Drill hole: features

Drills are used exclusively for working with a hammer drill. They are not used for drills. There are a number of different types of drill bits available, depending on the material you plan to work with. Metal, masonry and wood can be drilled using specially designed structures. They are adapted to the properties of a specific material and will help achieve the desired result with minimal effort and time. The range of drills also includes special products, for example for creating holes in glass surfaces or tiles. For these purposes, manufacturers produce drills with diamond tips made of tungsten carbide.

The quality of drills is determined by the material from which they are made. Accordingly, the type of material that they can drill is determined. Most often, drills are made from materials such as high-speed steel, with the addition of carbide, titanium, cobalt and other substances that improve the properties of the material.

Drills differ in the type of shank. Thus, straight shanks are used for chucks with and without a key for holes with a diameter of 10-13 mm. SDS shanks are used for corresponding rotary hammers. Hex shanks are used for screwdrivers.

Drills for stone and metal can be spiral-shaped, drills for wood can be twisted or flat. Drills come in different diameters and lengths. Extensions can be used if necessary.

How to choose a drill

Before considering the rating, we will mention several key parameters that should be taken into account when choosing drills. Combined with information about the best manufacturers, this will help you choose the best product for your specific needs. Drills are selected paying attention to:

- Suitability for materials

. Products are produced separately for wood, concrete, glass, ceramics and metal. The equipment is not interchangeable, therefore, only drills suitable for it are used for a specific material. - Color.

The tool is made of high-speed tool steel, which has a silver color. This is the cheapest, but short-lived option. Black drill bits are steam hardened and keep their cutting edge sharp longer. The bright gold ones are coated on the outside with titanium nitride, which reduces friction and increases strength. The pale gold ones were hardened, but the internal stress was removed, eliminating the brittleness. - View of the cutting part

. The edge is sharpened at a different angle, depending on the diameter of the drill, and can be triangular (spiral) or with a centering rod (trident). The latter is necessary for quick drilling without punching. Drills with crowns help create a large-diameter hole for inserting a lock, etc. Pen tips are used for wood and fast passage of thicknesses of 5-15 mm. Diamond ones are applied to a tubular base and are suitable for glass and tiles. - Labeling.

There is a marking on the shank indicating what the drill is made of. HSS refers to conventional high speed steel. Prefixes in the E, Co, TiN index indicate various additives in the form of cobalt, titanium, etc., which increases strength and resistance to overheating. The CV specifies chrome vanadium steel. - Type of working part.

The body of the drill can be cylindrical in the form of a spiral (for creating through holes), conical (for deepening or quickly drilling shallow holes of different diameters), stepped (instant transitions to different hole diameters when drilling sheet steel without changing equipment). - Shank

. The cylindrical type is suitable for hand drills and screwdrivers. Conical is used only for machine tools. Cylindrical with grooves, suitable for installation in hammer drills with SDS-Plus and SDS-Max chucks. The hexagon is inserted into a screwdriver with a similar chuck instead of a bit. The three-edged cylinder is clamped by the three-blade drill chuck and prevents rotation when resisted against viscous material. - Diameter

_ Drills with diameters from 1.0 to 55 mm are produced. The equipment can only be inserted into an electric drill chuck with an indicator of 13 mm; all the rest are suitable for machine tools. The diameter is selected taking into account the future hole that needs to be obtained. When drilling 10 mm in size, the finished hole will be 11 mm, because 1 mm is “eaten up” due to active rotation. - Length

_ Selected depending on the required hole depth. The indicator varies from 3 to 90 cm.

How to choose metal drills?

To start working with a drill, you need to determine the characteristics of the metal that you will drill. All metals have different levels of density. The density of the metal determines the design of the drill, as it must be harder than the metal into which it is pointed.

