There can be many breakdowns associated with a chainsaw, and some can be quite difficult to solve. If you have been working with this gas-powered tool for a long time, you have had a problem when gasoline does not enter the carburetor or it does, but it is very difficult and does not allow the chainsaw to start normally. Fortunately, experts long ago found the causes of such a breakdown and therefore we have compiled the main repair methods.

First of all, we check for trivial reasons, for example, the presence of gasoline in the tank. If there is one, we check the process of fuel supply from the tank through the wire. To do this, just disconnect the gas line from the carburetor and try to pump fuel. It is correct to supply fuel through the hose in jerks, this will make sure that there are no problems with the gas tank. If the fuel does not flow even jerkily or drips too slowly, the reasons may be the following:

The fuel filter is clogged with dirt and dust;

The gasoline supply channel is dirty.

Surprisingly, even having a full tank can cause no fuel to flow. Therefore, try not to fill the tank to the maximum. An overfilled fuel tank can press out the tube that connects to the carburetor.

Poor quality gasoline

Every experienced chainsaw user knows that fuel cannot be left in the tool tank for a long time. The fact is that during long-term storage, unnecessary processes will occur inside the tank with the formation of resin and polymerization of various components. Do not leave fuel in the tank for more than 2 weeks, and even if your tool starts on such fuel, this can lead to the formation of carbon deposits on the CPG parts (rings, piston).

Air filter

If the chainsaw does not supply gasoline to the carburetor, pay attention to the type of air filter. Due to its improper operation, the chainsaw begins to operate unsteadily, which subsequently becomes difficult to start or stalls during operation. It is more difficult for air to enter the device and makes the mixture too rich. You are unlikely to be able to start it, and the reason for this is the formation of dust.

You need to remove the air filter carefully, because if dust is stored on it, it can fall onto the carburetor. The air filter can be cleaned well with water and detergent. Be sure to dry the filter before installing.

Chainsaw carburetor design

Most modern chainsaws are equipped with almost identical carburetors. They are practically no different from each other, and work on a similar principle. The only difference between cameras from different manufacturers is the material from which they are made. In expensive American, Swedish and German-made chainsaws, the chambers are made of reliable alloys, onto which protective coatings are applied. Cheap Chinese and Korean chainsaws are equipped with components made from cheap materials.

Each carburetor consists of the following elements:

- aluminum body with unibody construction. Inside the housing there is an inlet fitting, a main screw, a pulse channel, a bolt for adjusting the engine when idling;

- throttle valve - it is responsible for regulating the amount of air required to enrich the fuel mixture;

- diffuser – located next to the chamber inlet;

- sprayer - designed to supply the fuel mixture directly into the carburetor chamber;

- float chamber - it contains a float that is activated in case of insufficient fuel;

- jets - are valves that are responsible for regulating the amount of fuel.

This chainsaw carburetor circuit is as simple and effective as possible. In some models of garden tools, it can be supplemented with additional pipes, seals or filters.

The operating principle of a chainsaw carburetor is quite simple. When the engine starts, the air damper located at the bottom of the housing opens. At the same time, a vacuum is formed in the float and air chambers caused by the movement of the piston. As a result of this, the standard diffuser is activated, which begins to suck in air. The amount of air taken in depends on the degree of opening of the damper. When the piston is activated, fuel begins to flow into the chamber through the inlet fitting. Its quantity and flow rate depend on the position of the jets.

Subsequently, the fuel in the air chamber begins to mix with air. After this, the finished air-fuel mixture passes through the intake valves, from where it is directed into the combustion chamber of the saw engine.

Gasoline does not flow into the carburetor of a chainsaw Video

Content

Gasoline does not flow into the chainsaw carburetor

Amateur and professional chainsaws are complex devices. The motor life of their two-stroke engines, components and assemblies has its limitations. Therefore, completely reliable and expensive tools, on par with cheap Chinese units, sometimes become unusable and refuse to start. The situation when the chainsaw does not start, or the chainsaw stalls, is not very nice and sometimes confuses the user. How to find and remove the malfunction, restoring the functionality of the tool.

Identifying and eliminating trivial chainsaw defects.

To determine the reason why the chainsaw does not start or stalls when starting, you need to troubleshoot the tool. The essence of the procedure is to inspect the condition and operation of the main working parts of the saw motor one by one. During this period we check:

- Presence of a spark on the spark plug;

- Fuel supply;

- Filter status;

- Operation of the breather built into the fuel cap of the stalling unit;

- Functioning of the exhaust channel.

Checking the spark on the spark plug and eliminating the circumstances.

The first step in finding the circumstances why a gasoline saw will not start is to check the spark on the spark plug. There are many reasons that affect the operation of this element. But the main ones at the initial stage of tool troubleshooting are:

- Incorrect carburetor adjustment;

- The presence of more than the required amount of oil in gasoline;

- Air filter clogged.

They promote the formation of carbon deposits on the electrodes of the spark plug. In 50 cases out of 100, saws do not start when cool due to the lack of a spark due to carbon deposits on the electrodes and their corrosion. For this reason, either the gap decreases or it increases.

Checking the spark plug of a non-working chainsaw

Checking for a spark is quite easy. For this purpose you will need:

- Remove the tip of the high-voltage wire;

- Remove the spark plug;

- Put the tip back;

- Place the candle skirt against the cylinder;

- Start with the starter.

If at the moment of starting the chainsaw engine there is an excellent spark between the electrodes, then our client remains in order with the ignition unit. When it is not there, it is worth cleaning the element itself and checking the electrode gap. If necessary, use a special probe to adjust the distance between the contacts.

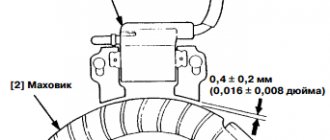

For spark plugs from different manufacturers, the distance between the electrodes may vary. For some you will like it, it is equal to 0.5 mm. Others have 0.4 mm. Therefore, carefully study the manufacturer’s advice.

There may be no spark at the spark plug for other reasons. The main defects that affect poor starting of the chainsaw and unbalanced operation of the internal combustion engine at idle, which can cause the tool to stall, include the following:

- Overfilling of the spark plug channel with fuel;

- Lack of contact between the high-voltage cradle and the tip of the spark plug;

- Ignition unit failure.

How to start a cool chainsaw if the spark plug channel is constantly flooded with gasoline? Remove the problem while launching the tool, of course using the following method:

- Unscrew the candle with a special key;

- Wipe it with a clean and dry cloth;

- Dry for 20...30 minutes;

- Remove carbon deposits with a file and adjust the gap between the electrodes;

- Drain the remaining fuel from the spark plug channel and dry it;

- Collect what remains for our client to do and try to start the mechanism.

Usually, these measures are enough to start the chainsaw and get the job done. But this last measure does not eliminate the main reason why the engine does not start or stalls - incorrect operation of the carburetor, which needs close adjustment.

If there is no spark due to poor contact of the high-voltage cradle with the tip of the spark plug, you need to check the connection. Of course, check using a regular tester. If a defect is detected and corrected, the chainsaw should start without any problems.

If the check shows that the contact is reliable, but the saw still does not start, look for the cause in the ignition unit. Typically, a faulty unit cannot be repaired or restored. Here it will need a complete change.

We determine the presence of fuel and its supply.

First you need to make sure that there is a fuel mixture in the tank of the chainsaw that does not want to start, and that it is properly supplied to the carburetor. With a full tank, check how the mixture is supplied through the gas line. We disconnect the fuel pipe of the accounting software complex from the carburetor and try to pump it up. For which the complete order design is intended, when pumping, gasoline will be supplied jerkily in accordance with the standards given by the manufacturer. A weak fuel supply or its absence will result in:

- The fuel supply channel is clogged;

- Fuel filter clogged with debris.

