What is a hammer drill

A hammer drill is a universal tool that has great capabilities. Inside it there is a pneumatic device that pushes the piston, which comes into contact with the striker. The latter forces the equipment to perform reciprocating movements. As a result, the nozzles destroy any surface. The presence of the impact function allows the tool to make holes in hard materials.

Its purpose depends on the built-in modes: drilling, chiselling and drilling . There is a toggle switch to switch modes.

Manufacturers produce models of different weights:

- up to 4 kg – light;

- from 4 to 5 kg – average;

- from 5 kg – heavy.

The power and impact force depend on the size of the hammer drill .

Perforator device

Rotary hammer equipment

Most often it is used to work with :

- concrete;

- brick;

- stone;

- reinforced concrete;

- metal.

Rarely - with wood. The variety of materials requires the presence of a large number of attachments (working body) :

- drill;

- borax;

- chisels;

- crowns

All of them are designed to perform different jobs. Drills are used to make neat holes in the surfaces of the required diameter and depth.

Products that are intended for work on such a durable material as concrete are made using carbide plates . They are soldered onto the cutting part. But during use they wear out.

How to sharpen concrete drill bits for a rotary hammer? Sharpening can be done on a corundum grinding wheel, which is installed on appropriate equipment. The drill must be sharpened so that the worn cutting edges become straight, and the place where they intersect exactly coincides with the axis of rotation of the hammer drill. You should also pay attention to the sharpening angle of the two cutting edges . If this parameter is uneven, the edge with a large sharpening angle will be more heavily loaded. As a result, the hammer drill will quickly fail.

Drills are designed for piercing high-strength materials . A tool with a drill bit simultaneously drills, vibrates or impacts. This work is necessary when installing an outlet. When a chisel or spatula is installed on the device, it works like a jackhammer.

The type of fastening for all attachments, except for drills, is only suitable for a hammer drill, because it has fastenings in the form of grooves and a mounting tail . You can attach a regular drill bit from a drill to a hammer drill; you need a removable chuck (adapter). It comes in two types: cam and quick-clamping. A special key is used to secure the cam clamp. It is inserted into the thread on the outer perimeter and turned. At this time, the collet mechanism, which is installed inside the chuck, is compressed or unclenched, depending on the direction in which the key is moved.

The keyless chuck is activated by applying slight force by hand. The drill hole will open when you press down on the chuck.

There is also a small elongated design that allows you to lengthen the drills . Thanks to the extension, you can make deeper through holes in different materials. When drilling using it, you should carefully adjust the cutting conditions.

Different drills are needed for different materials

How a regular drill is inserted into a chuck

If there is a need to make a hole in metal or wood, but the drill is not working, then there is a way out - take a tool, a drill and an adapter. Of course, many will think that it is easier to buy the appropriate SDS metal drill for a hammer drill, but that was not the case. Even if you manage to find such a drill of the appropriate diameter, it will cost at least 1.5 times more than a regular drill.

This is interesting!

Manufacturers produce sds plus , which are designed for drilling metal and wooden structures.

However, due to the special design of the shank, the cost of such devices differs from the price of drills with ordinary cylindrical shanks. As a result, it turns out that it is much more profitable to buy an adapter for a hammer drill for a drill, and use a nozzle of the appropriate diameter, than to buy a drill with a special shank shape. Many people don’t even know what an adapter or adapter for a drill to a hammer drill is, so let’s look at the design of the device.

Structurally, the adapter consists of two parts:

- The shank is the part that is inserted into the chuck of the unit. The tail part has a similar design as drills and other sds plus type attachments

- Threaded part - a collet chuck from a drill and screwdriver is screwed onto it. At the end of such an adapter there is a screwdriver bolt for fixing the devices. When choosing adapters, you need to take into account the size of the thread onto which the chuck from the drill and screwdriver is screwed.

