Recently, sales of walk-behind tractors have increased significantly, as such garden equipment helps to easily cope with planting or harvesting potatoes, plowing the ground, transporting cargo, or in some cases, removing snow. But, like any other unit, a motor cultivator can break down sooner or later. If this happens, the farmer needs to be prepared for the fact that he will have to adjust the ignition of the walk-behind tractor.

To carry out such work, the master must have skills in working with tools and understand the structure of such equipment. If you don’t have such knowledge, it’s better not to start work. The ignition system of a modern walk-behind tractor is not a highly complex design. Therefore, after several training sessions, a person will be able to make adjustments on his own.

You can adjust the ignition system yourself

Ignition adjustment

During operation, sooner or later a person will have to adjust the ignition of the walk-behind tractor. If this is not done in a timely manner, the equipment will work intermittently, which will affect the rapid wear of other mechanisms that are fundamental to the functionality of this unit. First, in order for the farmer to have a chance of successfully adjusting the ignition on a walk-behind tractor, he must study in detail this system of agricultural machinery that runs on diesel fuel or gasoline.

In this video you will learn how to adjust the ignition system:

If you configure this part of the unit correctly, the system will be able to create a spark exactly in the place where it is needed, and at the most opportune moment. It is worth considering here that the magneto is responsible for the distribution of the resulting spark, which you should also not forget to check. The setup must be performed following the following procedure:

- First of all, the master checks the functionality of the flywheel, which is located in the engine until the contacts located in the magneto open.

- At the next stage, it is necessary to measure the distance between the so-called “hammer” and “anvil” built into the ignition design.

- Next, turn the flywheel so that the piston is compressed. When the flywheel reaches the upper limit, it is turned again. As a result, the person should hear a one-time knock. It will indicate that the overrunning clutch has worked.

- At the next stage, the flywheel is turned counterclockwise so that the mark on it aligns with the one located on the body.

- The next step is to adjust the distance between the cam and the nearby breaker contact. Here it is worth considering that the minimum distance for proper operation of the walk-behind tractor is a quarter of a millimeter, and the maximum is 0.35 millimeters.

- At the last stage, all that remains is to secure the built-in cam using a special screw located on top.

Note! In order not to make mistakes at each stage of setup, professionals recommend using videos from the Internet as instructions. If the technician sets the ignition for the motor cultivator taking into account all the rules, the engine will start faster and the operation of the unit will become smoother. This is necessary in order to reduce wear on the piston system, as well as other parts of this equipment.

How to set the ignition on a walk-behind tractor

Let's look at how to adjust the ignition of a walk-behind tractor. The ignition system of the walk-behind tractor is quite simple. Before installing the ignition, it is important to make sure that this design produces a spark, which in turn will ignite the fuel liquid located in the internal combustion chamber.

In order not to turn to specialists for trifles and save your money, you need to understand how the ignition and ignition coil settings are adjusted. Let's look at how to set the ignition on the MB 1 and MB 2 walk-behind tractor.

You can set the ignition using a spark. It is necessary to turn the crankshaft so that the marks of the pulley and the gas mechanism coincide. The slider distributing the gas flows should point to the high-voltage wire of the cylinder.

You need to slightly unscrew the nut that changes the position of the mechanical structure that determines the moments of the high-voltage pulse.

Then you need to remove the high-voltage wire from the system cover. He is at its center. Then place the contacts at a distance of 5 mm from the cultivator.

After this, turn on the ignition.

Next, you need to turn the mechanical structure, which determines the ignition timing, clockwise to the 200 mark. Carefully turn the above-mentioned structure in the other direction.

All this must be done with extreme caution; the mechanical structure should not change its position in relation to the walk-behind tractor.

A spark occurs between the central high-voltage wire and the ground of the cultivator. After this, you need to quickly tighten the breaker nut to prevent ignition.

You can set the ignition by sound. If the owner has fairly good hearing, then this method of checking and adjusting the ignition is quite suitable. In other words, this is a non-contact test of candles.

The non-contact method involves the following procedure:

- First you need to start the engine.

- Then you need to loosen the distributor a little.

- Rotate the breaker body slowly on both sides.

- The mechanical structure, which determines the moment of spark formation, must be strengthened in the state of greatest power and the greatest number of revolutions.

- Next, listen carefully. When turning the intermittent system, clicks should be heard.

- After all the steps taken, you need to tighten the distributor nut.

The strobe method works like this:

- First you need to warm up the engine.

- After this, attach the strobe light to the walk-behind tractor.

- A sensor that responds to sound must be connected to the high-voltage wire of the cylinder.