Often, a very full tank will be a prerequisite for a disgusting start of a chainsaw. In this case, it is worth examining the presence of smudges under the saw crankcase cover. If they are found, then look at the connection of the gasoline supply pipe to the carburetor. In most cases, it is squeezed out by pressure when screwing on the tank cap, tucked under the best neck, which prevents the engine from starting.

The quality of the fuel consistency may also be the main reason why the chainsaw does not start. If, after completing the work, you do not drain the remaining gasoline and leave the tool for long-term storage (more than 2 weeks), then the processes of resin formation and polymerization of the components will begin to occur inside the tank. What will be the prerequisite for the occurrence of carbon deposits on the piston, rings and cylinder liner. Therefore, before starting work, always prepare the mixture only in the required quantity.

Checking the condition of the fuel and air filters.

If our client’s fuel quality remains fine, the chainsaw engine may not start due to clogged fuel and air filters. To diagnose these parts, it will be necessary to perform a number of manipulations related to their dismantling.

For fuel filter:

- Disconnect the gasoline supply line from the carburetor;

- Pump up the fuel.

If there is little or no pressure in the pipe, disconnect the filter. Before doing this, empty the tank of the mixture and remove the filter element itself. Dismantling is done using a wire hook. A clogged replacement cartridge, which has become a prerequisite for poor starting of the chainsaw motor, can of course be cleaned, but it is much safer to replace it with a new one. When working with equipment in dusty conditions, cleaning should be done constantly.

A clogged air filter can be a prerequisite for unbalanced operation of the chainsaw motor, causing it to stall or be difficult to start. Dust and dirt deposited on the adsorbent material make it difficult for air to enter the system, making the fuel mixture so rich that it will be difficult to start the tool immediately.

Checking the air filter is one of the first steps in finding the right products for the circumstances of a disgusting start.

Removing the air filter should be done with care because dust that has accumulated on its surface during use of the saw may enter the carburetor. As you know, it is fraught with more expensive repairs. After disconnecting the cartridge, carefully clean it of accumulated dirt and wash it with detergent. Dry the element and then carefully place it at its destination.

Checking the breather and cleaning it.

The breather is an additional element, due to incorrect operation of which the chainsaw may not start, or, in other words, stall during sawing. This element is located on the fuel tank cap in the area of the air hole. This is a typical valve that prevents gasoline from leaking out and smoothes out the air pressure necessary for the free flow of fuel into the carburetor.

If the breather is contaminated, the running chainsaw stalls, and when starting, it refuses to start. Our client is left with the fact that air stops flowing through the hole. As a natural result, negative pressure (vacuum) is created inside the fuel tank, preventing the flow of gasoline to the carburetor.

Finding the problem is easy. Disconnect the fuel supply hose from the carburetor and see what happens to the gasoline. If it flows out unhindered in a good stream, then our client is fine with the breather. If there is no passage or it flows weakly and intermittently, then the reason is identified - the breather is clogged with dirt. The problem can be solved by cleaning the air hole with an ordinary needle or a strong jet of high-pressure air.

READ Husqvarna Chainsaw Chains Not Lubricated

Checking the exhaust channel of the chainsaw.

The main reason why a chainsaw does not start well is a clogged exhaust channel or muffler. With all this, there is a drop in power during sawing of lumber and logs. In most cases, this occurs due to tarry deposits on the spark arrester, or the muffler channel, formed during the combustion of gasoline and oil of poor consistency, preventing the exhaust gases from being removed.

A resonator clogged with carbon deposits can lead to a disgusting start of a gasoline saw.

To remove the cause of the disgusting start of the chainsaw, in this case, there is an option by removing the accumulated combustion products. For this purpose, you perform a number of manipulations:

- Remove the muffler by unscrewing the screws;

- Remove the cooling panel and sealing gasket;

- Remove the spark arrester;

- Disassemble the resonator body;

- Wash our client's remaining carbon deposits using detergent;

- Let them dry completely;

- Collect what remains to be done for our client in reverse order;

To prevent dust and sand from entering the cylinder when cleaning the muffler, cover the exhaust channel of the chainsaw motor with a clean rag.

What to do if the chainsaw continues to not start?

If the initial inspection did not reveal anything, or the deficiencies were eliminated during the search, and the chainsaw still does not start, then it is necessary to find more severe conditions. The best place to identify and fix such breakdowns is at a car service center. But, if you have experience, you can find and remove them without the help of others. What to diagnose and inspect?

- Compression in the cylinder;

- Compression in the crankcase;

- Carburetor operation.

First, checking the compression in the cylinder will allow you to find out the condition of the cylinder-piston group (CPG) of a chainsaw that does not want to start when cold. A compression gauge is useful for this purpose. The device is screwed into the spark plug destination and the engine is started idle. The frozen readings allow one to judge the condition of the CPG. If you don’t have a compression gauge, you can find the compression in the cylinder offhand like this:

- Place your finger on the spark plug hole;

- Try starting the chainsaw engine.

By placing your finger on the spark plug hole and pulling the starter, there is an option to check the compression in the cylinder

If you feel that your finger is being pulled very deeply into the spark plug channel, then our client will be fine with compression. The absence of vacuum in the chamber indicates a malfunction. The cylinder-piston group needs a more detailed inspection, which will give an idea of the condition of the piston and cylinder, piston rings and bearings.

A chainsaw may not start when it’s cold due to a lack of compression in the engine crankcase. The main reason for this is damage to the gasket placed between the cylinder and the crankcase. It is quite simple to detect the lack of compression:

- Disconnect the upper tube from the carburetor;

- We pour gasoline into an ordinary cork;

- We immerse the removed tube in the fuel;

- We pull the starter a couple of times.

If fuel is sucked out of the cap when the chainsaw starter starts, then our client remains fine with compression. If not, look at the gasket.

If the fuel is drawn in, then our client is left with nothing - the gasket is intact. Otherwise, you will have to purchase a repair kit and make a change. How to do this, watch the video why a Chinese chainsaw won’t start:

Starting the tool may be complicated by incorrect operation of the carburetor or its breakdown. It often happens that during sawing the fastening screws become loosened and air is sucked into the cylinder. Check that the carburetor is securely fastened. Inspect it for fuel leaks. You will like a lot of circumstances of the malfunction. Find the fault accurately, remove it and make fine adjustments to the carburetor exclusively at the service center.

After going through a step-by-step troubleshooting of the chainsaw motor, you can find the fault, remove it without the help of others and successfully start your own working tool. Don't take on jobs you don't know about. Entrust troubleshooting and troubleshooting to specialists from the service center.

Why won't my chainsaw start? Common malfunctions and methods for eliminating them

Chainsaws are lightweight in design and reliable in operation.

When handled correctly, breakdowns occur occasionally and are quickly eliminated if the owner knows where to find the cause.

And yet, the question of why the chainsaw won’t start cannot be answered with complete certainty. The myth is a tool in its own right—an ordinary two-stroke gasoline engine. For its normal operation, four conditions are needed: fuel, air, spark and lubrication.

The carburetor is responsible for producing the air-fuel mixture, the filter cleans the air from dust, the ignition unit and spark plug provide the spark, and the lubricant is found in gasoline.

Prerequisites for which the chainsaw refuses to start . it is necessary to find one by one, from ordinary ones and moving on to more complex ones. Anyone who immediately rushes to disassemble the carburetor when the chainsaw has trouble starting when hot is taking a very big risk. It is better to repair and adjust this unit in a special workshop, and not on your knee.

When some Russian auto industry chainsaws, in order for users not to get into the carburetor to configure the composition of the fuel consistency, make the jets unregulated.

For trouble-free operation of the chainsaw, it is necessary to pay increased attention to fuel . If the fuel mixture is not prepared correctly, then even a reliable Husqvarna will not start. With all this, the owner will begin to find the cause of the malfunction in any way, but not in the fuel. To eliminate this factor, it is always necessary to prepare a fuel mixture from high-quality gasoline and the brand of oil indicated in the annotation.

