Dear customers, you can leave feedback about good work using the following links Flamp, Yandex

Parcels are stored for no more than 7 days, please be careful. We thank you in advance for the parcels being picked up on time

Original and analog spare parts for the following brands

MAKITA SPARE PARTS | BOSCH SPARE PARTS | MTD SPARE PARTS |

| HITACHI SPARE PARTS | SPARE PARTS INTERSKOL | FUBAG SPARE PARTS |

| HUSQVARNA SPARE PARTS | STIHL PARTS | PARTNER SPARE PARTS |

| SUNGARDEN SPARE PARTS | HUTER SPARE PARTS | TEXAS PARTS |

| CHAMPION SPARE PARTS | ECHO SPARE PARTS | OLEO-MAC SPARE PARTS |

CARVER TOOLS AND SPARE PARTS | TOOLS AND SPARE PARTS PARMA | SPARE PARTS CALIBER |

| HONDA PARTS | BRIGGS & STRATTON STOCK | ROBIN SUBARU PARTS |

| STURM SPARE PARTS | HAMMER PARTS | STERN SPARE PARTS |

| ABAC SPARE PARTS | LIFAN SPARE PARTS | EFCO SPARE PARTS |

| REBIR SPARE PARTS | METABO SPARE PARTS | DEWALT PARTS |

| SPARE PARTS FOR PETROL SCROWERS, TRIMERS, MOTOR DRILLS | SPARE PARTS FOR CHAINSAWS, ELECTRIC SAWS | SPARE PARTS FOR CULTIVATORS, MOTOR-BLOCKS |

| SPARE PARTS FOR DIESEL HEAT GUNS | SPARE PARTS FOR SNOW BLOWERS | SPARE PARTS FOR ELECTRIC AND GAS GUNS |

| SPARE PARTS FOR PETROL GENERATORS, POWER PLANTS | SPARE PARTS FOR DIESEL GENERATORS, DIESEL ENGINES | SPARE FOR VIBRATING PLATES, VIBRATING FOOT, VIBRATING RAMMERS |

| COMPRESSOR SPARE PARTS | SPARE PARTS FOR CONCRETE MIXERS | SPARE PARTS FOR MOTOR PUMPS, PUMPS |

| SPARE PARTS FOR BATTERY SCREWDRIVERS | SPARE PARTS FOR WELDING MACHINES, WELDING | CONSUMABLES |

Spare parts for tools and household appliances

is one of the largest suppliers of spare parts and consumables for electric and gas-powered tools in Russia. Having a huge network of dealers throughout the country, it has established itself as a reliable and competent company. Today it is the official supplier of original and analog parts of such brands as: Hammer, Sial, Fubag, Abac, Interskol, Echo, Partner, Rebir, Sturm, Fiolent, Lepse, Kipor, Lifan, Loncin, Grost, Forza, Stiga, Profi, Piran , spare parts Caliber and others. A staff of qualified specialists will be happy to help you with your choice and answer all your questions. Our store also sells spare parts for household and garden equipment.

Do-it-yourself Husqvarna 236 carburetor adjustment

The question of how to adjust the carburetor of a 236th model chainsaw is quite relevant. The modification of the chainsaw in question has a carburetor from the Zama brand, the design of which contains an accelerator pump. Any situation that is accompanied by unstable operation of the device’s engine, the formation of copious amounts of exhaust and a sharp increase in the consumption of the fuel mixture indicates the need to reconfigure it.

It is produced in several stages:

- tighten screws H and L clockwise;

- setting idle and maximum speeds - turning the jets clockwise will increase them. To do this, you will need a tachometer and operating instructions with nominal engine parameters.

If the engine runs smoothly under load and at idle, the chain is motionless at idle - the carburetor reconfiguration was successful.

Unpretentiousness is the advantage of the original Husqvarna chainsaws, the country of origin of which is Sweden. Unfortunately, this cannot be said about Chinese fakes, which are unpredictable in operation and repair.

Reasons for low trimmer speed

If users complain about a trimmer that does not gain speed, this means that at idle it works fine, but when you press the gas it does not develop the necessary power. This can happen as a result of the device being idle for a long time without activity. These problems are typical for gasoline devices, including Husqvarna 128r, STIHL FS 38 and Hitachi of various modifications.

Husqvarna 128r no power, no revs, stifling

When working with a trimmer, you need to constantly monitor its behavior - a drop in speed and unusual noises indicate problems with the unit. Sometimes you give it gas, but the trimmer floats. In such cases, work should immediately be suspended, the mechanism should be allowed to cool, and the search for possible problems should begin. They can be of a different nature, both technologically and external factors associated with the conditions and characteristics of the operation of the device.

The engine stalls when you press the gas: causes and solutions

- fuel filter clogged;

- depressurization of fuel hoses;

- muffler malfunction;

- jamming of the valve in the float chamber due to which the mixture does not flow in full;

- Air filter contamination;

- failure of the crankshaft seals.

Eliminating all the identified causes comes down to:

- cleaning working bodies associated with liquids or air working environment;

- external inspection of the listed parts for problems;

- replaced old parts with new ones.

Correct adjustment of the carburetor, which is quite feasible at home, plays an important role in stabilizing the working stroke of the Husqvarna chainsaw.

Starter for a chainsaw: device, breakdowns and do-it-yourself repairs

In the design of a chainsaw, the starter is responsible for properly starting the tool’s engine. Over time, chainsaw owners are faced with the need to repair this important unit. And, the sooner the malfunction can be eliminated, the less other important parts and mechanisms of the tool will be subject to wear.

READ Husqvarna Chainsaw Carburetor Adjustment

Replacing the cord

When it is pulled out, there is constant friction of the cable against the starter housing. To replace, disassemble the unit body and carefully lift the ratchet drum so as to prevent the return spring from jumping off its sockets. It is better to do this work together: an assistant fixes the spring while the cable is being replaced. After securing the cable in the handle and in the grooves of the drum, the cable is wound onto the roller, and the body is assembled.

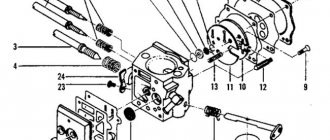

Main problems and malfunctions of the carburetor.

Mesh filter. There are most often only two tasks with this element:

In order to find out the cause of the breakdown, unscrew the fuel filter cap to remove the strainer. If dirt has simply accumulated on it, then washing it in gasoline or blowing it out will help.

If there is visible damage to the mesh filter, it is imperative to install a new one. There may also be damage to the fuel supply pipe (during repairs, it is practiced to check this element).

The carburetor starter almost always does not work due to blockages. You should use acetone or the same gasoline for washing.

Blowing clogged carburetor parts with compressed air is an acceptable and comfortable repair practice.

The throttle body, joints of carburetor parts, intake or exhaust pipes - all of these parts are subject to depressurization. You can probably check it using a simple method - smear the problem area with soap foam.