- Remove the vacuum hose and plug it.

- The strobe light will emit a light that should be aimed at the pulley.

- Start the unit engine again and leave it idling.

- Turn the distributor.

- Fasten as soon as the pulley mark points to the mark marked on the cover of the walk-behind tractor.

- Tighten the breaker nut.

The above describes how to check the ignition coil. When installing the system, it is advisable to use the instructions, especially for owners who are encountering this for the first time.

Adjusting the reel is not a difficult task.

What causes malfunctions in the ignition system of Mole walk-behind tractors?

If we look at the situation using walk-behind tractors from as an example, malfunctions can occur here due to the fact that the spark plug insulators are faulty. If such a situation arises, each of the systems must be replaced; if this is not done, the ignition on the Mole walk-behind tractor will constantly suffer from problems of varying degrees of complexity.

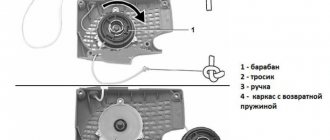

The unit has a “Stop” button; a short to ground may occur here in order for the engine to start; this problem must be eliminated. Other violations may be associated with the contacts of the spark plugs, in which case they need to be put in order. In some cases, the engine may not start if the clearance between the magnetic shoe and the starter is not provided, as indicated in the instructions. If the starter is not working properly, it will also have to be replaced.

Several reasons for the failure of the ignition system in this walk-behind tractor

How to set the ignition on a walk-behind tractor?

Adjusting the ignition may be necessary if you have to repeatedly pull the starter cable or the engine does not start immediately, but after a delay.

You need to do the following:

- Place a square on the spark plug. The body is securely pressed against the cylinder head, the element rotates in the other direction from the hole on the cylinder head;

- The crankshaft turns. You need to tighten the starter cable a couple of times. When the cable is pulled, a blue spark should be visible that jumps between the electrodes;

- If there is no spark, check the gap from the flywheel magnetic shoe to the starter. The optimal distance is 0.1 millimeters.

So, installing the ignition will not take more than half an hour. If you perform simple manipulations correctly and in a timely manner, you can prevent wear of other parts and systems of the walk-behind tractor under high loads.

Malfunctions and ways to eliminate them

If the equipment stops working, the first thing you need to do is check the ignition coil installed on the walk-behind tractor. There may be several reasons for such malfunctions:

- wiring problems;

- breakdown in the ignition coil;

- faulty spark plugs;

- lack of spark from spark plugs installed on the walk-behind tractor (this is one of the most common causes of problems).

To check the spark plug, unscrew it and carefully inspect the side and central electrodes. If carbon deposits are found here, you can easily get rid of it using a gas burner. When inspecting these parts, you need to pay attention to whether there is moisture on them. If the spark plug turns out to be dry, this will indicate that fuel is not getting into the cultivator engine.

If this part is wet, this may indicate that the cylinder is filled with engine oil. To get out of this situation, you need to find the cause of the breakdown, and then dry the cylinder and wipe the spark plug well. To dry the cylinder, you will need to pull the starter cable several times.

After this, it is recommended to check the coil, taking into account the recommendations of agricultural machinery repair specialists. This can be done in the same way as with a candle. You need to put a tip on it, and move the lower plane towards the magneto body. If there is no spark when the flywheel rotates, then the problem lies in the coil.

Important! Before you adjust the ignition on your walk-behind tractor, it is first better to ask yourself which spark plug is best suited for the existing unit. Experts advise selecting those parts that have a short heat dissipation path. This is due to the fact that these candles do not overheat the equipment and last much longer.

Features, pros and cons

The Neva MB 2 walk-behind tractor is one of the most popular units of this type. It is versatile and has excellent technical characteristics. Ideal for working in private farms, vegetable gardens, and orchards.

There are engines with markings:

- 2K;

- 2B;

- 2C;

- Motoblock Neva M-2K;

- Model 2K.

The letter “2K” means that the walk-behind tractor has an engine made in Russia, it has a good service life and an average price. The single-cylinder engine has a power of 6.1 and 7.6 liters. With.

Much depends on what kind of unit it is: DS 1 or DS 2. The first can run on 76-grade gasoline, DS 2 requires 95-grade fuel. On average, gasoline consumption is about three liters per hour if the walk-behind tractor is almost 100% loaded.

The walk-behind tractor with the letter “2B” has an imported power plant (most often Briggs Stratton). Such mechanisms are considered to be the most reliable. Model “2C” on such models there is a Japanese “Subaru” engine with a power of up to 7.1 liters. With. Diesel options have more power.