Manufacturers take this rule into account, so they are made from different materials containing different elements to increase hardness and improve cutting ability. Conventionally, there are two groups of metal drill materials:

- made of high-speed or alloy steel: it is an alloy consisting of a metal element combined with a chemical element that gives the steel certain properties;

- made of hard metal or carbide. powdered forms of tungsten carbide are heat treated with binder metals such as titanium or cobalt to produce a solid.

Set SDS-plus DeWALT Extreme 2 DT9701-QZ

Photo: market.yandex.ru

A set of drills DeWalt 9701 series EXTREME 2 chambered for SDS-plus cartridge, characterized by a carbide tip made of wear-resistant carbide tips with a cutting edge angle of 160 degrees. These are one of the most productive drills - maximum drilling speed in concrete and brick.

Set SDS-plus DeWALT Extreme 2 DT9701-QZ

Advantages:

- Chambered for SDS-plus

- Carbide tip

- Wear-resistant carbide tips with a cutting edge angle of 160°

- High level of performance

- Maximum drilling speed for concrete and brick

Popular types of metal drills

Drills are classified by type, cutting method, and connecting element. The following types of drill according to the material used are available on the market:

- made of high-speed steel. The most popular steel, characterized by high hardness, strength and sharpening ability;

- from colbate. provides strength and resistance, increases the hardness of the drill. Cobalt retains its properties better at higher temperatures than titanium, so a higher operating speed of the hammer drill is acceptable;

- titanium. Titanium coated drill bits provide a stronger and more stable alloy. When choosing titanium drills, pay attention to the percentage of the auxiliary component;

- Wolfram carbide. This component gives drills an increased level of strength and hardness. The combination of tungsten and carbon produces a harder or softer metal depending on the percentage of carbon in it.

Drill bits should be used with cutting fluid at low speeds using even and constant pressure. Monitor the condition of the crown, which should always be sharpened. If the drill is used incorrectly, it will quickly become unusable.

With different ratios of components in the mixture, metals with different properties are formed. A low percentage of impurities will have little effect on the quality and durability of the drill. The quality of the drill is also influenced by its processing and production processes.

The drill hardness rating is determined using the Brinell scale. The indicators are determined in newtons per square millimeter. A higher indicator means a more stable and reliable drill.

Creating holes with drills in stone and concrete

When choosing a drill bit for a stone hammer drill, it is not so difficult. It is important to determine how soft or hard the material needs to be drilled. Most rock drill bits are made from tungsten carbide.

Tungsten carbide drills are effective on concrete, granite, silicate masonry and natural stone. The overall quality of concrete drills depends on the quality of their tip and the number of cutting edges - 2,3,4.

The most effective will be a drill with four cutting edges made of carbide. Less durable drills have no more than 2 edges. Reinforced concrete must be hammer drilled using a standard or impact drill.

For concrete work, drills with the following types of shanks are used:

- straight shank;

- Slotted Drive SDS: A drill with a knurled shank that snaps into the chuck. Used in most hammer drills;

- hexagonal. More suitable for screwdrivers. These drills are designed for use with impact-type screwdrivers

Most concrete drills have SDS+ shanks. SDS Max shanks are used for heavy duty applications.

To work with a stone drill, various product designs are used. They most often differ in the type of groove. There are: a double L-shaped groove - this is a universal option, a U-shaped one - for better chip removal, with four teeth - to increase the stability of the drill. Grooves differ in the number of edges.

What are crowns needed for?

The table below contains types of crowns according to various criteria.

Kawabanga! To spite scrap metal collectors: homemade products from a washing machine engine

| Varieties of nozzles according to different separation criteria | |||||||

| edge material | way of working | tail type | cutting method | ||||

| diamond | victorious | drums | unstressed | SDS-max | SDS-plus | to "dry" | with water cooling |

There are models with a steel cutting edge and tungsten carbide.

Diamond bits allow you to perform work on reinforced concrete and concrete, but are expensive. They have a diameter of 25 to 130 mm and are used mainly by professionals.

Pobedite crowns have a lower price, but they do not use reinforced walls. Their diameter ranges from 35 to 120 mm.