The thread on the tip of the adapter is not right-handed, but left-handed, that is, in order to secure the cartridge to the adapter, you will need to rotate it to the left. The chuck from the drill is installed on the adapter for the hammer drill, and after that all that remains is to insert the corresponding drill into it and use it on the hammer drill.

This is interesting!

If you plan to install a concrete drill into the collet chuck structure and work with it in a hammer drill, then it is not recommended to do this for a long time.

The impact actions performed by the unit mechanism are quite strong, so collet keys and quick-release chucks can quickly fail. The adapters are made of tool steel, so they can withstand heavy loads. The cost of such an adapter does not exceed 150-200 rubles, while for that amount you can buy only one attachment. An adapter for a hammer drill is a universal device that significantly expands the capabilities of the tool. Moreover, in a collet chuck from a drill, which is fixed in the power tool chuck through an adapter, you can fix not only drills, but also crowns, mixer attachments for mixing mixtures, as well as polishing and other types of working attachments.

Installing a drill into a hammer drill

The tool itself also has a quick-release mechanism . The drill is securely secured in it with the help of special balls; when locked, they fit tightly into the grooves that are located on the bottom of the drill. The installation procedure looks easy. To secure the bit or drill bit, the lower part of the chuck is moved towards the hammer drill (down). Holding it in this position, install the necessary equipment and release the cartridge. It happens that the balls do not fit into the grooves, and as a result the nozzle moves; you need to turn it until the structure is completely closed.

If a drill needs to be inserted into a hammer drill using an adapter, then you first need to install and fix a removable chuck with grooves for attaching it to the tool, and then the drill itself.

Before inserting or removing a drill into a Bosch hammer drill, be sure to check the condition of the tool . Then they turn it on, set the desired mode, and press the start button. You can start working if there is no smell of burnt plastic or burning, and there are no strange sounds.

How to insert a drill into a hammer drill quickly and easily

The ability to work with a drill or auger is basic today. Below we will describe how to correctly insert them into the hammer drill.

Today the tool uses an SDS+ cartridge. Its peculiarity is that it does not require a key. Unlike a jaw chuck, the process of removing and installing the drill takes a couple of minutes. You must do the following sequentially:

- Lower the chuck down while holding the base

- Insert the bottom end of the drill into the hole

- Release the cartridge, the spring will fix it in the starting place, the fixing balls will firmly secure the cutter

- Check that the drill is secured in the chuck by pulling it down. There should be no backlash. The maximum permissible distance at which the drill should extend from the chuck should not exceed one centimeter

- If a jaw chuck is installed, the drill is secured by rotating the chuck, thereby tightening the thread

How to remove a drill with a working chuck

With a working chuck, getting a drill is absolutely not difficult. If the cartridge has a key clamp , a special key is needed; in the quick-release fastener, manipulations are performed by hand. In the first option, remove it by inserting the key into one of the recesses on the cartridge and rotating it counterclockwise. Thanks to the teeth present on both objects, unwinding occurs.

In a situation with a quick-release fastening, the hammer drill is switched on in reverse rotation mode . Hold the outer body of the cartridge with one hand and press the start button with the other.

After removing the used nozzle and before replacing it, the shank is cleaned of construction dust and old grease. The shank of the drill being installed must be cleaned and lubricated. When prepared for work, it will last much longer; lubrication extends the life of the hammer drill and attachments.

Tools without reverse only use key chucks. Rotary hammers without reverse are considered a bad purchase.

What to do if the drill does not budge

The drill may become stuck so that it cannot be moved. How to remove the drill from the hammer drill in such a situation? To remove the part of the nozzle that sticks out, you need to clamp it in a vice. Tap the chuck with a hammer to avoid damaging the tool; use a wooden adapter. When the tail of the jammed drill appears from the chuck, stop knocking.

If these steps do not help remove the nozzle, the cartridge is completely removed and placed in gasoline. Pour car oil and leave for 1 hour. Afterwards they try to extract it again.