Japanese technology requires proper configuration, only then will it work without failures. Before buying a Neva walk-behind tractor, you should understand what kind of work it will do.

If the plot at the dacha is too large, more than 16 acres, then the engine should be chosen at least 9-10 liters. With.

" Neva MB-2" is fixed on the frame, and various equipment can be assembled there. The power plant is equipped with a gearbox with six gears, this is a significant help in processing even the most dense soils.

The machine can move at speeds of up to 10 km per hour, and even large heavy loads can be transported. The walk-behind tractor has four speeds, 2 of them are rear. The controls are very convenient, mounted on the steering wheel.

READ Ignition Chainsaw Shtil 180

Problems with the Neva Motoblock, where to look for a fault?

The V-belt drive can quickly rearrange the pulley, lever and belt. The unit is well equipped; there are cutters for a wide variety of purposes.

The device weighs only 99 kg and is compact in size. It can be transported over long distances in the trunk of a car.

The machine can do the following work:

- plow;

- sow;

- to harvest;

- serve in public utilities;

- work like a pump.

- depth of penetration into the soil up to 21 cm;

- the grip can be realized up to 130 cm;

- The set includes 6 cutters;

- turning radius 112 cm;

- cutter diameter 37 cm;

- traction force 172 N;

- dimensions LxWxH, meter – 1.75 by 0.66 by 1.4;

- operation is permissible at temperatures from – 26 to 39 degrees Celsius.

In the cold season, it is necessary to drain the “summer” oil and fill in the “winter” oil. It is unacceptable to use the wrong oil, this will lead to damage to the unit, the same statement applies to fuel. American power plants are extremely picky about the purity of gasoline. It is better to filter domestic fuel before pouring it into the tank of a walk-behind tractor .

The unit service package includes:

- running in the engine and tuning it;

- adjustment of gearbox and transmission;

- adjustment of attachments;

- preventative maintenance and testing;

- timely oil change.

Checking the ignition coil

Before you check the ignition coil of your unit for possible problems, you need to understand exactly what it looks like in a broken state. First, the farmer should conduct a visual inspection. Often, breakdowns are caused by cracks, dents or similar mechanical damage occurring on this spare part. If there are no such problems, the coil is intact, without visible defects, some additional checks of this element will be required.

To do this, you need to know how to disassemble a walk-behind tractor and at the same time study ways to troubleshoot problems and their causes.

The test is to change the coil resistance readings. This is interesting: why does the Cascade walk-behind tractor have no spark?

This technique is not the most popular today, since not every farmer has information about what the optimal winding resistance parameter for an existing unit should be. Another difficulty in testing may be due to the fact that the resistance indicator includes semiconductor elements used to generate the required high-voltage pulse. Against the background of this situation, when trying to ring the coil of a motor cultivator through a high-voltage or negative wire, a person will receive a resistance value that is too high, unless a circuit break occurs before this.

Another way to check ignition system parts is to use a spark plug. To do this, turn it out and attach it to the cylinder. Next, you need to pull the starter cable and see if a spark forms between the contacts. At the same time, the master must understand that such a technique will not allow one to accurately determine which of the elements is the cause of the breakdown.

This is due to the fact that during the test, the spark plug is under some pressure, due to which the flywheel is able to rotate faster than usual. Each of the above methods is advisable to use only in cases where the farmer does not have the opportunity to contact a highly qualified specialist. To do this, a person must have skills in working with electricity, otherwise there is a risk of electric shock.

Characteristic features of the device

Motoblock "Luch" Motoblock MB 5040 "Luch", of course, is very far from ideal. Although, all modifications of this walk-behind tractor are far from it. Many details require improvements, such as the muffler, which its owners eventually change to a quieter one - the noise during operation is really quite disturbing.

Some small, but very important parts are made of not the strongest materials - duralumin connecting rods can quickly fail and interrupt field work, which is completely dependent on the walk-behind tractor. But there are no less positive aspects in the operation of this technology.

Its low cost, thanks to which “Luch” and similar walk-behind tractors Cayman, Texas, Foreman, Viking, Forza, Sadko outperform more expensive modern equipment, immediately attracts attention.

Manufactured in accordance with GOST, these walk-behind tractors are as strong as steel, because, oddly enough, they are made of steel that is quite strong and of high quality - the small and not the most powerful MB 1, if necessary, can cope with a load weighing up to 900 kilograms.

For more information about the MB 1 walk-behind tractor, watch the video:

The same applies to cultivating the land - no matter how “heavy” it is, he will cope with the task , although it will take time. But, when starting work, the Soviet walk-behind tractor requires setup and minimal maintenance, especially after a long period of inactivity. However, like any technology.