History of the device

A screwdriver is a power tool. Its main purpose, as the name suggests, is to tighten or unscrew a fastener. After the electric drill was invented in 1868, the development of power tools became widespread. Founding companies DeWalt, Bosch, Black & Decker, Makita and Hitachi developed the industry by creating new devices.

The introduction of the Phillips head screw in 1934 created a demand for electric tools to tighten them. It was especially in demand in mechanical engineering. The first device of this kind was called a wrench. With the advent of batteries, the device gained mobility, and the name screwdriver came into use. Its mass production began in the early 80s .

Modern devices are constantly improving, but to a greater extent this relates to the method of autonomy and control. The design of the device remains unchanged.

Operating principle and main components

Before you start repairing a screwdriver with your own hands, you need to understand the principle of its operation and what parts it consists of. The main difference between a screwdriver and other power tools is the use of a mechanism that stops the rotation of the working part of the device. This happens when the maximum resistance configured for the instrument is reached. This value is not constant and can be adjusted. There are two types of device:

- operating from a 220 volt network;

- using a rechargeable battery.

Regardless of the type of device, their operating principle is the same and is based on the transmission of torque. It determines which fastening tool the screwdriver can tighten. To increase torque, devices use gearboxes with a large gear ratio, but the rotation speed is reduced. For screwdrivers operating on AC power, the torque value is related to the power consumption of the tool. The main parts underlying the device of a screwdriver, be it Makita, Hitachi or Bison, are as follows:

- electric motor;

- push button;

- speed controller with reverse;

- chuck;

- the electronic unit;

- gearbox

The electric motor rotates the spindle at a set speed using a planetary gearbox. The torque is controlled by a clutch, and a chuck or hex holder is placed on the spindle. A replaceable device called a “bit” is installed in this cartridge. The screwdriver is controlled by an electronic circuit and reverse switching .

Reverse occurs by changing the polarity of the power supply. The motor is a single-phase continuous current commutator motor. This motor is designed to be connected to an alternating current network. The field winding is connected in series with the armature winding and is divided into two parts. One turns on before the anchor, and the other after it.

Light and powerful - it's Hitachi! Super screwdriver for finishers.

Greetings to all visitors to the site, we continue to disassemble the tool and today we have a professional screwdriver from Hitachi. This model DS12DVF3 is selling out in droves, and in this article I will tell you why. The most important thing is that the tool is professional, so it can withstand decent loads, so there is no point in buying one for home. So, a full review with photos, as well as reviews from our customers.

Technical characteristics and equipment:

Power supply - 12 Volts The screwdriver comes in a convenient suitcase Number of batteries - 2 Convenient charger indicating when the battery is charged Convenient folding flashlight powered by the same batteries Small case with bits Torque - 26 Nm Battery capacity - 1.3 Ampere/hour Accelerated battery charging 30 minutes

So, why is this Hitachi screwdriver model so popular? In fact, there are a lot of advantages here, let's figure it out.

Advantages of the tool.

1. The screwdriver is very light and compact; if you use it all day, then convenience and weight are decisive. That is why it is so loved by finishers and craftsmen who work as a screwdriver all day long. Fits in your hand like a glove.

2. Accelerated charging - only half an hour. Of course, the first 3-4 times it will take about an hour to charge, and then the charging speed will increase. Very convenient, no need to wait 3 hours like other models.

3. There are two batteries, which means there will be no downtime; while you work with one, the second one is charging. And it charges quickly.

4. The rubberized body really protects against damage from falls. Recently, an acquaintance of a finisher came in and got to talking, so they all work with Hitachi screwdrivers, accidentally dropped them from 2 meters - the “Shurik” just bounces on the floor. You pick it up, insert the fallen battery and continue working. Other models have also been dropped, in particular Bosch, it is not rubberized - it breaks.

5. A good set of accessories - a set of bits and even a flashlight powered by the same batteries. The thing is convenient and useful.

6. Convenient charger - shows with the help of diodes that charging is in progress and that the battery is charged.

7. High torque - 26 Nm, 3 times more than that of household models, which means that such a small screwdriver can even twist roofing screws. By the way, all professional models have high torque compared to household ones. I recommend reading my article on how to choose a screwdriver. Adjusting the torque is convenient, everything is clearly visible and understandable.

Another note: Professional grinder for 1,500 rubles - what's the catch?

8. 2 speeds, so in addition to tightening screws, you can drill anything, especially drilling tiles is very convenient.

9. And of course, its price is also a plus, low compared to similar professional models from Makita and Bosch. A screwdriver costs 3,300 rubles. Makita and Bosch with the same characteristics are at least 1000 rubles more expensive.

However, not everything is as rosy as I described, there are also disadvantages, or rather there is only one - batteries. According to numerous reviews from our customers, Hitachi batteries fail very quickly. But there is one caveat!!! First of all, the age of the batteries is to blame; there was a batch of batteries from 2009, and they were sold in 2011, so they broke down very quickly. So, first of all, when you decide to buy a Hitachi screwdriver, ask the seller what year the battery is. According to reviews from customers who bought a Shurik with batteries from 2011 and worked for a year, everything is just super, the batteries last a long time and reliably. In general, this model of screwdriver is simply wonderful; it is a bestseller in many stores. So I definitely recommend it.