Impact attachments are designed to be used when the hammer drill operates in impact-rotational mode. They are used to drill hard materials, non-reinforced walls or ceilings. In the non-impact drilling method, diamond bits are often used.

A number of models of crown bits have a drill located strictly in the center, extending beyond the working plane - this design feature helps to accurately drill according to the markings. The central drill acts as a guide.

Creating holes with a drill in wood

Most wood drill bits are made from hardened steel. There are several types of drills for wood processing:

- flat drills are used for drilling large diameters over 13 mm;

- spiral drills are supplied with a diameter of up to 17 mm, although there are exceptions;

- auger drills designed to remove chips when drilling wide holes;

- Triangular drills are suitable for drilling small holes.

Spiral drills are more suitable for working with denser materials, flat drills for smaller ones. Drills have different types of shanks. The straight shank is considered the most versatile.

How else are there drills?

In addition to the most popular types of borom, there are other types. They will be useful for effectively solving specific problems. The list of universal drills for metal, concrete, and wood is supplemented by the following types:

- stepped drills – conical-shaped products with different diameters;

- short drills - for drilling very hard metals and spot welding;

- Forstner drills - for drilling large holes;

- sliding drills – suitable for creating holes in wooden structures. Available in diameter sizes from 13 to 45 mm;

- drills with countersinks - for creating new holes with a drill or working with thin materials, for example, chipboard;

- installation drills are long products designed to create holes for pulling wire.

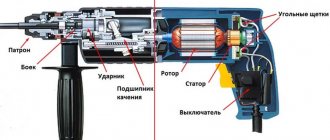

Drilling with a rotary hammer

A hammer drill is one of the most important power tools in the repair industry. Without it, it is difficult to imagine major repairs and solving everyday problems. When choosing a rotary hammer, it is important to pay attention to several factors that determine the quality and efficiency of its operation.

If you are looking for a rotary hammer, first, better determine its technical and mechanical features:

- Hammer Size: Determines the size of drill bits you can use with this tool. The larger hammer drill is designed for industrial projects, while the smaller hammer hammer is typically used at home.

- Motor Speed: The motor speed of a hammer drill determines the power of the motor. A faster spinning motor usually results in higher hammer drill performance. The description of the hammer drill should contain information about the number of revolutions per minute.

- Motor power: It is imperative to check the motor power of the rotary hammer before purchasing. Like various other power tools, the motor power of a hammer drill is usually specified in amps. Universal size - 6 or 7 amperes.

- Durability and build quality. The high-quality plastics and metals used to make the hammer drill allow it to last a little longer.

- Type of food. Although all hammer drills are electric, they may use a different method of power delivery. Most popular impact drill options are corded hammer drills that charge by plugging into an outlet. Another method is battery power. This tool can be used regardless of the power source.

An advantage when choosing a hammer drill is the set of drills included. Different drills are suitable for specific conditions and applications. The hammer drill may also be sold with a carrying case. It will come in handy when using the tool.

Review of the best drills for rotary hammers 2021

- Bosch 2608833778. This product is suitable for working on hard surfaces. It is used for rotary hammers with an SDS-plus chuck. This model is equipped with a reinforced tip, which provides a centering position when drilling. The manufacturer wisely approached the shape of the head, making it asymmetrical. Due to this, less dust is generated during the drilling process.

During operation, the drill withstands any manipulation and is considered wear-resistant. The drill also contains four edges responsible for cutting the material. They are located in such a way that the drill will not jam in the hammer drill. High-strength carbide and tungsten are used to produce drills. This composition is responsible for wear resistance and impact resistance. The benefits of products from a well-known brand will be guaranteed for the entire operational life of the product. Such drills cost around 160 rubles, so the only downside is their price.