Very often during repair work, the drill gets stuck in the wall . When you have to pull it out, you don’t have to pull the trigger and pull. This way you can break it. It is also impossible to loosen the tool too much, as the drill may break and a piece of debris will remain. You can drill another hole nearby with a drill, slightly loosen the hammer drill, and try to remove it.

If this does not help, use a gas wrench . They screw it onto a drill and hit it against the handle with a hammer from the wall. If the key is very large, use a steel plate as a spacer.

If you need to remove a drill that is stuck through, you can do this with a sledgehammer . They hit it in the direction of drilling. Do not hit the drill itself. To soften the blows, you need to put a board or any padding.

To avoid this problem, you need to remove the attachments more often. Remove dust from the drilled hole, remove various contaminants, and pieces of the material being processed.

The drill can jam in the surface if too much pressure . The hammer drill should be easy to operate. The reinforced concrete structure contains metal reinforcement, so a drill can easily get stuck in it. Before starting work, experts advise using a special device to check where these metal elements are located.

The drill is easily installed in a working tool

If the nozzle gets stuck

Like any tool, even the highest quality hammer drill can jam. When performing work, this becomes a problem that has several options and reasons.

Firstly, when the drill is stuck in a removable chuck, and secondly, if the nozzle is jammed in the hammer drill itself.

When the problem is in the tool clamp itself or the removable head, then simply pour a little liquid like WD-40 into the chuck and wait a little. The composition will relax the grip of the clamping device and the drill can be removed without problems.

There are times when there are no special mixtures or auto stores at hand. The solution may be ordinary kerosene. It is also filled in, and after waiting 10 minutes, they try to release the nozzle. In this case, light tapping on the clamp and slight shaking of the drill are acceptable. After completing the procedure, the clamp must be thoroughly cleaned and lubricated.

The cause of the malfunction can also be the poor quality of the drill itself. If a cheaper and softer metal alloy was used in manufacturing, the nozzle may be damaged by the hammer drill during operation.

There are several ways to fix this problem. The first thing you need to try is to hold the drill in a vice and, holding the tool in your hands, loosen the attachment and pull it towards you. If the deformation is not very serious, then the nozzle can be pulled out.

The second option involves double fixation with a vice - a hammer drill on one side, and a drill on the other. Then take a small hammer and hit the drill towards the exit from the clamp. For this operation, you can use WD-40.

When no other method helps, you can try removing the chuck parts and turning the drill in the opposite direction about 90 degrees. However, this technique can completely damage the parts of the clamping device.

But if this option does not work, it is better not to try to disassemble the device. It is better to take such a hammer drill to a workshop of competent specialists.

It should be noted that in order to reduce the possibility of such breakdowns to a minimum, it is better to choose high-quality attachments from leading brands. As a rule, such investments are recouped by the long operating time of the tool.

The nozzle can get stuck not only in the mechanism of the unit, but also in the wall during operation. In this case, you can try to free the drill or drill by turning on the reverse motion on the device.

If this method does not work, then the nozzle is released from the clamp, another one is inserted, and after drilling out the wall around the stuck tip, it is removed. If the drill breaks during work, then its remains are removed from the clamp, and the piece stuck in the wall is drilled out or simply cut with a grinder flush with the working surface.

Detailed instructions for attaching a drill to a hammer drill are in the video below.

Today, a hammer drill is one of the most popular tools, so it is difficult to underestimate its benefits. The tool is used by both experienced professionals and ordinary amateurs. In many situations it would be difficult without this device. In this article we look at how to insert a drill into a hammer drill without damaging it. Masterful ability to use the tool correctly will help bring your work to perfection. To insert a drill bit into a tool, you will need a hammer drill, drill bit, chuck, and lubricant.

Table of contents:

What is a hammer drill

Before installing a drill in a hammer drill, you should first of all understand. Today it is difficult to complete repairs or construction without resorting to the help of a hammer drill. When drilling is necessary, this tool is simply irreplaceable. The hammer drill is used when working with concrete and brick; it is also often used for working on metal or wood as a regular drill.