Signs of imbalance

The carburetor must be debugged during the manufacture of the device. As a rule, owners learn about the need to adjust the fuel supply with their own hands only after quite serious breakdowns, during the process of correcting which the module was removed and, for example, cleaned.

Signs of a settings failure include the following:

- starts, but the engine immediately stalls - since the engine can only work when a certain amount of gasoline is supplied, if the fuel is too “lean”, that is, the supply channel is blocked, the engine will stop;

- too much fuel consumption, a lot of exhaust gases - the result of incomplete combustion of the mixture. In this case, on the contrary, there is too much fuel and the mixture turns out to be excessively dense.

Husqvarna 125R carburetor adjustment without tachometer (temporary solution)

How to adjust the carburetor

, if you need to work, but the service with a tachometer is far away.

Carburetor

Stihl, Makita, Husqvarna and other lawnmowers are adjusted using adjusting screws. Sometimes the cause of malfunction is a violation of fixation - due to vibration or damage to the protective cap. Such a breakdown can be detected by simply trying to slightly turn the screw: if the fixation is not tight, it is worth checking the setting.

Do-it-yourself trimmer carburetor adjustment

Setting up the module is not a repair and replacement of spare parts is not required. Cleaning the carburetor of a Honda lawn mower. In this case, the lawnmower carburetor repair kit will not be needed.

There are three screws for debugging:

- L – is regulated first, since it is responsible for fuel supply at low speeds;

- H – it is responsible for the supply of gasoline at high speeds, as well as fuel consumption and temperature;

- T – it is used to debug the idle speed.

There are options, as a rule, this is the carburetor of a Chinese lawn mower, when for debugging there is only one screw left on the body - for adjusting the idle speed. This does not mean that the module is configured automatically - it means that even such a type of repair as debugging will be difficult. The photo shows the adjustment of the carburetor of a Chinese lawn mower.

- The module is configured only when the engine is warm: to do this, the device is first turned on for 10 minutes. Adjusting the carburetor of cedar lawn mowers. If the mowing head rotates at idle, then begin debugging immediately: turn screw T counterclockwise until rotation stops.

- The adjustment begins with screw L. The screw is turned to the right and left until a position is found at which the idle speed does not become maximum.

- Then the screw is turned ¼ turn counterclockwise

. This will be his working position. - The idle speed must be adjusted by turning counterclockwise to increase the speed and clockwise to decrease it. Its debugging consists in achieving a mode in which a sufficient number of revolutions are made before the mowing head begins to rotate. In this case, the engine must operate stably in different positions.

- The position of screw L is determined last - at maximum speed the trimmer should not operate for more than 10 seconds. The throttle opens, the screw is turned clockwise, very slowly, until a decrease in the number of revolutions is heard by ear.

- Then the screw rotates slowly counterclockwise until the motor begins to malfunction. After which the screw is turned back clockwise until the engine starts working normally again.

If there is a tanometer, and if the recommended speed values are indicated in the product data sheet, the correction can be carried out more accurately, focusing not on hearing, but on the readings of the device.

on recording & adjustment

and repair of lawn mower carburetor

Please clarify. Is there an error in the adjustment section, step 5, screw L? Should you read screw A? Thank you.

tell me the initial position of the HL LA screws

PROMPT THE STARTING POSITION

tell me the initial position of the HL LA screws

Husqvarna 128r trimmer starts and stalls EVDIRAL.RU

A gas-powered scythe is a necessary thing for owners of personal plots and lawns, and when the trimmer suddenly stalls, the work of clearing the area of grass stops. The device itself is a rather complex mechanism, therefore there are many different events of its breakdown. For the most part, problems that arise are contained in the instruction manual. You should know the reasons why the trimmer stalls so that you can repair the device without the help of others.

READ How to Wind the Line Correctly on a Trimmer

Problems with a lawn mower, related to the fact that this device does not start, are classified in a specific way by service specialists. They highlight malfunctions with the following mechanism components:

- an engine in which the piston and bearings may wear out or fail, or the crankcase may crack;

- fuel supply system, while at the same time you are clogging the filter or problems with the carburetor;

- mechanical damage to wires, tubes, hoses;

- ignition circuit.

In order to correctly find the unit where the breakdown occurred, you need to study the circumstances under which the trimmer stalls.

If the lawn mower stops when you press the gas, then the following conditions occur.

- A more common option is a carburetor adjustment failure, which appears under significant loads on the drive, after a long period of inactivity of the mechanism, or when it is used in heavy conditions.

- Clogging of the fuel valve, which is relieved by loosening it, under the influence of which gasoline begins to flow normally through the system.

- Loosening and hanging of the cable located in the carburetor. There is also a stretching of the fuel hose right up to its rupture, caused by the action of a significant load.

- The breather (return valve) is clogged; for this reason, fuel does not flow into the tank.

The agricultural branch evenly includes means of small-scale mechanization, which makes it possible to significantly simplify the process of carrying out excavation work. Walk-behind tractors from different manufacturers, distinguished by their compactness and relative size, play an important role here.

How to tighten a chain with a chainsaw? We are responsible! Dear visitors, check out the prices of managers at an inconsistent rate. Thanks for understanding! If you look closely at the work of a professional woodcutter, he conducts mail.

Comparative review of lawn mowers AL-KO Classic 3.82 SE (112856) and AL-KO Classic 3.22 SE (112805) comparative review of lawn mowers AL-KO Classic 3.82 SE (112856) and AL-KO Classic 3.22 SE (112805). from the Internet.Lawn mower AL-KO Classic 3.22 SELawn.

We know that resonance phenomena. increasing the amplitude of forced oscillations of the system. occur when the frequency of the Motive Force matches the natural frequency of the system. Anyone who has ever tuned a guitar knows that if two strings are tuned in.

Chainsaw starter: device, operating principle and self-repair A quick start of any chainsaw will NOT complete without a starter. During operation of the tool, due to the accelerated rotation of the crankshaft, the air-fuel mixture is supplied to the engine, compressed.

Chainsaws are a working tool not only for professional lumberjacks or builders, but also for private land owners. Using low-power household appliances, you can quickly cut down trees and bushes and make minor repairs. for solve

Almost every country homeowner has a chainsaw. And we can’t even talk about rural people: such a tool is vital for them. And it requires a chainsaw to be respected and serviced promptly. All service rules are clear.

How to remove a bearing from a crankshaft - practical advice The question of how to remove a bearing from a crankshaft may NOT appear to car enthusiasts over many years of operation of cars from the VAZ traditional series. Support or axial.

The brush cutter often stops when it gets hot. With all this, it starts, works “with a jerk” and stops evenly. This process occurs when gasoline boils in the carburetor or the damper is installed here as a rotary rather than a disk type. In the latter case, the part is changed.

It is common for the trimmer to become hot if the ignition wire or coil is damaged. In order for the device to start working normally, parts are replaced.

