The overall efficiency of the entire mechanism depends on each of its individual parts. In the case of a modern electric jigsaw, with a relatively complex design, this is exactly the case. Each element of this device is designed to perform a specific function for the sake of the overall result - performing a controlled cut. If problems occur on one of the mechanism components, the performance of the tool may decrease, down to zero. To return your device to service, it is enough to find and eliminate the “weak link”. We will tell you further how to repair a jigsaw with your own hands and reduce further wear of its parts.

Design and principle of operation of an electric jigsaw

To learn how to identify and troubleshoot a mechanism, you must first understand how it works.

The numerous components of a jigsaw design may seem quite difficult to understand at first glance. In fact, the operating principle of this device is very simple, especially for those who know at least a little about technology. Next, we will tell you how an electric jigsaw works, outlining the main points in the most popular language, understandable even to an inexperienced reader in electrical engineering. The mechanism of any electric jigsaw is based on an electric motor, gearbox and rod. These are the main elements that force the file to make the necessary movements. Often a cooling fan and a pendulum mechanism are connected to the engine. The function of power supply and in some models of speed control is performed by a special start button with an electrical circuit. All of the above elements are compactly and securely placed in a plastic case, interacting with each other.

To obtain high-frequency reciprocating movements of the saw blade, the energy supplied to the power tool undergoes significant transformations in its body. Bypassing the start button, electricity passes to the graphite brushes of the motor, causing the rotor to rotate around its axis. The torque is transmitted to a special “gearbox” mechanism, which converts the movement from rotational to reciprocating, directing it to the rod. The final unit is a fastening element that reliably connects the rod to the saw blade, forming a strong movable structure.

Types of faults

Prolonged or improper use of the tool can most likely cause it to break. A malfunction of the device occurs as a result of excessive contamination, wear of mechanism parts, or a short circuit of the electric motor. Repair of a jigsaw, depending on the nature of the breakdown, boils down to cleaning and lubricating the elements, or completely replacing them. Below, we will look at the most common types of breakdowns.

Mechanical problems

This category includes contamination, wear, or complete breakdown of mechanism parts.

The engine of the tool is running, but it is not possible to obtain the required cut. There may be several reasons for mechanical breakdowns that require repair of jigsaws. Here are the most typical ones. The jigsaw cuts crookedly

A significant deviation of the fork blade away from the intended line is often associated with the saw attachment mechanism or the rod. The reason for this may be severe contamination of the parts or their wear. To correct the situation, you need to remove the parts, clean them with a rag and put them back together. If the problem persists, the stem or fastener should be replaced.

Severe vibration and noise

Strange noises that are not typical for a running power tool usually come from a faulty gearbox. This may be due to lack of lubrication, contamination or breakage of the gear teeth. To find out the exact cause and its further elimination, it is necessary to remove the side part of the case and visually inspect the mechanism for the presence of the above problems. In case of breakdown, the mechanism should be replaced with a similar one.

The jigsaw hits when cutting

Regular jolts of the tool during operation may be associated with the pendulum mechanism or the rod. The reason for this is mainly damage to parts, and in rare cases, severe contamination. To repair a jigsaw with a similar malfunction, it should be disassembled, the faulty unit should be identified and replaced with a similar one. If there is no obvious damage, all parts should be completely cleaned and lubricated.

Engine malfunctions

Oddly enough, numerous jigsaw breakdowns occur not only on moving parts, elements interacting with each other. Very often, a device stops functioning (partially or completely) due to damaged electronics. To identify such faults, you need a special “multimeter” device that determines the characteristics of the current in the device circuit. It is necessary for a complete diagnosis, although some problems can be identified without it.

The jigsaw does not turn on.

The complete lack of vital activity of the tool is due to the lack of contact between the motor and the network. The reasons for this problem lie in the wiring or the start button. To identify a malfunction, it is necessary to completely inspect, or better yet, ring the instrument cable and internal wiring. The functionality of the button is checked by connecting the wiring directly to the motor. If the tool works when plugged into the network, then the problem lies there. The faulty contact must be replaced.

Doesn't cut under load

At first glance, the working tool is completely unable to cope with once simple tasks and slows down even on materials of small thickness. Significant loss of power is associated with engine damage. The jigsaw anchor, due to a short circuit, does not create a sufficient rotational impulse, creating the illusion of work. Typically, an instrument with such a breakdown sparks and emits a characteristic burning smell. To accurately determine the location of the short circuit, parts of the stator and rotor of the motor are alternately tested with a multimeter. The solution is to replace the damaged part or the entire motor.

Floating speeds and a burning smell

When, during operation, a tool periodically loses its strength, reducing its power and accompanying all this with a burning smell, it is worth paying attention to its wiring. To identify a weak contact, it is necessary to remove the housing cover and visually inspect all wires and their connections for defects. It is better to do this using a multimeter, paying attention to the start button and the motor windings. To restore the integrity of the circuit, the conductors should be replaced or the charred contacts should be cleaned.

