At the heart of any building - from a small private house to a large shopping center - is a foundation. The strength of the entire building and its service life depend on its quality. But not only the quality of the concrete used is important, but also the exact adherence to the entire technological process. For example, poorly performed compaction of sand for the foundation can lead to the fact that the erected building may shrink, accompanied by the formation of cracks, both in the foundation itself and in the walls of the building. This, in turn, can lead to increased heat loss and, as a result, increased heating and air conditioning costs for the entire building.

Device selection criteria

Several conditions influence the quality of work. To obtain an excellent result, it is necessary to take into account all the properties of the model and select a site compactor, focusing on the tasks facing the unit.

Characteristics by mass

This is the main quality of a vibrator for compacting any surface, which affects the effectiveness of the task at hand.

You need to pay special attention to this when purchasing or making a homemade vibrating plate. A self-assembled device is often skewed towards one feature, so it is necessary to understand all the characteristics of the mechanism

The weight of vibratory ramming devices is distributed as follows:

- Lightweight models weighing up to 75 kilograms are suitable for working on surfaces with a small (up to 15 centimeters) soil layer thickness: paths in the garden, local areas for laying tiles or rugs.

- Medium ones with a draft thickness of up to 25 cm are quite versatile. They can cope with light work with equal efficiency and help with laying asphalt and paving slabs. Their weight is in the range of 75–90 kg.

- At a construction site, when pouring the foundation and strengthening the bottom of communication ditches, as well as laying several layers of asphalt pavement, medium-heavy vibrating machines weighing up to 140 kilograms and a compaction depth of up to 60 centimeters are useful.

- Heavy slabs perform the same work as the previous ones and weigh more than 140 kg.

The balance between the mass of the sole and the power of the power plant is the main thing that influences the device’s performance of its tasks. A skew towards the heaviness of the slab will drown the installation in the ground; low weight with excessive pressure on the base will not achieve the required surface density. The optimal ratio of the mass of the plate is 100 kilograms to the drive power of 5 horsepower.

Additional criteria

In addition to the main ones, there are also characteristics that need to be paid attention to. They have no less impact on the efficiency and control of the mechanism:

- Vibration strength.

- Sole dimensions.

- Engine power.

- Type of fuel.

The pressure force of the slab per unit area being processed depends on the size of the base.

The fuel that vibratory rammers consume is traditional - gasoline, diesel and electricity. All professionals recognize the advantage of a stove that works with a gasoline engine. They are unpretentious to working conditions, their cost is in the middle when compared with analogues. Diesel units are the most expensive and noisiest of all. The only advantage is the economical engine. An electric tool is the cheapest; in terms of performance, it does not lag behind gasoline ones, but is connected to the electrical network.

Light vibrators have the most balanced power. The range of work they perform does not imply serious technical characteristics. A motor with power corresponding to the nature of the work and the weight of the sole will move on its own, and the operator will only have to set the direction.

Useful features

All vibration installations have additional devices that make work easier or provide additional protection. In order to move the device to a new place of work, the presence of wheels and a folding handle will make this task performed without unnecessary effort.

Various covers will protect the machine from particles from the compacted surface. The slab wetting system is effective when rolling hot asphalt. Without it, it will stick to the top layer.

Work to strengthen the bottom of trenches or compact soil in narrow places is practically impossible without ensuring reverse movement.

Purpose of vibrating plates

A similar mechanism is used for compacting crumbly areas of earth and building materials, as well as uncured surfaces of asphalt and concrete. It is especially effective in small areas and sidewalks, as well as where heavy equipment cannot enter.

The use of this device will greatly facilitate manual labor in homestead or country landscape construction. The easiest way to compact the soil on a garden path or a small parking lot near a house is by mechanized method.

The tamping vibrodynamics will also help out during excavation work on laying underground communications, when you need to compact the soil at the bottom of the trench.

This device operates due to vibrations that occur during the rotation of a flywheel mounted on eccentrics:

- By displacing the ballast through the drive, the vibration created is transmitted to the iron base - the sole.

- The heavier it is, the stronger the oscillatory process and the denser the compaction.

