How does this tool work? Let's understand the nuances

Let’s immediately make a reservation that all models of circular hand-held electric saws operate on the same principle. The body of the unit contains an electric motor, through which the cutting disc rotates. As for the main differences, they are usually associated with the type of construction - it is electric or manual. In the second case, the cutting disc is driven, as the name suggests, manually, that is, by human effort, while the electrical equipment is equipped with electric motors.

Also note that these two varieties differ from each other not only in size or weight, but also in the characteristics of torque transmission. Thus, in a manual unit with the possibility of stationary installation, the disk is installed directly on the shaft, while in electric saws a drive belt is used to transmit torque.

In addition, regardless of the specific type of saw, it must have a special support platform that allows you to adjust the depth and angle of the cut.

Electric mini-circular saws - units that operate on battery power - deserve special attention. Of course, they cannot boast of the same high power as their counterparts operating from the electrical network, but they allow manipulations to be carried out remotely from sources of electricity.

Note! If you are building a country house, then it is most convenient to use a cordless saw. It weighs a little and is also compact, so you won’t get tired quickly while cutting wood, and the battery itself can last for several hours without recharging.

Circular hand saws, like any other complex equipment, can be of several types.

- Household . Such units are distinguished by the fact that they have relatively few settings and insignificant power, but they are extremely simple to use, and they cope quite well with small volumes of building materials.

- Semi-professional . Obviously, their power is slightly higher than that of household ones, but they cannot be compared with professional ones.

- Professional . They are capable of functioning for a long time under heavy loads, usually have many useful additional options, and are intended, as the name suggests, for professional construction.

Note also that if you have to cut large volumes of wood, you will need a professional hand-held electric circular saw. But in the case of ordinary repairs, a semi-professional unit will be sufficient.

Features of hand and table saws

The second type of tool is a mini table saw. It has smaller dimensions than the previous version. This type of device is characterized by its mobility and the ability to process workpieces up to 60 cm wide. The cutting depth of such a tool is 4-7 cm. The disadvantage of such a tool is the increased level of vibration during operation of the device, which negatively affects the quality of sawing.

A mini-circular machine is a hand-held tool that is characterized by mobility and the ability to process workpieces in different planes. This saw has low power and requires periodic rest. Hand tools have a limited range of work.

The tabletop circular mini saw has smaller dimensions than the stationary version.

In addition, the device is characterized by a low level of safety, which is manifested in the proximity of hands to the working surface, incomplete protection of the saw blade, and the need to monitor not only the cutting process, but also the position of the electric motor in order to reduce the likelihood of cut distortion and tool kickback.

More expensive equipment of this type is a hand-held circular saw with the possibility of permanent installation. The body of the unit is massive, but safe. The tool has a special platform with which the saw is mounted on the machine.

Criteria for choosing an electric circular saw – what to look for?

The modern construction tools market is replete with a large number of different circular saws. And if you don’t know which hand saw to choose, we recommend that you familiarize yourself with some important nuances. First of all, when choosing a specific model, pay attention to some basic characteristics (all of them are presented below).

Criterion No. 1. Equipment power

The efficiency of the unit directly depends on this characteristic. If you need a circular hand saw, which will be equipped with a large cutting blade, preference should be given to a tool with a powerful engine. The power of rotation of the disk, as well as the depth of the cut, directly depends on the power. A low-power model may well get stuck in hard wood while cutting it, and at the most inopportune moment for this.

Note! The disadvantage of any high-power saw is its significant weight. For example, if the engine power of a hand-held circular saw is 1.2 kilowatts, then the weight of the unit will be approximately 4 kilograms, and if it is 2 kilowatts, then all of 7 kilograms.

Criterion No. 2. Cutting depth

And this indicator, as we just found out, completely depends on the previous one. The higher the engine power, the larger the diameter of the disk that can be installed on the unit. In this regard, there are only four standard sizes:

- No. 1 – household, equal to about 4-4.5 centimeters;

- No. 2 – semi-professional, from 5 to 5.5 centimeters;

- No. 3 – professional, in this case the depth ranges from 6-7 centimeters;

- No. 4 is the last one, at which this figure reaches 14 centimeters.

It is worth noting that units of the latest standard size are used in industrial production, while they are practically impossible to use in everyday life. How to choose the saw described in the article depending on the cutting depth? Compare your own needs with this characteristic. By the way, some models are equipped with a function for adjusting the cutting depth.