It must be done in such quantities that it is completely developed in 10-15 days . If you keep it in a canister for a month, the gasoline will lose its octane properties and problems with the saw’s service are guaranteed for you.

Sometimes chainsaw malfunctions occur due to the spark plug being filled with gasoline at the time of start-up. This problem can be solved by turning out and drying the spark plug (without calcination!) The excess fuel is drained through the spark plug hole, after that they take a 20-30 minute break, then put the spark plug in the area and repeat the start. A good owner always has new spark plugs in stock so that when troubleshooting, they can exclude this part from the list of suspects.

The lack of a spark is often caused by more than just a spark plug failure . but at the same time there is poor contact between its tip and the high-voltage wire. If this connection does not cause suspicion when checked, but a spark does not occur when the starter is turned on, the electrical ignition unit will be at fault. Such a unit is not repaired, but replaced with a new one.

Don't forget that inspecting the spark plug provides important information. If it is dry, it means that no fuel is entering the cylinder and it is necessary to inspect the entire supply chain from the carburetor. Dark carbon deposits indicate an incorrect adjustment of the carburetor, which supplies too much fuel to the mixture, or an overflow of oil into gasoline.

If the chainsaw starts and stalls when you press the gas, this indicates a poor fuel supply. The most likely cause is a clogged fuel filter or carburetor jet. Of course, the first unit should be checked and cleaned in a short time, but in the second case it is better to trust the specialists.

Disassembling and cleaning a chainsaw carburetor requires experience and accuracy . Therefore, it is usually taken up only by those owners who have already successfully performed this function more than once.

Why does gasoline not flow from the chainsaw tank to

carburetor

? There is only one reason, the formation of a vacuum in the tank. The solution to the problem is to pull out the snow-white plug and clean it.

Chainsaw repair, fuel pump does not work

Online store Gasoline tool repair VKontakte group.

The air filter should also be given attention . so as not to find the cause of malfunctions in the chainsaw in the wrong direction. If it is clogged with dust, then you cannot count on easy starting and smooth operation.

Each model of chainsaws, of course, has its own corresponding and easily removable faults . Don’t rush into disassembling and repairing, but rather read the owners’ reviews on the forums. For example, Stihl chainsaws will not start due to obvious clogging of the breather.

Myth valve smoothes the pressure in the gas tank during fuel consumption. When it becomes clogged, a vacuum appears in the tank and fuel stops flowing into the carburetor. This disease is treated by cleaning the breather using an ordinary sewing needle.

READ Which Chainsaw Is Best For Harvesting Firewood

It is not difficult to exclude breather from the list of suspects . For this purpose, it is necessary to disconnect the fuel hose from the carburetor and see if fuel flows out when using it. When gasoline flows in a working stream - the breather is clean, on the contrary, fuel does not flow from the gas line, or in other words, flows out very slowly, then the cause of the malfunction has been established.

Many owners of new Shtil chainsaws are frightened by the increase in idle speed after the first tanks of gasoline are used up. Experts consider this behavior of the saw to be normal and indicating that the running-in of the engine and carburetor is proceeding normally. Do not rush to contact the service center, but simply slightly reduce the engine speed with the carburetor idle screw.

If the power has dropped and the chainsaw stalls at idle . Don’t forget to check the muffler, which you may find clogged with resinous exhaust deposits. Cleaning the exhaust channel and muffler eliminates these difficulties.

It is especially unpleasant for the owner when our client is left with the probable preconditions essentially eliminated: a brand new serviceable spark plug has been installed, the carburetor has been carefully and correctly cleaned, the fuel is normal, but the chainsaw indifferently does not want to start.

In this case, you need to look into the cylinder-piston group . Visual inspection of the cylinder and piston helps to find the cause. If they have noticeable chips or nicks, then the saw will work normally only after changing these components. This problem can be solved, of course, by boring the cylinder for a new repair size piston.

If there are no visible flaws on the cylinder and piston, then the piston rings are checked. For this purpose, the piston is inserted into the cylinder and slightly rocked by the connecting rod. If you feel free movement, it means the rings are worn out and require replacement.

Chainsaw breakdowns often occur due to insufficient chain lubrication due to leaking oil lines and clogged channels. If the chain becomes dry, it is urgent to clean the channels supplying oil to the tire. Then the connections between the tubes and the oil pump fittings are inspected. If severe oil leakage is found from the contact points or cracks in the oil line, the tubes are replaced and the joints are sealed with high-quality sealant.

Some parts of chainsaws definitely need to be replaced after the expiration of their certified service life. Don’t forget to look at the annotation, where they are spelled out correctly. Such parts include a tire, a drive sprocket, a chain, and anti-vibration parts that allow accounting (software).

If the replacement is not made to fit, wear of these components will have a bad effect on the serviceable parts of the chainsaw. For example, a long delay in changing the drive sprocket leads to an increase in vibration, which quickly breaks the crankshaft bearings.

Therefore, it is necessary to frequently inspect the toothing depth, which should not exceed 0.5 mm. The bus resource is usually enough for 3-4 chains; after completion, it also needs to be replaced.

Useful video on how to operate a chainsaw:

Why does gasoline not flow from the chainsaw tank to

carburetor? There is only one reason, the formation of a vacuum in the tank. The solution to the problem is to pull out the snow-white plug, clean it, blow it out, this will allow air to pass into the tank. It was not possible to insert it back, I had to disconnect the tank from the body, it’s easier. Honored guest of my channel. Hurry to God with faith and repentance. Jesus desires to save you, no delay. The scooter won't start. gasoline does not enter the cylinder. Why does the chainsaw not start? First malfunction. Production of fuel mixture for two-stroke engines. Chinese chainsaw. Carburetor repair and adjustment. Carburetor diagnostics. started up on its own! watch until the end))). The fuel pump won't pump at all! Otherwise there is a problem in the stock. With a slight movement of the hand. The headlights are transformed. Repair of a Chinese chainsaw EUROTEC(EURO CRAFT,CRAFT-TEC) 45 CC PART 1. Repair of a Royal Einhell chainsaw, will not start. The most worthy candidate is the Husqvarna 365 for 200. Adjusting the carburetor on a Chinese chainsaw (practice). How to correctly adjust the carburetor on a Husqvarna chainsaw. Dismantling the chainsaw Shtil 180 part 1. Repairing the carburetor of lawn mowers and chainsaws. The chainsaw does not start, in other words, the chainsaw does not start well. Reason and how to remove it.

[f] Share this video on

FunnyCat.TV © | 2014-2017 Best funny cats videos.

Powered by public API's

Chainsaw carburetor: device, operating mechanism, problems, service and repair

It doesn’t matter which chainsaw is equipped with a two-stroke single-cylinder carburetor engine. Early models of chainsaws were equipped with contact ignition, but now almost all domestic manufacturers use electric ignition, so there is no need to constantly clean the contacts and adjust their clearance.

The fuel-air mixture to perform engine work is mixed in the carburetor. Using a special damper, of course, you can manually lean or enrich the fuel mixture for a specific purpose - for example, for cutting hard wood.

Both the health of the engine and the performance of the chainsaw directly depend on the good technical condition of the carburetor. Let's take a closer look at how a chainsaw carburetor works.

Chainsaw carburetor design

In fact, all models of chainsaws use a similar carburetor design. As an exception, today we can safely call the carburetor of a certain very cheap Chinese chainsaw - there may not be some parts, and most of the components are made of very cheap materials.

The main components of the carburetor are:

- Frame. Made from aluminum to make the structure lighter, it has a one-piece shape. The housing contains a diffuser, an inlet fitting, a pulse channel, a main screw and an idle screw, a damper that regulates the air supply, and other elements.

- Diffuser. Placed at the carburetor inlet.

- Jets. Special valves that regulate the amount of fuel.

- Spray.

- Float chamber.

Approximate diagram of a chainsaw carburetor

The mechanism of operation of a chainsaw carburetor

Before you adjust the carburetor on a chainsaw, you need to understand the principle of where it works.

