Operating principle

The basic principle of operation of the tool is the production of impact force using the tool itself. This is possible due to the ability of the hammer drill to convert the rotational movements of the engine into translational piston impulses. The piston makes the firing pin work, which performs the task.

The power of the tool can vary from 1.5 to 20 kJ. To imagine the power of its work, you can compare the device to the fall of a weight. If a weight weighing 1 kg is dropped onto the floor from a height of 1 m, it will act on it with a force of 1 kJ.

Device

Actions in different modes

For drilling, the toggle switch is moved to the appropriate position. With the engine idling, apply the nozzle to the place where the hole should be punched. To control the speed of torsion of the drill and attachment, use a special trigger. Drilling occurs if you switch the hammer drill to another mode. It is usually indicated by a picture showing a hammer and a drill. Speed adjustment during drilling is rarely done.

To work in the material chiselling mode, the hammer drill is switched to the program indicated by the image of a hammer. But that's not all - you will need an attachment that can act like a chisel.

Such a nozzle is attached at the required angle in relation to the surface being treated. To set the required number of blows, as well as their strength, the trigger is pressed with varying amounts of force. This kind of work, which is important, requires a certain skill, and may not work out right away.

Separate hammer drills can be used as a screwdriver. The necessary information is always indicated in the instructions for the device. To tighten or unscrew screws, you need a specific attachment. There may not be a special screwdriver mode; usually the “Drilling” program is used instead.

General rules of use

This tool is very often used in construction and repair, as it has managed to replace monotonous and inefficient manual labor. However, when working with it, there are certain nuances that every user should know.

It is allowed to use only a working hammer drill in exactly the mode specified by the manufacturer. It is prohibited to work with a device whose cable is damaged or whose cross-section does not meet the declared power standards.

If the hammer drill was transported to the desired site during the cold season, you should wait 30 minutes after entering a warm room. In the opposite situation, the lubricating fluids in the mechanism will not have time to soften, and there will be a risk of breakdown. The user of the device can only work if he is in good health and well-being. He should also carefully study the safety rules in advance.

Rules for safe use of the tool

To ensure safe use of the hammer drill, it is recommended to use personal protective equipment. It is important to protect your eyes, face and hands.

During operation, there is a risk of the drill heating to elevated temperatures. This is due to its strong friction. Therefore, before removing this element, you need to let it cool or carry out the procedure with gloves.

Important! To understand how a hammer drill works, you need to study the instructions in advance. It includes many useful tips on the operation of the device.

When using a hammer drill, you must use protective equipment

In what cases can the lights flash?

If the hammer drill design has light signaling lamps, their blinking may indicate a breakdown or malfunction of a certain component or mechanism. If the red light on the instrument is flashing, it is recommended that you read the instructions for use.

How to insert a drill?

Types of drill tips Rotary

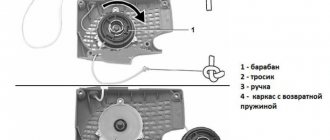

hammers are available with one of three types of chuck (jaw, quick-clamp, SDS system).

Most devices use the latter type, so you should consider installing a drill using this example.

To change and secure a drill in a device with an SDS system, proceed as follows:

- The chuck sleeve is pulled down.

- The nozzle is inserted into the resulting socket.

- The chuck clutch is released.

The SDS system is considered the most reliable; it allows the drill to be firmly fixed in the hammer drill and will significantly save time when replacing attachments. Its use is permitted on devices with low or medium power.

To use a drill with a conventional cylindrical shank, you will have to purchase a special adapter for the SDS system. When used, the hammer drill is able to work as an electric drill with conventional drills.

Read also

Lean concrete. This is a building material that has lower characteristics than regular quality concrete mortar. A special feature of this mixture is the reduced amount of binder. Cement in relation to the proportions of other components (sand, water, gravel or gravel). There are coarse and fine-grained analogues of building materials. When laying, the BSG is distributed and compacted with a vibrating plate or roller.