Advantages of buildings on a sand bed

Among the numerous advantages that are worth noting when using sand cushion technology, it is almost impossible to single out the main and minor ones. Each individual characteristic makes its own unique “contribution” to the strength and reliability of the entire structure. The first and obvious advantage of a sand cushion is its low cost and simplicity of all work on the device, which will require a minimum amount of time.

A house with such a foundation can be built on almost any soil - weak, watery or heaving. At the same time, the service life of the building can be significantly increased if high-quality geotextiles are placed under the cushion, and a high-quality drainage system is provided at the site where construction is taking place. As a result of this, such common problems with a new home will be eliminated, such as:

- the formation of cracks in the walls and the foundation itself, caused by uneven shrinkage of the building;

- freezing of the foundation and, as a result, an increase in the cost of heating the house;

- accumulation of water in basements, often observed in houses located in areas with high groundwater levels, especially in spring;

- constantly high humidity, which is observed throughout the house, and not just in the basement, which leads to the formation of mold, damage to furniture, and various allergic reactions among residents;

- the need to install a serious supply and exhaust ventilation system, the cost of installation and operation of which can amount to quite decent amounts.

How to Compact Soil Without a Vibrating Plate

How to compact sand?

Overview of methods Tamping is required for construction on the ground, filling a cushion under the foundation (on any soil), installing a sand layer for the floor, and laying paving slabs . It is performed either manually (using homemade or factory-made tools), or mechanized using various vibration devices. When working with equipment that operates by transmitting strong mechanical vibrations, it is mandatory to use hearing and vision protection, as well as special gloves, shoes and clothing.

The goal is to obtain a dense layer that is not subject to heaving, shrinkage, compression, and to create reliable support for the foundation, floor, and road surface. According to the technology, several passes are usually made over the entire surface, then the quality of the compaction is visually assessed. Well-compacted material does not collapse when stepped on.

Where is sand compaction needed?

1. Sandy soil

.

The main distinguishing feature is that it does not retain water well. Therefore, this type of soil is not susceptible to frost heaving, which means it is suitable for buildings, including residential ones, but only one-story or very light ones. Heaving soils begin to push out the foundation in winter. This is because the water they contain freezes and expands. Such soils, unlike sandy ones, are little or completely unsuitable for construction. They, as well as weak soils, are often completely removed and replaced with sand. In any case, in preparation for installing the foundation, careful compaction is required either manually or using special tools.

During the process, the site is passed through three times. If after the third time it was not possible to achieve the desired result, then make a thinner layer. When compacting sand, including when preparing the soil, it is necessary to wet it, but moderately. Dry bulk material does not stick together, and if it is too wet, it is impossible to compact it

. It’s easy to check the degree of moisture - if, when you squeeze it in your hand, it doesn’t stick together into a lump or crumble, then you can start working. In the hot season, you will have to constantly wet the surface, as it dries quickly.

2. Sandy foundation pad.

Foundation bedding is used in the construction of light buildings: frame, foam block or one-story buildings made of heavier materials. It is not suitable for installing the foundations of multi-story buildings, since it does not have a high load-bearing capacity.

Coarse river or washed quarry sand is suitable for constructing a foundation cushion. It’s not worth buying a cheaper (unwashed) one. The difference in price is insignificant, but at the same time, the dirty contains a high content of impurities, primarily clay, which has a bad effect on the strength of the base of the building.

Positive characteristics of the foundation cushion:

- ease of manufacture - simple backfilling, without the use of complex equipment;

- accessibility - sand is easy to buy with delivery in any region;

- low price;

- reduces soil load well;

- Easy compaction even by hand.

It is not recommended to use in soils with high water levels. If this material is the only possible option, then geotextiles are laid at the bottom of the trench or pit. The thickness of the layer is selected taking into account the expected load and type of soil. The sand is poured in layers, moistened (but not filled with water) and compacted tightly.

Tamping accessories

Made of metal, it weighs from 5 to 10 kg. It consists of a handle and a base (“paw”) - a plate measuring approximately 20 x 25 cm or a channel (the smaller the dimensions of this part of the device, the greater the impact force). The handle of the tool is straight (in the form of a pipe) or T-shaped, with two handles on the sides. If necessary, a manual tamper with a channel can be made heavier by filling it with cement.

If you need to save money, then it’s easy to make the device yourself. Two manufacturing options:

- Make a handle from a heavy wooden beam about 1 m long and nail a “paw” from a strong board to it from below.

