- 1 What is it for?

- 2 Characteristics

- 3 Pros and cons of use

- 4 Operating principle

- 5 Types of vibrators for concrete

- 6 How to use it correctly?

- 7 Tips for choosing

- 8 Examples of manufacturers

- 9 Conclusion

To create concrete of good quality and the desired homogeneous structure, special tools and various devices are used. For example, there are internal vibrators that are used to compact solid concrete structures or reinforced concrete products for prefabricated construction. This installation is very useful when creating foundations, floors, and concrete floors.

Such equipment improves the properties of the concrete mixture by removing excess air remaining after mixing the ingredients, simplifies the process of producing structures, and also reduces costs and construction time. Types of vibrators may differ in design and application, but the principle of operation is the same for all.

Pros and cons of using

When working with a vibrator, the following advantages are distinguished:

- durability of a single base, in the installation of which a concrete vibrator is used;

- no manual work required, the process is automated, which reduces labor costs;

- when working with vibrators, the time for work processes associated with concrete is reduced;

- the construction of structures is accelerated, since compaction with a vibrator increases the solidification rate;

- the seal can be transported without problems;

- the range of products differs in quality and price category;

- the sealing mechanism for removing air bubbles in concrete does not create much noise and creates comfortable use;

- a manual mechanism for compacting the solution requires a workforce of one person;

- hand-made is possible;

- 220 volt concrete vibrator increases adhesion between concrete mortar and reinforcement, which improves the strength characteristics of the structure.

The 220 V concrete vibrator has the following disadvantages:

- high cost;

- poor protection against possible mechanical damage;

- electricity costs.

Return to contents

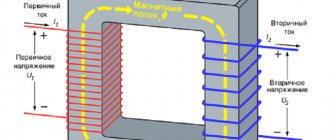

Operating principle

A concrete vibrator has the following principle of operation: a vibrating tip is immersed in the mixture, which transmits vibration through the nearby layers of the solution. This helps to reduce viscosity and acquire heavy liquid. The process of filling the mixture under the influence of gravitational forces occurs. The result is a dense mixture with a homogeneous structure and no air bubbles. The compacted solution acquires high strength and quality, which increase the service life of the structure being built using a concrete mixture.

Return to contents

Why do you need a deep vibrator?

The structure of freshly prepared concrete (granulometric composition) is very heterogeneous. It contains coarse crushed stone and fine sand, cement laitance, water and air. If you simply “plop” the concrete mixture into the formwork, nothing good will come of it. Air pockets will reduce the strength of hardened concrete, and crushed stone and sand need compact packaging.

A construction vibrator makes the concrete mixture fluid by moving its solid particles. As a result, air is squeezed onto the surface, and the filler is evenly distributed inside the structure.

Anyone who used this tool noticed that the vibrating concrete literally shrinks before our eyes in the formwork and its original volume is reduced by almost a third. After such treatment, the main enemy of concrete – voids – disappear, and its strength reaches the standard maximum.

Types of vibrators for concrete

There are different types of vibrator for concrete:

- Surface, which is used for floor slabs, screed pouring and for large working surface areas.

- Construction, used in the process of erecting heavy structures. When constructing private houses, they are used to construct foundations and monolithic walls.

- The electric compactor operates from a two-phase network and single-phase 220 V. A 220 V electric vibrator is more often used in the construction of private buildings. The most common compactors are electric deep ones, which are required for particularly important purposes, namely when pouring a foundation.

The 220 V concrete vibrator is different:

- vibration characteristics (low-frequency, medium- and high-frequency vibrations);

- influence on the solution, namely internal and external;

- types of engine.

Seals according to engine type are divided into:

- hydraulic;

- motor;

- electromagnetic;

- pneumatic;

- electromechanical.

Return to contents

Purpose of the vibrator

In the process of pouring the mixture, it is necessary to strive to obtain a homogeneous composition, to eliminate, if possible, the appearance of water and gas bubbles, and to avoid unevenness in filling the working volumes. If a reinforced concrete structure is created, in addition, it is necessary to achieve high-quality adhesion between the mixture and the reinforcing grid.

Since during the production of reinforced concrete products, as well as during the laying of the mixture, air is introduced into the mass of the solution in any case, there is a need to remove it. Otherwise, this can lead to a porous structure of the finished concrete, which reduces its quality. The best way to remove air bubbles is by vibrating the solution. This vibration is created by a deep vibrator.