- When the engine starts, the air damper located at the bottom of the housing opens.

- A vacuum is created in the air channel and the float chamber due to the stroke of the piston, and as a result, an air flow is sucked through the diffuser.

- The intensity of the air flow suction is regulated by the position of the air damper.

- Gasoline enters the float chamber through the inlet fitting from the gas tank.

- The speed of passage of gasoline from the chamber to the diffuser is controlled by means of jets.

- In the diffuser, gasoline is mixed with air.

- The prepared air-fuel mixture enters the intake channels, from where it is directed into the working combustion chamber of the cylinder.

The main malfunctions of the carburetor on a chainsaw

Please be aware that all holes are very small. Even minor contamination can block the flow of air, or fuel, which is why filter elements are installed at the inlet openings. Often, they do not manage the task at hand every time. The following signs indicate defects in the chainsaw carburetor:

- High gasoline consumption and thick smoke from the exhaust;

- The engine “does not pull”;

- Floating speed;

- The engine starts, but stalls immediately or after a very short time;

- The engine does not start at all.

- Chainsaw shoots at carburetor

These malfunctions are a sign that the carburetor on the chainsaw is not adjusted correctly or that it is dirty. This implies the need for adjustment, cleaning and other repairs. Let's see how to do this below.

How to correctly adjust the carburetor on a chainsaw on your own

Factory options for the chainsaw carburetor provide rational fuel and air suction characteristics. However, during operation they can become confused due to vibration - even a shift of ¼ turn in any of the screws leads to a severe change in the characteristics of the air-fuel mixture and the carburetor of the chainsaw needs to be adjusted.

Adjustment of the chainsaw carburetor is done using 3 screws marked H (High), L (Low) and S. The last screw, depending on the brand and manufacturer, has other names, for example T or LA.

- H: is responsible for the operation of the head jet and regulates the highest speed.

- L: adjusts the position of the idle jet and allows you to set low speed.

- S/T/LA: designed to regulate engine idle speed.

To know how to correctly adjust the carburetor on a chainsaw, you need a technical passport - information about the angles of rotation of the adjusting screws is indicated here. After this fact, we move on specifically to the adjustment. When, a screwdriver for adjusting the carburetor of a chainsaw or an ordinary flat-head screwdriver is useful here:

- Place the chainsaw on a flat surface, preferably a table or something similar. Fundamentally: The chainsaw must be positioned so that the tire is oriented in the opposite direction. The engine is expected to be turned off.

- Using a wrench or a screwdriver, unscrew the fastenings of the housing casing cover and remove it to get to the carburetor.

- Remove the air filter that covers the carburetor for the chainsaw. The manufacturer may install a shock-absorbing foam insert on top of the carburetor; this must also be removed.

- Now the adjustment of the chainsaw carburetor begins. Screws L and H must be fully tightened. Tighten them slowly and carefully so as not to break them.

- Unscrew both screws approximately 1.5 turns.

- Start the engine and let it run for about 7-10 minutes so that it warms up perfectly - it is impossible to adjust the chainsaw carburetor on a cool engine.

- When the engine warms up, set it to run at medium speed.

- Slowly begin to tighten the idle speed screw counterclockwise. It is necessary to turn until the motor runs smoothly. If the passage, if the engine begins to stall, you need to continue adjusting the chainsaw carburetor and gradually return the screw clockwise.

READ Sharpen a chainsaw chain with a file and a screwdriver

When the carburetor of a Chinese-made chainsaw, or otherwise, is adjusted, you need to “drive” the engine at different speeds.

How to remove a carburetor from a chainsaw?

Either the engine does not start or stalls immediately, most likely the carburetor is clogged and needs to be cleaned. How to check a chainsaw carburetor? We'll have to take it apart - there's no other way.

Before cleaning the carburetor on a chainsaw, it is still recommended to check other components: air and fuel filters, spark plug and muffler. It is possible that they are clogged - it is easier to clean the filter or change the spark plug than to clean the carburetor on a chainsaw. When, specifically, a problem with spark plugs is the reason why a chainsaw shoots into the carburetor - very late ignition leads to the fact that an excess of fuel-air mixture appears, because it does not have time to burn completely.

If the problem is not resolved, you will have to remove the carburetor. This is explained very simply:

- We remove the plastic back cover - it is held on by a latch, or in other words, by a thread.

- Remove the air filter.

- Use a flat-head screwdriver to pry up the air rods and remove them. You will like two or three rods, depending on the model.

- The carburetor is secured with 2 fasteners - they are placed diagonally. You need to unscrew them.

- Disconnect the gasoline hose where fuel is supplied to the carburetor from the gas tank.

How to clean the carburetor on a chainsaw?

The chainsaw carburetor should be washed or cleaned only when it is removed and disassembled. Before cleaning, we need to prepare in advance what our client needs to do: two screwdrivers (plus and minus), open-end wrenches, alas, a head with nozzles is better, a clean rag, a special cleaning agent, a pump and an ultrasonic cleaner (recommended). Before you start cleaning, you need to drain all the gasoline - this is a must. When the remaining fuel has been drained and the entire instrument has been prepared, we proceed to cleaning:

- Detach the top cover and remove it.

- Carefully remove the fuel pump diaphragm.

- There are spring clips on the left side of the housing. When they are disconnected, there are screws under the brackets - they also need to be removed.

- Unscrew the bottom cover.

- By unscrewing the screw, you gain access to the needle valve. It and the spring located underneath must be carefully removed, so as not to dull the needle.

- The air damper is dismantled with a small longitudinal force, after which the damper axis is removed.

- At the end of the process, remove the throttle valve, lever and axle.

If the carburetor is disassembled, what remains for our client to do is to lay out the parts on a flat surface on a clean rag. Carefully inspect each part for clogging or wear. Pay special attention to the jets and inlet fitting. Their clogging is the main reason why gasoline does not flow into the carburetor of the chainsaw.

If a certain part shows that it is very worn out, it is better to immediately replace it with a new one, so that in the future you will not have to think about how to repair a chainsaw carburetor. Cleaning a chainsaw carburetor at home is done using a special detergent. It is necessary to thoroughly wash each part, then dry them with a lint-free cloth, or better yet, with compressed air. What remains for our client to do, the channels are also blown with air.

If you have an ultrasonic cleaner at home, of course, then that’s even better. Pour diesel fuel into the bath, carefully place the dirty parts there for 5-10 minutes and after cleaning, dry them with compressed air.

Assembly is done in reverse order. A very important point is the installation of the needle valve - it must rotate freely in the seat. If the petal sticks, press it a little or press it down so that it sits deeper.

After cleaning, it is always recommended to wait 20-24 hours - this is necessary so that the cleaning agent has completely evaporated. Otherwise, it will mix with the fuel-air mixture and enter the cylinder, leaving carbon deposits on the walls after combustion.

Husqvarna chainsaw will not start. What to do?

Remove the “cradle9quot; spark plugs, turn the spark plug out.

With normal mixture formation, the candle must have an even brownish or grayish color.

Maybe you just got sucked in? cylinder with gasoline, then the spark plug will be wet.

Pull the starting cord a couple of times to ventilate the cylinder from excess gasoline. Blow it out as you go, and then massage the spark plug body onto the cylinder, this is best done in the shade, and see if there is a spark.

You need to start the saw on the choke, pull out its pull, pull the cord a couple of times until it yaps. If you yap, turn off the choke and start it without it.

If it doesn’t help, then unscrew the screws “L9quot; and "H9quot; 1/8 turn, more than just gasoline will flow into the cylinder.