- Makita D-00050 is compatible with SDS-plus type chucks. The average price on the market is around 80 rubles. The cost is quite justified. The design has two cutting edges. Due to this, the drills take a little longer to make a hole than the previous model. Despite this, the drill is quite functional, and the drilling itself proceeds without delay. The tip is weighted due to its pointed shape. Therefore, you can count on drilling in a given direction. No vibration will be felt while working with the drill. This version of the drill is suitable for working with materials of increased hardness, such as concrete, brick or stone.

- DeWalt DT9571-QZ 14 costs around 600 rubles. The main feature of the drill is increased strength due to the reinforced core structure inside. There are several advantages of the drill:

- Excellent carbide alloy for long life and better strength;

- optimized groove design to eliminate debris and formed chips;

- hardened case for added strength and reduced risk of breakage;

- 160 degree tip design provides better penetration, increased drilling speed.

The drill is suitable for models with SDS-plus chucks. This is an example of a modern drill with excellent mechanical properties.

- ZUBR 29380-340-12 is a product adapted for working with SDS-max rotary hammers. The domestically produced drill has a screw spiral. It provides increased space through which dust is removed. Durable steel is used to produce the drill. The tip has two cutting grooves. This is the standard option. The advantage of the drill will be the presence of a reinforced core. Minimal vibration during operation and extended service life attract buyers. When used in a hammer drill, jamming of the drill is excluded.

- Granite 425100. Drills of this model are compatible with hammer drills with SDS-plus cartridges. The presence of four cutting edges made of carbide and tungsten provides increased wear resistance of the drill. The issue of dust formation and edge accumulation was resolved thanks to the double helix. It also guarantees increased operating speed of the tool. Alloy steel is used to produce drills. Granite drills are suitable for working with all types of concrete and brick. According to customer reviews, this model is not always found in stores. Overall, the drill is worth its price and is considered a popular model with a good service life.

- DeWalt Extreme Kit. The drill bits in this case have No-Walk tips for clean, precise drilling. High quality work is achieved thanks to recessed cutting wings. They are suitable for drilling alloy and non-alloy steel, and can be used to create holes in wood and plastics, thin metals and sheet metals. The set includes 6 Extreme drills and 11 drill bits for screwdrivers and 2 holders for quick drill replacement. The cost of the case is 2300 rubles including a suitcase made of high-strength plastic.

How to choose drills for a hammer drill. Crowns, chisels and other attachments

5 / 5 ( 1 voice )

Properly selected tool accessories are half the success of the work done, and attachments for rotary hammers are no exception. Poor-quality or improperly used hammer drills can have a detrimental effect on the quality of work and the safety of the tool. Therefore, after reading this article, you will not make a mistake, and a positive result will not be long in coming.

Of course, the main purpose of a hammer drill is to work with concrete, stone and brick, but if the tool has certain modes and special attachments are used, then it is quite possible to go into the “element” of wood and metal.

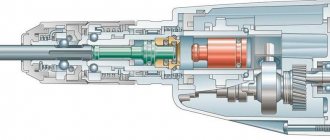

Equipment fastening system.

Currently, the most common mounting system on a rotary hammer is the “SDS” system, which in turn is divided into two types: SDS-Plus and SDS-Max. It was invented, patented and put into operation by Bosch, and is now used on the vast majority of rotary hammers. The essence of this fastening is in special slots on the chuck and the shank of the equipment, which are rigidly fixed to each other and clamped by a skirt on the chuck. Light hammer drills are equipped only with the SDS Plus system, heavy SDS Max, the middle class can be found with one of these types.

Hammer drills have shanks that should be lubricated with a special graphite lubricant before being inserted into the chuck. Further, during operation, the lubricant spreads throughout the shank and the rubbing part of the cartridge. This mandatory procedure will significantly increase the service life of the cartridge and equipment.

Accessories for rotary hammers.

Drill bits for hammer drills

with the use of impact drilling in concrete, brick and stone - this is the most popular and necessary attachment. It is a consumable item and is used on a hammer drill in hammer drilling mode. This makes this analogue of a concrete drill much more effective than its “brother”. There are some differences in drill design that are worth noting.