At the same time, the air moves upward, the fluidity of the composition improves, and the filler in the solution mass is dispersed with better uniformity. The elimination of voids and liquid pockets strengthens the bond between the reinforcement and the mixture. As a result, when hardened, a denser structure with better characteristics is obtained.

We suggest you read: Choosing a bathhouse for a summer cottage

How to use it correctly?

In pouring concrete screeds, concrete vibrators are increasingly used.

When working with a sealing mechanism, to obtain maximum effect, the subtleties of its application are taken into account. Thus, each type of seal has requirements for its use. Deep equipment consists of a flexible shaft, which is immersed in the solution depending on the length of the shaft. The vibrating tip should not come into contact with the walls of the form and a distance of more than ten centimeters should be maintained from the formwork.

To assemble the vibrator, follow these steps:

- attach the vibrating tip to the flexible shaft;

- connect the opposite end of the part with torque to the engine;

- fill the joints with sealant;

- fix the shafts.

Upon completion of assembly, the equipment is tested for possible damage. If no faults are found, start a test run. Install the equipment on a flat surface and easily hit the formwork, so as to create vibration waves.

When using this sealant, vibration is transmitted to the solution along the surface that touches the equipment body. Before turning on the sealing mechanism, it should be checked for possible damage and the strength of the threaded joints. After this, the tamping equipment is placed on the workplace and secured with bolts. It is important to make grounding for the safe operation of the vibrating mechanism. During the tamping process, the bolts are tightened after five minutes and one hour of using the equipment, then the possibility of the device loosening and the bolts popping out is eliminated.

Return to contents

How to make a deep vibrator with your own hands?

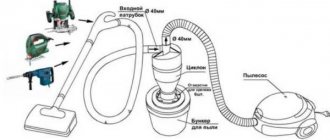

Despite affordable prices, many craftsmen try to make a concrete vibrator with their own hands. The simplest method is to adapt a construction hammer for vibration compaction. It cannot be called very effective, but such a device will bring some benefit to a construction site.

The idea of the modification is to install a standard lance with a metal thrust plate welded to it on a hammer drill with a power of 1.5-2 kilowatts. To vibrate the concrete, the plate is applied to the formwork and the tool is turned on in impact mode. The shocks of the lance are transmitted to the concrete through the formwork. For deep compaction, the lance is immersed in concrete and “bayoneted” it, periodically raising and lowering the hammer. Obviously, such a primitive mechanism can only be used to compact concrete, the thickness of which is equal to the length of the steel rod.

For deeper compaction, craftsmen create homemade vibrating attachments for drills, grinders, hammer drills and brush cutters. The basis of such structures is a steel pipe in which a homemade eccentric shaft is mounted on bearings. Through a coupling, it is attached to a flexible steel cable rotated by a motor.

Tips for choosing

If you are going to buy, rather than construct, a vibrator for concrete with your own hands, then the choice is influenced by the types of work for which it is used - for fine-grained concrete, purchase high-frequency compactors, and for coarse-grained concrete, low-frequency devices are suitable. Also pay attention to the size of the tip. The wide vibrating tip is used to cover large areas.

When choosing equipment, you need to pay attention to the depth of the flexible shaft.

When choosing equipment, they look at the depth of the flexible shaft, which affects the depth of entry into the concrete solution. The length of the flexible shaft depends on the type of construction. The use of an overly long shaft will result in a decrease in effect due to loss of productivity on the way to the concrete solution. A shaft with a short length does not provide the required immersion.

When choosing tamping equipment, pay attention to the diameter, which indicates the possible spanning distance. With a large diameter of the working surface, the vibrator will have to be immersed fewer times. When choosing equipment, take into account the characteristics of the conditions in which it is planned to be used.

The pneumatic vibrator operates under conditions of constant air supply at the required temperature. They are used in industry and in the construction of heavy, large-sized structures. An electric vibrator requires constant access to electrical networks, which creates difficulties during construction. To simplify the working process with an electric vibrator, use equipment compatible with gasoline.

If reinforcement is present in a concrete structure, a surface vibrator is used that does not come into contact with the metal structure. When choosing equipment for compacting concrete mortar, pay attention to the price, which is one of the main indicators of quality. Having the desire to save money and purchase a cheap mechanism, there is a risk of rapid failure of the working equipment.