Press the gas a couple of times, the carburetor will spray gasoline into the cylinder, which may not be enough to start.

the system chose the myth as the best answer

Chainsaws and brush cutters of this brand usually start up perfectly. While you should panic and immediately disassemble everything down to the screw, you need to start with the most ordinary thing. In most cases there is a problem with fuel. It is necessary to prepare the correct mixture of gasoline and oil and fill the tank. Don’t forget to move the choke lever to the “closed” position. Then, you need to pull the starting cord a couple of times and the saw should start. Didn't start? We assume “over-sucking9quot;. We move the choke lever to the “open” position, give full throttle and pull the cord again. From time to time the saw starts at this stage. If not, then just take a short walk, calm down, and begin what remains to be done for our client at first. And only after the third lap you need to start unscrewing the spark plug and everything else if you have experience fiddling with two-stroke engines, for example, a moped. If you have no experience, then you need to turn to those who have. In the most experienced hands, the saw will quickly come to life, and they will also teach you how to start it.

When the saw started up, worked, the user was very experienced, properly looked after, kept clean, then he immediately realized that something was going completely wrong and the saw was in need of serious repairs.

add to favorites link thank

Let me mention one more reason. What exists, that Husqvarna chainsaws - even 5 years ago they became the object of counterfeits by unfamiliar Chinese. On the outside, although they are practically no different from the original (although there are certain execution errors), the main distinguishing feature is that such saws are sold or used (like “I needed the money urgently, I took it for 12 thousand rubles. Now I’m discounting it for 5”) , in small shops with “super promotions9quot; and “sales9quot;. A common feature: the declared price is 2-3 times lower than that of large dealers. The real service life of such saws is a few 10 (most likely) operating hours, then irreversible mechanical damage occurs (for example, cracks in the cylinder). What, repair and restoration they are not intended for.

add to favorites link thank

There are several circumstances that you will like best; I will list only the most common ones:

- Spark plugs are damaged. To be able to determine whether the spark plug is faulty, remove and inspect it. If the porcelain insulator is cracked, the electrode is burnt out or damaged, or there are heavy accumulations of carbon on the electrode, the spark plug should be replaced. If the candles have worked for several seasons, it is also best to change them.

- The carburetor is clogged. Over time, some of the ingredients in the fuel, evaporating, settle into a layer of sticky substance that can clog the carburetor and prevent the engine from starting. Clean it with detergent.

- The ignition coil is faulty. Before changing it, make sure that the spark plugs are in good condition.

Source

Adjusting a chainsaw carburetor - what does a beginner need to know?

Initially, all adjusting bolts are in the factory positions - this guarantees the absorption of the optimal amount of fuel and air. However, due to prolonged use of the saw in difficult conditions, the factory settings of its carburetor may be disrupted. Even a slight shift of one of the bolts by 1/5 of a turn will lead to serious disruption to the operation of the saw motor. Therefore, the operator must constantly ensure that the adjustment bolts are in the optimal factory-set positions.

If for some reason the operation of the node was disrupted, it will need to be configured again. For this purpose, the unit has 3 adjusting bolts. The first of them is designated by the letter H - it is needed to tune the chainsaw engine when operating at maximum speed. The second screw, marked L, is used to adjust the motor while it is running at low speeds. The third screw may be marked T, S or LA. Its task is to adjust the internal combustion engine when operating in idle speed mode.

Setting up a chainsaw carburetor must be carried out with a fully functional engine. Immediately before adjustment, you will need to inspect the air filter and, if necessary, clean it or replace it.

How to properly adjust the carburetor on a chainsaw?

To adjust the unit, place the tool on a hard, flat surface. It is best to adjust the chainsaw carburetor in a place protected from dust and moisture.

The node setup process should look like this:

- First you need to unscrew the mounting bolts and remove the protective housing of the saw. This will make it possible to inspect the carburetor and, if necessary, clean it;

- Next, you will need to remove the standard air filter of the instrument. If the saw is equipped with an additional foam insert, then it must also be removed;

- After this, you will need a screwdriver, which you need to tighten the bolts marked H and L clockwise until they stop. This must be done very carefully so as not to break the bolts;

- Then both screws should be unscrewed 1.5 turns in the opposite direction;

- Next, you need to start the chainsaw motor and let it run for about 7 minutes;

- As soon as the engine cylinder warms up, you will need to start turning the bolt L until the internal combustion engine begins to operate at maximum speed. Immediately after this, the bolt must be turned 1/4 turn in the opposite direction;

- Then you will need to adjust the engine to operate at high speeds. To do this, you need to connect an electronic tachometer to the engine and start turning the H bolt until the indicators on the instrument display coincide with the instructions for the recommended maximum speed in the instructions for the saw;

- In the end, all that remains is to adjust the operation of the saw’s internal combustion engine at idle speed. To do this, you need to slowly turn the T bolt counterclockwise until the motor runs stably and without failures. If the engine begins to stall, then bolt T should be turned in the direction of the clock hand.

To adjust the carburetor on a chainsaw, you should work with the adjusting bolts as accurately as possible. Over-tightening the screws will place increased stress on the engine and other important components of the garden tool.

Doesn't Pump up Gasoline on a Chainsaw

Why it’s bad, as it’s also called, the chainsaw won’t start : prerequisites and solutions from the experts

Almost all power drives of chainsaw equipment produced in the latest period are equipped with easy start and electric ignition systems, decompressors and booster pumps. When asked why the chainsaw won’t start

With such rich equipment, service specialists do not give a specific answer.

Depending on the class and purpose, carburetor power units of a similar design are installed on household and professional models, running on high-octane gasoline with a small admixture of motor oil for two-stroke engines.

The working volume of chainsaw engines varies from 26 to 60 cm3, power during 6-plus hp. The corresponding feature of chainsaw drives is the greatest compactness, comfortable service, and access to setting points. The standard lifespan of economical models is 1,500 hours, while branded ones are more than 4,500.

Content

Features of returning chainsaw scrap

It is rarely possible to check the work of a tool purchased in a store, since even decent trade organizations, citing the lack of criteria and fire regulations, reduce pre-sale preparation to a minimum.

- Any new model may be structurally different from previous developments. Therefore, the beginning of preparation by the owner of the tool for the first launch is preceded by a study of the operation management. The work is carried out in accordance with the manufacturer's recommendations.

- If the new tool has obvious damage, does not start or is dismantled, it is better to return the chainsaw to the dealer.

- The store must accept the defective product, exchange it for an identical model, or return the money. Chainsaws that have obvious signs of disassembly or operational damage are not eligible for return.

Defective brand new chainsaw, subject to exchange at the place of purchase within two weeks. After this period, warranty obligations come into force, allowing the faulty tool to be repaired free of charge in the service.

Limitations in independently finishing the warranty instrument

Even with an easy start that allows accounting (software), it is relatively difficult to start new, untested equipment. It is not recommended to disassemble the recoil starter before the warranty period and repairs have expired.

- For service departments, such modifications can be a reason to refuse free replacement of broken, more valuable equipment.

- gasoline

does not flow ” or “the air intake is loose,” penalties are not used. - As practice shows, problems with starting up economical chainsaws appear after 2-3 years of operation. Under these circumstances, the owner has to put up with additional repair costs or rely on his own plumbing abilities.

READ Replacing Shock Absorbers on a Chinese Chainsaw

Thanks to the higher quality of materials and factory assembly, branded models have significantly fewer problems with starting. Nevertheless, the tips given here may be useful to owners of middle and high-class chainsaws.

The acquired information will give a hint in the direction of solving the problem when the Chinese chainsaw does not start. In fact, all Chinese chainsaw imports are developed on the basis of European models, therefore the design and operational differences are insignificant.

Possible reasons for a problematic start-up

In general, it is not excluded:

- unqualified setup of the fuel accounting system;

- ignition malfunctions;

- dirty air absorber filters.

In most cases, the chainsaw does not start when cold or does not start well after long-term storage, refueling with substandard fuel, or the presence of a huge gap in the spark plug electrodes.

In the private sector, the peak of operational failures occurs after winter in late autumn, as a result of intensive work on harvesting and sawing fuel wood.