Criterion No. 3. Disk rotation speed

It should depend on the density of the wood to be cut. In addition, the higher the rotation speed, the cleaner the cut will be.

Note! There is a misconception that the speed will be higher if the power of the electric motor is greater. In reality, these parameters are not directly related to each other. Low-power units designed for working with chipboard have a high speed, thanks to which this fragile material is cut quite cleanly.

Criterion No. 4. Possibility of adjusting the cutting angle

Let us immediately note that almost all modern models have this function (with rare exceptions). It is usually used in professional construction, but is not required for cutting plywood/boards at home.

Read also: Horizontal milling machine NGF 110 sh4

Engine power

The efficiency of the circular saw depends on the engine power parameter.

The relationship here is direct - the greater the power, the larger the diameter of the disk the tool will “pull” during operation. Accordingly, the depth of cut and the force with which the disk rotates increases. Power is very important when working with dense materials. A saw equipped with a low-power motor may jam when sawing through a knot in thick wood. It is always worth purchasing a tool with a power reserve - this will extend the life of the engine. However, as power increases, the weight of the tool increases. For various country work, a middle-class circular saw is suitable, which makes a cut of about 65 mm. This is enough for repairs and construction operations around the house. If you have to cut thick boards or timber, then choose a professional model. Conventionally, units are divided into classes:

- household up to 800 W;

- average up to 1200 W;

- professional over 1200 watts.

A medium-power saw is suitable for home use.

Additional functions

As noted earlier, almost every modern electric hand-held circular saw is equipped with additional functions that allow you to make more accurate cuts, as well as a number of other things. Let's take a closer look at these useful options.

- Immersion in wood . An extremely useful function that allows you to start working from any place when cutting wood, not just from the edge.

- Start blocking . We are talking about a function in which you need to press two buttons at the same time to start the tool. Thanks to this, you will not be able to start the saw suddenly (and accidentally), which significantly increases the level of safety during use.

- Possibility of connecting a vacuum cleaner . An equally useful option, thanks to which you can remove sawdust that inevitably forms during work. This way you will not only clean the air (which is especially important if work is carried out indoors), but also significantly improve your visibility of the material being processed.

- Smooth start . After starting, the disk begins to rotate smoothly, and not immediately at maximum speed. Thanks to this, the service life of the saw is extended.

- Stationary device for removing chips/dust . This is also very convenient, especially if the volume of work is not very large. For example, the Makita 5017 RKB model is equipped with a special container that increases the convenience of cutting in a confined space.

- The laser pointer is the last feature we're looking at today . If available, a guide rail will not be required. But the work will require certain skills, since a person who picks up a saw for the first time will hardly be able to make an even and accurate cut.

In addition to the options listed above, it is important that the handsaw has a hinged guard that covers part of the cutting blade.

How to choose blades for a hand-held circular saw?

This disc is the main working element of any circular hand saw. He just cuts the wood. However, how to choose a model with suitable wheels? First of all, you need to find out what kind of material is to be sawed. Blades, for example, with trapezoidal teeth enable precise cutting of many materials, while variable teeth are ideal for cutting wood along the grain.

Note! It is recommended to cut harder wood with carbide-tipped discs or hardened teeth. Sharpening discs with such soldering is more expensive than conventional ones, but they last longer, and the operating efficiency in this case is an order of magnitude higher.

The main characteristics of the discs include the outer diameter, number of teeth and blade thickness. The 20-centimeter disk is universal, and therefore the most popular.

Important information! The inner diameter of the disc is more important than the outer diameter, as it is considered a fitting parameter. And if you select the blade incorrectly, you are unlikely to be able to attach it to the circular saw.

The speed and quality of work largely depend on the number of teeth. The more teeth there are, the more accurate the cut is, but the lower the speed of work will be when compared with a disk with fewer teeth. We also note that a home craftsman must have several different discs on hand to work with a particular material as efficiently as possible.

Do-it-yourself stationary circular saw from a manual circular saw

The operational capabilities of a hand-held circular saw are significantly increased if it is converted into a stationary tool. To understand how to turn a manual circular saw into a stationary one, you should first understand the methods of rigidly attaching a power tool.