The most popular sizes used in everyday life are drills with a diameter of 6, 8 and 10 mm. In professional activities, a wide variety of sizes, both in length and diameter, can be used. When purchasing this nozzle, you should pay attention to the quality. By the way, this will be hinted at by the noble color and markings on the body of the drill. More on this a little later.

At the moment there are a huge number of manufacturers. The most famous of them, proven by craftsmen and time, are Bosch, Metabo, D*Bor, DeWalt, Hilti. Among budget manufacturers, users note Zubr and Praktika.

Type based on the number of cutters on the solder and spirals on the body of the drill | |

| double helix | 1) single-shaped carbide tip for precise drilling and long-lasting performance; 2) a narrow chisel-shaped tip increases the speed of drilling small diameters; 3) a single spiral extending from the tip along the body of the drill effectively removes waste material from the hole, which increases the drilling speed; 4) the load on the drill is balanced, which reduces friction and vibration. |

| 4 spirals | 1) a solid X-shaped soldering flows into 4 separate spirals along the body of the drill, has an excellent service life and good performance; 2) this form of carbide brazing allows you to drill into material with reinforcement, when another drill can jam or twist the head; 3) during operation, harmful vibrations are reduced, which increases the life of the drill and dampens the vibration of the nozzle; 4) high drilling precision. |

It is worth noting that hammer drills with four spirals are optimal for professional use. Only at the same time it is more expensive compared to double drills. A double helix will work more efficiently when drilling small diameters; it is more often used in the SDS-Plus system. The four-spiral type is more often used in the SDS-Max system and is optimal for impact drilling large holes in strong materials, including those with reinforcement.

If there is a need to use SDS-Plus drills, and the chuck is installed SDS-Max, then you can use an adapter from Max to Plus. There is no return adapter.

Drills for hammer drills, as stated above, have a variety of sizes (diameter and length). When drilling with long drills of large diameter, you should initially go through the hole with a smaller drill. This is necessary to reduce the load on the body of the drill and, most importantly, on its shank.

| working length | drill diameter | |

| SDS-Plus | 50-950 mm | 4-32 mm |

| SDS-Max | 200-860 mm | 12-55 mm |

Chisels

are auxiliary equipment for a hammer drill, which are used when it has a third mode - chiselling.

They have a number of varieties in shape and purpose. A sharp peak-shaped chisel (a) is used for dismantling brickwork and gouging out various holes, for example for mounting boxes. A flat chisel (b) is suitable for leveling the surface and knocking out material from the finished groove. A wide chisel (c) is more convenient to use for beating tiles, porcelain stoneware and plaster. The groove chisel (d) is adapted for gouging out grooves during electrical installation.

When working with chisels, the operator requires some effort to enter in the desired direction. In this case, there is no need to press too hard, the process will not go much faster, and the load on the engine and the hammer drill mechanism as a whole will be unnecessary. The overall length of these nozzles comes in many sizes. So in the SDS-Plus system it is usually 250 mm. If it is longer, then a critical load on the chisel shank is likely. The SDS-Max system has a total length range from 300 to 600 mm.

Carbide bits

for hammer drills are designed for impact drilling of round holes of large diameter in brick, stone and unreinforced concrete, for example for mounting boxes. They are a metal glass, with a centering drill for concrete and carbide tips on the outer cutting edge.

If necessary, impact drilling of through holes for laying pipes, including deep ones (with extensions), is permissible. The universal standard thread allows you to install any crown on the extension. The main thing is that the potential of the hammer drill is designed for this.

Diamond crowns

for a hammer drill they are a metal cup with a cutting edge, which in turn is made not of carbide tipped, but of industrial diamond sputtering. The design provides for the possible presence of a centering drill.