It happens that the unit stalls when the air damper is opened, idling normally. This is due to air leaks in the system, caused by the presence of cracks in the fuel hose, also called problems with the seals. The carburetor metering system may also malfunction; at the same time, the lawn mower will stop after opening the damper.

What remains for our client to do are the probable reasons that the lawn mower is stalling, and methods for eliminating them are contained in the following video

READ STIHL petrol trimmer does not develop speed

There are many reasons for a lawn mower to stop, but for the most part there are operational problems associated with its carburetor. They arise in any variant. The most problematic option is when a serious breakdown occurs, and it will be necessary to get new parts or change the lawn mower.

Will not start when trimmer is cool. Eliminating the cause

If the problem is related to the carburetor unit, then it can be recognized when the lawn mower vibrates. When a hose bursts or a cable stretches, these devices are replaced.

When the scythe stalls at high speeds, this is due to the following problems:

- clogging, in other words sticking of the valve located on the gas tank cap;

- the carburetor has become misregulated due to vibrations that occur during operation of the mechanism;

- problems with the circulation of fuel mixture;

- atmospheric air suction;

- the hose designed to collect fuel is cracked or loosely connected.

Description and characteristics of gas station 128R

To quickly turn on the device even after a long period of inactivity, it has a built-in primer for pumping fuel and a Smart Start system. The maximum possible working width is 45 cm. Husqvarna 128R. gasoline trimmer with a straight bar and professional handles made in the shape of bicycles.

The weight of the device without fuel, installed cutting parts and protective casing is 4.8 kg. Thanks to this, the Husqvarna petrol pump version 128R can be used for a long time without interruption. The gas trimmer's fuel tank is made of white plastic to make it easier to control the amount of fuel remaining in it.

The tool kit includes:

- knife with 4 blades for tough and tall grass or bushes;

- trimmer head (semi-automatic);

- fastening straps for 2 hands;

- a set of keys;

- bicycle handle;

- operation and maintenance manual;

- protective covering;

- unassembled rod.

The line is used to remove only small grass.

Algorithm and description of Husqvarna carburetor settings

The Husqvarna carburetor is adjusted in the same way as carburetors on chainsaws from other manufacturers are adjusted.

Immediately before adjustment, it is necessary to conduct a complete diagnosis of the saw and make sure that there is no difficulty in supplying fuel or air leaks into the crankcase of the chainsaw. You also need to make sure that the air filter is clean and, if necessary, replace it with a new one.

The work order is as follows:

- On the muffled saw, the factory settings of the Husqvarna carburetor are installed.

- The engine starts and the saw warms up for several minutes.

- By turning the screw (L) clockwise, the position at which the engine develops maximum speed is found, after which the screw must be turned back 1⁄4. If the chainsaw chain rotates, then it is necessary to reduce the idle speed by adjusting the position of the screw (T).

- The next stage is adjusting Husqvarna's power at maximum speed and adjusting its quantity. To do this, the tachometer is connected to a running chainsaw, the throttle is squeezed to full, after which the tachometer readings are checked. If the maximum speed value differs from the maximum number recommended by the manufacturer, then by changing the position of the screw (H), the tachometer readings are returned to normal.

How to replace a chainsaw starter spring?

In order to replace the old spring in a disassembled starter, you must proceed in the following order:

Before installing the chainsaw starter spring, you will need to remove the mechanism cage - this should be done extremely carefully so as not to break the part; Then you need to look inside the cage - in it you will see a spring wrapped around a C-shaped element. To remove the spring, fix its upper part with your finger and slightly pull the starter handle to the side; After removing the old spring, you need to wind a new part

At the same time, try to avoid kinks and twisting of the new spring element; To assemble the chainsaw starter spring, you will need to act as carefully as possible, otherwise one wrong movement can lead to the spare part unwinding; After you have managed to completely insert the spring into the starter, you need to carefully fix the cage.

At the last stage, all that remains is to assemble the chainsaw starter and try to start the tool. It is quite possible that you will have to make from 10 to 20 jerks - this is necessary for the spring to finally fall into place.

Basic malfunctions of gasoline trimmers

The most common breakdowns of brush cutters are associated with the following structural elements:

- engine (in particular with a piston system);

- carburetor;

- barbell;

- starter (rope break, spring breakage or disengagement);

- with an ignition or fuel supply system;

- transmission mechanism (gearbox);

- filters and muffler.

- the appearance of uncharacteristic sounds when operating the lawn mower;

- the lawn mower does not turn on, does not reach the required speed, or stalls;

- when the engine is running, the working part does not rotate or skips;

- gasoline leak;

- excessive heating of individual components.

Smaller breakdowns can also occur, which are detected without any special diagnostics:

- start button sticking;

- limiter drop;

- line break or breakage (loss of sharpness) of the knife.

Minor problems are easy to fix. Repairing a gasoline trimmer in more complex cases will require preliminary diagnostics to determine the exact causes. If you have the appropriate knowledge and skills in plumbing, you can fix problems yourself by replacing failed parts.

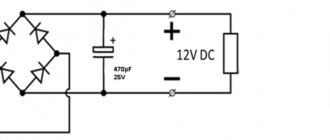

Disassembly and repair of electrical parts

Disassembling the electric scythe in order to repair its electrical part is carried out in the following sequence.

- Place the trimmer on a flat surface (for example, a table) that does not contain unnecessary objects.

- Unscrew the cover screws located on one side.

- Remove the unscrewed half of the housing, gaining access to the start button, electric motor, brush assembly, bearings, electrical connections (these elements are shown in the photo below).

The brush and bearing units are shown in the photo below.

The scythe will work without a thermal relay, you just need to constantly check the temperature of the electric motor yourself, periodically letting it cool down. You can also install a new similar sensor.

The electric motor start button can be checked by closing its contacts with a jumper. If the trimmer works, then the problem is clear. But this option is unsafe. Everything should be done carefully so as not to receive an electric shock. To change the button, you should use a screwdriver to remove it from its seat and connect the wiring from the old to the new. After replacement, you need to assemble the electric scythe and then check its functionality.

Replacement of brushes is required if they are damaged. In this case, it is enough to pull out the old ones from the grooves and install new ones in their place.

The connecting terminals on different models of trimmers are almost identical, so connecting and disconnecting wires is done in the same way.

Replacing a bearing is a rather difficult operation because it can become stuck and cannot be removed from the motor shaft. It should be pulled or knocked down carefully so as not to damage the rotor or seat.

When the trimmer motor fails and needs to be replaced with a new one, you should carefully remove the fan and bearings, and then install them in their original place. In terms of costs, replacement is almost comparable to purchasing a new mechanism. If you have no experience working with electric motors, it is better to entrust it to specialists.