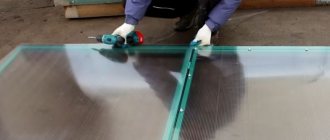

You can use metal or wood trestles as a stand. This can be either one or two products (if the sizes are small), connected to each other by boards with a thickness of at least 50 mm or bars with a similar cross-section. Next, you need to attach a tabletop to the top of the stand, which will serve as a bed.

For these purposes, it is convenient to use thick plywood (at least 10-12 mm) or two sheets of thinner material joined together, which together will give the same thickness. Panels made of particle boards or metal are also suitable. If the metal is thin, it is better to attach it to a wooden base.

The hand saw is installed from below. First, the necessary groove is made in the tabletop to extend the disk.

You need to attach a tabletop to the top of the stand, which will act as a bed

Important! It is necessary to fix the tool so that the saw blade is positioned strictly parallel to the cutting lines, that is, at the same distance from the sides. Otherwise, it will not be possible to correctly install additional devices and achieve high-quality cutting.

Using the above technical methods, you can make a circular saw from a grinder. But this hand-held power tool has certain differences, so a slightly different assembly scheme will be required.

Features of assembling a circular saw with your own hands from a grinder

Not every home workshop has a circular saw, but almost any owner who does certain household work with his own hands has a grinder. To create a stationary saw installation, you will also need a workbench or a special table; the tool will be attached from below, like a circular saw.

The connection to the grinder occurs using bolts

But then the assembly process is somewhat more complicated. To make a circular grinder with your own hands, as practice shows, you need to think carefully about the option of attaching a hand tool to the frame. This could be the following way:

- A metal band clamp is pulled on the grinder, the tie of which should be at the bottom.

- A strip of metal folded in half is attached to the holes for the sliding stop.

- Holes are made in the gearbox of the power tool. The body is first disassembled and drilling locations are marked.

- Using the holes made, an additionally manufactured axial handle is attached.

The handle can be made from a metal tube or rod. The workpiece needs to be shaped like a staple. In those places with which it will be attached to the gearbox, it is also necessary to make holes. Great and serious help for making a circular grinder with your own hands - drawings. They will allow you to correctly calculate the dimensions and number of elements, and prevent errors when calculating fastening locations. If it is difficult to complete the diagram of the future unit yourself, you can use ready-made drawings offered on the Internet.

To make a circular grinder from a grinder, you need to think carefully about the option of attaching the tool to the frame

Possible options for small, DIY circular saws

Any stationary circular machine, even a homemade one, requires a fairly spacious workshop. The space should allow not only to install the unit itself, but also to place the workpieces intended for cutting in the desired position. If the task is not to cut large-sized wood, but simply, if necessary, you need to make your own slats or bars for repairing furniture, etc., it would be more rational to acquire a mini table saw.

You can make such a device yourself, using the same principles as when creating stationary machines from an angle grinder or a circular saw. Only the stand will not be a trestle, the support of which is the floor, but a frame on which a small table with a fixed hand tool is installed.

Helpful advice! When making a circular saw of this type, it is important to take into account the overall height of the structure, that is, the plane on which the material intended for sawing will be located. Overestimating or underestimating the level will cause significant inconvenience.

The miniature machine is more functional and safer to use

If you need to create a mini circular saw with your own hands to make very small workpieces (aircraft, ship modeling), you can assemble the tool using a PVC pipe as a body and borrowing an engine from children's toys. It is easy to make a hole for the shaft in such a pipe. You can use a glue gun as a connecting material. Such a circular machine can be powered either from the mains or from a battery. To ensure autonomous operation, it is necessary to provide a special compartment for batteries in the housing.

Making a carriage for a circular saw with your own hands

The functionality and quality performance of a stationary circular saw is greatly influenced by the availability of accessories. One of these is the carriage. It’s not difficult to do it at home, but trimming and sawing the material at an angle of 45° will be much easier.

You can make this device for a circular saw from a sheet of plywood as follows:

- plywood is cut out to a size slightly wider than the circular table;

DIY table saw table can be used as a cutting machine

- in the lower part, guide bars are attached to it using glue or screws, the distance between which should be equal to the width of the table;

- In a similar way, using screws or glue, thrust bars are fixed on top.