A similar, to put it mildly expensive, attachment for a hammer drill is indispensable when drilling the most durable materials. There are specimens that are capable of drilling a strong monolith with reinforcement. A diamond bit is used on a hammer drill in drilling mode without impact! The main advantage of such a crown is its high wear resistance; the holes are almost perfectly straight, which is important for precision work. This is why professionals use a diamond crown, for example, for laying socket boxes (standard diameter 68 mm).

We must not forget that diamond spraying varies in hardness; the hard matrix (T) has an increased resource and will wear out longer than spraying diamond chips with a soft binder (M). For reinforced concrete, options with polycrystalline diamonds are suitable, some fractions of which can be replaced over time according to the degree of wear.

Let's note a couple of important rules:

- When working with a crown, especially a diamond one, it is worth considering the level of load on the hammer drill so that this does not become his last work shift. Drilling concrete is a very labor-intensive process in itself, especially if you need to drill a large and deep hole. In such cases, it is better to use a more powerful hammer drill, and preferably with an SDS-Max system.

- It would not be superfluous to wet the working part of the bit and the hole itself with water, especially when diamond drilling without impact, in order to minimize heating of the nozzle and facilitate its entry into the material.

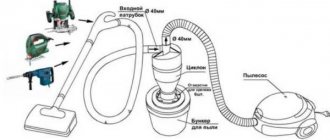

Other types of adapters and attachments

involves using a hammer drill like a powerful drill. Therefore, the most common approach is to switch from the SDS system to a conventional chuck like an electric drill or cordless screwdriver. There are two ways to do this:

The hammer drill is initially equipped with an additional quick-release chuck, which is installed instead of the standard SDS chuck and does not create an additional connection. A very convenient and practical solution, but this option significantly increases the cost.

An adapter with a left-hand thread is fastened into the SDS chuck, onto which a regular chuck is screwed. This creates an additional connection and makes the tool bulky, which is not very convenient during the drilling process.

There are adapters from the SDS system directly to an adapter for bits and even to a standard square for heads (1/4, 3/8, ½). It is even rarer to find accessories not intended for “perfing” with a standard shank, be it a mixing attachment or screw drills.

Working with any attachment from this section must be carried out in drilling mode without impact, otherwise the impact mechanism on the hammer drill will simply break any of them that is not designed for this. It is worth noting that these adapters are intended for light and medium class “perfs”. On heavy machines, using them is completely inconvenient and impractical.

Quality and manufacturers.

The main indicators are wear resistance and performance. A good drill or crown will be enough for a larger number of holes, and a spatula or chisel will not become dull longer. This depends on several factors:

- The quality of the raw materials from which the equipment is made.

- Precise technical design of the nozzle, which should not be crooked, play during operation, etc.

- Thermal stability, the longer the drill does not heat up, the longer it can be drilled.

- Speed of cuttings removal, especially with long drills and bits.

We will not ignore the numerous manufacturers of drills and other accessories for hammer drills. Often their quality is determined by the status of a particular company. Some have proven themselves to be the best, while others have negative user reviews.

So how do you know which is better and which is worse? After all, everyone praises their own, and you can write whatever you want in the recommendation of your product, but this is how it will happen in reality! Basically, such knowledge is achieved through trial and error, but if there is no time and money for this, we will distinguish two categories:

Professional equipment

designed for drilling and chipping the hardest material and will last many times longer, but at the same time has a high cost. Of course, such items pay for themselves in any case, so they are popular not only among professionals, but also among the average home craftsman.

Site rating: professional drills and equipment | ||

| 1. | Bosch | A huge range of all types and sizes, equipment of excellent German quality. Excellent performance and high market availability. |

| 2. | PROJAHN | Another German manufacturer, long service life and a decent range, especially for drill bits and breakout drills. |

| 3. | HILTI | Extremely positive reviews from professionals, let down only by the very high price and poor distribution in our market |

Budget (household) class equipment

do not have high wear resistance. They are more affordable and a good option. For example, if you need to drill several holes, and also if the material is not the strongest.