Disassembling a screwdriver

Most often, in order to find a fault and repair the device, you will need to disassemble it. Since all devices are similar in appearance, resembling the shape of a pistol, their disassembly can be presented in the form of recommendations given for repairing an Interskol screwdriver:

- First of all, the battery pack is disconnected. To do this, you need to press the latch and unfasten the module.

- Unscrew all the screws around the perimeter of the device using a Phillips screwdriver.

- After unscrewing the screws, the two halves of the housing are separated, while holding the structural parts installed in the grooves.

- The speed switch, start button and reverse mechanism are carefully disconnected.

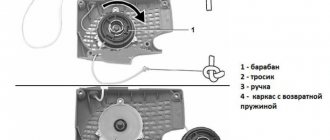

- The gearbox is removed from the removed half. To remove it, you will need to rotate the gearbox in its seat.

Assembly occurs in reverse order . In this case, it is necessary to ensure that all removed elements and wires are located in specially made recesses for them.

To lubricate the mechanical parts or restore the gearbox, the latter often has to be disassembled. To do this, first remove the protective plate, then unscrew the screws in a circle and remove the top cover. Viscous materials, for example, Litol, are used as lubricants. It is important to note that it is almost impossible to carry out serious repairs to a screwdriver gearbox with your own hands, since gears are not produced separately by manufacturers. Therefore, if it is damaged, you will have to replace the entire unit.

Positive reviews

Many users are satisfied with the ergonomics of the presented screwdriver. It has a rubberized body that fits well in the hand.

It is also noted that even with prolonged use, this equipment does not heat up thanks to the coating provided in the motor area. Thanks to this feature, the screwdriver is used in professional activities.

Among the positive user reviews, the presence of a flashlight should be noted. This element adds convenience when working in dark rooms. It is enough to illuminate the place of work and the entire room as a whole.

The presence of a hook adds to the ease of use, which is appreciated by users carrying out the construction and repair process on the roof. This element is not inherent in every screwdriver. The presence of a hook is provided in fairly expensive models. Considering the low cost of the presented screwdriver, such an element became a pleasant surprise for many.

The Hitachi DS12DVF3 screwdriver has a fairly low cost and good quality product. By correctly choosing and using the presented tool, you can count on its durability and high quality of work performed. Many users, both professionals and amateurs, have appreciated this model of screwdriver. This is evidenced by a lot of positive reviews about it.

Finding the cause of the breakdown and eliminating it

The final breakdown of a tool is often accompanied by preliminary events, by paying attention to which you can prevent a serious malfunction: the appearance of extraneous sounds, sparking, burning odors, increased vibration, rapid battery discharge.

By disassembling the device, you can understand which unit is faulty. All device problems are divided into two types:

- electrical;

- mechanical.

Each type has its own primary characteristics, by which the damaged part can be easily determined. A special type of problem is related to the battery. The nature of the failure is due to the fact that the battery is quickly discharged, or the device does not want to start at all.

If purchasing a new battery is problematic, you can try to disassemble it and replace the faulty element.

The battery is disassembled by removing its latches from the grooves. Under the casing there are elements with a container. Their connection to each other is made by contact welding. You can use a multimeter to measure the voltage on each bank. The normal value of a charged cell is 1.2 volts. Faulty elements are removed - to do this, they are carefully bitten off with pliers at the point of contact, and similar ones are installed in their place. If there is no welding, you can use a soldering iron. Then the battery must be assembled and installed in a screwdriver for testing .

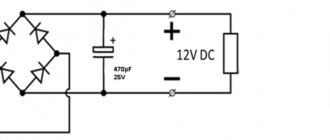

But the problem is not always related to the battery. For example, when repairing a Bosch screwdriver with your own hands, you often find damage to the charger circuit, not the battery. Repair of the charger consists of testing the radio elements. First of all, the mains fuse and rectifier bridge are checked.

Usually, when opening the charger case, external signs in the form of blackening of radio elements or a PCB board immediately show which element requires replacement. Most often, transistors located on radiators and the operational amplifier fail.

Electrical damage

Most often, malfunctions in the electrical part are associated not only with the inability to turn on the tool, but also with the lack of switching to reverse mode or the ability to adjust the speed.

Battery

The screwdriver uses nickel-cadmium (Ni-Cd) batteries. Each of them contains 10 elements, and the capacity, depending on the modification, ranges from 1.2 to 2.0 ampere-hours. Such removable batteries are capable of producing 12 volts. The presence of an additional battery and timely charging allow you to use the unit without any time restrictions, with the exception of technical breaks.

When charging, you must follow certain rules. This process should occur at an ambient temperature of 10-40 degrees. If the temperature is below the set limit, overcharging is possible, causing damage to the battery. At temperatures above 40 degrees, the battery will not charge at all.