Failure detection technologies

Why does gasoline not flow from the chainsaw tank to

carburetor? There is only one reason, the formation of a vacuum in the tank. The solution to the problem is to pull out the snow-white plug and clean it.

Chainsaw repair, fuel pump does not work

Not

reason

the chainsaw starts

The MAX 3216

chainsaw no

signs of life. The cause of the problem has been found.

There are real methods for searching for more relevant failures and defects, developed over many years of implementation. Methods for eliminating starting problems prescribe a certain sequence for checking the functionality of the fuel complex, accounting programs and ignition. What to do immediately?

Mechanical jamming of the piston or crank mechanism

This malfunction occurs due to the piston sticking in the cylinder or the destruction of the crankshaft bearing. This happens when the engine overheats or runs for a long time on pure gasoline.

READ Why Brushes Spark on a Rib Circular Saw

First, it is recommended to cool the unit, then pour a few drops of engine oil into the spark plug hole. Most of the engine can be wedged, but the consequence of this incident is the appearance of scuffing on the piston. The tack is not reflected on the shiny surface of the cylinder mirror.

If the measures taken do not produce the desired result, the saw must be repaired in a special workshop.

Checking the supply of flammable consistency and a set of accounting ignition programs

First of all, you should make sure there is fuel in the carburetor float chamber. After several attempts to start the engine, a dry spark plug that is turned out will give a clue as to the reason for the disgusting start without supplying a flammable mixture.

Recommended sequence of actions:

- checking the fuel filter;

- patency of the gas pipeline;

- cleanliness of the drainage hole of the fuel tank cap;

- It is possible that the carburetor float valve may become stuck in the closed position.

To clean the cylinder volume, with the spark plug removed and the ignition off, make several vigorous jerks with the starter. In the absence of a new, serviceable spark plug, you need to carefully dry and check the old one for a spark. Warming it up over an open fire is not advisable, since there is a high possibility of cracks in the insulator and its complete failure.

To check spark formation, a spark plug with the cap on must be applied to the saw body and cranked with a starter. A working spark plug produces a strong discharge, accompanied by a corresponding crackling sound.

A small, reddish spark indicates a malfunction of the ignition unit, high-voltage conductor, or internal resistor of the standard spark plug.

Pro tips for controlling working consistency

If the checks performed did not give the desired result, we move on to checking the ignition. A damp spark plug that is turned out indicates an excess of fuel and a lack of air; the mixture that floods the spark plug at startup is not capable of igniting in such proportions even by a powerful spark.

To adjust the properties and quantity of air-gasoline consistency to the best parameters, a wide range of operational adjustments are used. The reason for the overflow of fuel in old chainsaws is the leakage of the fuel flow valve and the carburetor float valve.

In standard situations, after briefly purging the cylinder with the spark plug removed or the decompressor turned on, normal starting is restored one hundred percent.

Consequences of operation with rich and lean consistency

- Due to the engine operating with an over-enriched consistency, a layer of conductive carbon deposits appears on the insulator of the central electrode, which can cause interruptions in spark formation.

- The snow-white or grayish color of the central electrode insulator indicates high-temperature combustion corresponding to a lean consistency. Both options negatively affect the traction properties and durability of the power drive.

- Setting the carburetor to a lean mixture will be a prerequisite for the phenomenon when the chainsaw does not start when hot, in another case it starts, but does not start.

READ How to Remove the Clutch on a Patriot Chainsaw

Proof of the usual, in a 16:1 ratio, properties of the air-fuel consistency is the brown color of the insulator and the absence of traces of soot.

Air absorber and muffler condition

The reason for a problematic start-up is that the air cleaner filter is clogged with sawdust. If the engine starts with the air absorber removed, special attention should be paid to cleaning the filter. A huge selection of carbon deposits in the muffler affects the power and thrust of the unit; alas, the engine must start freely.

Checking the tightness of the connection between the carburetor and the body

When the threaded fasteners are loosened, air leaks appear, which leads to a depletion of the gasoline-air mixture and, accordingly, a deterioration in its performance characteristics.

To change a warped gasket, it is recommended to use a repair kit; if you don’t have one, make the gasket, of course, from a gas- and oil-resistant material of similar thickness.

Flushing the carburetor and checking the condition of the jets

If, during the work performed, a measured start is not established, we look for a fault in the carburetor. If you do not have the necessary experience, disassembly should be entrusted to an experienced specialist.

A prerequisite for difficult starting and possibly, not counting the previously mentioned air leak:

- contamination of jets;

- water entering the float chamber and depressurization of the float itself;

- loose fit of the float valve , which stabilizes the fuel level in the carburetor;

- refilling the fuel accounting system with a fuel substitute, otherwise expired consistency.

Severe malfunctions blocking the standard start-up, such as air leaks through worn out oil seals of the crankshaft shanks, changes in the ignition angle, due to the lack of appropriate tools and technological equipment, are eliminated in repair shops.

Tips for storing fuel and lubricants

Fuel with an oil component can be stored in iron containers for as long as a month. An old gasoline-oil mixture is prone to the formation of coking resinous deposits, which limit the mobility of the piston rings.

Water enters the fuel system not only with gasoline, but with huge temperature changes it appears in the form of condensation on the internal walls of the carburetor.

The presence of water in the fuel is manifested by snow-white smoke from the muffler, interruptions in the operation of the engine, and the operational version stopping when ice forms in the system.

Source

How to flush a chainsaw carburetor?

To clean the unit from heavy contamination, it is best to use a product that is sold in pressurized cylinders. The cleaner comes with a dispenser and a long thin tube, which makes it possible to spray the product in any hard-to-reach places.

It must be remembered that cleaning the carburetor on a chainsaw is done using flammable chemicals. You need to work with them wearing a special protective mask and only in well-ventilated areas.

Read also: Do-it-yourself compressor from an oka engine

To clean the carburetor on a chainsaw, the unit will need to be partially disassembled. The throttle valve, adjusting screws, body and other parts of the carburetor will need to be washed with the product from the bottle and set aside until completely dry. Once all the elements are dry, the assembly can be assembled and installed back on the chainsaw.

Gasoline does not enter the chainsaw carburetor

If fuel does not enter the standard chamber, this may indicate several breakdowns at once. First of all, you need to check the air and fuel filters. During long-term operation of the saw, these elements absorb large amounts of dust, which subsequently prevents the infiltration of clean air and fuel. A slightly dirty filter can be cleaned with gasoline, but if the part is clogged with a large amount of dust, it will need to be replaced.

Another cause of malfunction is the needle. This part tends to stick, especially in Chinese-made chainsaws. In most cases, simply moving the needle will be enough to fix the problem.

If fuel does not enter the chamber, the saw owner should inspect the tool seals. After several months of using the tool, these parts lose their tightness. Over time, they begin to leak gasoline, as a result of which the tool stops starting. Repair is carried out by replacing the seals.

When starting the saw, the breather plays an important role. It is located near the gas tank cap of the saw, and performs 2 tasks at once - it maintains optimal air pressure and prevents fuel from leaking out. To check the breather, you will need to disconnect the fuel supply pipe and see how much gasoline flows out. If it does not flow out at all, it means that the standard breather is clogged with debris and dirt. In this case, you will need to clean the element and reinstall it.

If fuel does not enter the chamber, then you need to check the fuel line. Most often, to complete a budget class tool, a Chinese hose is used, which loses its tightness over time. In this case, it will be necessary to replace the line, paying special attention to the tightness of the channel joints.

Why is there no gas flowing into the chainsaw?

According to reviews from owners of Chinese chainsaws, the equipment breaks down quite often and the breakdown is accompanied by a lack of fuel supply to the carburetor. If you have applied the above tips, you need to diagnose the following elements:

Carburetor needle. On cheap chainsaws, the needle in the carburetor often gets stuck, which prevents fuel from flowing. Sometimes all you need to do is move the needle and get it positioned correctly.