Many functions make this tool universal - rotation with impact, impact without rotation, rotation without impact, drilling in concrete, jackhammer function, drilling in wood and metal and many others. You need to know that there are many types of hammer drills. The principle of using the tool is the same, but if you need to drill a wide and deep hole, it is better to use a larger and more powerful device.

Rotary hammer equipment

To work with this tool, you need various equipment - drills, concrete drills for a rotary hammer, chisels, shovels and crowns. Drills and crowns are used when drilling holes, drills are intended for concrete and stone, chisels are used for slotting work, and spades are needed for knocking down plaster or old tiles. All hammer drill attachments have a shank shape, which allows for quick and reliable fixation in the chuck.

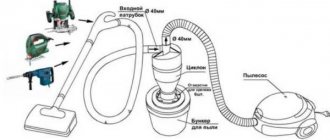

Read also: Brush attachment for an angle grinder

The hammer drill can also be used with special angle attachments, a dust removal system, stirrers for stirring mortars or paints, chisels and various types of attachments (drill sharpening, water pump, attachment for cutting metal in sheets). Before starting any work with a rotary hammer, make sure it is properly equipped and suitable for the job to be performed. A tool that is too small may not be able to handle a large load.

Means of protection

When working with a hammer drill, be sure to remember about protective equipment. Such means are glasses, earplugs and gloves. You should also work in special clothing, excluding anything that could accidentally get wrapped around the drill or drill. When working with the device, you should not put pressure on it, this may end badly.

Try not to let the tool run idle for too long; this is only allowed before checking it. When working with porous material, use non-impact drilling to prevent it from crumbling. If you have to work with hard material, it is better to use a cooling lubricant emulsion. If the work involves using a long drill, to save money, you can start working with a shorter metal drill for a hammer drill, but of the same diameter.

Lubricate the drill shanks every 180-200 holes. Pay attention to the heating of the instrument; if it gets too hot, it’s better to take a break. Alternate periods of working and resting the tool. As a rule, a break is taken every thirty minutes. Its duration is about ten minutes.

How to insert a drill into a hammer drill: step-by-step instructions

If, when working with a hammer drill, you take into account all the rules and pay attention to the subtleties, the work will be done competently and easily. Always follow construction techniques and do not forget to periodically check the tool for malfunction.

Functionality check

Before you start replacing the drill or working with the tool, you need to make sure it is working. To do this, insert the plug into the socket, and put the hammer drill in the drilling mode without fighting (leftmost position). After this, the start button is pressed. If you hear a smooth sound, devoid of glitches and jerks, you can start working.

Before starting work, do not forget to check walls or other surfaces for water supply or electrical wiring. The handle must be securely fastened and not dangle during operation. A timely check or inspection will help avoid injuries and damage to the device.

Please note: never touch the rotating parts of the tool, otherwise this may lead to a tragic outcome. For the same reason, it is necessary to install a drill chuck and a drill bit for a bosh hammer drill only with the plug unplugged.

Purchasing a chuck

You need to purchase a special chuck that fits your model of hammer drill. If you cannot choose or do not know which cartridge is needed, the best thing to do is take the tool with you and try compatibility on the spot.

Today, rotary hammers are equipped with two types of chucks - quick-release and key. The key option is traditional; a wood drill for a hammer drill is clamped in it using a special key. In this case, the fastening is reliable, but less convenient than with a quick-release chuck. The keyless chuck clamps the drill easily without the help of any tools. Simply select the most suitable option and follow the further instructions.

Choosing a drill for a hammer drill

Today, drills are made from carbon, high-speed and alloy steels. If you have to work with durable materials, the drill can be equipped with a heavy-duty, durable tip. Drills can be feather, centering, straight fluted and spiral (for deep drilling).

You can also purchase a drill designed for wood, metal, stone, concrete, glass, ceramics, diamond, or a universal version. Before you fix the drill in the hammer drill, you need to decide on the type if you want the job to be done correctly. The color of the drill indicates the appearance of the final result.

