Are your nickel-cadmium batteries no longer holding a charge or not wanting to charge at all? Is it possible to restore a screwdriver battery?

What do you do with batteries when they die? Do you just throw them in the trash (which is harmful to the environment), or do you recycle them?

The best solution would be to bring dead batteries back to life, which will save you from unnecessary expenses and the environment from pollution.

One way to restore nickel-cadmium batteries is using a welding machine. But not everyone has such a device... Therefore, we need to choose another way to repair a screwdriver battery at home.

ATTENTION! You will have to open the device, which has a dangerous voltage of 300 volts. Therefore, you must be very careful and follow safety precautions when repairing a screwdriver battery with your own hands.

Adding distilled water to nickel-cadmium batteries

One of the most common problems with Ni-Cd batteries is evaporation of distilled water. Most often occurs when the battery overheats. To solve the problem you need to:

- Disassemble the battery.

- There will be small batteries inside (about 14 pieces, depending on the screwdriver model). Using a multimeter you need to find the failed part. The voltage on the working “barrel” will be in the range from 1 to 1.3 volts. Anything below this mark requires repair.

- Faulty items are carefully removed. The plates that attach them to other batteries will be useful for assembly later.

- On the side, closer to the top or bottom of the battery, there is a bend where you need to make a hole with a diameter of no more than 1 mm. You only need to drill the wall, without going deep inside.

- Now you will need a syringe with a needle and distilled water (in no case ordinary tap water). The syringe is inserted into the hole made, and the battery is filled to the brim. It is advisable for it to remain in this state for a day.

- The device charges nickel-cadmium batteries (IMAX is suitable), after which the battery must be allowed to sit for another week.

- After 7 days, check to see if the voltage has dropped. If all is well, you need to seal the holes using silicone or a soldering iron.

- Next, the batteries are assembled in reverse order and placed in the battery case. For soldering, spot welding or a regular soldering iron is used.

- After checking the functionality, the battery is completely discharged under light loads and charged again at least three times.

Read also: The best way to pinch geese

Lithium-ion (designation – Li Ion)

Installed on professional or semi-professional screwdrivers with high intensity of use. Battery repair for Hitachi screwdriver. How to redo it. Such batteries

used by famous domestic manufacturers in models of the mid- to high-price segment. The operating voltage of a serviceable, uncharged cell is 3.6 volts. Advantages:

Read also: What oil for hardening knives

- No memory effect

Recharging can be performed at any percentage of discharge.

Self-discharge is practically absent

Of course, store it in a charged state for a long time.

Therefore, when calculating the cost, it is worth studying this characteristic.

High voltage per cell makes the battery more compact and not lighter

Battery restoration by replacing several elements

Restoring a screwdriver battery by replacing several elements can be successful for all types of batteries. It also does not pose any risk to them, as does manipulation with distilled water, provided that care is taken during soldering.

Read also: Electric motor speed controller

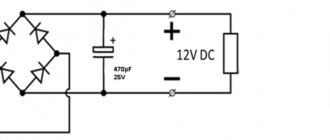

First, the output voltage of each “can” is measured using a multimeter, which in total should be 12-14 V. Accordingly, the voltage of one “can” should be 1.2-1.4 V. The U indicators are compared with each other, the most weak elements. Read more about how to check a screwdriver battery with a multimeter →

After this, the battery is inserted into the screwdriver and works until the moment when the power begins to noticeably decrease. The voltage readings are taken again, and those “cans” whose voltage difference is 0.5-0.7 V compared to the “stronger” ones should be desoldered, disposed of and replaced with new ones, similar to the old ones, having previously ordered them from the online store.

It is recommended to solder the battery chain using spot welding, but if this is not available, there is nothing left to do but use a regular soldering iron and do everything as quickly and accurately as possible, in order, if possible, to prevent the battery from overheating.

The “original” battery connecting plates should not be lost; they must be soldered back without reversing the polarity. In addition, all elements of the chain must have the same capacity.

After soldering is completed, insert the battery back into the screwdriver and carry out 2-3 complete charge-discharge cycles to equalize the energy potential of all batteries. In order for the updated battery to last longer, it should carry out such training 2-3 times a month. How to quickly and completely discharge a screwdriver battery →

Types of batteries used in screwdrivers and their differences

As you know, the battery of any screwdriver includes several batteries that are connected in one chain in a certain sequence. There are nickel-cadmium (Ni-Cd), nickel-metal hydride (Ni-MH) and lithium cells.