Oil seals. Chinese and even branded chainsaws may have low-quality oil seals with poor sealing. Fuel stops flowing when the fuel mixture begins to squeeze out through the seals. Gasoline leakage is quite possible through the seals.

Breather check

It is the breather that plays a serious role when starting a chainsaw; you can find such a part near the gas tank cap, or rather in the area of the air hole. The breather performs a simple but important role - it prevents fuel from leaking and establishes the correct air pressure. It is thanks to this air that fuel enters the carburetor, and a malfunction of this element is a common reason when fuel does not enter the chainsaw. A malfunctioning breather will create negative pressure, which will prevent gasoline from flowing to the carburetor when you try to start the tool.

Checking the functionality of the breather is quite simple; disconnect the gasoline pipe from the carburetor and check how the fuel flows. If gasoline flows in a small stream, everything is in order, if it does not flow at all, the breather is most likely clogged with dirt. If done correctly, you can clean the part, sometimes it’s easier to replace it with a new one. The cleaning procedure is performed either manually or by applying a strong jet of compressed air.

Video

Why does a chainsaw shoot into the carburetor?

If, during startup and operation of the tool, its owner hears sounds reminiscent of gunshots, this indicates a malfunction of the unit in which the fuel is mixed. The reason for this, most likely, is the following malfunctions of the chainsaw carburetor:

- overdrawn ignition - in this case, the fuel does not burn out, which leads to specific sharp shots;

- supplying a mixture with a low concentration of gasoline to the carburetor - to correct the problem, you will need to adjust the jets.

If the shooting sound comes from the muffler, then the problem is the fuel mixture is oversaturated with gasoline. If there is too little air in the fuel, it will burn not only in the chamber, but also in the muffler. This will be evidenced by a large amount of carbon deposits on the inner walls of the muffler.

Every modern chainsaw, regardless of its purpose and design features, is equipped with a fuel system. It is based on a carburetor, the main function of which is to mix the fuel mixture with pre-purified air. Any malfunction of the carburetor leads to loss of power and other problems with gas-powered garden tools. You can solve them yourself - to do this you need to study the design of the fuel unit, the features of its adjustment and methods of self-repair.

Chainsaw carburetor design

The carburetor of any new chainsaw is an integral part of the engine, which continuously regulates the amount of air required for constant mixing with fuel and supplies the finished mixture to the internal combustion engine cylinder.

In most modern chainsaws, built-in carburetors initially have a similar design and almost the same principle of operation. There are certain differences only in the fuel units of Chinese models.

The main elements of the carburetors of all chainsaws include:

- float chamber - a small compartment whose main task is to maintain the optimal amount of fuel filled;

- atomizer is an important mechanism that is initially responsible for injecting fuel into the intake air flow;

- diffuser - located next to the standard inlet through which air enters the engine compartment of the chainsaw. The main function of the diffuser is to forcefully accelerate the suction of air masses;

- tube - required to supply air in small volumes - portions, the sizes of which depend on the needs of the fuel system.

The operating principle of a chainsaw carburetor is also quite simple. When the chainsaw is running, the engine throttle valve is activated, which, when open, allows air to flow through the factory rubber tube. With the gradual opening of the standard valve and the tube connected to it, the float located in the chamber with fuel is activated. Continuously passing through a standard diffuser, the air intensively mixes with fuel. After this, the used ready-made air-fuel mixture is sprayed through the factory intake channel into the working cylinder of the standard engine.

When spraying fuel, the pressure inside the float chamber of the chainsaw is almost identical to atmospheric pressure. At the same time, the pressure in the factory air tube is rarefied. Due to the difference in these indicators, air is continuously sucked into the tube. As engine speed increases, it requires more fuel. Accordingly, the tube should suck in more air. Thus, the ability of the engine to intensively gain speed required for sawing large wood largely depends on the carburetor.

Why doesn't gasoline get into the chainsaw?

Carburetor needle. Cheap chainsaws often have a needle resting on the carburetor to prevent fuel from getting in. Sometimes simply moving the needle and positioning it correctly is enough.

Oil seals. Chinese and even branded chainsaws may have low quality seals with poor sealing. Fuel stops flowing when it begins to compress the fuel mixture through the seals. Gasoline leakage is possible due to gaskets.

Check your breath

It is the fan that plays a significant role when installing a chainsaw; such a part can be found near the fuel tank cap, more precisely. There is an air hole in the area. Breathing serves a simple but important role. It prevents fuel leakage and sets the correct air pressure. This is why air gets into the carburetor, and failure of this element is a common reason when fuel does not get to the chainsaw. A malfunctioning blower will create negative pressure, which will prevent gasoline from entering the carburetor when attempting to start the tool.

Checking the fan is quite simple, disconnect the gas pipe from the carburetor and check how the fuel is consumed. If gasoline flows in a small stream, everything is fine, if it does not flow at all. The breathing apparatus is quite clogged with dirt. If everything is done correctly, the part can be cleaned; sometimes it is easier to replace it with a new one. The cleaning procedure is carried out manually or using a strong jet of compressed air.

Source

How to properly adjust the carburetor on a chainsaw?

In order for self-adjustment of a chainsaw carburetor to bring the desired result, you need to carry out preparatory work. First of all, the operator must ensure that the engine is in good working order. To do this, be sure to remove the top cover of the protective plastic case and carefully inspect the engine cylinder-piston group for burrs, cracks and other defects. If they have formed, the surface of the assembly will need to be sanded. It is important not to damage the protective chrome or nickasil coating of the cylinder.

Next you need to inspect the spark plug. If a thick layer of dried carbon deposits forms on it, the part will need to be unscrewed and thoroughly cleaned. To do this, you need to heat the candle and carefully scrape off any remaining dried oil from its tip.

At the end, you will need to inspect the parts of the entire fuel system of the chainsaw. Clogging in the pipes, accumulated debris in the fuel and air filters, unstable operation of the diffuser - all this leads to the engine losing the required speed. As a result, the operator does not receive accurate information about the operation of the motor and cannot set the correct settings. To prevent this, you need to wash the carburetor parts, filter and tube. After they are completely dry, they can be installed in their original place.

Do-it-yourself chainsaw carburetor adjustment

To independently adjust a standard carburetor, the chainsaw owner will need a Phillips or flathead screwdriver, as well as a manual tachometer.

Read also: How does a bug for wiretapping on clothes work?

To adjust the carburetor of a chainsaw, spring-loaded adjusting screws are provided in the basic structure of the carburetor.

Depending on the brand of chain saw, the markings of its adjustment screws may vary. However, in order to initially correctly configure the carburetor on a chainsaw, you can always follow the same algorithm:

- First, the operator must look in the saw's instruction manual for the exact incremental angles for turning the spring-loaded adjustment screws. Immediately after this, on the saw in use with the engine turned off, they must be turned according to the instructions in the manual. Failure to do this may result in the operator breaking the tool's motor;

- Next, the chainsaw used on the farm will need to be placed motionless on a flat, stable surface. In this case, the bar and factory chain must initially be directed away from the operator;

- Then you need to start the internal combustion engine of the saw and give it at least 10 minutes to warm up;

- After this, you need to find the correct position of the screw L. To do this, the operator must slowly turn it along and counterclockwise until the motor runs quietly and without failures;

- If as a result of this the chain begins to rotate, then it is necessary to find the position of the screw T at which the chain will stop in place:

- Next, you will need to connect a tachometer to the internal combustion engine cylinder. Then you need to start turning screw H. As soon as the readings on the tachometer match the instructions in the saw instructions, the screw can be released.

To check the operation of the carburetor and chainsaw engine, you need to start the engine again and slowly press the gas lever. If the internal combustion engine smoothly picks up speed, then the adjustment was performed correctly. If this does not happen, you will need to turn screw L 1/8 turn counterclockwise and check the motor again.

Why is oil leaking?