Concrete is a material in demand in construction, consisting of cement, sand, coarse substances and water. If necessary, the composition can be optimized using special plasticizers, water repellents, antifreeze and much more. However, even an improved mixture is subject to deterioration, which manifests itself in the dispersion of frozen concrete blocks.

Filling gravel with bitumen is an effective way to insulate basements, basements, and sidewalks from the negative effects of moisture seepage from the soil. Let's consider the main features and nuances of the technology.

Concrete. This is a material that is used on almost any construction site. The need to purchase it arises at different stages of building construction. However, to maintain the quality characteristics of the solution, it must be properly organized for its transportation and delivery to the site. You can use different vehicles for this.

Concrete is a material in demand in construction. To ensure the durability and longevity of the structure, it is recommended to choose quality solutions purchased from reliable suppliers. Meanwhile, many inexperienced developers cannot understand which mixture, by definition, will meet the quality criteria. Let's look at the solution to this problem in more detail.

READ Disassembling the dauer hammer drill ie 4716

Your message has been successfully sent.

Thank you for your interest

Our manager will contact you soon

Source

Both in construction and in repairs, the hammer drill has become an indispensable assistant. This powerful power tool, one of the already respected types, is designed for working with brick and concrete, but can be used just as successfully on wood or metal, like a regular drill.

How to work with a hammer drill so that the tool you choose lasts for many years? Proper operation of the hammer drill not only increases the service life of the tool, but also significantly reduces the risk of injury when using it. You should use certain operating techniques that do not overload the tool, and also ensure that it is alerted in a timely manner.

- Brief Description of Rotary Hammers

- How to prepare a hammer for work

- How to work with a hammer drill in different modes

- Drilling mode

- Impact drilling mode (drilling)

- Hit mode

- Technique for proper operation of a hammer drill

- Care and maintenance of the rotary hammer

- When can you make noise with a hammer drill?

Brief Description of Rotary Hammers

To understand how to work with a rotating hammer, let's look at its capabilities.

The purpose of this powerful hand tool is to hammer heavy structural materials such as reinforced concrete, metal and stone. Using a drill, you can not only drill holes of different diameters, but also chip away old tiles, punch holes in floors and walls, and drill holes for utilities.

The hammer drill is capable of operating in different modes, which makes it an almost universal tool. This is rotation with or without impact, drilling in concrete, stone, metal and wood, impact without rotation. A professional hammer drill can also replace a jackhammer.

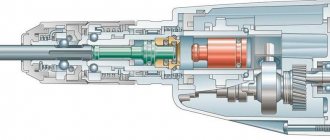

Inside the shock is the impact mechanism. Electropneumatic or electromechanical. To activate it, simply press the button. The mechanism itself is amazing; no additional effort is required.

Features of drilling different surfaces

Using a hammer drill, you can drill various surfaces - metal, concrete, wood, ceramic tiles. Each material has its own subtleties. Only if they are strictly followed can you expect a high-quality result.

To work with metal, you must use the hardest and most durable bits. Thin metal plates are the hardest to drill because they can move out of place. It is recommended to use special devices for fixing to the surface. It is better to place a piece of rubber under the sheet to prevent scars from forming.

The tree should also be securely fixed. A piece of wood with sandpaper is placed under it. During operation, you need to press lightly on the hammer drill itself.

To work correctly on concrete, use nozzles with a Pobedit tip. First, a small depression is made in the material using a conventional drill, and then it is expanded with a Pobedit nozzle. For the best passage through concrete, the drills are periodically pulled out and lowered into a jar of water.

When making holes in ceramic tiles, special nozzles with carbide tips are used, which can reduce the load on the surface. If the coating has already been laid, it is better to take a drill designed for glass.

Recesses for socket and switch boxes

Owners of apartments and houses often make the mistake of making recesses for boxes of sockets and switches, proceeding as follows: with a Ø 5-10 mm drill, they drill holes in the concrete wall along the circumference of the diameter of the box, and then gouge out the required recess with a spade chisel inserted into a hammer drill.

