A saw chain is a metal base with links connected in series, which have teeth characterized by cutting properties. You can improve them by sharpening your chainsaw chain at home, but you must follow the rules and use a tool specially designed for this. The latter can be homemade or factory-made.

Chainsaw chain design

The chainsaw chain consists of three types of links made of high-alloy steel:

- Cutting - the main elements of the chain. There are right-hand and left-hand ones, which are arranged alternately, their cutting edges are located above the plane of the tire. The design of the teeth includes cut depth limiters.

- Drive (shanks) - used to transmit torque from the gasoline engine to the chain through the drive sprocket. This feature extends the life of the sprocket and gives the chain a more stable grip on the bar.

- Connecting - connects the shanks and cutting teeth of the chain.

How to understand that a chainsaw chain is dull and it’s time to sharpen it: signs

The long service life of any chainsaw depends on proper care and use, including the chain set. The good performance of the latter affects the performance of the device and performance parameters. Untimely sharpening can cause some problems in the operation of the saw itself. Most often this is:

- crooked cuts;

- heavy loads on the saw, resulting in increased wear of device parts, and hence a decrease in the service life of the entire device;

- increased fuel consumption.

If, as a result of the cut, small dust-like chips are formed, and the saw itself goes deep into the cut with great effort, it means that the target has become dull.

There are other signs of a dull chain:

- the speed of the tool has decreased;

- uneven and sharp sawdust is formed;

- it is necessary to make great efforts to cut wood;

- the chain has stretched or begun to sag.

Why does the tool become dull?

Sharpening a chain is required when it becomes dull, therefore, to increase its service life, the following influencing factors must be avoided:

- use old sprockets and new chains or vice versa;

- do not use lubricant;

- pour low-quality oil into the chainsaw;

- do not change the sprockets after their profile has been ground down and there is visible wear;

- do not control the degree of tension.

If you follow the rules for using the tool, it will last as long as possible. Turning should be performed only if this procedure is truly necessary, since it reduces the service life by an average of 30%.

Why does a chainsaw chain get dull?

A chainsaw chain can quickly become dull for the following reasons:

- if you use the saw too often;

- when the operator presses hard on the saw while sawing;

- if the chain is made of low-quality metal, or the steel has undergone improper heat treatment;

- when frequently cutting raw or resinous wood;

- when sawing trees with hard wood, such as: oak, Karelian birch, cherry, acacia, elm, ash and others;

- if the chain encounters obstacles in the form of sand or stones along the way;

- if the chain is not sharpened correctly or has insufficient tension during operation.

How to remove a chain from a chainsaw

The design of all chain saws is similar, so the algorithm for removing the chain will be the same:

- Protective cotton gloves should be worn first to avoid cuts from the cutting teeth.

- Remove the protective cover from the working part of the chainsaw and place it on its side on a flat surface.

- Using a socket wrench of the required diameter, unscrew the fixing nuts that hold the body and tire in place and remove the top cover of the body.

- Now you need to move the bar all the way down to the sprocket, thereby relaxing the chain, and remove the working elements from the mounting bolts.

- Disconnect the chain from the tire.

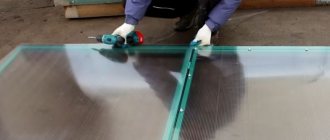

How to restore sharpening of a saw using a grinder

A more rational solution for quickly restoring the sharpness of teeth is to use an angle grinder, or, more simply, an angle grinder. Doing this is not as difficult as it seems at first glance. It is necessary to set the saw with the blade towards you and, tilting the tool in accordance with the angle of sharpening the tooth, restore the working edge of the latter, pressing the side of the rotating disk against it. Each subsequent tooth is sharpened at an opposite angle, so the position of the grinder will have to be alternated.

In this case, sharpening each one will take a second or two, no more. This procedure should be carried out carefully so as not to damage the chain, and especially the saw guide, due to careless movement.

Sharpening angles and chainsaw tooth configuration

The chain teeth of a chainsaw have the following characteristics:

- The sharpening angle for longitudinal sawing should be in the range of 6-12°, and from 25° to 30° - with a predominance of cross-cutting.

- Chain profile height: professional models have a high profile of 0.762 mm, and household saws have a high profile of 0.625 mm.

- The shape of the chain teeth can be rounded, half-chisel, chisel-shaped and with carbide plates.

- The thickness of the drive links - this parameter is the same for most household chainsaws, and has a value of 1.27 mm. There are edges 1.1 mm thick on low-power saws that are only suitable for sawing branches. Thicker shanks (1.5 mm, 1.6 mm, 2 mm) are typical for semi-professional and professional saws.

- The tooth pitch is the distance between the connecting elements of the chain. It has a value that depends on the power and torque of the tool engine - the higher these parameters, the larger the pitch: 1/4″ (6.35 mm), 0.325″ (8.25 mm), 3/8″ (9.53 mm), 0.404″ (10.26 mm), 3/4″ (19.05 mm).