- Buy a separate ready-made plate (costs about 1000 rubles) and attach it to a shovel handle or a metal stick.

To compact soil and bulk materials, including sand, in a limited space, a “vibrating foot” is used. The engine of this device runs on gasoline or diesel fuel. At the base of the apparatus there is a “heel” plate with a width of 15 to 30 cm and a length of about 33 cm. Vibratory rammers also differ in power. The principle of operation is based on a vertically directed force, like a manual device, but the efficiency is much greater. This type of equipment is used on sites where it is impossible to operate large-sized equipment: vibratory plates and vibratory rollers.

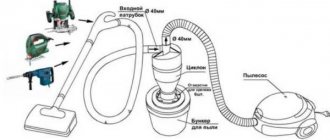

For work over a large area, subject to the possibility of free movement, tamping using a vibrating plate is suitable. This apparatus consists of a motor, a basket or “shoe” and a guide handle. The unit moves back and forth, transmitting strong mechanical vibration (vibration) to the sand particles, due to which compaction occurs.

Types of equipment for soil and bulk materials with a slab base:

- gasoline;

- diesel;

- hydraulic;

- electrical;

- with remote control.

Vibrating plates vary in weight. The lightest ones are suitable for sand.

For the largest volumes of work, vibratory rollers are used. Their types:

- with manual control due to the guide handle;

- self-propelled with an operator's cabin, single-drum (wheeled at the rear);

- with a two-roller cabin;

- trench with remote control.

The design of a high-quality vibratory roller allows compaction to be carried out along the edges of the site, that is, the use of additional equipment (manual or vibratory rammer) is not required.

The price for the services of professional builders to compact sandy soil or sand backfill is from 90 to 600 rubles per m2. If the area that needs to be compacted is large, or we are talking about permanent work, then you need to compare these prices with the cost of the equipment. In many cases, it is advisable to purchase a device or rent one and do everything yourself.

| Type of device | Price, rubles |

| Manual rammer with straight handle and plate base | 1800 |

| Manual with T-handle and channel base | 2800 |

| Vibratory rammer | 27 500 |

| Vibrating plate | 21 000 |

| Manual vibrating roller | 270 000 |

| Vibratory roller with control cabin | 2 000 000 |

Depending on the type of equipment, either a vertically directed impact force or vibration transmitted from the roller shaft or the base of the slab acts. In any case, the technology does not include any secrets or complications.

In the first part, I talked about the design of floors on the ground, now I will move on to the practical part of implementing floors on the ground in a private house.

Methods for compacting soil and sand

Creating a dense sand layer is one of the main tasks of the stage of preparing the bases for screeds or foundation structures; it is important to use the right methods and tools to expel air and compress particles. The price when involving professional firms depends on the depth of processing and other factors and varies from 70 to 900 rubles per 1 m2. The choice of a specific method determines the purpose of the layer, the area to be captured and the budget.

- Purpose of work

- Compaction methods

- Price

Goals and objectives of ramming

It is carried out when preparing sandy and finely dispersed soils before building houses, backfilling a cushion under slab or strip foundations, forming a rigid underlying layer when arranging floors on the ground or laying a base for paving stones and fencing. Among the tasks are:

- Protection of erected structures from frost heaving and removal of moisture from them.

- Leveling the base and strengthening its rigidity.

- Preventing deformation of structures under the influence of compression and bending loads, eliminating the risk of their destruction during shrinkage processes.

- Obtaining a dense and stable layer separating the base of the foundation or screed and direct soil.

- Elimination of voids and expulsion of air.

Review of the methods used, selection of the optimal option

Depending on the equipment and the direction of the efforts applied, the following methods for preparing and compacting the sand base are distinguished:

- Rolling of self-propelled or trailed construction equipment with rollers or wheels, carried out in 1 or several passes.

- Slabs weighing 1-2 tons dropped by a crane.

- Activation of the vibration device.

- Manual tamping using an expanded beam or channel with an attached slab.

When compacting soils and sands by rolling, the desired effect is achieved due to the static pressure of rollers having different working widths and weights from 10 to 25 tons for single-axle self-propelled varieties, up to 50 tons for biaxial ones and up to 100 tons for trailed ones. Lighter models are used in loose areas; they ensure successful processing of a layer of 20-30 cm in one pass. The heaviest and most productive equipment is used for compacting 40-50 cm with a pass width of up to 30 at a time.