The chisel-shovel in the hammer drill is designed for dismantling wall and floor coverings

This approach takes a lot of effort and time to achieve the goal, and in addition, the space under the box ends up being sloppy. This method can be justified only if you need to make a recess for one place, but if you need about a dozen of such recesses, it would be more rational to proceed as follows.

Drilling holes for sockets

Instead of drilling several hundred holes with a Ø 5-10 mm drill, use a diamond core bit of the appropriate diameter. First, a hole is made with a crown to the required size, and then all unnecessary fragments are removed with a chisel inserted into the puncher. Believe me, it’s faster and much more accurate.

Crown for socket with pobedit teeth or teeth coated with diamond coating

Someone will say that a drill is cheaper than a diamond bit and they will be right. However, once you buy the latter, you will have in your arsenal of cutting tools for a hammer drill a very necessary and useful thing, and besides, it’s still unknown how many drills can simply burn out when drilling holes. In addition, it should be noted that when working with a diamond crown, it is advisable to moisten the recess with water, using a regular spray bottle for spraying indoor plants. By doing this, you will save the cutting tool and make your work easier.

Where else can you use the tool?

The possibilities of using a hammer drill do not end with drilling stones and metals. With the help of impact technology, it is also used in other areas.

How to drive a pipe into the ground

The heaviest hammer drill models (from 8 kg with a power above 20 kJ) are also used by specialists for driving an Abyssinian well. To do this, a galvanized tube with a sharp end is placed in a vertical position and driven into the ground using the hammer mode of a hammer drill. Fence posts are driven in using the same principle. For driving, the diameter of the pipe should not exceed 1 inch, but this is enough to construct a full-fledged well for a family. Most often, this method is used to provide water to houses that cannot be reached with heavy drilling equipment.

How to compact soil in a greenhouse?

It is very convenient to use a hammer drill for compacting soil. To do this, purchase a special nozzle made in the form of a metal plate to “trample” the earth. Most often it is used during the installation of greenhouses and when creating beds.

How to mix cement mixtures?

The main part with which you can work with a drill is a rotating chuck. Therefore, it can also be used for mixing cement screed or tile adhesive. You just need to buy a mixer-shaped attachment with an SDS+ shank in advance.

Important! It is prohibited to use a hammer drill to mix concrete mixtures (concrete mixers are used for this). The mixture contains abrasive elements (crushed stone) that will damage the device.

A hammer drill is a tool designed not only for making holes in any material. It can also help with chiseling walls, dismantling tiles, and mixing cement compositions. Don’t be afraid to use it in everyday life, even if you don’t have much experience in using it. At the same time, we must not forget about safety rules and periodic maintenance of the device.

Hammer repair: tool disassembly

Disassembling the Makita 2450 at the first stage requires the need to place the tool on a clean surface. First you need to remove the mode switch knob. It needs to be set to “impact” mode, and then remove the latch using a screwdriver. The handle should then be moved to the left position, which indicates the drilling mode. The handle must be held between your fingers and removed from the grooves of the body.

At the next stage, the Makita 2450 quick-release chuck is disassembled. Its design is quite simple, which is why anyone can handle the repair. Repairing the chuck involves installing the tool in a vertical position on the back cover of the case. The assembly work will allow you to complete the diagram of the hammer drill. Using a screwdriver, you need to remove the boot, freeing the cartridge from the ring, and at the next stage you need to remove the ball by removing the guide washer and conical spring.

Read also: What is saline solution used for?

Repair of the Makita 2450 may be required if the protective rubber boot is worn out, the locking ring may become loose and partially worn out. Sometimes the ball becomes unusable, the conical spring loses its elasticity, and it can also stretch. Replacing a new ball requires the operator's attention, but replacing the retaining ring, rubber boot and conical spring does not. When choosing a new ball, you should pay attention to its dimensions, which are 7 mm. As a lubricant, you should use a composition that is developed for the Makita rotary hammer. If we are talking about shanks, then it is necessary to use Makita 2450 196804-7 lubricant. When assembling the chuck, the conical spring should face the hammer with its narrow side.