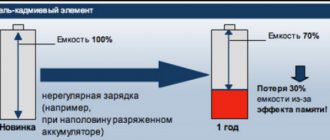

Nickel-cadmium batteries, in this case, are the most popular and frequently used. The voltage of each individual cell is 1.2 Volts and the capacity is 12000 mAh if we have a 12 Volt tool. It’s worth noting right away that, unlike lithium ones, they can be restored because they have the so-called “memory effect” in the form of a reversible loss of capacity.

Read also: How to repair an angle grinder's anchor

As for batteries that contain lithium, it is unlikely that it will be possible to restore their capacity using the popular Imax B6 charger - due to the fact that lithium tends to decompose over time.

Restoring a screwdriver battery in a similar manner may also not be successful for cadmium batteries. Such a battery differs in that the electrolyte in them sometimes completely boils away. However, in the case of cadmium batteries, the chances of “reanimating” them are much greater. But at the same time, it is important not to rush and not to rashly use common methods of “quick recovery” of Ni Cd batteries. Read more about which battery is best for a screwdriver →

How to restore a Bosch screwdriver battery

Bosch screwdrivers are perfect for non-professional use. They contain batteries with Ni-Cd cells. They can withstand high load currents, but quickly self-discharge (in 3-4 weeks). They must be restored at least once a month to prevent them from breaking down. In addition, during operation, the elements become unbalanced and capacity is lost over time.

One of the restoration methods is to disassemble the case and “train” each element separately. If this doesn't help much, some of them will have to be replaced. Then the battery will last for a long time.

Restoring a screwdriver battery by purchasing new Ni-Cd cells

In this case, we are talking about a complete replacement of battery cells and the so-called “erasing of the memory effect” from new batteries in order to ensure their more productive operation. The memory effect is that the battery “remembers” all possible charging cycles that it could theoretically be subjected to in production before it falls into someone’s hands. The more such cycles in its “memory”, the more likely it becomes that the capacity will begin to decrease much earlier than expected. Also, nickel-cadmium batteries love similar “boosting” processes. If they are carried out immediately before use, they will work much better.

The required number of batteries can be ordered online, for example, on Ali-Express. You need to keep in mind that they already have a certain factory charge, which it is advisable to “remove” in order to “save” the battery power during operation. This can be done using the same Imax B6 charger, the menu of which is easy to understand.

Let's say the screwdriver battery should consist of 10 elements with the following indicators: the output voltage of each is 1.2 V, and the capacity is 1200 mAh, which is a total of 12 V. The advantage of completely replacing the battery with subsequent “erasing” is that In any online store you can order elements with higher capacity than the old ones. For example, 1800 mAh. And the battery will last an order of magnitude longer. Of course, such batteries will be more expensive. But their price always justifies itself.

First, the voltage on each “bank” is checked with a multimeter. This will immediately help determine what quality the new batteries have and whether there is dishonesty of sellers who could sell old elements instead of new ones. The voltage level on each battery should be approximately 1.3 V. When taking measurements, it is important not to confuse the terminals.

Next, “memory erasing” is carried out with each element in turn. The following charging parameters are set on the charger: if the capacity is 1800 mAh, it can be set a little more - 1900, with a little margin. Then you should switch to the charging mode for nickel-cadmium batteries. The charge parameters should be as follows: current indicator 0.9 A (half of the capacity of 1800).

Each new element is subjected to training according to the “charge-discharge” principle in order to remove the factory parameters. At a current of 1A, all batteries are discharged one by one to a voltage of 1 V (the minimum permissible voltage so as not to kill the battery).

Then you should switch to the “charge-discharge” cycle mode and start it with the “start” button. After discharging and removing the factory memory, put the batteries back into the block, focusing on how the old ones were placed there before. Therefore, when disassembling the plastic case, you need to remember how the batteries were stored before.

Thus, there are many ways to restore a screwdriver battery with your own hands. Each of them has certain nuances, disadvantages and advantages that should be considered depending on how you restore capacity. Sometimes you should try to purchase a particular tool or necessary ingredient (for example, distilled water) in order for the restoration to be as successful as possible. But this is exactly what will help you avoid additional costs in connection with the purchase of a new screwdriver or a completely finished battery.