Sparking brushes during operation

The abundant formation of sparks that occurs in the commutator area during operation of the tool can be associated not only with a malfunction of the engine, but also with a defect in the graphite brushes. In the modern world, this component is one of the most frequently replaced parts when repairing equipment, so many jigsaws have special grooves for quick and convenient removal. You can make the replacement yourself. It is enough to disconnect the old brushes from the contacts and connect new ones in their place.

Characteristic

The manufacturer of the instrument in question is Simferopol, created in 1913, named after the Sevastopol cape. An important feature of the power tools produced by the plant, including jigsaws, is their high reliability, achieved through a combination of high-quality materials and thoughtful design solutions that have stood the test of time.

Another important advantage of Crimean-made tools is the availability of spare parts on the Russian market and the presence of an extensive network of service centers. Thanks to this, it is usually possible to repair a damaged instrument within a few days from the moment of breakdown.

The entire model range of the company is designed for use both for cutting wood and for processing plastics, ceramics and metal (both aluminum and steel). This versatility is achieved due to the fact that, at a similar cost, the company’s products are characterized by noticeably greater power than competitors’ products.

Read also: Steel cast iron carbon content

The cutting speed is controlled by changing the force of pressing the start button, which significantly facilitates the operation of the tool, although it requires certain skill from the craftsmen. The power button is also equipped with a lock that allows you to lock the tool in the on or off state.

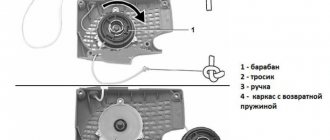

Replacing the rod

The procedure for removing a damaged rod and installing a new one is quite trivial and boils down to a banal disassembly of the tool. Depending on the design of the jigsaw, you can access the element by unscrewing the front panel or the side panel, if the first is missing. The faulty rod is removed and a new one is installed in its place. When installing, pay attention to the moving metal parts located on the base of the rod. They must be positioned in such a way that they fit into the grooves of the upper fastening and the metal frame that serves as the base of the rod. The assembled structure must be generously lubricated with a thick lubricant such as litol-24. A more visual demonstration of replacing the rod can be seen in the video below about repairing a fiolent jigsaw with your own hands.

How to use: operating instructions and safety precautions

- If the cutting speed needs to be increased, there is no need to put pressure on the jigsaw handle and “adjust” it. It is better to adjust the rotation mode of the motor and pendulum. The correct selection of the file is also important.

- The workpiece must be securely mounted on the workbench. You should never saw while holding the workpiece suspended in your hands. Good fasteners will give good results - cutting accuracy, speed and quality of sawed edges.

- Straight cuts are made using a ruler that is included with the jigsaw (linear clamp).

- Round holes and curved lines on thin plywood or plastic are cut better when the jigsaw is secured with the blade up and the part is fed to the cutting tool. Smooth circles can be made using a circle cutter.

- Making a cut on a thin metal surface is much more convenient if you put plywood under the sheet. This will prevent the edges of the metal from deforming.

- If there is a noticeable decrease in sawing speed, it is recommended to immediately replace the saw blade. Prolonged use of a dull blade will cause engine overheating with all the ensuing consequences.

- If the cut needs to be made at an angle, the support sole is shifted by the required number of degrees.

- When working in cold weather, it is advisable to run the engine at idle speed for 1–2 minutes. After this, you can work in load mode.

- Take breaks from work whenever possible. Stop for 5-10 minutes every half hour.

We also list the basic safety rules.

- When working, it is recommended to wear work clothing that does not have fluttering hems or dangling sleeves. Hair must be tucked under a headdress. Body position is stable.

- Do not slow down the movement of the saw with your hands or a clamp.

- It is unacceptable to leave a switched on and working tool unattended.

- Use the tool only for its intended purpose. Do not hammer nails with a saw.

- If you discover damage to the housing or other functional breakdowns, you need to stop working and fix the problem.

- The power cord can only be turned on and off when the engine is off.

- Do not allow minor children to play with the instrument. Is it dangerous.

With practice and experience comes knowledge. But at first, a novice user will need information on how and with what to cut different parts.

- Wood, plywood and laminate are the main materials that a jigsaw is designed to cut. If the cut is rough, you can use high speeds and oscillations of the pendulum. This will increase speed, but reduce quality and accuracy. Precise sections, depending on the density of the material, are sawed at medium speeds, with the pendulum turned off. This is especially true for laminate if it is precisely adjusted. On a six-point scale - 5.6.

- Metal parts, including pipes, are cut at low speeds without turning on the pendulum (or use the pendulum at low speed). 1.2 speed. Corrugated sheets and sheet iron are sawed at speed 1, making sure that the edges do not curl. For aluminum and other non-ferrous metals, the speed can rise to 3–4 levels.

- Plastic and plexiglass can be cut at high speeds, but care must be taken to ensure that the material does not melt. 4–6 on a six-point scale.