The choice of a specific type of skating rink, in addition to the thickness of the layer, depends on the size of the area and ease of access. Small self-propelled rollers are distinguished by good maneuverability; heavy semi-trailers work only in conjunction with a tractor.

To achieve an optimal result, compaction is carried out in several passes, most often using a spiral-ring pattern of movement of the rollers and sequential addition of the missing bulk material. The advantage is the high quality of preparation of sand foundation pads with a thickness of 20 to 50 cm (impossible when done manually), the disadvantage is the use of expensive equipment.

Tamping using the drop compactor method is selected when it is necessary to expel air from cohesive soils with voids or layers of pulverized sand and clay.

When implementing it, solid slabs weighing up to 2 m are lifted and dropped using a crane or escalator to a height of 1 to 2 m.

This load makes it possible to process the base to a depth of up to 2 m; the maximum effect is achieved when preparing round or rectangular slab-type foundations. The tamping element remains attached to the crane boom or escalator, the process is carried out continuously and quickly.

An analogue of the previous method is manual, selected when the thickness of the pillow is small or when its area is small. The easiest way to make the tool yourself is by nailing a thick board to a wooden beam, welding or screwing a metal sheet to a channel, or a combination of these materials.

The output should be a heavy, but manually lifted, expanded slab with a vertical handle. To enhance the effect, it is recommended to weight the part in contact with the ground with cement or metal.

The advantages include independence from expensive equipment and the ability to process hard-to-reach areas, the disadvantages are labor intensity; when compacting manually, it takes more time and effort to expel air.

The most popular and effective method is the use of vibration equipment: mechanical high-frequency vibrations directed at the sand help make it as compressed and even as possible. For these purposes, equipment with different designs and drive types is selected, namely:

1. Vibrating rammers are a compact and ergonomic tool that transmits impacts from a gasoline or electric drive to a relatively wide heel - a flat strip of compacted rubber with a width of 15-30 cm and a length of up to 33.

Their power and dimensions vary, but the principle remains the same - the impact is directed vertically.

They are used on any construction sites, both in combination with rollers and slabs, and on their own; their use is especially important when it is impossible for large equipment to move, for example, in trenches.

2. Vibrating plates that have a wider working platform and, based on weight and performance, are divided into light, universal, heavy and super-heavy.

Their range includes manual and remote models with electric, diesel, petrol or hydraulic drive, each of which has its own pros and cons.

Vibrating plates have a universal scope of application, but for soil, cushion or sand under a screed, light varieties with a weight of 75 and 200 kg, respectively, are best suited.

3. Vibratory rollers that combine wheel pressure with mechanical vibration and are selected primarily when it is necessary to compact large areas. Their functions depend on the model; the most advanced ones quite accurately process edges and difficult areas without using vibratory rammers or plates.

The choice of drive type is directly influenced by work conditions and safety requirements. In the absence of connected electrical networks and a large area for processing medium-thick layers, the optimal solution would be to use a vibrating plate with a gasoline or diesel drive.

If it is necessary to compact soil and sand to a depth of 1 m and similar conditions, preference is given to the same vibratory rammer.

In enclosed spaces (for example, when preparing floors for screed) or when ventilation is limited, an electric vibrating plate or similar equipment is used.

It is advisable to combine the process with wetting with water. In this case, it is important to know when to stop; moisture should not be excessive or accumulated, but in general, wet particles adhere better.

The achieved result is also largely influenced by the quality of the bulk material, namely: the size of its grains, the purity of the composition, the proportion of fine fractions and dust.

In some cases, it is advisable to completely replace the soil in the pit with coarse-grained or gravelly sand; the increase in construction costs is justified by obtaining a reliable foundation.

The number of passes of a vibrating plate or roller depends on the given compression ratio, the recommended average value for pillows under foundations and screeds is 0.95. This parameter can be easily checked using a density meter.

The traffic pattern is selected in advance; there is no need to walk or move loads on the prepared surface.

During compaction, the equipment is protected from dirt and overheating; the corresponding filters of the vibrating tool must be cleaned.