Technical characteristics of Husqvarna 236

The main characteristic of the Husqvarna 236 chainsaw is the power indicator; Husqvarna 236 has a power of 1.9 horsepower, which in terms of kilowatts is approximately equal to 1.4. The weight of the saw is 4.7 kilograms, which makes it possible for women to use it.

The Husqvarna 236 chainsaw develops maximum power at 9000 rpm. The cylinder volume is just over 38 cm3, the fuel tank capacity is 0.3 liters, and the oil tank is 0.2.

The tool is equipped with an oil pump to supply lubricant to the saw chain, which automatically regulates the flow in proportion to the increase in crankshaft speed. This system allows not only to effectively lubricate the rubbing elements of the saw set, but also to save oil in idle mode.

As standard, the Husqvarna chainsaw is equipped with a saw chain with a pitch of 3/8, a groove width of 1.3 mm and a length of 52 links. If necessary, you can replace the tire and drive sprocket, which will allow you to install a chain with the required number of links and chain pitch.

Model range of Husqvarna trimmers accepted for repair

We repair the following models of Husqvarna trimmers (petrol mowers):

- Models of gas trimmers and gas trimmers Husqvarna repair of the Husqvarna 128R gasoline trimmer

- repair of Husqvarna 133R petrol trimmer

- Repair of Gasoline trimmer Husqvarna 135R

- Repair of Gasoline trimmer Husqvarna 143R-II

- repair of Husqvarna 236R petrol trimmer

- repair of Husqvarna 323R II petrol trimmer

- repair of Husqvarna 324Rx petrol trimmer

- repair of Husqvarna 327RDx petrol trimmer

- repair of Husqvarna 327Rx petrol trimmer

- repair of Husqvarna 524R petrol trimmer

- repair of Husqvarna 525RX petrol trimmer

- repair of Husqvarna 525RXT petrol trimmer

- repair of Husqvarna 535RX petrol trimmer

- repair of Husqvarna 545RX petrol trimmer

Models of Husqvarna cordless trimmers

- Husqvarna 536LiRX Cordless Trimmer Repair

Husqvarna 136LiC Cordless Trimmer Repair

Trimmer Husqvarna 128R – model description

The Husqvarna 128R petrol mower is designed for regular maintenance of small garden plots. The model is equipped with a reliable motor developed using proprietary E-Tech II technology. The introduction of innovative solutions in the development of internal combustion engines has significantly reduced its harmful emissions, without the slightest reduction in its power.

The Husqvarna 128 R petrol trimmer is equipped with an improved starting mechanism with a Smart Start system. The manufacturer managed to reduce the resistance of the cord by 40%, which minimizes the load on the main parts of the starter.

The main characteristics of the brush cutter include:

- built-in motor power – 1.1 l. With.;

- capacity of the standard fuel tank – 400 ml;

- the maximum permissible cutting width with fishing line is 35 cm;

- knife cutting diameter – 25.5 cm;

- generated sound pressure – 114 dB;

- working weight – 5.1 kg.

The manufacturer has provided free access to the main consumable parts of the brush cutter, which makes it possible to quickly replace faulty spare parts.

Husqvarna Petrol Mower Remove From Gearbox Bearings Show

Trimmers and chainsaws

Trimmer gearbox - malfunctions, prerequisites and methods of elimination

A trimmer gearbox (petrol trimmer gearbox, brush cutter gearbox) is a mechanical device located in the lower part of the trimmer (petrol trimmer or brush cutter) and designed to transmit torque from the motor to the cutting equipment at an angle of 30°, ensuring that the cutting equipment operates in a horizontal plane (parallel to the surface ground), also reducing the angular speed and increasing the torque of the output shaft in a ratio of 1:1.40 (for example, if the engine runs at 12 thousand rpm, then the knife will spin at a speed of 8.6 thousand rpm ).

Possible malfunctions of the trimmer gearbox, lawn mower gearbox, and lawn mower gearbox

- Malfunction - the trimmer gearbox gets very hot. The malfunction of the lawn mower gearbox and the lawn mower gearbox is the same as that of the trimmer. The causes of the malfunction are a lack of lubrication in the gearbox, inappropriate lubrication, or the new gearbox has not been run in (when the parts have not yet been ground in). Do-it-yourself trimmer repair - add lubricant to the trimmer gearbox, change the lubricant, or run the trimmer in a gentle mode (use three tanks of fuel at low loads and with repeated stops for natural cooling).

- Trimmer malfunction - knocking, free movement and jamming when rotating the trimmer gearbox shaft, lawn mower gearbox or lawn mower gearbox. The cause of the malfunction is the destruction of one of the bearings in the trimmer gearbox due to lack of lubrication in the gearbox, inadequate lubrication, strict operating conditions of the trimmer, damage to the boots on the bearings during their installation. Do-it-yourself trimmer repair - order bearings from the dealer and change them (there are two or three sealed bearings) - for more details, see below “How to disassemble a trimmer gearbox / lawn mower gearbox / brush cutter gearbox.”

- Trimmer malfunction - the gearbox wobbles or falls off the trimmer pipe. The cause of the malfunction is mechanical damage to the gearbox housing - for example, if a piece of the housing breaks off due to a strong blow with a knife on heavy metal or stone (or if the gearbox housing is destroyed, for example, with a hammer during repairs). Do-it-yourself trimmer repair - change the gearbox housing. Or, if a small piece breaks off, make an iron clamp to tighten the fracture site. Repairing a lawn mower yourself is similar to repairing a trimmer.

- Trimmer malfunction - the reducer on the pipe does not clamp. As practice shows, the gearbox does not completely fly off the pipe, but on a theoretical level, it can fly off the pipe together with the rotating knife. A malfunctioning lawn mower is like a trimmer. The reason for the trimmer malfunction is wear of the gearbox seat on the pipe (the aluminum of the pipe under the gearbox is worn out). Do-it-yourself trimmer repair - wrap fabric tape around the pipe under the gearbox or change the pipe.

- Trimmer malfunction - the trimmer blade does not turn at all (with a corresponding iron sound) or stops turning under heavy loads (with a hard gnawing sound). The cause of the malfunction is wear of the teeth on the bevel gear in the trimmer gearbox. Do-it-yourself trimmer repair - change the pairs of bevel gears (a pair is replaced) in the gearbox - for more details, see below “How to disassemble the trimmer gearbox / lawn mower gearbox / brush cutter gearbox.”

How to disassemble the trimmer gearbox

In order to disassemble the trimmer gearbox, you need.

- Remove the gearbox from the pipe by loosening the two coupling bolts under the gearbox.

- Wash the gearbox with a brush, for example, in gasoline without oil and dry it.

- Use a pair of pliers to bring the ends of the retaining ring together and pull it out.

- Remove the 2nd retaining ring in the same way.

- Then you need to very warm up the housing of the trimmer gearbox, brush cutter gearbox or lawn mower gearbox with a factory (technical) hairdryer at an outlet air temperature of 600°C.

