When laying ceramic tiles, it will not be possible to do without cuts. Moreover, they can be straight or curved, in the form of a circle. Each type of work requires a certain type of tool. At home, you can use a grinder or an angle grinder. But in order to make high-quality cuts, you need to know which grinder blade to choose for ceramic tiles. It is also advisable to familiarize yourself with the features of using this tool.

The process of cutting tiles with a grinder requires certain skills

Which disc to cut ceramic tiles with a grinder

There are many types of grinder blades that are suitable for cutting ceramic tiles. However, you should immediately stop purchasing cheap equipment, since their service life is short and their use can be dangerous.

Important! How smoothly and without chips the cut will be made depends on the correct choice of disk.

Stone discs

The most budget option, but in terms of reliability it is inferior to all other types. When using it, the cutting thickness will be much thicker, and a lot of dust will be generated during operation.

During use, you need to monitor the condition of the stone circle. And as soon as chips appear on it, replace it.

Steel wheels

This is the most reliable and durable type of equipment for an angle grinder. The steel wheels have a diamond-coated edge. And their service life depends on its intensity.

Using a steel disc on tiles for an angle grinder, you can make straight and shaped cuts without much difficulty.

Segmented dry cutters

This type of equipment is distinguished by the fact that its surface is divided into identical segments. And the cutting edge is coated with diamond.

Thanks to the slots, the disc is able to partially cool during use. This increases the duration of continuous operation to 1.5 minutes. After this, you need to let the tool cool, moving it to the side and keeping it idling for 30 seconds.

Segmented blades are for dry cutting only

Solid dry cutters

This is a solid circle with diamond coating applied around the edge. This equipment is convenient for processing tile edges. After using a solid disc on tiles for an angle grinder, the edges of the material are as smooth as possible.

To cool, it is recommended to periodically wet the tiles and also spray them with a spray bottle.

Combined disc models

This type of equipment is suitable for dry and wet cutting. But unlike segmented ones, they are inferior in terms of cooling, and solid ones do not produce such a high-quality cut.

Important! The disadvantage of combined types of equipment is that they quickly become clogged with small dust particles, and only concrete and sand-lime brick can be used to clean them.

Diamond wheel

To perform complex types of work, it is recommended to use this type of equipment. Its peculiarity lies in a special coating, which consists of small particles of industrial diamonds applied on top of a metal base. This allows the disk to withstand increased loads.

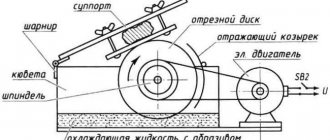

How to make a tile cutter from a grinder

When cutting tiles, it is not always comfortable to hold the grinder suspended and carry out all the work only by hand. To simplify this task, you can transform the tool into a device that will allow you to leave both hands free.

It resembles an electric tile cutter, and the transformation of the grinder itself is carried out as follows:

- The first step is to choose a suitable place to place the machine. The base of the tile cutter can be made of sheet metal, in which you will need to make a cut to deepen the circle. In the future, all work will take place along this strip, and it will also make it easier to navigate during the cutting process.

- The next step is to secure the grinder. To fix the device in the required position, you must use special clamps. If necessary, you can do them yourself, but it should be taken into account that in this case there is a possibility of the fastening bolts breaking off during the cutting process.

Note! This self-made electric tile cutter can be improved in the future with a container of water and a nozzle for performing wet cuts, which will allow you to get rid of dust and completely cool the cutting element during operation.

- After securing the tool, you can make a test cut. To do this, you need to lay the tiles according to the marks, after which you should turn on the grinder and slowly lower the circle. In this case, cutting the tiles must be done on the outside, feeding the product away from you.

If the work is done correctly, you will be able to get ceramic tiles cut into two parts with smooth edges and no chips, cracks or roughness.

If necessary, you can bring the tiles to perfect condition using fine-grained sandpaper or a file.

How to choose the right disk

When choosing equipment for working with ceramic tiles, you need to take into account the complexity of the work and the thickness of the material. It is recommended to use steel circles with laser-brazed diamond coating, as well as with positive locking. These types can withstand increased loads and have a long service life.