Cost of work

| Type of service | Unit of measurement, conditions | Price, rubles |

| Compaction with a vibrating plate, roller or vibrating rammer | m2, with a layer thickness of up to 50 cm | 90 |

| The same for thicknesses up to 100 mm, with layer-by-layer filling | 150 | |

| Compacting sandy soil with a roller | m3 | 230 |

| Hire a crane with a stove | day | from 700 |

| Rental of self-propelled or semi-trailer rollers | 15 000 |

The prices are influenced by climatic conditions, the presence or absence of convenient access and a connected electrical network (renting gasoline vibrating rammers and slabs is more expensive), seasonality and the quality of the material being compacted. The starting price for mechanized equipment and machinery is 20,000 rubles, for rollers and cranes - from 1.5 million; for one-time work it is more profitable to rent them.

Source: https://cemgid.ru/sposoby-uplotneniya-grunta-i-peska.html

Features of self-installation of a sand cushion

Before starting work, it is necessary to determine several points on which the quality of the resulting base directly depends:

- the thickness of the pillow must be at least 200 mm;

- the most successful option is the trapezoidal shape of the pillow;

- The optimal base thickness is considered to be a value that does not exceed the width of the foundation by more than 3 times.

Installation of a pillow under the foundation

All work on installing a sand cushion can be divided into several main stages.

- Careful marking of the site, carried out in accordance with the selected foundation parameters. All measurements and marks should be verified as accurately as possible, using a tape measure and a building level.

- In strict accordance with the intended lines, a pit or trench is dug to a depth slightly exceeding the freezing point of the soil.

- Be sure to level the bottom of the trench or pit and compact it as much as possible.

- Sand is poured in “thin” layers, and the width of each of them should not be more than 20 cm in width.

- Before compacting the sand, it must be moistened with water, without, however, allowing it to be excessively moistened. You can check “readiness” in a simple way - you won’t be able to form a lump out of optimally moistened sand.

- Each layer is compacted separately. When performing work in the summer at high ambient temperatures, it is necessary to constantly moisten the layers of sand, since the moisture evaporates from it quite quickly.

- In order to ensure high-quality compaction of sand for the foundation, it is best to use a special vibrating plate. Since its cost is quite high and its scope is limited, it would be most convenient to rent it.

- If the use of such a tool is difficult or impossible for some reason (lack of power supply, for example), manual tamping with your own hands can also be done using homemade devices. For example, you can attach side handles to a round beam (log) and roll each layer of poured sand.

It should be borne in mind that if you provide special drainage in heaving soil, this will eliminate the possibility of the sand cushion being flooded with water in the off-season, which directly affects the durability of the foundation and the entire structure as a whole.

Methods

In order to carry out preparatory work for construction, a sand cushion can be formed using various methods. Their choice directly depends on what kind of tool is available, how large the working surface area is, and also what requirements are imposed on the level of density of the sand substrate.

There are several methods for performing work related to sand compaction.

- self-propelled machine is used which compacts sand with the help of its wheels. Sometimes trailer-type special equipment is used, equipped with rolling rollers, with the help of which layer-by-layer compaction is carried out in several passes.

- Using a crane , slabs weighing up to 2 tons are dropped onto the work site.

- Sand can be compacted with a vibrating plate - a special mechanical device.

- Using a channel or wide beam, sand can be compacted without a vibrating plate, that is, manually.

The selection of mechanized methods for compacting bulk material depends on the convenience for the operation of specialized equipment, the availability of access roads for it and the thickness of the sand base required by the project. On large areas, work is carried out using tractors, and small areas are processed with self-propelled rollers. If you need to compact sand in a very small, confined space, a hand tamper may well be suitable for this case.

In order to efficiently compact sandy bulk material, several passes are made using a tool on the same working surface, and the tamping movements are performed in a spiral direction - this way you can be sure that there will be no untreated areas of the substrate surface. If the material has sagged significantly after compaction, it is possible to add sand to those areas where there is clearly not enough of it. To compress the sand particles more tightly, it is regularly watered with water, which helps push out the air between the sand grains.