Site rating: budget drills for rotary hammers | ||

| 1. | Practice | This company is becoming more and more popular. Excellent performance at an affordable price, making them in demand even among professionals. |

| 2. | HAMMER | Chinese equipment with a German name, cheap and cheerful. A good option for home use |

| 3. | Information | Quite a good product for the money. Quite a “tenacious” equipment, the only thing is that the productivity is not the highest. |

So, when choosing a drill, crown or chisel, always take into account what material you will have to deal with. After all, even concrete is divided into strength classes. If you need to make a hole in strong marble, a simple cheap drill will do no good, it will just be a waste of money, it is better to purchase an expensive, but high-quality option. And don’t forget about safety precautions and good work to you!

0 0 vote

Article rating

Drills for rotary hammers: what you need to know about their use

Despite manufacturers' claims about the durability of drills, they can fail. Most often, the period of use depends on the materials with which it comes into contact. The cause of a drill malfunction may also be considered to be improper use. Also, the owner of a hammer drill should not forget about the mandatory lubrication of tools.

The drill is practically not subject to restoration and repair. This is a consumable item, so it will be easier to buy a new drill. During the working process, the drill does not need to be removed from the hammer drill and cooled. There will be no overheating, and the drill itself heats up to a temperature that it can withstand.

Choose high-quality drills and use them for the specified purposes.

The best metal drill sets

Such drills can be made of different grades of high-speed steel and differ in appearance and color. Products are flat and spiral, cylindrical and conical. Their gray color indicates low quality of the product, black indicates an increased working life. Drills for metal with a light golden color are capable of working for a long time in intensive mode.

Titanium components are present in products of a bright golden color. They help reduce the level of friction and significantly extend the working life, but their disadvantage is their increased cost.

BOSCH PointTeQ 2.608.577.351

The products of this German company are made of high-speed steel HSS, which ensures efficient drilling of metal. The sharpening angle of 135 degrees allows you to perform the drilling operation with minimal losses. The product has a cylindrical shank.

Pros of the set:

- A variety of drills of different diameters (19 pieces).

- Convenient packaging.

- It is easy to find the required drill bit in the marked slots.

- Good sharpening of cutting edges.

- Excellent product quality, withstands drilling of thick parts.

- They note the high quality and ease of use of such a tool, despite its Chinese origin.

Cons of the set:

- When drilling at an angle they fail.

DeWALT DT 7926

These drills allow you to quickly and efficiently make holes in cast iron, non-ferrous metal, and steel products. The set is suitable for use at home and at work. Their use makes it possible to perform drilling operations twice as fast as, for example, drilling metal parts with similar high-speed steel products.

Pros of the set:

- Large selection of consumable tools. The set includes 29 drills with a diameter from 1 to 13 mm.

- Convenient packaging in which each socket has a drill diameter designation.

- Cute set design.

- The presence of a special tip on drills from 3.2 mm allows for quick and accurate drilling.

- Innovative production technology prevents damage to the edges of the product.

- The triangular end of the cylindrical shank ensures reliable fixation of the drill in the chuck.

- Product markings are located above the working part, which makes it visible even during intensive work.

Cons of the set:

- Small working resource.

- Unsuitable for sharpening.

- At the exit, when drilling, the metal is undermined.

Gigant DBM 11025

Products of a Russian company, which, as the manufacturer declares, are produced at enterprises in our country and China. Ground drills are treated with a special coating. This protection prevents the consumable tool from overheating during operation and increases the working life of the product.

Pros of the set:

- Convenient and compact case dimensions: 190x121x54 mm.

- Large selection of drills (25 pcs.) of different diameters: from 1 to 13 mm.

- Excellent quality metal alloy: products do not crumble or break.

- Withstands sharpening for a long time.

Cons of the set:

- Complaint to the manufacturers: regarding the quality of the case - fragile material, unreliable lock.

Consumers are quite satisfied with the performance quality of this tool.