Interesting Facts

- In Romania, the name “Friendship” has become a household name: in the colloquial language, the word “drujbă” is used to refer to a chainsaw in general, regardless of the model (although this meaning of the word is not recorded in academic dictionaries).

- An absolutely similar situation can be observed in Georgia, where over the years the name “Friendship” (დრუჟბა)

has become a common noun and in informal speech it is used to refer to any model of chainsaw (this is especially noticeable in rural areas). However, just like in Romania, in Georgia this word is not displayed in academic dictionaries. K: Wikipedia: Articles without sources (type: not specified) [source not specified 2186 days

]

- The name was transferred to a two-handed saw, which, when used, requires the coordinated actions of two people, for which it is sometimes jokingly called “Friendship-2.” K: Wikipedia: Articles without sources (type: not specified) [ source not specified 2186 days

] - The “Friendship” saw is mentioned in Vladimir Vysotsky’s song “There was an escape for a snatch”[ significance of the fact?

]. - One of the first samples was made in a sharashka near the Lapshanga station by Kyiv aircraft manufacturers.

- The life-affirming name of such a traumatic object has become the reason for the appearance of jokes and anecdotes.[ significance of the fact?

]

Chainsaw chain sharpening template

In order to properly sharpen a chain at home, it is recommended to use a special template to set the desired sharpening angle of the teeth. It allows you to control the degree of the leading edge (65-80°), as well as the rear angles of the top (50-60°) and end cutting edge.

To find out the sharpening angle using the template, you need to look at the value between the upper end of the tooth and the line perpendicular to the chainsaw chain guide. As mentioned earlier, this angle should be within 6-12° for longitudinal sawing, and 25-30° for transverse sawing. The harder and denser the wood species, the lower the sharpening angle should be maintained. When working with particularly dense wood, you need to sharpen the chain as often and carefully as possible, because a critically small tooth angle contributes to rapid wear of the chain (especially if it is made of a steel alloy containing manganese or silicon).

Features of mechanized restoration of saw chains

Despite significant disadvantages, machine sharpening is practiced in large forestry enterprises and industrial logging enterprises. In the private sector, owners of chainsaws prefer to restore the functionality of their sawing equipment with their own hands.

You can read about how to sharpen a chainsaw chain with a machine in the attached instructions, but real skill is developed gradually in the process of work. Thorough skills are acquired after independently sharpening 10 or more chains.

Currently reading: Customer reviews about Chainsaw Sturm GC99452B

To restore the working properties of saw chains with carbide cutting links, standard methods and technologies are not effective. In such cases, a diamond chain sharpening attachment comes to the rescue. The increased cost of fine-tuning a wear-resistant chain is compensated by its 4-5 times increased service life between overhauls.

How to sharpen a chainsaw correctly: the best methods and methods

Timely and competent sharpening of a chainsaw chain with your own hands will not only extend the time of use of the device, but also save effort and time on wood processing. Signs of a sharp chain are the formation of sawdust of the same size and regular geometric shape. To ensure the required level of sharpness of the teeth, any device for sharpening chainsaw chains, for example, any sharpening tool, is suitable. These are a file, a grinder and a machine.

How to sharpen a chainsaw chain with a file

This method is valued for its ability to perform work in any, even field, conditions, the simplicity of the procedure and the absence of the need to use expensive tools. A tool with an exclusively round cross-section will help to properly sharpen a chainsaw chain with a file. To determine the file parameters, you need to know the dimensions of the saw itself, in particular, you need to determine the pitch of the teeth. To process the sawing depth limiter of the guide tooth, the use of a flat variation is allowed.

Templates or patterns will give the desired direction to the tool and can make the work easier. They must be attached to the treated area. After completing the preparatory work, you can proceed directly to the procedure according to the recommendations of specialists:

- Secure the chain to the clamp.

- Align the file for sharpening the chain according to the template.

- Grind the teeth directed in one direction at the selected angle. The latter should not change. The working tool itself should be held so that its tip protrudes only a fifth of its thickness. You need to move the file as smoothly as possible, the movements should not be forceful. The reverse stroke must be done at idle. It is recommended to rotate the tool periodically, which will reduce the risk of wear on the sharpening side.

- The angle of inclination of the tool must be straight, and the sharpening angle of the chainsaw chain horizontally must be sharp, and its changes are allowed in the range from 10 to 30°. The smallest tooth in the row should be taken as a basis.

- Turn the tire over and do the same work for the teeth that go in the opposite direction.

This method also has some minor drawbacks. In particular, a large investment of time is required. But you won’t need to purchase expensive equipment or special tools.