Using guides, the carriage is fed along the table onto a saw blade, which makes a through cut on the device. The height of the sides, which should be greater than the protruding saw blade, allows you to maintain the integrity and rigidity of the carriage. If the task is to make a cut at an angle of 45°, it is necessary to use an additional bar, which in this device is a removable element. The cut is made by pressing the workpiece against an angled plank.

In order for the plywood surface of the carriage to be easily cleaned of sawing waste, it must be coated with several layers of varnish.

The plywood should be slightly wider than the circular table

How to make a shaft for a circular saw with your own hands

In the general design of a circular saw, the shaft is the main element that forms the entire machine. To make it, you will need round steel grade 45. But you can only make this important part yourself if you have your own lathe or have access to it. The diameter of the workpiece must correspond to the size of the saw blades that are intended to be used.

Main standard sizes of disk mounting holes:

- 16 mm;

- 20 mm;

- 22 mm;

- 30 m;

- 32 mm;

- 50 mm.

From the indicators listed above, the size of the shaft for the circular is selected.

∠

The most common hole diameter is 32 mm. This is the mounting socket that discs with different outer diameter sizes have. Alternatively, you can make a thinner shaft so that you can do “jewelry” work. Then an adapter will be used to use large disks. It is worth complicating the design of a home circular in this way only in cases where it will be used by a professional.

The saw blades are installed between two flanges and pressed using a nut, which is screwed onto a thread made on the edge of the working surface of the shaft.

Important! The thread must be left-handed. During the inevitable jerk when starting the circular, the nut in this position will tighten, and not vice versa.

Seats for bearings are determined taking into account the dimensions of the latter. The middle part of the shaft has the largest diameter. If the indicator is significant, additional load on the belt will be created during rotation. Drilling will help get rid of the problem, which will lighten the heavy part of the shaft.

What discs should you use for circular saws?

The productivity and quality of work largely depends on the correctly selected disk for a hand-made circular saw made from an angle grinder, a hand saw, or one assembled from separate mechanisms. It should be remembered that there are differences between discs for wood and metal. Even if thin, soft aluminum will be sawed, the appropriate blade must be installed. Metal cutting wheels have finer teeth. There are universal disc options that are suitable for working with both wood and metal.

There are also differences between the discs intended for longitudinal and transverse sawing of wood. Longitudinal sawing is carried out with a cutting attachment with sparse large teeth. But cross-cutting will be of better quality if discs with fine, frequent teeth are used.

As for the material and method of manufacturing disks, they can be monolithic or carbide. Monolithic ones are made from a single piece of high-carbon steel. Such bits are inexpensive, but have a significant drawback: they quickly become dull and require sharpening and re-wiring.

Discs for wood and metal differ

Carbide discs are made of tool steel with cobalt and tungsten brazing. They are more wear-resistant, but the price of such products is much higher.

The outer diameter of the disks for a homemade circular saw is limited by the dimensions of the protective casing. The standard disc thickness is 3.2 mm. There are thinner and thicker saw wheels. Thin ones are used when working with wood of valuable tree species to make a clean cut. For rougher work, thick discs are recommended.

Features of working with circular hand saws - a brief excursion

Despite a number of auxiliary accessories and protective measures, the hand-held electric circular saw described in the article is still a rather dangerous unit. And to minimize the risk of injury during work, you need to follow some simple rules. First of all, it is advisable that the saw has a circular guide, otherwise the blade may accidentally move to the side. The fastening of the element should be as reliable as possible, and the pressure of the saw against it should be as strong as possible. If a model has additional functions, it is recommended that you familiarize yourself with them in advance.

So, what should you pay attention to in order to choose the model that best suits all your requirements? In the absence of experience working with such equipment, it is advisable to consult with professionals. It is also worth remembering that the most advertised units (for example, Bosch - we will talk in more detail about the models a little later) are by no means universal, and therefore a set of different disks or even saws should still be on hand.

Video - Demonstration of working with a hand-held circular saw

Video – Review of the SPARKY TK 65 model

How to make a homemade circular saw

For a homemade machine, a hand-held circular saw with the possibility of stationary installation and a frame with a mount for its installation are used.

Before carrying out work, you should create a drawing of the future installation, taking into account the characteristics necessary for convenient and safe operation of the device. To make a table for a circular saw with your own hands, you can use boards, metal sheets or plywood. It can also be made from angle steel or wooden blocks. The choice of material is determined by the needs and capabilities of the master.

To make a circular table with your own hands, you can use boards, metal sheets or plywood.