- After this, with strong blows of a wooden block on the upper part of the gearbox housing, knock out the driven shaft with the bearing and gear (at first it’s worth trying to knock out the bearings without heating). You only need to hit wood with a block, because an iron hammer, for example, can break the body.

- In the same way, we remove the drive shaft with the bearing and gear (we very much heat the place where the bearings sit and hit the housing coaxially with the shaft with a wooden block, knocking out the shaft with 2 bearings and the gear). How to disassemble a trimmer gearbox, a lawn mower gearbox and a brush cutter gearbox. To avoid heating, you can try using a film.

How to fix a trimmer yourself

Trimmer repairs should be carried out as soon as possible when the first signs of breakdown appear, so that minor faults do not lead to more serious problems. All models are characterized by the presence of the following main components and structural elements: drive system (motor), transmission devices, working part (knife or fishing line), belts and handles. Failure can occur in any part, but some components fail much more often than others.

Lawn mowers powered by gasoline or electricity (as well as different models from different manufacturers) differ in design and the nature of the problems. Some of them can be easily fixed with your own hands, while others will require more extensive repairs or contact a service center.

Clutch

If the cutting part of the trimmer constantly spins at idle engine speed, and an uncharacteristic metallic grinding noise is heard, these are signs of a faulty clutch. Usually the cause is a broken or stretched spring. If slippage is added to this, then the pads are also faulty.

READ Petrol Trimmer Doesn't Start Spark Yes

On a note! To repair the trimmer, the clutch is disassembled, the spring, bearings and pad are inspected. Faulty elements should be removed and replaced with new ones.

Gearbox

The gearbox on the trimmer is used to transmit rotation from the shaft to the cutting part. It includes the housing, bearings and gears. It may have the following faults.

- The transfer unit is heating up. The reason is the absence or poor quality of lubricant. It needs to be added or completely replaced . This phenomenon can also occur when new gears are installed. In this case, you need to let the tool work under light loads, regularly interrupting work to avoid overheating of the equipment.

- Knocking, play, or sticking of the shaft indicate deformation of the bearings. Replacement required.

- The transmission mechanism wobbles or falls off the boom. This means the case is damaged. It is necessary to replace the rod or tighten it with a metal clamp if the damage is minimal.

- The gearbox does not stay on the rod. This is typical for a worn joint. You can change the barbell or rewind the electrical tape.

- The knife does not rotate or stops when loaded. This means that the gears are worn out (fully or partially). Parts need to be replaced.

Cutting blade

One of the possible breakdowns of the cutting blade is that the cassette cover is displaced or stuck. This occurs due to a misaligned axle or installation of an unsuitable mowing head. As a result, rotation becomes more difficult, the load on the motor increases, and it overheats.

If the cutting blade does not rotate, checking the assembly depends on the design of the bar. For a curved shape, you need to inspect the bushing and the rod itself, and for a straight shape, you need to inspect the shaft, gearbox and clutch. All connections between parts must be intact. The check is performed only if the trimmer motor is in good condition. Sometimes confusion occurs and users think that the problem is with the cutting unit, but in fact the motor is faulty.

Nuances of adjustment

After the adjustment, the chainsaw should easily pick up and drop speed, and operate stably at low and high speeds. If the saw chain rotates at idle speed after adjusting the carburetor control screws, this is a sign that the adjustment was made incorrectly and the position of the screw (T) needs to be adjusted.

Also, when adjusting the Husqvarna carburetor, it is worth taking into account the response time of the chainsaw to the rotation of the screws. The settings do not change immediately, but within five or ten seconds.

One of the indicators of incorrect adjustment is heavy smoking when the saw is operating, which indicates a large amount of fuel entering the combustion chamber. If such a situation occurs, the position of the screw (L) must be adjusted.

Husqvarna – the founding and development of a famous brand

The now world-famous Husqvarna brand was founded in 1689 in the Swedish town of the same name. At the beginning of its long history, the then small enterprise specialized in the production of weapons for the Swedish army.

In 1867, dramatic changes occurred in the company's work. In addition to producing rifles and cartridges for them, the brand began actively developing sewing machines and wood-burning stoves. A little later, the company managed to launch the production of the first models of hand-held garden tools.

Today the Swedish company specializes in the production of high-quality garden equipment. The company's products include various models of chainsaws, snow blowers, blowers, and lawn mowers.

Among the variety of Husqvarna products, electric and gasoline scythes stand out. They combine high reliability, endurance, and long service life. Each Husqvarna trimmer is able to withstand prolonged loads, which makes the Swedish equipment a reliable assistant when caring for large areas around the house.

When to contact the workshop

If the device is under warranty, at the first sign of incorrect operation, you can safely take it to a specialized workshop. Repairs will be made free of charge, regardless of the nature of the damage, if it was not the fault of the owner. If there is a breakdown in the engine, it is better for a person ignorant of technology to immediately contact a specialist. In any case, the severity of problems with the unit is determined by the user himself.

Summarize. Both gas and electric trimmers are designed to provide years of reliable service. Most of the problems described above occur due to insufficient attention of the owner to his assistant. Subject to strict adherence to the manufacturer's requirements and regular maintenance, the manual mower will work rhythmically and without interruption.

READ How to Put a Knife on a Stihl Trimmer

Tools required for work

Before you start setting up the Husqvarna carburetor, you need to make sure you have all the tools that may be useful. To carry out this type of work yourself, you will need:

- a screwdriver for adjusting screws (H) and (L), it can be bought in specialized stores;

- electronic tachometer for determining crankshaft speed readings (with some experience, you can make adjustments by ear);

- Phillips screwdriver for adjusting screw (T);

- compressor with a blow gun for cleaning the saw before work.

A regular slotted screwdriver will not work for adjustment, since the adjusting screws on Husqvarna chainsaws can have different cross-sections. You will have to purchase a special one, this is a feature of repairing Husqvarna chainsaws; they did everything so that the saw could be repaired only in a specialized Husqvarna service center.

Features of the trimmer

All trimmers are classified according to the type of power supply: gasoline or electricity (from the mains or battery). It should be noted that gasoline mowers are superior to their electric and battery-powered counterparts in many ways. Although they all perform similar functions, the differences in performance, maneuverability and efficiency are very noticeable. However, the general principle of operation of all types of manual mowers is almost the same - the devices are equipped with engines (two- or four-stroke internal combustion engines or electric motors) that drive the cutting unit (a reel with fishing line or a metal disk). All elements are mounted on a straight or curved rod, including the handle for controlling the trimmer, on which the main buttons are located.

