Remove the protective cover from the tire.

- If the model has a decompression valve, it should be set to the on position, which will make it easier to start the tool’s motor.

- Press the fuel pump to reduce the number of pumps and make starting easier.

- The combination lever must be turned on in cold start mode. To do this, you need to lock the gas lever and press the combination lever all the way down.

- Before starting the system, it is necessary to ensure a level surface. In this case, the cutting part must be at a distance from the ground, otherwise it will become dull when starting.

- Hold the tool with both hands and keep it on the ground. The left hand should be on the chainsaw handle, and the right hand should be on the starting cable. Secure the tool with your right foot by stepping on the rear handle.

- Gently pull the starter rope with your right hand until you feel strong resistance. Using force, pull the starting rope several times, starting the engine briefly. In this case, to avoid abrasion, it is recommended to pull the cable upwards from the body.

- After a short start, the engine stalls. Now move the combination lever up one click. The lever should take the half-throttle position.

- Pull the starter cord again to start the chainsaw engine.

- When the engine is started by briefly pressing your finger, operate the throttle lever. The combination lever will automatically return to idle speed.

- Without touching the gas lever, move the chainsaw.

- Pull the handle towards you to release the chain brake. The position of the left hand remains unchanged, the hand is on the handle. The chain will be unlocked after the appropriate click.

You can see a detailed description on how to start a chainsaw correctly in the video. Using these detailed instructions, you can gain skills on how to start a chainsaw.

What to do if the chainsaw does not start?

But what to do if all the steps specified in the operating instructions have been followed, but the chainsaw still does not start? Regardless of the manufacturer of the chainsaw - Shtil, Husqvarna, Partner, Ural, Druzhba - a number of general activities can be identified for the tool factory.

Below are practical tips from professionals that have been tested in practice and have proven effectiveness:

- Don't be nervous and don't try to adjust the chainsaw's carburetor.

- Set the instrument aside and let it rest. The reason may simply be that the candles are flooded. Give them a chance to dry.

- Take the instruction manual. Try starting the saw again. There is no need to turn on the saw brake.

- If this does not help, try removing the cover from the chainsaw body and removing the air filter. This way you can check the cleanliness of the filter and at the same time make the starting process easier.

- Replace the spark plugs. If it is not possible to install new spark plugs, you can use the old ones by first removing and calcining them.

- If a strange, pungent odor appears, it means that excess fuel has entered the chainsaw engine. To correct this situation, you need to remove the spark plug and, turning the saw over with the hole down, drain the excess. Without returning the saw to its normal position, sharply pull the starter several times. This way you will ensure that combustion products leave the chamber. The spark plug must be wiped dry and calcined, and then screwed in again and started without installing the filter.

- It is necessary to check the surface of the piston for the presence of fuel. If you unscrew the spark plug and notice through the hole that it is dry inside, you need to inject some fuel into the chamber using a syringe. The cause of problems in this case may be a blockage that interferes with the supply of fuel to the engine. If the engine can be started with a small amount of fuel, then the thrust will clear the blockage and the problem will be solved.

- The last two actions can be performed only if the candle is dry.

- Check the starter for serviceability. It is impossible to start a chainsaw without a starter.

- Check the ignition unit for spark.

- Try carefully removing the tool's muffler and starting it without it.

Each saw has its own manufacturing characteristics. You can watch the video on how to start a Husqvarna chainsaw. Follow the instructions carefully and the saw will serve you for a long time.

Mechanical jamming of the piston or crank mechanism

This malfunction occurs due to the piston sticking in the cylinder or the destruction of the crankshaft bearing. This happens when the engine overheats or runs on pure gasoline for a long time.

In the first case, it is recommended to cool the power unit, and then pour a few drops of engine oil into the spark plug hole. In most cases, the engine can be wedged, but the consequence of this incident may be the appearance of scuffing on the piston. The tack is not reflected on the chrome surface of the cylinder mirror.

If the measures taken do not give the desired result, the saw must be repaired in a specialized workshop.

Checking the fuel mixture supply and ignition system

First of all, you should make sure that there is fuel in the carburetor float chamber. After several attempts to start the engine, a dry spark plug will indicate that the reason for poor starting is the lack of fuel mixture supply.

Recommended sequence of actions:

- checking the fuel filter;

- patency of the gas pipeline;

- cleanliness of the drainage hole of the fuel tank cap;

- It is possible that the carburetor float valve may become stuck in the closed position.

To clean the volume of the cylinder, with the spark plug removed and the ignition off, make several vigorous jerks with the starter. In the absence of a new spark plug that is known to be in good working order, it is necessary to thoroughly dry and check the old one for a spark. Warming it up over an open fire is not advisable, since there is a high probability of cracks in the insulator and its complete failure.

To check spark formation, a spark plug with the cap on must be applied to the saw body and cranked with a starter. A working spark plug produces a strong discharge, accompanied by a characteristic crackling sound.

A small spark with a red tint indicates a malfunction of the ignition unit, high-voltage conductor or internal resistor of the standard spark plug.