If the drill is painted black, it means it has been treated with superheated steam, but this does not affect the quality, despite the popular belief that black drills are stronger. If the drill has a brown or slightly golden tint, it has most likely been tempered to relieve internal stress. Drills treated with titanium nitrile have a bright golden color; these options are the most expensive and durable.

As a rule, good companies indicate on the drill box its characteristics, such as the grade of steel and the material that can be worked with. If the drill becomes very hot during operation, it means that it has become dull or was sharpened incorrectly.

How to remove a drill from a hammer drill

If an old drill bit is inserted into the hammer drill, it must be carefully replaced. Before pulling out any attachment, be sure to pay attention to the type of its cartridge. Remember about the keyless chuck and key chuck. The key one is more reliable, especially when working in shock mode. This cartridge is made of metal, so it is less susceptible to mechanical damage.

Read also: Zinc physical and chemical properties

Before removing the drill from a hammer drill with a double-clutch keyless chuck, be sure to switch the device to reverse mode. After this, you need to fix the lower coupling with one hand, and unscrew the upper one with the other. In a single-sleeve chuck, the nozzle can be replaced using only one hand, since it is installed on rotary hammers with automatic shaft locking.

If the drill gets stuck

There are times when the working tool gets stuck in the chuck and does not want to be pulled out. Here you need to know the following. To carefully remove the bit, you need to clamp its free part in a vice and hit the chuck jaws with a hammer through a wooden adapter until the drill tail comes out of the quick-release chuck. If the drill is stuck firmly in the hammer drill and this does not help, you can remove the chuck and place it in gasoline, and drop a little car oil into the key chuck.

There are also often situations when a drill gets stuck in a wall during concrete construction work. This occurs during clamping between concrete and reinforcement. You must stop pulling the trigger and loosening the hammer drill as it may break. First, remove the drill bit from the chuck, replace it, and begin to carefully knock out the concrete around the stuck drill bit. Avoid hitting a stuck drill bit. After this procedure, the stuck drill can be removed without difficulty.

Chuck insert

For proper operation of the tool, it is necessary to lubricate the hammer drill with special lubricant. It is better to purchase a branded product that is resistant to water and prevents moisture from entering metal surfaces, which prevents corrosion.

To do this, you need to open the tube of lubricant and squeeze a little into the hole into which the nozzles are inserted. Next, the tool is placed on the floor or other hard, comfortable surface with the handle, after which the back of the hammer head is pulled down, the chuck is inserted, and the lower part of the head is returned to its previous position.

How to remove a drill from a damaged chuck

in the chuck are often damaged or the cam breaks . The drill may break when twisted between the jaws. Chips appear and fall into the cracks, preventing them from rotating normally. Using 2 gas keys, each part of the cartridge is clamped with one of the keys and rotated and unscrewed. You can use 1 key and a vice, in which case one part is clamped in a vice.

If there is no gas key, one half must be inserted and clamped in a vice , the other half should be lightly hit tangentially with a hammer.

If the threads on the cams are torn off, these methods are useless. In this case, the cartridge is twisted. Place in a vice. The drill is knocked out from the inside with a punch. It is threaded through the hole into which the spindle .

What to do if the drill breaks

If you can get caught on the tip of a stuck drill bit, pull it out :

- pliers;

- wire cutters;

- tweezers.

Often it gets stuck very deep. To remove a piece of debris, you need to take into account its diameter, size and type of metal, where it is stuck, and also how deep. To remove a small fragment, the hole in which it is lodged is enlarged. The fragment is pryed with a suitable device and pulled out.

You can remove a piece of a broken drill with a diameter of 8 mm or more that remains in the metal using a bolt with welded spokes or a spring wire . But this is if its end sticks out, which you have to cling to.

The tail part remaining in the socket can be removed using a welding machine, thin electrodes, or a thin plastic tube . The latter must match the diameter of the cartridge bore. The tube is inserted into the socket and rests against the fragment. Turn on the welding, connect the mass to the tool, press the chuck lock to the nozzle release mode, and carefully insert the electrode into the plastic tube. And they quickly weld the electrode to the shank in order to later remove the broken part.