How to work without dust

Often you have to drill into walls and ceilings with a hammer drill, in which case dust will inevitably spread throughout the room. To avoid this, savvy builders have come up with several devices:

- A plastic cup. You need to make a hole in the center of the bottom, and then put the glass on a drill or drill. During operation, all dust generated will fly directly into the cup. Once the drill stops, it can be easily emptied into a trash can or thrown away. This method is suitable for a drill whose length is at least 10 cm. For shorter attachments, you will have to cut the cup.

- Glued package. Before drilling holes, you need to glue the bag with the hole made in it to the wall. Once drilling begins, your partner can connect a construction vacuum cleaner to it so that it can remove all the debris.

- Paper envelope. You need to take a piece of paper and bend it vertically almost in half so that there is a free strip on top. Then the sides of the sheet are folded vertically to form an envelope. The resulting structure is glued to the wall under the intended hole. During drilling, all the debris flies there.

You can purchase special plastic bags for collecting dust in the store. They are put on the drill, after which the debris collects inside the grooves of the drill.

Main requirements and safety precautions

It is important to understand that regardless of the manipulations performed, the hammer drill is not a toy. This is a serious mechanism, and also under tension. Whatever the purpose, you should only work with special gloves and safety glasses. Outerwear - strictly with long sleeves. All buttons, zippers and other similar elements must be fastened all the way to prevent accidental capture of the drill.

A useful addition for any home craftsman working with a hammer drill would be a shield that fits over the chuck. It will stop the flow of various particles of matter flying from the holes. You should act especially carefully wherever there are hidden communications. It is useful not only to familiarize yourself with the drawing, but also to mark wire routes and pipe routing on the surfaces themselves. Workers should hold the hammer with both hands at chest level, and it is also helpful to spread their legs slightly to gain more support.

It is unacceptable to use such equipment while standing on flimsy and unreliable ladders, on various types of boxes, or on other supports of dubious quality. Of course, using a hammer drill in low light is prohibited. When chiseling or drilling holes, the tool is directed at right angles to the wall. The slightest misalignment results in cracking of the cartridge. It cannot be repaired, only replaced.

Safety precautions at work

To work safely with a rotary hammer, you will have to follow some rules. Otherwise, there is a risk of damaging the instrument or causing serious injury:

- During work, the master must be protected by individual means that protect the organs of vision, hearing and breathing from dust and small fragments. Goggles or a protective mask, gloves, and a helmet are used.

- Before starting work, you must check the tool for serviceability. The hammer drill must operate without braking or extraneous sounds, and the cord must maintain its integrity.

- If you need to make a long hole, start with a short drill first. Then they move on to longer ones gradually.

- The hammer drill must not be operated continuously, otherwise it may overheat. Recommended operating times at idle and under load are indicated in the technical manual for the tool.

- The shanks of each drill need to be lubricated periodically. It is advisable to do this before each installation of the nozzle, but you can limit yourself to lubrication every 150-200 operations.

- It is necessary to carry out maintenance of the rotary hammer from time to time. Its frequency is indicated in the instructions for the device.

- When cutting through hard surfaces, it is recommended to use a liquid cooling system (water the hole).

- Do not grab the hammer drill bits with your bare hands immediately after they stop; they can be very hot. To do this, it is better to wait a couple of minutes, or use gloves.

- It is necessary to promptly cool not only the holes, but also the drill. Otherwise, it can quickly change its properties (elasticity, hardness) and fail.

There is a special liquid system to cool the drill and holes in the material. It works by supplying cooled emulsion or water to the required zone. For this purpose, tubes or water couplings are used.

How to operate and use a hammer drill?