Return to contents

Deep vibrators for concrete and their prices

And it's not that simple. There are two types of devices of this type:

- Manual (portable) with built-in electric motor. They have a small mass, the length of the hose and vibrating tip can be from 1 m to 2.5 meters. Prices for this type of equipment are low - the portable vibrator itself without a mace hose costs from 3.2 thousand rubles, plus another 1.5 thousand rubles for the vibrating tip. But there are models that are equipped with a hose right away, and their cost is not much higher: Sturm CV71101 in the basic configuration is equipped with a vibrating hose with a tip with a total length of 1 m, costs 3.5-3.7 thousand rubles.

The manual (portable) concrete vibrator is small in size and weight. They are convenient to work with small volumes - Portable concrete vibrators with flexible shaft and mace. They are mainly sold separately - a motor unit, to which a flexible shaft and tip of the required size are purchased. The motors themselves cost from 5.7 thousand rubles, hoses are sold at a price of 2.5 thousand rubles per 6 m; vibrating maces from 2 thousand rubles.

Hand-held deep vibrators consist of a durable sealed housing that houses an electric motor of relatively low power - up to 1 kW. This motor is an asynchronous type; unbalances are connected to it, which create oscillations. The working part - the tip or mace - is connected to the body with a rubberized sleeve through which the cable passes. The vibrations created by the motor are transmitted to the handpiece.

The weight of such a device is 6-10 kg. They can work with not very large volumes: they do not have very high power and, accordingly, a small radius of action.

The second type of deep vibrators consists of a motor, a flexible shaft and a working vibrating tip. Unlike the previous version, the motor stands still, and vibrations are transmitted through a flexible shaft. In this case, an important parameter is the length of the shaft, since it limits freedom of movement, as well as the depth of immersion of the club. To compact concrete in the foundations of small structures, a shaft length of 4 m is sufficient, but for larger ones it is better to take 6-10 meters.

Diagram of an internal vibrator for concrete with a flexible shaft

How to choose

Important characteristics of deep concrete vibrators are:

- The diameter of the seal is the area in which vibrations propagate. The larger it is, the faster compaction occurs and the fewer movements are required to achieve results.

- Frequency and amplitude of oscillations. The higher these indicators, the more active and faster the air displacement occurs. But the vibration frequency is also selected depending on the type of concrete: for fine-grained concrete compositions, high-frequency vibrators are used from 10,000 to 20,000 kol/min;

- for medium-grained - medium-frequency - from 3500 to 9000 kol/min;

- for coarse concrete, low-frequency models with oscillation frequencies of up to 3500 kol/min are required.

Since fine-grained concrete is mainly used for pouring foundations, the vibration frequency should be above 10,000 counts/min.

This is what a model with a flexible shaft looks like

In the case of concrete vibrators, price is an indicator of quality. In fact, in the characteristics there is such an indicator as time to failure. It is indicated in hours. This parameter shows how many hours the equipment can operate before the first breakdown. And the higher the price, the greater this resource.

How to use

Improper use of vibration will not only not bring any benefit, but can also cause harm: excessive duration of exposure will cause delamination of the solution, which will negatively affect its strength.

The exposure time depends on the plasticity of the solution and its fluidity. On average, the duration of treatment in one place is 30-60 seconds. As soon as the precipitation stops and cement laitance appears on the surface, the mace must be pulled out.

The step of repositioning the vibrating tip or mace depends on the radius of action (diameter of the compaction). It is 1-1.5 its size.

When compacting foundations or other structures in formwork, you need to ensure that the tip does not touch the walls of the formwork. The minimum distance to the shields should be about 10 cm.

Watch the video to see how to prepare a deep concrete vibrator for use. And one more important nuance: for vibrations to start, you need to lightly hit something with the mace. Then the fluctuations will begin.

Examples of manufacturers

Manual mechanism for tamping "Caliber".

The range of vibrators for compacting concrete mixtures is huge. Manufacturers offer the following types of equipment:

- Compacting mechanism "Rusinstroy". This manufacturer produces various models that are popular due to their high-quality hand-held device. The immersion hose is up to fifteen meters long. This installation is carried out in a mace, which ensures safety for the operator and increases the quality characteristics of the equipment. Using this mechanism simplifies the workflow due to the absence of large converters.

- Manual mechanism for tamping "Caliber". It has a low price, but at the same time has good technical performance. It is a professional high-frequency equipment with a power of up to 1.3 kW.

- Vibrators "IV". They are most in demand when used for dense concrete solutions. Working under such conditions, the units do not overheat, which is a big plus and does not require additional time for periodic cooling of the device.

Return to contents