If the shank is dented, the chuck will have to be partially disassembled. The fragment cannot be pulled out even by welding the electrode .

Most often, poor quality attachments break. It is advisable to purchase high quality equipment . During operation, try not to jam. If you have to drill with a low-quality drill, do not put pressure on it. You can understand the quality of the equipment by making several holes and then looking at the shank. A good product does not wrinkle.

Sometimes the drill breaks and this requires additional work

Is it possible to insert a regular drill bit into a hammer drill?

In some situations, you need to screw a drill from a simple drill into a . This can be done using a special adapter, which is a regular cartridge. Electric drills are equipped with it. It comes in 2 types: key and quick-clamping. A special adapter is inserted into the cartridge, which must be tightened tightly. On one side there is a shank, like a regular drill, on the other there is a thread. It can be different. Mostly 1/2 inch and metric type - M12. The adapter must have similar threaded fittings . It is screwed into the cartridge and secured with a special screw with a left-hand thread. It is included in the kit.

The assembled structure is placed into the hammer drill in the same way as a drill. This turns out to be a standard electric drill. You just need to keep in mind that in such a tool the cartridge will have some play . The assembled adapter is not able to withstand heavy loads, so the shock mode must be disabled. Manufacturers produce rotary hammers that already come with similar adapters. There are also models that contain several cartridges at once, which replace each other. One for installing the drill, the other for the drill.

This configuration has an important advantage - no backlash , since the adapter is suitable specifically for a specific hammer drill model. This one costs more.

How to correctly insert and remove a drill bit into a hammer drill, screwdriver and drill

The popularity of the question of how to insert a drill into a hammer drill or electric drill can be explained quite simply: such devices are actively used both in industrial and domestic settings.

The cartridges are different, as are the attachments attached to them.

An incorrectly installed drill can lead to a number of problematic situations:

- inability to work with a hammer drill or drill;

- obtaining uneven holes with a broken inner surface;

- the drill may fly out, which can result in serious injury.

Despite the fact that inserting a drill bit into a rotary hammer or drill is not so difficult, this issue should be approached responsibly.

Correct installation of the drill in the drill chuck

Before you figure out how to properly install a drill in a hammer drill, it is advisable to figure out how to insert a drill into a drill. The element of its design in which the drill shank is fixed is the chuck. Most models of modern drills are equipped with jaw-type chucks consisting of:

- cylindrical bodies;

- rings or sleeves that rotate around the outer surface of the housing;

- cams installed in the inside of the housing.

Jaw chuck design

When the sleeve rotates clockwise, the cams simultaneously move closer to each other, thereby securely clamping the shank of the drill being installed.

Accordingly, the question of how to remove the drill from the drill is not difficult to solve: just start rotating the sleeve counterclockwise. At the same time, the cams will begin to diverge, which will make it easy to remove the drill from the drill.

It should be borne in mind that before installing the drill, the cams should be opened with a margin, in which case the tool can be easily inserted.

The convenience of using cam-type chucks lies not only in the efficiency and high reliability of tool installation, but also in the fact that drills of almost any diameter can be inserted into them.

When using such cartridges, as a rule, there are no difficulties with how to change the drill bit in a drill. A correctly inserted tool is held securely in such chucks and allows you to drill a precise hole.

If you begin to notice teeth slipping when tightening the chuck, replace the worn key with a new one.

Jaw chucks are used in both industrial and household drilling tools. Clamping devices for household drills are available for two ranges of drill diameters: from 0.8 to 10 and from 1.5 to 13 mm.

The design of jaw chucks can provide two different ways of clamping a tool: key and quick-clamping.

In the first case, the sleeve is activated using a special key, the conical working part of which has teeth.

To activate the clamping mechanism, the key must be inserted into the holes on the side of the chuck body and rotated. There may even be three such holes in some models.

