What is a rack vibratory compactor

In fact, a vibrating screed for concrete is a standard rule on which a three-phase asynchronous motor with eccentrics is attached. When the shaft rotates, the displaced center of gravity of the eccentrics causes mechanical vibrations that are transmitted to the rule in the form of vibrations of various frequencies. As a rule, a metal frame made of interconnected hollow profiles is used. To control the structure, handles with a vibration-insulating coating are provided, and for carrying, transport handles are provided.

Vibration treatment of the concrete mixture prevents the formation of voids in the hardened mortar and cracks on its surface, thereby improving its performance properties.

Rack seals are also used when working with dry screeds (at a humidity level of 20%). With the help of vibrating slats, you can quickly and efficiently lay paving slabs.

Types of vibrating slats

Vibration processing tools differ in several ways.

Differences by engine type

Rack and pinion vibration compactors are distinguished by the type of drive, which can be gasoline or electric.

A gasoline vibrating screed is more productive than an electric one. Independence from the power grid makes the device completely autonomous and indispensable for working in large areas.

In closed or residential areas, an electric vibrating screed is used, which does not emit exhaust gases and has a low noise level when the engine is running.

The electric motor is significantly lighter than a gasoline motor, which has a positive effect on the maneuverability of the unit. In addition, the electric vibrating screed is economical to operate.

Classification by type of construction

The configuration of the units determines their functionality and cost. Taking into account the design features, the following types of rack and pinion vibration equipment are distinguished:

- Floating vibration screed (finishing) - lightweight structures for thin-layer (up to 15-20 cm deep) finishing leveling. They work without guides.

- The aluminum profile ensures low weight of the unit and better glide over the surface, which is why the floating vibrating screed is also called a vibrating mop.

- Surface reversible. Equipped with a reversible forward motion mechanism and a profile with rounded edges. The installation can move in forward and reverse directions. The profile is rotated in the opposite direction by rotating the handle.

- Vibrating screeds with a fixed length. They work along guides and provide a compaction depth of up to 30 cm.

- Double telescopic (sliding). The telescopic vibrating screed is compact when folded, which is important when transporting equipment to a construction site. The length of the tool increases due to the retractable structure and can range from 2.5 to 4.5 m. The sliding vibrating screed is made from steel or aluminum profiles. The telescopic vibrating screed is heavy and works only along guides.

- Sectional. They are assembled from separate fragments and can reach a length of 20-30 m. Increasing the length of the slats allows you to process a larger area in one pass. By making the structure heavier, the effective compaction depth increases. These are universal devices for large-scale construction.

Features of operation of vibrating slats

Vibrating screeds are easy to use, but working with them has its own characteristics.

Rules for working with rack and pinion vibration compactors:

- Before starting, the serviceability of the equipment is checked. Rubber boots and gloves are worn to protect against possible electric shock.

- The floating vibrating screed should slide over the surface of the solution. Heavier equipment that operates along guides is installed before the concrete mixture is supplied and should be located slightly below its level.

- The guides for the vibrating screed are set strictly horizontally at the zero mark, which corresponds to the final level of the finished floor covering.

- After supplying the solution, the vibration installation is started and, using cables, it is pulled along the guides. Areas where the mixture subsides below a given level are filled with small portions of the solution until leveled at the required level.

- After finishing the work, thoroughly clean the frame from the solution. Particular attention is paid to the frame bolts that were in contact with the wet concrete mixture.

- Minor defects on the hardened surface can be easily removed with a grinder.

Features of using the device

A vibrating screed is a device that passes over the surface of the concrete being laid and performs several important tasks at once:

- Tamping the mixture, making the future coating more durable.

- Compaction of the solution - it contains a large amount of air impurities that require removal.

- Leveling the surface.

As a result, the structure of the concrete surface will be of higher quality and more durable.

This treatment of concrete makes it possible to achieve good performance characteristics of the future coating and remove possible voids, water and air bubbles from it. After vibrating lath, the coating is completely ready for finishing: laying tiles, laminate, linoleum, heated floors and other options.

Read also: Router for end mills

The product is used in private construction and on an industrial scale.

With its help, the following are built:

- bridges;

- hydraulic structures;

- overpasses;

- floors;

- blind areas;

- foundations and other similar objects.

How to make a vibrating screed with your own hands

A tool made independently from available instruments and materials allows you to solve the necessary problems and at the same time save on the purchase of expensive equipment.

As a rule, an electric vibrating screed is made with your own hands. However, in home-made units there are also gasoline engines (most often from broken chainsaws).

To make a vibrating screed for concrete with your own hands you will need:

- Basis for the working frame: aluminum or steel profile pipes of square section or channel 2-3 m long.

- Two corners with a cross section of 40x40 mm and a length of about 20 cm.

- Two pipes for handles (their length is determined by the height of the worker).

- Motor with vibration mechanism (for surface compaction 20 cm deep, a motor power of 1.5 kW is sufficient).

- Bolts for fastenings.

- Rubber for insulating handles.

- Three-phase wire.

- Drill and screwdriver.

- Welding equipment.

- Starting device.

Note! It is possible to carry out work without a welding machine, since a vibrating screed can be made using bolted fasteners.

If you have minimal skill, you can assemble a vibrating screed with your own hands quite quickly in a few steps:

- Corners are welded in the center of the profile at a certain distance from each other (in accordance with the engine dimensions). During the welding process, the ends of the profiles and corner joints of the structure are welded tightly, preventing the formation of gaps. Otherwise, during operation, the solution will fall into the holes, increasing the weight of the unit.

- Handles are formed from pipes or fittings, bending them at your discretion for convenience. They are welded to the profile (or bolted) on both sides of the engine.