How to sharpen a chainsaw chain with an angle grinder

When sharpening a chainsaw chain with a grinder, you must constantly monitor the level of sharpness of the chain and treat the drive sprocket with machine oil. At the same time, this method has one significant advantage - you do not need to remove the chain set from the saw, you can visually select the sharpening angle.

Although many owners of chainsaws and motor saws believe that this tool can damage the cutting teeth of the chain, if the work is performed by an experienced specialist, then the risk is minimal.

Only a special disc for working with metal is suitable. Its diameter must be at least 2.5 mm. It is recommended to choose an already used disc with rounded edges.

Before you start sharpening, you need to insert a wedge of wood between the chain and the bottom of the bar to prevent the headset from moving.

Sharpening a chainsaw chain using a drill

In order to sharpen the chain yourself using a drill or screwdriver, you will need a file with a round cross-section. To select it, it is necessary to clarify the value of the rounding diameter of the cutting tooth of the chain. Most household chainsaws can be sharpened with a 4.8mm file.

In addition to the sharpening tool, you will need any bearing that will be comfortable to hold with your fingers on the outer race.

Let's prepare the tool:

- First you need to remove the file shank with a grinder.

- Insert the file into the chuck and secure it.

- Make a bushing from plastic, cork or a small piece of wood of such a diameter that it fits snugly into the bearing.

- Fix the free end of the file in the resulting sleeve inserted into the bearing.

Sharpening the chain with the resulting device occurs as follows. First you need to fix the saw; it is best to clamp the bar in a vice, having previously loosened the chain so that it can move freely. Before starting sharpening, it is advisable to mark the first tooth with a marker. Now you need to place the file in the rounding of the blade of the cutting element, focusing on the required sharpening angle, which is usually marked with a mark on the outside of the teeth. Next, holding the homemade device with both hands (one by the handle of a drill or screwdriver, and the other by the outer race of the bearing), you should turn on the power tool and, bringing the file to the edge of the tooth, sharpen it. Sharpen each cutting link in the same way, gradually moving the chain along the saw bar.

You can learn more about this method of sharpening a chainsaw chain by watching video or photo instructions from various craftsmen on the Internet.

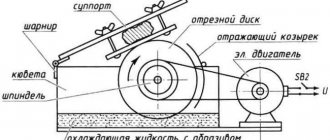

Sharpening a chainsaw on a machine

A do-it-yourself chainsaw chain sharpening machine also copes with the task without any problems. There are various options for using such a tool - automatic sharpening or manual sharpening. In addition, you can make a homemade chain sharpening machine.

Electric sharpening machines for chainsaw chains

Automatic devices for sharpening saws are equipped with an electric motor, from which the main abrasive element rotates.

Electric sharpening machines involve installing a saw into a special hole in the device, after which you will need to select the optimal angle for sharpening the teeth and turn on the chainsaw. After this, the chain teeth self-sharpen on the emery stone. But the best sharpening machines are not cheap, so they are rarely purchased for home use.

Chainsaw sharpening machines with “manual drive”

Using the machine to sharpen chains by hand is easy. Actions will have to be performed in the following sequence:

- Loosen the screw that secures the chain.

- Set the appropriate level of sharpening, in this case it is necessary to determine the maximum degree of sharpening after visual inspection of the most blunt tooth. The sharpening angles are also selected on a manual machine. You can use special tables that are presented in the instructions for the saw.

- Perform sharpening according to all selected parameters.

- Treat the chain with clean machine oil.

There are 2 ways to use a manual machine for this purpose:

- Sequential involves acting on each tooth one after another, and it is necessary to periodically change the polarity.

- Sharpening every second tooth, that is, the right tooth is sharpened first, and then the left. In this case, no polarity change is required.

How is manual sharpening inferior to an electric machine?

- Sharpening on a mechanical machine by hand is a very long and painstaking process.

- Manual sharpening requires some skill, perseverance, attentiveness and accuracy.

- The manual method is less accurate, as there is a human factor.

If you own a professional chainsaw that you use constantly, it makes sense to purchase an electric automatic sharpening machine. It will save your time and extend the life of the tool.

PowerSharp sharpener

Oregon's unique PowerSharp system for sharpening amateur gas and electric saws includes:

- plastic box with a push mechanism and a compartment for installing a grindstone;

- a tire with an additional hole for subsequent fixation of the plastic box of the sharpener;

- low profile chain;

- sharpening abrasive stone.

PowerSharp kits are available in a variety of sizes. To select the right size, simply remove the chain set from your saw and select a bar that matches the length of the sample.

Install the chain on the new bar and assemble the saw. This headset can be used instead of the “native” one until the first need for sharpening.

To sharpen with a sharpener, you need to install the whetstone in the box and secure it to the bar using a latch, and then turn on the saw at full power and rest the push mechanism of the device vertically down on a hard surface (stump, log, stone, earth), and press lightly. This way, the abrasive stone will touch the chain teeth and sharpen them in just 3-5 seconds. After dismantling the sharpener, you can start working again.