READ Grinder Fiolent 125 With Speed Control

Since the problem of low speed is more typical for gasoline versions of trimmers, more attention will be paid to them. Thus, the brush cutter is very comfortable to use and unpretentious in maintenance. Moreover, most of its malfunctions are caused by the user’s ignorance of the basic things described in the instructions. Therefore, before starting to operate the unit, you must carefully study the manufacturer’s manual. In particular, to start the engine, you must perform the following sequential steps:

- turn on the ignition button;

- press the silicone button several times to pump gasoline;

- close the air damper;

- set the throttle lever to the high speed position;

- First make gentle jerks with the starter handle to feel the resistance of the engine, then pull sharply.

If the lawn mower starts but stalls, you need to put the air damper in the middle position and try again. When the engine starts, you need to slow down the gas and open the air damper, since the trimmer functions only on suction.

Important! The trimmer's operating mode depends on various environmental influences. In hot weather, the unit needs to be given more time to cool down. When operating in dense thickets or high vegetation, the engine also overheats greatly. It is necessary to take five-minute breaks every 15-20 minutes.

1.2. Husqvarna's top car-class model

The Husqvarna 128 R is popular among home users for treating small areas. It has the following main technical characteristics:

- two-stroke two-stroke gasoline unit with a displacement of 28 cm3;

- engine power 0.8 kW or 1.1 l s;

- fuel tank with a volume of 0.4 liters with a fuel consumption of 507 liters per hour;

- straight fixed rod with a diameter of 24 mm;

- T-type bicycle handle with engine control parts, increased ergonomics;

- presence of an anti-vibration system;

- The cutting system consists of a 2.4 mm wide blade and a metal four-bladed knife;

- cutting width 25.5 cm of knife and up to 40 cm of fishing line;

- overall dimensions 286 × 244x1829 mm;

- weight 5.0 kg.

Gasoline trimmer Husqvarna

The multifunctional petrol machine Husqvarna 128 R, capable of easily and quickly changing cutting elements, is designed for convenient and productive work in garden and lawn care. Safety in operation is ensured by the presence of a protective casing. This prevents accidental contact with cutting parts.

The development of the Husqvarna 128 R has been equipped with the latest E-TESN 2 technology, which reduces exhaust emissions. This does not affect engine power, but ensures environmental friendliness with low exhaust gases.

The ergonomics of the handle and the ease of holding the device are ensured by an optimal angle of inclination and an anti-vibration system. This allows you to work with the Husqvarna gasoline pump for a long time without experiencing fatigue or discomfort.

Customer Reviews

The model does not make noise, starts up the first time - two pluses. practically does not vibrate, the belt is comfortable, the disc is high quality and durable.

this trimmer for 4 years now. There is an easy start system, so you don’t need to put all your strength into the jerk. As soon as you feel the resistance of the cord, give a smooth jerk and it will start. In order for the mower to work for a long time, you need to maintain the proportions of the fuel mixture. I use 20g of Husqvarna per liter of 92 petrol. The diluted mixture can be stored for no more than two weeks. When storing for a long period of time, you need to drain all the oil and run it on an empty tank to burn out the remaining fuel. I recommend working at full power, then the mixture burns completely without forming carbon deposits in the exhaust pipe and inside the engine.

easy start-up, minimal vibration level

I have little experience using the trimmer - only one day. But there are already impressions. I started it like this - gently pulled it a couple of times with the valve closed, which is what the instructions recommend. With one full tank I mowed a ten-meter path 2 meters wide and a square clearing 5 by 5. I consider the consumption to be normal. I filled it with 92 gasoline and branded oil for two-stroke engines. I liked the suspension system, even in space! The straps are durable. I set it up for myself in three minutes. So far I’ve only tried fishing line, but it worked well with grass. I hope that further use will provide new experience that I will share.

READ Piston Group for Gasoline Trimmer How to Select

I was given a trimmer, so I use what I have. The area for processing is 13 acres. The first time I mowed down weeds with a disc, now I use a fishing line because I can’t get enough of it. I don’t use it often – 3-4 times a season, but I’m very glad that I have this thing, because it saves enormous time. Now I would buy such a trimmer myself.

Light in weight and in operation. Everything is very clearly described in the instructions. You can work all day. The cutting equipment is changed within five minutes.

The flexible shaft is unusual at first, but then you realize how convenient it is.

The lightweight, portable Husqvarna 128R trimmer is useful for housekeeping and gardening. Light weight (5 kg including cutting attachment) and extremely easy start-up are designed for ordinary users who have no previous experience with motor mowers.

The power of the 0.75 kW petrol two-stroke engine is sufficient for mowing the lawn, grass and small shrubs. The working width of the trimmer is 45 cm.

Starts quickly (patented Husqvarna Smart Start system. Has a fuel pumping function and auto-return switch. The adjustable handle and comfortable straps on both shoulders allow you to “fit” the device to your body type, thereby reducing the load on the arms and shoulder girdle.

Model 128R is the most compact (due to the small size of the fuel tank), easy to carry and transport, and has a modest fuel consumption. The trimmer is equipped with a grass blade and fishing line, and a protective cover.

Please note: the trimmer does not operate on pure fuel, but on a mixture. It is recommended to use only original Husqvarna in a ratio of 1:50.

Ergonomic handle Comfortable handle design. Tap 'n Go Trimmer Head The Tap 'n Go trimmer head provides easy, fast line feeding.

The lightweight, portable trimmer is useful for housekeeping and gardening. Light weight (5 kg including cutting attachment) and extremely easy start-up are designed for ordinary users who have no previous experience with motor mowers. The power of the 0.75 kW petrol two-stroke engine is sufficient for mowing the lawn, grass and small shrubs. The working width of the trimmer is 45 cm. It starts quickly (the patented Husqvarna Smart Start system has a fuel pumping function and auto-return switch. The adjustable handle and comfortable straps on both shoulders allow you to “fit” the device to your body type, thereby reducing the load on the arms and shoulder girdle . Model 128R is the most compact (due to the small size of the fuel tank), easy to carry and transport, and has a modest fuel consumption. The trimmer is equipped with a grass blade and fishing line, and a protective cover. Please note: the trimmer does not operate on a clean