What to do if the chainsaw stalls when you press the gas

One of the most common questions regarding the operation of this device is: why does the chainsaw when you press the gas and what needs to be done to solve this problem? In such a situation, you need to do the following:

- check the fuel filter;

- inspect the fuel hoses for leaks;

- check the muffler;

- try to increase the speed a little;

- Check the condition of the rubber seals on the crankshaft.

READ Chainsaw Starter Won't Crank

Pro recommendations for controlling the working mixture

If the checks performed did not give the desired result, we proceed to checking the ignition. A wet spark plug that is turned out indicates an excess of fuel and a lack of air; the mixture that floods the spark plug during startup cannot even be ignited in such a proportion by a powerful spark.

To bring the quality and quantity of the air-gasoline mixture to the optimal setting, a wide range of operational adjustments is used. The cause of fuel overflow in old chainsaws may be a leak in the fuel supply valve and the carburetor float valve.

In standard situations, after a short period of purging the cylinder with the spark plug removed or the decompressor turned on, normal starting is completely restored.

The chainsaw does not work: reasons and solutions

During operation, components and saw sets are subject to significant load, which means they wear out. Therefore, a tool that was working just recently refuses to start. To understand the cause of the breakdown, you need to know the reasons that affect the operation of the tool more often than others.

Spark plug

This reason is easy to determine. If the spark plug malfunctions, the device starts and immediately stops working. The malfunction of this element is caused by the accumulation of the fuel mixture on the electrodes and the build-up of carbon deposits on them. To get rid of this problem, remove this element, remove the carbon deposits with a file, turn it out and wait half an hour until it dries. Drain off the remaining mixture, put the candle in place and you can continue working.

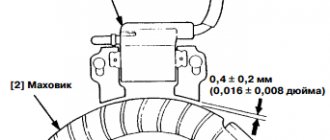

If this element is dry, its malfunction lies in the large distance between the tip and the wire that produces the spark. Check the spark: remove the tip, remove the spark plug, put the tip in place, place the spark plug so that its skirt touches the cylinder. Launch. If the spark is visible and large, the problem is not with the spark plug. If the spark is weak, reduce the distance between the electrodes using a special feeler gauge.

READ Which Side to Saw Laminate

Consequences of operating on a rich and lean mixture

- Due to the engine running on an over-enriched mixture, a layer of conductive carbon deposits forms on the insulator of the central electrode, which can cause interruptions in sparking.

- The white or gray color of the center electrode insulator indicates the high-temperature combustion characteristic of a lean mixture. Both options have a negative impact on the traction characteristics and durability of the power drive.

- Setting the carburetor to a lean mixture can cause a phenomenon where the chainsaw does not start when hot; in another case, it starts but does not start.

The normal quality of the air-fuel mixture, in a ratio of 16:1, is confirmed by the brown color of the insulator and the absence of traces of soot.

Plant structure

The first and practically main element of a chainsaw is the engine, namely a two-stroke carburetor (see carburetor adjustment). Its direct power can be varied, it all depends on the model of the device and its intended purpose. For example, the power of the Ural chainsaw is 3.68 kW.

The second no less important part of the tool is the headset (saw), which consists of a chain (cutting), bar, sprocket, wheel (chain) . It is worth adding to this that completely different manufacturers provide their own specific range of this headset.

Read also: How to properly harden a knife from a file

It is important that it always needs to be directly selected from the specific characteristics of the engine. Since the larger the pitch of this type of headset, the deeper the chainsaw’s cut will be, one might even say that the more powerful and productive it will be. But do not forget that for the device to fully operate, the engine should also not be inferior to it in terms of power.

Its lubrication is carried out using special oil directly from the second tank, which is located on the hand unit. It is worth noting that the mass of this type of tank has such features that the oil and fuel intended for the engine run out at the same time.

We have figured out the general outline of the device, and most likely its basis, and now it’s time to start understanding why the chainsaw stopped working, what the reasons could be for this and how to eliminate them.

Flushing the carburetor and checking the condition of the jets

If, during the work performed, a stable start is not established, we look for the fault in the carburetor. If you do not have the necessary experience, disassembly should be entrusted to an experienced specialist.

The reason for difficult starting may be, in addition to the previously mentioned air leak:

- contamination of jets;

- water entering the float chamber and depressurization of the float itself;

- loose fit of the float valve that stabilizes the fuel level in the carburetor;

- filling the fuel system with a fuel substitute or expired mixture.

Serious malfunctions that block standard starting, such as air leaks through worn oil seals of the crankshaft shanks, changes in the ignition angle, due to the lack of appropriate tools and technological equipment, are eliminated in repair shops.

Recommendations for storing fuels and lubricants

Fuel with an oil component can be stored in metal containers for no more than one month. An old gasoline-oil mixture is prone to the formation of coking resinous deposits, which limit the mobility of the piston rings.

Water enters the fuel system not only with gasoline, but also with large temperature changes it forms in the form of condensation on the inner walls of the carburetor.

The presence of water in the fuel is manifested by white smoke from the muffler, interruptions in engine operation, and complete engine shutdown when ice forms in the system.