- Ceramic tiles, as well as other hard types of stone cladding, are processed at speed 4–5. The pendulum is installed in the initial positions.

- Drywall can be cut at high speed and with maximum swing of the pendulum. A natural limitation is the level of dust. If cutting occurs indoors, the dust from cutting can be very high. And so the speed is reduced.

Laminate is cut at high speed with the pendulum mechanism turned off

Replacing the saw holder

Replacing some types of fasteners is much easier than finding these parts. To perform a similar operation with block and screw clamps, you do not even need to unscrew the tool body. Saw holders of this type are attached to the end of the rod using one or two screws, which makes it quite convenient to change them. In the case of some screw fasteners, replacement will require removing the rod to more conveniently and securely fix the holder. The video below about repairing a jigsaw with your own hands clearly demonstrates the process of replacing the shoe-type fastening. If things are relatively simple with simple saw holders, then replacing a quick-clamping one can cause some difficulties, especially for an inexperienced craftsman. Let's start with the fact that these types of fastenings, according to the location of the levers, are divided into radial, lateral and frontal. The first type is the most common and spare parts for its repair can be found, but the last 2 are unique, which can be ordered directly from the manufacturer. In the case of a radial type of fastening, you can purchase a repair kit and try to sort it out yourself, but it would be best to buy it assembled, along with the rod.

Replacing brushes

Due to abrasion or burning of contacts, jigsaw brushes very often become the main contenders for replacement. In some models of power tools, this operation does not require removing the housing and occurs simply by unscrewing a pair of bots. Unfortunately, the quick access function is not provided on all models, so we will consider a more common option.

First of all, you need to gain access to the electric motor. To do this, we disassemble the housing or remove a certain part of it. Next, in the collector area, we look for brushes and study the principle of their fastening. On different models of instruments, the fastening of these elements can vary significantly. In some places they are pressed against metal plates, in others they are latched with special levers, and sometimes they are even held in place by the body of the instrument. The replacement process itself is not some incredibly complicated DIY jigsaw repair. It is enough to carefully remove the defective brushes and replace them with new, identical ones. This process is clearly demonstrated in the following video.

Replacing the start button

When the tool stops responding to the power supply command, the first thing to do is check the start button by ringing it with a multimeter. Having confirmed that the element is faulty, disconnect its contacts and remove it from the housing. At this stage, there are 3 options for the development of the event:

- You can try to disassemble the button and repair it yourself.

- Connect the wires directly and start the tool by plugging the plug into the outlet.

- Look for a suitable button in specialized stores or markets and replace it.

If you choose the latter option, all the difficulty will be in the search, since the trigger must be absolutely identical to the standard one. Perhaps you will be lucky and the necessary element will be found in the nearest store. It all depends on the location and model of the instrument. The installation process is exactly the same as removal, only in reverse order. We connect the wires to the contacts and tighten the device body.

If you want to repair the jigsaw button yourself, we recommend that you watch the video below, which demonstrates this process in great detail.

Rating of the best reliable jigsaws

| Place | Model | ||

| 1. | Makita 4329 450 W | Prices | Review |

| 2. | BOSCH PST 900 PEL 620 W | Prices | Review |

| 3. | BISON L-570-65 570 W | Prices | Review |

| 4. | Fiolent PM 5-750E M 750 W | Prices | Review |

| 5. | Interskol MP-55/500E 500 W | Prices | Review |

Tool prevention

The long service life and constant efficiency of the tool depend not only on the characteristics of its operation, but also on timely care of its mechanism. Regular preventative measures will significantly reduce the wear of parts, reducing the likelihood of serious breakdowns.

Carrying out such a procedure requires only a screwdriver, a piece of rag for cleaning and a little grease. The whole process takes no more than an hour and consists of disassembling the jigsaw and carefully cleaning its parts. The gearbox and rod assembly must be cleaned and lubricated most thoroughly. Prevention should be carried out as the tool becomes dirty, based on the frequency of its use.article from the Rating section

- 80

Power tools Repair and modernization Carpentry tools (for wood) For working with metal

Save this page on your social media. network and return to it at any time.

ADD A COMMENT

Jigsaw Metabo: ideal in quality, but difficult to repair

One of the best jigsaws on the world market are models from the German company Metabo. Everything about it is good. High power, aluminum body, pendulum device. In addition, the tool is equipped with electronics that allow you to configure the jigsaw to individual programs for each type of cut. And the cut is simply perfect both in quality and straightness. The Metabo power tool is the best jigsaw to date.

But not eternal. Breakdowns happen here too. The reasons can be very different. But as practice has shown, the weak point is the mechanics. After significant loads, and in particular, sawing metal, it may fail.

As a rule, the axle on the bearing bracket, lever and rod do not support. To restore the instrument, it is better to purchase all original spare parts and carry out the assembly at a service center by specialists.

When assembling a Metabo jigsaw yourself, you must apply Castrol LMX lubricant to all rubbing surfaces with the addition of RiMET grease in a 3:1 ratio.