To ensure the safety of the device during its operation and to prevent possible contact of a worker with rotating components, it is necessary to make a protective casing. To do this, you can use plywood with holes for air circulation, which helps cool the electric motor.

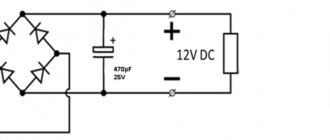

A hole is made on the working surface of the table for the saw blade. The manual circular is attached using screws. At the bottom of the table there should be a socket with a wire that is connected to a stationary switch. The cord of a hand tool is inserted into the outlet. Such a homemade circular can be installed anywhere.

Review of models and manufacturers

It is perhaps difficult to make a specific rating of models, since it is constantly changing, and the leading positions are occupied by one or another brand. However, the main manufacturers are always in the TOP 10. The products of some of them are presented in the table below.

Table. Characteristics and prices of some models of hand-held electric circular saws.

| Name, photo | Short description | Average market value, in rubles |

| 1. Makita SP6000 Set | A high-quality unit with a power of 1.3 kilowatts, a disc diameter of 16.5 centimeters and a maximum cutting depth of 5.6 centimeters. As for the rotation speed, it is 5,200 rpm. Finally, such a saw weighs 4.1 kilograms. | From 6 840 |

| 2. Makita HS7601 | The unit is from the same manufacturer, but the power in this case is already 1.2 kilowatts. The cutting depth is 6.6 centimeters, the rotation speed is the same, and the disc diameter is 19 centimeters. The saw weighs 4 kilograms. | From 3 230 |

| 3. Bosch GKS 190 | A high-quality device with a power of 1.4 kilowatts and a cutting depth of 7 centimeters. The rotation speed reaches 5.5 thousand revolutions per minute, while the diameter of the disk is 19 centimeters. The unit weighs 4.2 kilograms. | From 3 180 |

| 4. Bosch PKS 55 | Another model from the same manufacturer. The power indicator reaches 1.2 kilowatts, the diameter of the disk is 16 centimeters. The cut reaches a depth of 5.5 centimeters. The disk rotates at a speed of 5.6 thousand revolutions per minute. Weight – 3.9 kilograms. | From 2 390 |

| 5. DeWALT DWE560 | Another good circular saw powered by electricity with a power of 1.35 kilowatts and a blade diameter of 18.4 centimeters. The depth of the cut in this case reaches 6.5 centimeters, and the rotation speed is 5.5 thousand revolutions. The model weighs only 3.7 kilograms. | From 3 100 |

| 6. Interskol DP-165/1200 | A cheaper hand saw, the power of which reaches 1.2 kilowatts. The disc has a diameter of 16.5 centimeters, while the cutting depth is 5.5 centimeters. The disk rotates at a speed of 4.7 thousand revolutions per minute. The unit itself weighs 4.5 kilograms. | From 1 760 |

Read also: Laying heating cable under tiles

These are not all popular models. You can find the characteristics of some more of them in the table below.

Table. Characteristics of some more popular circular saws.

We sincerely hope that our practical advice will help you choose the appropriate saw model. But to make all this more useful, we advise you to familiarize yourself with the technical characteristics of the models you like in advance, and only then go for the purchase itself. And in conclusion, some rules for operating the equipment described above.

Rules for working with a hand-held power saw - some important tips

So, you already have a hand-held circular saw and are ready to get to work. How to do it? Now we will find out.

- It is important that the workpiece that needs to be sawed is fixed as securely as possible.

- In addition, there should be no obstacles or obstructions in the path of the tool.

- The unit must be driven as smoothly and gently as possible. If possible, give the saw some time to “rest.” Otherwise, if the equipment operates continuously for more than 2 or 3 hours, there will be a risk that the electric motor will burn out (this applies to even the highest quality and most expensive professional models).

- If maximum precision is required for cutting wood, give preference to blades with a large number of teeth.

- And if you need to cut aluminum or plastic, we recommend using special discs for this. It is also important that the disk rotates at a speed of no more than 4 thousand revolutions per minute during operation.

So, we got the job done. What about safety?

Basic safety rules

So, in order for the work to be as safe as possible, we recommend that you strictly adhere to the following requirements.

- First of all, it is necessary to understand that a circular saw is considered one of the most dangerous tools, as mentioned earlier.