Characteristics

| Characteristics | |

| Weight, kg | 5 |

| Air filter | Paper |

| Dimensions (LxWxH), cm | 28 x 24 x 182 |

| Guaranteed sound power, Lw dB (A) | 114 |

| Sound pressure near the operator's ear, dB(A) | 101 |

| Weight (without cutting equipment), kg | 4.6 |

| Engine power, kW | 0.85 |

| Engine power, hp | 1.15 |

| Fuel tank volume, l | 0.4 |

| Bore diameter, mm | 25.4 |

| Cylinder displacement, cm³ | 28 |

| Collapsible shaft | No |

| Package size, LxWxH, mm | 1829x243x286 |

| engine's type | Petrol |

| engine's type | Push-pull |

| Spindle speed, rpm | 8000 |

| Dimensions and weight | |

| Gross weight, kg | 6 |

| Packed height, mm | 380 |

| Rod diameter, mm | 24 |

| Packed length, mm | 340 |

| Rod length, mm | 1483 |

| Packed width, mm | 1920 |

| Engine Specifications | |

| Carburetor | Zama |

| Fastening | M10x1.25 LH |

| Maximum power take-off shaft speed, rpm | 9200 |

| Maximum torque, N/m | 2.0 |

| Gear ratio | 1:1.4 |

| Fuel consumption, g/kW | 507 |

| Fuel consumption, kg/h | 0.41 |

| Spark plug | Champion RCJ8Y |

| Ignition system | Walbro CD |

| Gearbox angle, ° | 30 |

| Clutch engagement frequency, rpm | 4200 |

| Idle speed, rpm | 2800 |

| Frequency corresponding to maximum power, rpm | 8000 |

| Equipment | |

| Grass knife | Grass disc 255-4 |

| Belt equipment | Standard harness (on both shoulders) |

| Handle type | Bicycle |

| OEM trimmer head | T25(L) |

| Drive system | |

| Drive shaft | Flexible , straight |

| Cutting equipment | |

| Cutting element | Line/knife |

| Line thickness, mm | 2.4 |

| Cutting width, cm | 45/25.5 |

| Performance | |

| Rotation speed, rpm | 8000 |

| Lubrication system | |

| Lubricant type | Mineral oil |

| Lubricant type | Husqvarna or equivalent at 50:1 ratio |

| Noise and vibration | |

| Sound pressure level, dB(A) | 100 |

| Equivalent vibration level on handles, m/s² | 3.5/3.1 |

| Contents of delivery | |

| Petrol trimmer Husqvarna 128R. 1 PC. | |

| Husqvarna Standard belt accessories. 1 PC. | |

| Protective cover. 1 PC. | |

| Assembly key. 1 PC. | |

| Fishing line. 1 PC. | |

| Transport cover. 1 PC. | |

| Semi-automatic trimmer head Husqvarna T25 M10. 1 PC. | |

| Grass knife Husqvarna Grass 255-4T 25.4. 1 PC. | |

| Restrictive cup for Husqvarna M10 trimmers. 1 PC. | |

| User manual. 1 PC. | |

Repair (rework) of the starter of the husqvarna 128r brush cutter. From the series “Private House”.

Minor change to the starter design.

For trouble-free and long service life, experts recommend using oil from Husqvarna.

You can repair Husqvarna gasoline pumps yourself, for example, replace a clogged air filter. In addition, it is located in a convenient and easily accessible place under the lid. You don't need tools to replace it. In the event of a breakdown, it is better to take the equipment to a service center, since ignorance of the principles of operation of individual parts can only aggravate the situation.

The most common problems with Husqvarna 128R gasoline pumps are problems with ignition or fuel supply. In the first case, the gas trimmer either stops within a few tens of seconds or does not start at all. To do this, check the spark plug system. If it is wet, then most likely you need to adjust the carburetor correctly. Or the problem occurs due to incorrect startup, then you should carefully study the instructions.

The petrol trimmer of this model can last for many years, that's the main thing. follow operating rules and promptly check and replace necessary parts. In addition, the Husqvarna 128R fully matches its quality and performance.

Maintenance

- Image

- Text

115302726 Rev. 2 7/15/10 Russian — 27

MAINTENANCE

The muffler is designed to reduce noise levels and direct exhaust gases away from the operator. Exhaust gases are hot and may contain sparks that can ignite if they come into contact with dry flammable materials. The mufflers are equipped with a special spark arresting mesh. The mesh should be checked and cleaned if necessary. If the mesh is damaged, it must be replaced by a service workshop.

If the mesh is often clogged, then the function of the catalyst has deteriorated. Contact your dealer for advice. A clogged screen can lead to overheating and, as a result, damage to the cylinder and piston.

ATTENTION!

Do not use the machine if the muffler is damaged or loose. Make sure the muffler bolts are tight.

WARNING! Silencers

with catalysts, they become very hot during operation and remain hot for some time after switching off. This also happens at idle. Touching them may cause skin burns. Be aware of the risk of fire!

WARNING! Muffler

contains chemicals that may be carcinogenic. Avoid contact with these substances if the muffler is damaged.

ATTENTION: Please remember that

engine exhaust gases contain carbon monoxide; this may cause carbon monoxide poisoning. For this reason, do not run the engine indoors or in other poorly ventilated areas. Engine exhaust gases are hot and may contain sparks, which may cause a fire. Do not run the engine indoors or near flammable materials!

Spark plug

The condition of the spark plug is affected by: ·

Incorrect carburetor adjustment.

·

Incorrect fuel mixture (too much oil or wrong type of oil).

·

Dirty air filter.

These factors cause carbon deposits to form on the spark plug electrodes, which can cause operating and starting problems. If the engine does not gain power, has difficulty starting, or idles poorly, first check the spark plug. If the spark plug is dirty, clean it and check that the gap between the electrodes is 0.6

mm. Spark plug required

change after about one month of operation or even earlier if necessary.

Muffler bolts

Net

Petrol trimmer Husqvarna 128R

We have received your message and will definitely contact you.

Please notify the operator of your desire to participate in the promotion, or when creating an online application, write “I want a gift” in the comments.

Reviews (9)

The trimmer is very easy to use, even a woman can handle it, as it is very light weight and has low vibration. After winter, the start is easy, refueled, pumped up and almost the first time it starts. And buy the original fishing line right away, it’s a little expensive, but the consumption is minimal.

When assembling for the first time, do not overdo the screws on the crosspiece that secures the control handles; uneven tightening can strip the threads. Also, a year after starting, the engine speed began to disappear - there was a vacuum in the gas tank, I removed the mesh in the filling cap, it became clogged, and everything works like clockwork to this day.

Take it and you will not regret it, I have never seen such an unpretentious and light, as well as powerful and cheap mower, the quality is excellent. All the Chinese and Japanese neighbors are falling apart, this one plows and plows, surprisingly, and will soon have to get a new coil due to wear and tear (6 years, 40-acre plot)

Great trimmer. Mows easily and cleanly. The weight is practically not felt if the straps are adjusted well. .

I bought it for my dacha. mow the grass along the fence and where it is inconvenient with a wheeled mower. Impressions for six months are only positive. The weight and comfortable straps allow even fragile women to operate the trimmer.

For 20 acres of my plot there is enough power, and it’s also enough to clear a second such neighbor’s plot. The back does not get tired, because... light weight. The components and housing are reliable and inspire confidence.

I haven't encountered any drawbacks yet. There is only a small note - the gasoline tank is small, but that’s good. But you can rest yourself and let your equipment rest, refueling it every 30-50 minutes.