Many owners of chainsaws are faced with the problem of oil leaking from under the unit. Most often, oil leaks due to damage to the oil hose connected to the oil pump. The photo below shows exactly the case when the end of the hose has torn and does not fit tightly onto the pump nozzle.

But to get to this place, you will need to remove the clutch mechanism from the shaft. In some models of chainsaws, oil may leak out at the junction of the oil pump with the oil tank hose (indicated by an arrow in the photo).

To eliminate the lubricant leak, you will need to pull this hose out of the seat. To do this, you can use pliers to pull the outer part. At the end of the hose you will see a rubber plug, which is the cause of oil leakage. This plug needs to be wiped well to remove any remaining oil, after which its seat needs to be sealed with something. You can use automotive sealant or fum tape, as shown in the following photo.

Next, insert the hose into the hole, install the plug in place and seal it using a flathead screwdriver. At this point, the operation to eliminate the oil leak can be considered completed.

How to flush a chainsaw carburetor?

You should think about cleaning the fuel unit of a power tool in the following cases:

- when it is difficult to start the engine;

- in case of unstable operation of the internal combustion engine at short-term idle speed;

- in case of failures when smoothly pressing the standard throttle trigger;

- with a significant increase in fuel consumption.

Most often, liquids that are found in almost every garage are used to flush the built-in carburetor of a chainsaw:

- kerosene;

- diesel fuel;

- pure gasoline;

- solvent.

Modern gardeners using powerful professional saws use more effective and gentle means:

- Mannol Vergaser Reiniger is a cleaner marketed in aerosol form. It quickly and easily breaks down even the oldest formations of resins, soot, oily deposits and other types of contaminants;

- Hi-Gear – This cleaner is distinguished by its high dissolution properties. It can remove old dried stains, oily crusts and the first signs of rust without harming the parts of the fuel system;

- Jet 100 Ultra is a high-tech spray designed to quickly clean the carburetor of a chainsaw. Shows a high rate of dissolution of the oldest oil stains.

Cleaning the carburetor on a chainsaw is performed in the following sequence:

- First you need to clean the outer part of the saw engine, and also remove and thoroughly rinse the factory air filter housing;

- Next, you can proceed to disassembling the power tool. To do this, you need to remove the filter housing and also unscrew the fasteners holding the carburetor together with the engine;

- Then you will need to carefully disconnect the thrust and gas cables from the carburetor. The springs included in the design must be removed so as not to stretch them;

- After this, you need to carefully pull off the fuel supply hoses from the factory fittings of the fuel unit;

- To clean the carburetor on a chainsaw, you need to remove it from the original mounting pins. At the same time, it is important to maintain the integrity of the gasket installed between the internal combustion engine cylinder and the fuel unit;

- The next step is to clean the outer walls of the carburetor. To do this, they can be treated with liquid cleaner or gasoline. In this case, you need to try to prevent dust and debris from getting inside the engine assembly or cylinder;

- Next, you will need to unscrew the screws securing the carburetor diaphragm, remove its cover and wash the internal cavity with an aerosol cleaner;

- After this, you need to dismantle the fuel pre-fine filter, and also disassemble the part of the assembly to which the fuel is supplied. All internal parts of the carburetor must be thoroughly washed with an aerosol cleaner. If the first cleaning does not bring results, then the washing should be repeated.

After all the internal parts of the standard carburetor have completely dried, you need to assemble the fuel unit in the reverse order and install it in place in the structure of the household chainsaw.

Gasoline does not enter the chainsaw carburetor - repair methods

Most often, the standard cause of this common breakdown is the formation of a blockage in the fuel foam filter or tubes responsible for the stable supply of fuel to the factory metal cylinder of the engine. Every third Chinese power tool regularly suffers from these blockages. This is due to the low quality of the built-in filters and tubes that come with inexpensive Chinese chainsaws.

Repairing a fault involves removing and washing contaminated parts.

To do this you need:

- Remove the cover of the plastic saw body;

- Clear the space underneath and begin dismantling the hoses and filters. The tubes are attached to the outlet fittings using clamps. To disconnect the hoses without damaging them, you need to loosen and remove the clamps. After this, the tubes will need to be blown out with compressed air and washed with clean gasoline;

- To dismantle the filter, you must first remove it from the factory housing. After this, the element will need to be placed in a container with clean gasoline. After a day, the filter can be removed and given time to dry;

- After washing, all parts must be carefully installed and secured in their original place in the carburetor.

This cleaning regimen will help thoroughly flush the most vulnerable elements of the fuel system without having to disassemble the entire carburetor.

Why doesn't gasoline get into the chainsaw?

Carburetor needle. Cheap chainsaws often have a needle resting on the carburetor to prevent fuel from getting in. Sometimes simply moving the needle and positioning it correctly is enough.

Oil seals. Chinese and even branded chainsaws may have low quality seals with poor sealing. Fuel stops flowing when it begins to compress the fuel mixture through the seals. Gasoline leakage is possible due to gaskets.

READ Electric Chainsaw Hyundai Xe 2400

Check your breath

It is the fan that plays a significant role when installing a chainsaw; such a part can be found near the fuel tank cap, more precisely. There is an air hole in the area. Breathing serves a simple but important role. It prevents fuel leakage and sets the correct air pressure. This is why air gets into the carburetor, and failure of this element is a common reason when fuel does not get to the chainsaw. A malfunctioning blower will create negative pressure, which will prevent gasoline from entering the carburetor when attempting to start the tool.

Checking the fan is quite simple, disconnect the gas pipe from the carburetor and check how the fuel is consumed. If gasoline flows in a small stream, everything is fine, if it does not flow at all. The breathing apparatus is quite clogged with dirt. If everything is done correctly, the part can be cleaned; sometimes it is easier to replace it with a new one. The cleaning procedure is carried out manually or using a strong jet of compressed air.

Source

There can be many problems with a chainsaw, and some of them are difficult to solve. If you have been working with this gas tool for a long time, you have a problem where gasoline does not get into the carburetor, but this is very difficult and does not allow the chainsaw to start correctly. Fortunately, experts long ago found the causes of such a breakdown, so we have compiled the main repair methods.

First of all, we check for trivial reasons, such as the presence of gasoline in the tank. If so, we check the process of fuel supply from the tank through the wire. To do this, simply disconnect the gas line from the carburetor and try to pump fuel. Properly supply fuel through the hose in spurts, this will ensure that there are no problems with the gas tank. If the fuel does not flow even jerkily or drains too slowly, the reasons may be:

The fuel filter is clogged with dirt and dust;

The gas supply line is dirty.

Surprisingly, even having a full tank can be the reason when fuel does not flow. Therefore, try not to fill the tank as full as possible. An overfilled fuel tank can compress the pipe that connects to the carburetor.

Low quality gasoline

Every experienced chainsaw user knows that fuel cannot be left in the tool tank for a long time. The fact is that long-term storage inside the tank will cause unnecessary processes with the formation of resin and polymerization of various components. Do not leave fuel in the tank for more than 2 weeks, and even if your tool starts with such fuel, it can cause soot to form on the CNG parts (rings, piston).

Air filter

If the chainsaw is not getting gas into the carburetor, pay attention to the type of air filter. Improper operation causes the chainsaw to become unstable and difficult to start later or stop while running. It is more difficult for air to enter the device, and the mixture becomes too saturated. You are unlikely to be able to start it and the reason for this is the formation of dust.

Care must be taken when removing the air filter, as if dust remains on it, it may end up on the carburetor. Clean the air filter fairly well with water and detergent. Be sure to dry the filter before installing.

Why does a chainsaw shoot into the carburetor?

The main reason for this malfunction is an incorrectly set distance between the ignition elements of a gas-powered tool. Because of this, the fuel that enters the standard cylinder of the internal combustion engine does not have time to completely burn in it. The result is a sound similar to an explosion. To effectively solve the problem, you need to set the ignition of the gas-powered tool, following the instructions in the user manual.