To obtain a smooth edge when cutting ceramic tiles, you should choose discs with a thickness of no more than 2 mm, and with a cutting edge width greater than the thickness of the material.

Types of diamond-coated discs can withstand increased loads

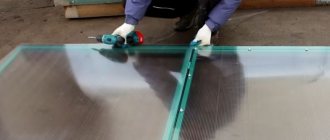

Making a cut

If everything is ready, you can start working. The cutting line must be marked with a marker, after which the tile is laid on a table or stool so that the entire marking is above the supporting surface. Exactly along the cutting line of the cut, a corner is applied on top, the vertical flange of which should be facing towards the cutting side. On both sides, the corner is pressed with clamps to the edge of the table, so the porcelain stoneware will be securely fixed, and the outer side of the shelf will act as a guide for making a straight cut.

Do not forget about safety precautions: it is strictly necessary to use safety glasses, gloves and earplugs. The switched-on angle grinder must be held in such a way that the disk is located almost parallel to the shelf of the angle. deviating from its edge by 1–2 mm and fitting closely at the bottom. By moving towards you, a thin groove is applied to the surface of the porcelain stoneware. There is no need to apply strong pressure, just scratch the surface a little. After this, the cutting line should be sprinkled with a little water and a shallow cut should be made again, moving towards you.

This must be repeated over and over again, carefully ensuring that there is always water in the cut. When the tiles have been cut to 2/3 of the thickness, it is necessary to remove the clamps and remove the corner. The tile should be placed on the edge of the table, the edges should be trimmed until a gap is formed, and then the part to be cut should be lightly struck with the palm of your hand. If the cutting is narrow, you can break it off with pliers.

This technique of cutting porcelain tiles produces a clean and straight top edge, but may cause chips at the bottom of the cut end. To remove them, the tile must be turned upside down and placed on the table so that it hangs slightly over the edge. After this, you should gradually grind the edge with the same diamond disk; it is not necessary to wet the edge.

READ How to Cut a Plastic Window Sill

How to cut tiles with a grinder without dust and chips

The main disadvantage of using an angle grinder to cut tiles is that a lot of dust is generated. This makes the job much more difficult. Therefore, experienced builders recommend initially sawing the glaze layer with a grinder. In this case, practically no dust is released. And only then break the ceramic tile along the cut.

Also, when using an angle grinder, chips often appear. Therefore, in order to saw off ceramic tiles with high quality, it is recommended to reduce the speed when entering and exiting the material. And also start sawing a little to the right of the marking mark. In this case, the chips can be cut off later with a grinding wheel.

Wet cutting

The appearance of scale and dust can be prevented by carrying out wet cutting. This method involves contact of the cutting edge with liquid. This can occur by immersing the working surface of the equipment in water or by applying a stream of water to it.

Types of cutting ceramic products

Unlike a flat cutter, an angle grinder allows you to perform different types of cutting. But each specific case has its own characteristics that need to be paid attention to.

Straight cutting or straight cut

This is the standard method for cutting ceramic tiles. It involves dividing the material along straight lines.

Algorithm of actions:

- Initially, you need to mark the cutting line. To do this, use a ruler and marker.

- Place the workpiece on a straight surface and remove all excess.

- Secure the tile with a vice.

- Make the first cut to a depth of 1-5 mm, depending on the thickness of the material. When entering the tile, reduce the speed and then increase it.

- The grinder needs to be driven away from you, at the same speed, evenly.

- When exiting the material, you should also slow down to avoid chipping.

- Break the workpiece along the cut line.

- Clean the edges with a jig.

Important! When making a cut, you must adhere to the chosen trajectory as much as possible.

It is better to make straight cuts not completely with subsequent breakage of the workpiece

Curly cutting or curly cut

This type of work is the most difficult. Therefore, it requires a certain skill for high-quality execution.

Work rules:

- Before cutting ceramic tiles with a grinder, you need to make markings with a marker.

- Place the tile on a flat surface and secure it.

- Next, make small vertical cuts, cutting off excess material.

- At the end, there will be some uneven areas that need to be sanded down with an abrasive wheel.

Cutting rectangular holes in tiles

In this case, you need to prepare a drill to make holes along the edge.