READ How to Clean the Air Filter on your Echo Trimmer

With my 20-acre plot of land, I have suffered enough with a hand scythe, so it’s time to choose a good gasoline trimmer . I was interested in this model for its price and size, but I was worried that its power might not be enough. Actually, I was worried in vain. All that was left were good impressions and a feeling of pride for the right choice. The back does not get tired, the fishing line cuts almost everything, there is no bone-shaking vibration like most other neighboring devices. To properly set up and run the scythe, you can watch videos on the Internet; there are a lot of them for this model. A little more than a liter of mixture and a day of work is enough to clear all 20 acres of land to zero, while destroying fallow, hogweed, weeds and waist-high tall grass. And yes, remember that a break-in is needed. The first couple of days, mow for 10 minutes at a time with breaks of 7-10 minutes. If you follow all the instructions, this horse will last for many many years.

I’m using it for the third season in a row, what can I say. The other day I took it out of the closet and looked at the object. It's time to change the air filter, the fuel filter is still fine. I mowed all the grass in the garden at once, I wasn’t tired, my hands didn’t tingle, my back didn’t ache. I took this trimmer instead of the Partner T330 Pro, which for some unknown reason cracked at the installation site of one single bearing. Husqvarna was pleased at this point - the 2-bearing crankshaft should be much more reliable. Plus, convenient control in one place on the steering wheel, and not a bar with high vibration, after which all the fingers buzz. The power is similar, fuel consumption is also approximately the same.

My advice to you. If you do not use the scythe for a long time, check the fuel filter before starting to see if there is any deposits or oxidation on it. Replace if necessary. The carburetor on my Partner was clogged, I had to clean the filter every time, but I only did it 3 times and clogged it. As a result, I mowed 25 acres by hand. When I bought the 128R, it took six hours to process the same area and no more than 2 liters of gasoline. I mix only branded oil, 1:50 as required.

I really like the braid, the harness with the belt fits like home, there are two handles, it’s comfortable to hold. Even with a fishing line, all the grass, any bushes, any twigs are demolished. The bevel goes evenly, gathers more or less evenly, without scattering to the sides. The main thing is to study the instructions correctly and do everything you need before the first start. If you have any problems, read the instructions or watch a video on the Internet, everything is described there and in 99% of cases you will solve the problems yourself.

Shaft for trimmer: drive, rigid, lower shaft for lawn mowers (mowers) and others

The disadvantages I found can hardly be called disadvantages. A slight vibration causes some discomfort, but not in the joints, but in the skin. This is probably my quirk. Plus, I don’t use gloves, even though the instructions say so. Be careful with the fishing line; bushes that are too hard can easily break it and you have to re-tighten it.

There is no better quality/price ratio on the market! No problems with winding the grass, which many people talk about. Over three years of operation, I did not find any significant shortcomings, it always started easily, and worked flawlessly. It's five!

Light weight, starts quickly, saves fuel, is quite quiet

Repair of flexible shaft (trimmer)

I bought it last week, and in three days I cleared 35 acres of dacha land from weeds and thickets, tall grass, and young trees. everything went under the knife! Surprisingly, it starts without any effort at all, just do everything according to the instructions. Initially I used a casing with a standard knife. I mowed fine, but the grass kept getting stuck between them. As a result, I removed the protective casing (yes, I know, unsafe, but very productive), and sharpened the knife with a regular file. The braid went like clockwork! Waste so much time with this knife, but I could have just done it as written. It consumes 20-30 percent less gasoline than the similar MTD728.

Interesting observation. I bought gasoline, poured it into old lawn mowers, and they didn’t start. It turned out that the carburetor was clogged. I noticed a small sediment like flakes in the canister, I don’t know what caused it, maybe it was oil and fuel. Now I always fill up my motorcycle using a regular disposable napkin as a filter.

Safe, quiet, lightweight, ergonomic. great helper for gardening)

In short, I recommend the braid! Grass, burdocks, nettles, weeds a meter high. with a bang! I processed the entire area in an hour and a half, with a couple of smoke breaks, it took 0.5 liters. Oh, and it’s also very quiet, I don’t use headphones. Don’t skimp on quality, such equipment is bought infrequently and lasts for decades, and Husqvarna is definitely the best among garden manufacturers.

The entire harness is excellent and comfortable, including the belt. The rest is in the comments.

The most important and scary episode for me went without any problems! The first start threatened to be the last minute for the starter and engine, but the starter started up as it should, the engine did not fall off after 10 minutes of load. This means it’s already better than the Chinese one I had before)) The main thing is to learn how to play with the suction and control the speed correctly. I called the service center and inquired in advance about the cost of repairing the starter in order to amuse my Jewish soul. There he also clarified how to start the engine correctly. So, there is NO NEED to jerk it in fits until the engine accelerates to its full three thousand revolutions. Pull gently, little by little, and then it will start smoothly and will not break under such abuse. As for the work process itself, it’s great, I like everything. Compared to the previous Makita, it’s simply a fairy tale - the grass is placed on the ground at any thickness and degree of density. The line does not fly out, it works almost like a knife. With a full tank (about 400 milliliters), it was enough for me to work intensively for 40-45 minutes on hogweeds, weeds and other tall evil spirits. I did a great job, so I'm very happy with my purchase.

The balance of the transmission and the power of the engine are a source of pride. Holding it in your hands, you feel as if you bought a professional tool, and not a household au pair. It starts without any complaints, no long jerks or swells at idle. In its price category, the best offer, equipment and characteristics are better than any well-known brands))

The bar cannot be disassembled. Maybe it’s stronger this way, but transporting it somewhere isn’t very pleasant.

Sources:

https://hitech-online.ru/tehnika-dlya-sada/trimmer/tipichnye-neispravnosti.html https://www.tool-store.ru/trimmer/Husqvarna-128-r/ https://husq.ru /trimmer-benzinovyj-Husqvarna-128r

Repair of Husqvarna lawnmower, loss of power.

Husqvarna 125R - 12 years of operation! Detailed video about troubleshooting that led to loss of power.

The technical characteristics of this model are as follows:

- two-stroke gasoline engine with a cylinder capacity of 24.5 cm3;

- power 0.9 kW or 1.2 liters;

- fuel tank with a volume of 0.5 liters with a fuel consumption of 0.495 liters per hour;

- straight rod with T-handle 1483 mm long and 24 mm thick;

- presence of an anti-vibration system;

- The cutting system consists of a 2.4 mm thick blade and a metal knife;

- Overall dimensions: 1844 × 270 × 285 × 132 mm;

- weight 4.5 kg.

Husqvarna 323 R Petrol

This machine also makes it easy and quick to replace the cutting element. The universal protective cover allows you to safely change the cutting part on the rod and the mowing process itself.

The model is equipped with a Smart start easy-start system; the primer pumps air into the carburetor. The fuel pump forces gasoline into the carburetor after a long period of inactivity and provides a quick start.

Ignition switch with return spring. The fuel tank is transparent, which allows you to control the amount of fuel.

The bevel gearbox has high torque up to 9000 rpm with the cutting edge parallel to the ground. This ensures the quality of the grass.