- Using this equipment, you cannot cut wood that contains metal inclusions (these can be screws, nails, etc.).

- We also recommend wearing headphones while working, as the saw will produce a very loud and unpleasant sound.

- To clean the instrument, use a special brush. Under no circumstances do this with your hands!

- Try to use only serviceable and high-quality equipment in your work. To ensure that your saw meets these requirements, you should regularly check how well all the nuts are tightened, whether the blade is damaged, and so on.

- In addition, wear safety glasses when working to prevent sawdust from getting into your eyes.

- Before cutting, check the workpiece for any defects.

- Finally, be vigilant. If, for example, you feel very tired, then it is better to stop working with the tool for a while.

Video - Understanding the design of circular saws

We also note that it is strictly forbidden to work with a faulty unit, which may manifest itself in:

- absence of a protective casing on the disk;

- the absence of a device to prevent the workpiece being cut from being thrown out;

- lack of a guide ruler;

- The width of the slots of the table intended for the saw blade is more than 15 centimeters.

As a result, we note that a hand-held circular saw, be that as it may, is a rather complex tool. It requires a responsible approach, and you need to work with equipment carefully and carefully. Before purchasing a circular saw, we recommend that you first think carefully about what specific purposes you need it for and what the load it will face. Taking into account all these important points, choose a model that meets all your requirements and wishes.

That's all, good luck with your work! Choose only the best! And don't forget to watch another themed video below.

Video - All about circular saws

A hand-held circular saw is an excellent alternative to the familiar hacksaw, which is very convenient for sawing boards crosswise, but lengthwise is a real pain. But a circular saw will make this task very quick, and the result will be much better.

This device appeared thanks to Tabitha Babbitt, who realized that sawing with a regular saw is only effective in one direction, so she created the idea of a round disk that rotates in one direction. And such thoughts crept into her mind while watching men, how they, strong and healthy, waste 50% of their energy in vain, moving the saw blade back and forth, while the work stands still and waits. All this happened as much as 200 years ago, but today the hand-held circular saw for wood has undergone many modifications and has been “overgrown” with various devices for ease of work.

This tool looks like a sharp-toothed disk that can be installed on any more or less powerful unit that has torque. But due to the popularity of using this idea in repair and construction, an autonomous machine is now being produced, which serves only for cutting, and in addition to the disk, it has all sorts of conveniences for work, for example, clamps and stops. Such a circular saw with a guide maintains the correct trajectory; you can even make cuts at an angle. There is also a device for collecting and ejecting sawdust, which certainly forms under the disk, but does not always fall down, but flies upward, clogging important “organs” of the instrument.

The modern market is overflowing with models of this household device. A stationary circular saw would look good in your workshop if you frequently cut lumber. And if you work all the time at different points on your site, or even travel around objects, then a mobile copy, which is small in size, will completely satisfy your needs. A small circular saw can even be the result of your skillful hands; there are many instructions on how to make one yourself.

Read also: Slingshot antenna for TV

Photo of a Hitachi circular saw, dismarket.ru In the photo - how to cut with a circular saw, remstd.ru Photo of a circular saw for metal, alfra.ru In the photo - a plunge-cut circular saw with a guide, toolnews.ru Photo of a circular saw, illeon.ru

Characteristics of the circular saw guide

To perform correct and precise processing of the workpiece, an additional device for a circular saw in the form of a tire is used. This guide ensures efficient, easy and safe operation of the device. Using a tire, you can make longitudinal and cross cuts, adjust the parameters of the workpiece being processed, and trim several elements.

The guide is fastened to the base of the installation using bolts and nuts.

Tires for circular saws are single- and double-sided, symmetrical and asymmetrical. There are also non-standard models with which you can process workpieces of complex non-standard configurations. Based on the method of use, guides can be divided into two types: universal and specialized. The first option is suitable for any type of saw, and the second solves a number of problems on specific professional equipment. Such guides can only work with circular saws.

The tire is made of wood or metal. It can be made in the form of a corner, rails, straight beam or have a U-shaped configuration. The guide is fastened to the base of the installation using bolts and nuts, screws or self-tapping screws.

Note! Before using the guide, you need to check its surface for deformation and test the clamps.

The guide ensures easy and safe operation of the circular saw.