Work progress:

- Draw the outline of the hole with a marker.

- Fix the tile on a flat surface.

- Use a drill to make holes in the corners of the intended rectangle.

- Using a grinder, walk along the contours of the intended rectangle.

- Remove the inner part.

- When finished, polish the edges with abrasive.

Cutting circles (round holes)

Before cutting the tiles with a grinder, you need to make a central hole with a drill. To do this, you need to use a carbide drill, the diameter of which is within 3-4 mm.

Work progress:

- Mark the center point of the circle with a marker on the tile.

- Use a compass to outline the outline.

- Use a drill to drill a hole at the center point.

- Using a grinder, make vertical notches from the center to the outer edge of the circle, crosswise.

- Cut off excess material and clean the edges with abrasive.

45° cutting

In order to perform high-quality work in this case, you need to use a metal circle coated with diamond.

Procedure:

- Mark a cutting line at a 45 degree angle with a marker.

- If possible, fix the material face down.

- Make the first cut with a grinder.

- Repeat if necessary to improve the result.

Important! When cutting tiles at an angle of 45 degrees, it is necessary not to reach 1.5-2 mm of the glaze, that is, only cut off the clay.

Cutting porcelain stoneware

When performing repairs, not only the walls are covered. Porcelain tiles are laid on the floors in the bathroom and toilet - an artificial material that replaces granite and marble. Its cost is several times less than natural ones, but in terms of hardness and abrasion parameters, porcelain stoneware surpasses them. Recently it has become widespread. It can also be cut using an angle grinder.

To do this, you need to know the basic methods of processing material at home.

- It is necessary to choose the right cutting tool. It should say what it is used for: porcelain stoneware , hard ceramics, etc.

- To reduce chipping, choose a disc with a continuous cutting edge. The thickness should be minimal.

- We choose a cutting wheel with a high diamond coating height.

- The grinder must have a speed regulator.

After choosing a tool, prepare the workplace and begin cutting porcelain tiles with a grinder. To do this, you need to perform the following sequential steps.

- Place the material on a flat surface with thin foam or similar material underneath it.

- Securely secure the tiles to the surface using clamps.

- To reduce chipping, apply masking tape and make a mark along which you need to cut off the excess part.

- Prepare a vacuum cleaner to remove dust.

- You need to cut from the front side, moving the grinder away from you.

- It is recommended to cut not along the marked mowing line, but slightly to the side. This is done for subsequent grinding of the end of the porcelain stoneware to remove irregularities and chips.

By following these simple recommendations, you can cut floor tiles with high quality with your own hands.

Notched neckline

Often there is a need to cut a round hole in a tile. You can do the job correctly using an angle grinder if you have certain skills. To do this, mark a hole on the workpiece and trace the line with a felt-tip pen, marking the center of the circle. They begin to cut at a slight angle, slowly, along the inside of the mowing line, gradually passing along the entire circumference. Then the sectors are cut and taken out one by one, trimming the ceramics if necessary. The edges are finally processed with a file, obtaining an even circle. This processing is called dry cutting.

Such holes are usually cut for sewerage or ventilation.

When performing shaped processing of a workpiece, it is easiest to make rectangular cuts. In order for the cuts to be smooth and without chips, it is necessary to regularly change the cutting wheel. If you use segmented discs, then chips will certainly appear on the cut mowing line.

Features of working with porcelain stoneware

Porcelain stoneware material is particularly durable and reliable. After all, it is made of natural stone. To cut porcelain stoneware without chipping with a grinder, like tiles, you need to use thin segmented discs up to 1.5 mm thick with intense continuous diamond coating. This will reduce the likelihood of overheating.

Porcelain tiles should be cut in the same way as tiles.

Safety precautions when working with an angle grinder

When working with a grinder with tile material, you must take precautions.

Basic safety rules:

- mandatory presence of a protective casing for the tool;

- cord length is at least 2 m;

- keep the grinder strictly vertical;

- use protective equipment;

- hold the tool with both hands and saw away from you;

- do not put pressure on the disc;

- Do not cut with a tool immersed in water.

Important! You can cut tiles with an angle grinder only in a room with good ventilation, as the resulting dust is explosive.