How to work with a hammer drill? - a stupid question, it would seem. Take it and go to work. However, there are still some rules for operating a rotary hammer, which not everyone knows about. Let's look at them in this not even an article, but a note.

1) Many people, when working with a hammer drill, try to press hard on the tool when drilling concrete, brick and other stone materials, thinking that this speeds up the process. I really don’t recommend doing this, since the drilling speed actually doesn’t increase, or, if it does, it doesn’t increase by much. But the load on the hammer drill’s impact mechanism becomes excessively high. The result is premature failure of this mechanism. Is it worth it to save a few seconds?

A lot of high-quality hammer drills at low prices in one place. Click to view

2) A three-mode hammer drill has a separate chiselling mode, when there is a blow, but no rotation. There is one nuance here, because of which it is worth writing separately how to hammer with a hammer drill in the hammer mode, so as not to break the tool ahead of time. But the nuance is this: the chiseling function is auxiliary, so I advise you not to constantly use a hammer drill as a chipper. There are jackhammers for this. On a hammer drill, use the chiselling function occasionally.

3) On rotary hammers, a parameter such as the maximum possible diameter of the drill is indicated. When constantly working with drills with the maximum permissible diameter or close to this value, the hammer drill will fail earlier than if it were working with drills of a smaller diameter. Therefore, if your work involves frequent use of a drill of a certain diameter, then I recommend that you have a hammer drill whose maximum permissible drill diameter is 30 percent larger than what you need.

4) Having bought a new hammer drill, many citizens immediately insert a drill into it and start working. Who should add drill lubricant to the chuck? If you do not use lubricant for drills, the cartridge will quickly fail, and it even happens that the shank of the drill simply flattens and then cannot be removed from the cartridge. So remember to put some lubricant in the chuck and then keep an eye on it.

5) Do you need to mix concrete with a special nozzle? Or drill a large hole in the tree? For this work, there are special low-speed drills with a reduction gearbox that can produce high torque. There is no need to use a hammer drill for this just because it is large. It does not have the same reduction gear as the above drills, so the motor can easily burn out. Moreover, the engine power of a conventional SDS+ hammer drill is approximately equal to the engine power of a conventional drill, which you did not want to use for the purposes indicated above.

This is the list. I advise you to arm yourself with the above tips, and also be sure to read the instructions before using the hammer drill. Then it will become easier and more pleasant for them to work, and it will serve you for a long time.

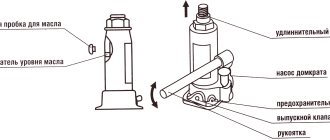

Instrument care and maintenance

In order for a hammer drill to last a long time, you need to take good care of it and not neglect this rule. First of all, it is recommended to periodically lubricate the tool. To do this, some rotary hammers provide access through the holes of the mode switches. In this case, lubricant is poured without completely disassembling the housing. In barrel models, a lid in the front is used for this purpose. The drill shanks also require constant brushing.

During operation, avoid dust getting into the housing. To do this, you can pull a nylon stocking over the air intake slot or come up with another homemade filter. Even if all the rules are followed, dust can get into the motor. Therefore, if you use the tool frequently, you should periodically disassemble its motor part and thoroughly blow it out.

Recommendations

When performing this work, care must be taken to ensure that the holes do not warp. You can avoid turning the holes by firmly resting the tool on the surface to be processed. If, nevertheless, the part is jammed, you must immediately turn off the tool, and then turn it on again in reverse mode. When there is no such mode, you will have to remove the hole manually. When drilling, it is unacceptable to clean the working channel with your hands - this could result in injury.

Many people are also interested in how to protect the room where renovations are being carried out from dust when drilling the ceiling. The classic method is to string a cardboard or plastic cup onto the working part of the tool. For the same purpose, you can use a special package. Sometimes they also take flat nylon jars without a lid.

To reduce the spread of dust that bypasses these devices, turn on an industrial vacuum cleaner.

To learn how to use a hammer drill correctly, watch the following video.