- The engine is mounted strictly in the center of the frame. With its minimal deviation from the central position, the structure, during operation, will be pulled to the side, which will make it difficult to move in the desired direction. It is better to secure the engine with bolts: this way it will be available for replacement or repair at any time.

- A starting device is mounted on the handle or engine.

- Connect the power cable. The engine is grounded, and the handles are wrapped with vibration and current insulating material.

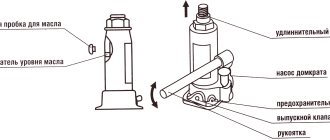

Operating principle and structure of the rack

The vibration screed consists of two elements:

- Rigid, durable frame. Consists of two parallel slats or wide strips made of high-quality alloy steel or thick aluminum. Lightweight aluminum does not corrode, is easier to maintain and lasts a long time. Steel planks are cheaper.

- Vibration system. A gasoline or electric engine drives the frame into asynchronous motion.

The device moves along the plane manually. When the motor starts, a rotational motion is transmitted, causing translational vibrations of the rack. The vibration of the frame compacts the solution, releasing air from the voids. A vibration screed with a gasoline engine is more powerful and efficient than an electric one. But a gasoline-powered unit emits harmful waste products into the environment, so it is recommended to compact concrete indoors using an electrically driven device.

The length of the planks reaches 10 meters, which allows the structure to be used for leveling surfaces of any size. On large areas it is more convenient to compact with an autonomous gasoline engine. The marks left behind are removed with a grinding machine while the cement screed hardens.

Types of vibration devices

Divided into 3 types:

- Floating, non-retractable. The simplest ones, intended for private use. Their power does not exceed 1.2 kW. The area of the compacted surface is limited by the length (no more than 3 meters) of the floating rigidly fixed strip.

- Telescopic, sliding. The devices are practical and versatile, allowing you to compact concrete screeds of any size. When extending, the slats increase the length to 10 meters. The leveling frame of such units consists of two bars. Designed for use by professional builders. Structurally more complex, they cost more than floating models.

- Sectional. The working part is increased by adding additional triangular frames to the rule. Functional, with convenient adjustment.

- Before starting, the tool is carefully checked: the bar must be clean, the fasteners are securely tightened;

- the operating engine must not be touched;

- after turning off the device, the rack is washed with water;

- if necessary, work with a gasoline model indoors, ensure good ventilation;

- The electric motor must be grounded.

Read also: Pipe cutting dies

Prices for vibrating screeds

The table shows the cost of some popular vibrating screed models:

| Brand | Nutrition | power, kWt | Weight, kg | Price, rubles |

| Impulse M35 | Gasoline 0.71 l/hour | 1,3 | 18 | 38 500 |

| TSS-MSD | Gasoline 0.73 l/hour | 1,2 | 13 | 69 400 |

| Masalta MSD4 | Petrol | 1,5 | 12,7 | 54 300 |

| RUSA VMAX (telescopic 4-7 m) | Petrol | 3,9 | 106 | 82 700 |

| TCC BP 2 (2 m) | 380 V | 0,34 | 39 | 13 500 |

| TCC BP 6 (6 m) | 220 V | 0,34 | 61 | 26 500 |

| TCC BP (telescopic) | 220 V | 0,34 | 48 |

Assembling a basic vibration screed with your own hands

To compact a concrete surface in a small room in 30 minutes, a disposable device is assembled from scrap materials. For production you will need:

- A smooth, strong board 3-3.5 cm wide, 25-28 cm long, 50-60 cm long.

- Handle made of a block or pole up to 1.5 m long.

- Drill with button lock.

- Aluminum mounting plates.

The tool is assembled in the following order:

- The surface of the board must be smooth; for this it is cleaned and sanded.

- The drill is fixed with aluminum plates and self-tapping screws on a wooden plank in the middle so that the axis of rotation of the chuck and the center of the board coincide.

- The handle is filed at an angle and similarly secured to the board with an oblique cut.

- A rod with a shifted center of gravity is installed in the drill chuck: a piece of reinforcement, a crooked drill bit, or a clamping key to the chuck.

The button of the drill connected to the network is clamped and fixed. The vibration created by the displaced center of gravity of an object inserted into the chuck is transmitted to the board.

The metal profile is more even and smooth than the board. And the weight and power of the units sold make it possible to use long slats and cover a large area, but for a single use such a vibrating screed will do.

Assembling a metal rail

For many craftsmen, the main difficulty is the lack of a welding machine and skills in handling it. In this case, welding of parts is replaced by a bolted connection.

For production you will need:

- steel channel, profile pipe or aluminum rail of the required length (1.5-2 meters or more);

- 2 corners 4x4 20x25 cm or channel sections;

- 2 pieces of pipe or fittings for handles of a convenient length;

- vibration motor, electric motor or internal combustion engine (for example, from a chain saw or walk-behind tractor, together with a clutch).

- Corners are welded on top of the center of the channel across the strip. The distance between them is determined by the size of the engine. Holes for mounting the motor are drilled and it is installed. The fasteners are tightened thoroughly so that the vibration is transferred to the frame and the motor does not come loose.

- Handles made of the selected material are welded on both sides of the engine. When working with an electrical device, they are isolated and the motor is grounded. Having the appropriate knowledge in electrical engineering, a speed controller is installed on the handle.

Craftsmen who work with concrete know that concrete is quite difficult to process and it is very difficult to create a smooth surface without too many defects. If a vibrating screed is used for laying concrete, the process is significantly simplified and accelerated, and the resulting surface will be much smoother and of higher quality.

The classic version of laying the mixture using a long row requires great physical effort from workers, has a number of difficulties and cannot give a high-quality result.

There are several varieties of this tool. Such devices are not too expensive, but many builders do not want to pay money for them, and using improvised means they build vibrating screeds with their own hands.