A planer is a tool that you cannot do without if you need to plan any wood. In most cases, the tool found on the market is manual. Using a hand-held wooden plane, you can quickly and easily give the surface a little roughness/straightness, reduce the size of a wooden craft, and make fairly neat notches in it.

The main job of the tool is to remove chips of a certain thickness in a short period of time. This occurs during any pass over the prepared surface of the product.

Flat type planing

Speaking about which plane to choose for planing this type, it is worth noting that the above category of tools consists of samples, using which you can perform almost any processing of the product.

All planes, which are called single, and which are used for quickly leveling wood surfaces, have a straight blade that is additionally slightly rounded with a neat edge.

After using such a tool, there will be no burrs left. It is usually used when it is necessary to finish planing any object after completing rough-type processing.

Looking at the photo of a hand plane, you can see that for the final leveling of the product, a cross-cut type of plane is often used. Their main blade, as a rule, is always duplicated by a knife used to break chips.

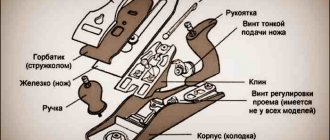

Planer device

During the evolution of the plane, quite a lot of its varieties have appeared, which can not only process the planes of wood, but also be used for figured cutting. To enjoy manual labor, you need to be able to choose the right plane, and then you will get real works of art from an ordinary piece of wood.

Modern planes can be divided into wooden and metal models. Each of them has its own advantages and disadvantages, but in terms of design, the instruments are similar, like twin brothers.

A standard plane consists of the following parts:

- sole, also known as body;

- cutter;

- wedge;

- slot for chip exit;

- cutter clamp;

- cutting depth regulator;

- horn - front handle;

- emphasis - rear handle.

The key element of the design is the cutter - this is a cutting tool made in the form of a pointed plate.

The blade is positioned at a given angle to the surface being processed. Thanks to the regulator, the knife extends to a certain distance, which allows you to finely adjust the depth of cut and the thickness of chip removal. In factory models, the blade sharpening angle is standard, but professional carpenters change it depending on the type of wood being processed.

The handles also play a certain role. The front one, called the horn, performs a guiding function and usually has a curved shape that provides a better grip on the hand. The rear one is a stop, thanks to which the force necessary for work is created.

With the sole, which can be wooden or metal, everything is not so simple. The main criterion for this structural element is a perfectly flat surface.

If this requirement is not met, it will be difficult to use a hand plane, and you can simply forget about planing accuracy. Taking these nuances into account, a metal sole looks preferable: it is made according to a template, so a priori it has the correct geometry. However, mistakes made by the manufacturer during casting reduce these advantages to zero. Moreover, the metal is susceptible to corrosive changes.

A wooden sole is lighter, and if deformed, you can straighten it yourself, breathing a second life into the plane. However, wood is not a durable material; it is subject to mechanical wear and loses its original properties when exposed to moisture or high temperatures for a long time.

Despite the standard design, there are more than 10 types of planes, and each tool performs a specific function when processing parts. Let's take a closer look at these products.

Sherhebeli

The above tool differs from the previously listed samples primarily in the slightly different shape of the blade. The angle is usually 45 degrees. It is thanks to this oval edge that it is possible to process wood material of any quality, even if necessary across its grain.

If there is a need to get rid of thick chips, then just for this case the hole for its exit is several millimeters larger than that of a standard tool.

The design of the tool makes it possible to achieve the desired configuration for the workpieces, but with its help it will not be possible to achieve a truly smooth surface, so be prepared in any case to perform additional actions with a jointer.

Design Features

To know how to choose a good hand plane, you should have an understanding of its design. Such instruments consist of the following main parts:

- Frame. This structural element is most often made of wood. It is in it that all the main components of the plane are attached.

- Knife. Sharpened at a certain angle.

- Clamp. Can be made from different materials. This can be a metal plate or bar.

- Chip breaker. Installed slightly higher than the knife. As you can already judge from the name of this element, it serves to break chips and guide them.

- Adjustment screw. This structural element is responsible for changing the position of the knife relative to the surface being processed.

All universal hand planes for wood have this design. The basic elements described above are also present in other, specialized varieties. On the body of any plane, among other things, there are two handles.

What are tsinubels and jointers?

A jointer works best for leveling the surface. It is possible to ensure finishing of even large areas in a short time using a chip breaker that is slightly longer than the tools mentioned earlier. All workshops involved in wood processing must have this type of plane.

Tsinubel is a type of instrument equipped with a single knife. After passing it through the plywood/wood, the surface will be left with a grooved surface that is best suited for gluing.

Knives for hand planes should always be of good quality, since the grooves left by the cutter will contribute to the ideal adhesion of all components to which the prepared glue will be applied.

How to work correctly?

It’s not difficult to understand how to operate an electric planer.

But first, it is important to study the instructions. After this, you need to check whether the front part of the plate is adjusted and whether it is in the correct position

If not, it should be adjusted. You also need to check the installation of the knives so that they do not touch the sole.

If the tool is in order and you can start using it, you should not immediately start working, practicing on good boards necessary for high-quality, beautiful processing. At first, it is recommended to train on unnecessary materials that you don’t mind spoiling.

In order for the final result to be as good as possible, it is important to use the right lumber: dried, smooth. It should not contain protrusions, depressions, knots, cracks, chips, metal elements: staples, nails, screws and others

Varieties

Of course, you should choose a hand plane based on the specific purposes for which it will be intended. There are several types of planes on sale today. The most popular are:

- Universal. This is a regular plane that can be used to do most carpentry work.

- Jointer. The body of this instrument is longer than that of a conventional one. A jointer is used to process large workpieces.

- End plane. The knife of such a tool is located at a flatter angle. This allows high-quality processing of end grain fibers.

- Zenzubel. A plane of this type is used mainly for making various kinds of carpentry joints and folds.