When choosing a guide for a stationary circular saw for wood, it is necessary to take into account the features of the working equipment, as well as the material that needs to be processed. The most popular tires are produced by German and Japanese. The domestic one has also proven itself well. The guides of these companies are able to ensure absolute accuracy of the cutting line.

Electric circular saw - selecting discs for the tool

But it’s quite difficult to make an effective tool yourself, so let’s determine the characteristics and find out which circular saw is better. From a geometric point of view, these devices can differ in shape and method of sharpening the teeth, this affects the smoothness of the cut and the accuracy of the edge. There are flat teeth (the result is very rough work), trapezoidal (can cut finely and accurately), variable teeth (they take wood along the grain well) and others. This parameter can also affect the ability to cut certain materials, for example, a circular saw for metal often has trapezoid-shaped teeth.

Among the characteristics of the disc itself, the outer diameter, number of teeth, and blade thickness are important. For miniature models, a very small disc diameter is used - 15 cm; the cutting depth, of course, will be small, which means that only simple work can be performed. The most popular large disks are considered to be those with a diameter of up to 20 cm. In general, when buying a tool, you need to choose this larger parameter so that other sizes of disks that are slightly smaller can be placed in the socket. You can't put a large disk in a small slot; it will cut the protective covers.

But it is important to know for sure the internal diameter of the disk; this is the seating size. If you choose it incorrectly, you will not be able to secure the disk in the tool, although now there are adapter rings, but this is not a very convenient option. The number of teeth affects the pace and quality of work. If we take a disk with a low concentration of teeth (for example, 24 teeth for a diameter of 20 cm), then the cut will be rough, but the work will be fast. If you are willing to spend a little more time on work and would like to see a neat cut, then the number of teeth should be larger. It’s good to have a set of disks so that you can choose the most convenient one for each case.

The parameters described above can be seen on the disc marking; it usually looks like this: 200*24*30, which means that the outer diameter is 200 mm, the landing diameter is 24 mm, and the number of teeth is 30.

Get acquainted with the electronics; it will be useful if there are speed control functions, a braking module for the saw blade in the event of a kickback, a system for maintaining constant speed when a load occurs, and protection of the motor from overheating. And, of course, when purchasing, choose several discs for different purposes, a stronger alloy and sharper teeth. We can talk about the features of the discs for a long time; it is better to navigate on the spot, based on what the seller has in stock. Good luck with your choice and enjoy working with your new “toothy” assistant!

This type of manual automatic saw is the main one in the tool kit of a carpenter, builder, or building restorer. The photo shows a 160mm blade. The larger blades are 235mm in size. Here are some basic tips and instructions for using circular saws correctly.

>

Stationary circular saw: tool design

The stationary circular plate belongs to the class of joinery equipment. It consists of a body equipped with one or two handles. It is located on a base in the form of a frame, which has a rigid structure. The working surface is made of cast iron or steel. In some models it is aluminum.

The presence of a cast iron frame and tabletop in the circular saw can significantly reduce the level of vibration.

The working surface can be cast or prefabricated. The first option is typical for a powerful circular saw. Such a tool is more stable and has a lot of weight, as a result of which a reliable concrete base will be required to place it. In small machines, the table for a circular saw can be prefabricated, which ensures mobility of the installation.

Note! For ease of cutting the material, guide rulers are applied on the working surface.

There is a groove on the surface that serves for free rotation of the saw blade. In some models it can be tilted, which is possible due to the presence of graduations on the leading sole. This allows you to make cuts at different (fixed) angles. In the non-working position, the disk is covered with a special casing.

Behind the saw blade there is a riving knife, thanks to which the sawn wooden workpiece will not rejoin again, which can happen under the influence of the elasticity of wood fibers.

The stationary circular saw has the ability to perform operations with large-sized workpieces.

Under the tabletop there is an electric motor, from the shaft of which, through a pulley, the torque is transmitted to the saw blade of the saw. A belt drive is also used here. However, there are models in which torque is transmitted using a cardan method. The pulley serves as a support for the saw blade, which begins to quickly rotate around its axis, cutting the material.

Note! A stationary saw cuts material exclusively in a straight line, without the possibility of shaped cutting.

The working surface can be equipped with expanding elements, thanks to which you can increase the area of the machine. The stationary saw is controlled using buttons that are recessed into the control panel. This prevents the unit from being turned on accidentally. Some models are equipped with an emergency switch.