Accordingly, in order to loosen or tighten the cams, the key must be inserted into each of them and begin to rotate counterclockwise or clockwise.

After loosening the jaws using a wrench, it is necessary to turn the cartridge itself counterclockwise, which will increase the distance between the jaws to the required value. The inserted tool is fixed in the reverse order: first the cartridge itself is clamped (while rotating it clockwise), and then the sockets are clamped using a key.

Pulling out and installing drills when using a keyless chuck is much easier and faster. In it, the sleeve is driven by manual rotation. To limit the force on the jaws, they are often equipped with locking elements.

Before inserting the drill, first make sure the drill is in working order and turn off the power. Only after this can you begin installing the drill.

Types of keyless chucks

Installing a working tool on a hammer drill

As mentioned above, the hammer drill must be checked for functionality before installing the drill. To perform such a check, the operating mode of the hammer drill is set to drilling without a fight.

If, after pressing the start button of the device, you hear and feel that its engine is running smoothly and without jolts, then the hammer drill can be used for its intended purpose, having first inserted a drill or auger into it.

To secure a drill with a cylindrical shank in a rotary hammer, use an adapter with a jaw-type chuck

Before inserting the drill into the hammer drill, it is necessary to treat the shank of the working tool with a special lubricant that will protect it from corrosion. The procedure for installing a drill in a hammer drill is as follows.

- The back of the hammer drill is installed on the floor or other hard surface.

- The movable part of the clamping device is pulled back.

- The tool is inserted into the hammer drill until it stops. In this case, the drill or drill, which must be inserted into the hammer drill, must be held vertically. If you neglect this requirement, you may encounter the fact that the tool will fly out or even break, and this may also lead to failure of the hammer drill itself.

You should press until it clicks, then pull the drill; if it doesn’t come out, everything is fine.

Considering the fact that the chucks on modern rotary hammers have a fairly simple principle of operation, questions about how to remove a drill from a rotary hammer, as a rule, do not arise.

After removing a used tool from a hammer drill to replace it with another, it is advisable to immediately clean its shank from grease and construction dust. In this case, the shank of the drill that you are going to insert must also be cleaned and pre-lubricated. The tool replaced in this way will not harm the clamping mechanism of the hammer drill and will last much longer.

Lubrication extends the service life of both the drill itself and the hammer drill

Using a hammer drill, you can not only get a drilled structural element, but also perform processing using a special chisel. You can also install a mixer as the working body of such a device.

Home craftsmen often also have questions about how to insert a drill into a screwdriver or how to change the chuck on a hammer drill.

Solving the first question is quite simple, since the design of the screwdriver uses cartridges of the same design as those on drills and rotary hammers.

But the question of how to properly replace a cartridge on a hammer drill should be approached with knowledge: it is not easy to carry out such a procedure without certain knowledge and skills.

Some tips for using drilling tools

To avoid the risk of flying tools or concrete chips harming your health, drilling work must be carried out in compliance with all safety measures.

Safety precautions include safety glasses, gloves, earplugs or hearing protection.

Naturally, all work must be performed in special clothing, in which there should be no hanging elements that could wrap around the drill.

To prevent overheating of the electric tool used for drilling, it is necessary to regularly rest it. It is very important to insert the drill correctly (this must be done until the tool stops).

Two ways to clamp a thin drill in a chuck if the jaws do not reach the shank a little

If the drill gets stuck in the wall during drilling, it should be removed without removing the tool from its surface. To do this, you need to remove the drill from the hammer drill and insert another one, with the help of which you need to begin to destroy the wall around the drill stuck in it.

If the drill cannot be removed from the drill or hammer drill, then it must be clamped in a vice, and then using a hammer, using a wooden spacer, knock on the cams of the clamping mechanism. Oil can help in this matter, a few drops of which are poured into a key type cartridge.

Source: https://met-all.org/oborudovanie/kak-pravilno-vstavit-vytashhit-sverlo-perforator-shurupovert-drel.html