PowerSharp technology

If your chain is PowerSharp compatible, you can save time and effort. Sharpening occurs without removal from the tire in just a few seconds. The system includes:

- sharpening device;

- abrasive bar;

- saw bar.

Let's figure out how to sharpen a chainsaw chain using PowerSharp in just three steps:

- Install the chain with the bar;

- Secure the beam installed directly on the tire;

- Place the end of the saw somewhere and run the equipment for a few seconds.

Sharpening with PowerSharp system Source greenindustrypros.com

Compliance with all recommendations will allow you to avoid damage to the chain and carry out the operation in compliance with technological requirements.

Watch the video on how to sharpen a chainsaw chain using traditional methods:

Consequences of using an unsharpened chain

If the chain saw chain is not sharpened in a timely manner, the user’s work becomes more and more difficult, and the cut becomes uneven. Such exploitation will lead to such negative consequences as:

- decrease in efficiency - cutting requires great physical effort, accordingly, the speed of work decreases;

- increased fuel consumption – overconsumption can reach 30%;

- reduced service life of the saw - the chain set wears out quickly, and the engine overheats, which increases the likelihood of tool failure;

- risk of injury to the user - if the saw operates unstable, the chain may break.

Preventing the chain from becoming dull quickly

You can extend the life of the chain without periodic sharpening if you pay special attention to careful maintenance of the headset. In particular, it is required:

- The use of specialized oil, which must be added when refueling the chainsaw. To select the required concentration, it is recommended to read the instructions for the oil itself.

- All unused volume must be disposed of.

- During operation, it is recommended to periodically check the size of the gap between the stopper and the tooth edge. Ideally it should be 0.7 mm.

- In order to minimize the risk of tooth bending and one-sided abrasion, you can periodically rearrange the tire by 180 degrees.

- The drive sprocket must be lubricated systematically. This must be done before each use of the saw. You can choose the oil that is diluted with gasoline and added to the fuel tank. But the M8 brand has the best performance indicators.

- Monitor tension indicators. The chain should be positioned exactly along the grooves of the bar.

Basic mistakes when sharpening a chainsaw

If, after sharpening, the saw continues to work unsatisfactorily, errors were most likely made during sharpening.

- Wrong sharpening angle: more or less than the required value. To prevent such an error, you must use a special template.

- The front angle of the teeth is inclined forward or backward. This may be due to improper file sharpening. It is recommended to use a different sharpening method, or try to maintain the same pressure when sharpening by hand and select the correct file diameter.

- The teeth of the chain differ from each other in length. To prevent such a situation, it is necessary to mark the approximate tooth before starting sharpening, and “adjust” the remaining cutting elements to it.

- The height of the cutting depth limiter of the cutting links is too small or, conversely, greater than required. In the first case, it is necessary to modify the limiter using a filing gauge. In the second, sharpen the cutting links or replace the chain.

Useful tips

You can increase the service life if you alternate manual sharpening with the use of a special machine. The latter allows you to align sharpening angles on the machine as accurately as possible. The stitching depth should not be large.

It is necessary to observe safety measures that allow you to cut wood of any size with maximum efficiency and with a minimum level of danger to humans:

- Before assembling the chain tool and installing the headset, it is recommended that you read the instructions for use. This is due to the fact that each tool has its own characteristics.

- When working with a saw, you must wear gloves and safety glasses.

- For work, it is recommended to choose close-fitting clothing made from natural dense materials and the most reliable shoes.

- It is necessary to cut wood using a chainsaw in a stable and safe position, and the material itself must also be positioned as stably as possible. Installing a toothed stop on the log will help ensure stability.

- During operation, the saw must be held with both hands and the cutting process must be constantly monitored.

Modern chainsaws are used in domestic and industrial settings. At the same time, it is important to maintain the productivity and high efficiency indicators of the tool, which directly depend on the condition of the sharpened chain set.

How do you sharpen a chainsaw chain: do you prefer artisanal methods or do you trust this task to professionals?

Additional recommendations

First of all, you must remember that before you carry out direct sharpening, you need to determine its level, starting from the most, let’s say, “dull” cutter, since it is a kind of guideline in this process.

Chain lubrication diagram

It is also important to remember that you do not need to get too carried away with manipulation and grind your chain deeply . Since in this way you will simply disrupt its direct functionality, and its immediate strength and the strength of the link will decrease.

It is also important that most experts recommend, after direct sharpening, to blow through the chain itself using compressed air. And after this process, place it in oil for several hours, but it must be clean.

Mini chainsaws are indispensable in gardening and hiking. They are light and compact.

In contrast, saw blade sawmills are industrial equipment used in woodworking.

Those who do not want to buy a circular sawmill can make one themselves. Read about this in our article.