Compaction is carried out by dropping monolithic heavy slabs if the cushion consists of clay and sand of the dust fraction. Such substrates contain air in their multiple cavities, which comes to the surface under the weight of the monolith. Using special equipment, the slab is lifted to a height of up to 2 meters and dropped flat onto the work surface. This method allows you to work the clay-sand mixture to a depth of 1.5-2 meters. Typically, this method is used when preparing the foundation for a capital building.

Sand cushion for the foundation - when it is needed

Before starting construction, it is necessary to assess not only the condition of the soil in the area where the house is being built (bearing capacity, proximity of underwater waters), but also the climate conditions, as well as the total weight of the structure. It is mandatory to compact heaving soil, which is significantly deformed during the process of freezing and thawing. If you make a mistake with the choice of material for installing a slab under the foundation, most likely the building will shrink greatly, which will lead to the formation of cracks in the walls and the foundation itself. In addition, if the soil in the construction area has a high bearing capacity and the groundwater level is extremely low, you can do without creating a sand cushion.

Of all the materials that are used to create a pillow, sand is the most acceptable. It not only allows you to save a decent amount compared to a slab of crushed stone or concrete, in addition, compacting sand with your own hands is quite acceptable - for example, working with crushed stone is much more difficult. There is only one limitation on the construction of a sand cushion - heavy buildings cannot be built on it (apartment buildings, shopping centers), but for private low-rise construction it is an almost ideal material.

sand cushion

A properly created sand cushion has numerous advantages:

The foundation created using sand fully complies with all standards used in low-rise construction. Complete protection of the entire building from the negative influence of groundwater. Creating a perfectly level site for construction without the use of complex and expensive technologies. Possibility of carrying out all work on our own. The cost of this important stage of work is quite affordable.

How to compact sand without a vibrating plate – Special equipment

Creating a dense sand layer is one of the main tasks of the stage of preparing the bases for screeds or foundation structures; it is important to use the right methods and tools to expel air and compress particles. The price when involving professional firms depends on the depth of processing and other factors and varies from 70 to 900 rubles per 1 m2. The choice of a specific method determines the purpose of the layer, the area to be captured and the budget.

- Purpose of work

- Compaction methods

- Price

Goals and objectives of ramming

It is carried out when preparing sandy and finely dispersed soils before building houses, backfilling a cushion under slab or strip foundations, forming a rigid underlying layer when arranging floors on the ground or laying a base for paving stones and fencing. Among the tasks are:

- Protection of erected structures from frost heaving and removal of moisture from them.

- Leveling the base and strengthening its rigidity.

- Preventing deformation of structures under the influence of compression and bending loads, eliminating the risk of their destruction during shrinkage processes.

- Obtaining a dense and stable layer separating the base of the foundation or screed and direct soil.

- Elimination of voids and expulsion of air.

How to Compact Sand with a Vibrating Plate

sand cushion

under the foundation

A foundation cushion is a layer of sand, gravel or crushed stone placed before construction of the foundation begins.

Mainly similar to oil, it is used for the belt type, especially if the foundation is being built on unstable soil.

The most common and not the cheapest is considered to be a sand cushion, since this popular rumor material softens the load of a building on the soil well, and its deposits can always be found in almost any area.

Safety precautions at work

Compaction of soil with a vibrating plate must be carried out in compliance with safety precautions. Among the many recommendations, the following basic rules can be highlighted.

- During work, it is necessary to use personal protective equipment

: appropriate clothing and shoes, glasses, headphones, and a hat. - Before starting operation, you need to check the equipment you are using for external damage: if any, they should be eliminated first.

- It is prohibited to leave operating equipment unsupervised; the operator must be positioned behind it and promptly move behind the unit.

- Every 40 minutes you need to organize a break of about 10 minutes to prevent operator fatigue.

- You cannot further speed up the mechanism by applying additional force.

- If you need to work on an inclined surface

(when the angle does not exceed the norm), then the operating personnel must stand above the unit, moving from top to bottom. - It is prohibited to operate the technical device near sources of explosive or flammable materials.

- When overturning a vibrating plate

, it should first be turned off and only then put into working position. - The unit can be deployed with one hand.

- To prevent injury, you should keep your feet and hands away from the working base of the stove.

- If you collide with any obstacle, you need to stop the unit, and then eliminate the obstacle and possible damage caused by it.

- It is required to be no closer to the edges of trenches, pits, ravines and other excavations than the minimum permissible distance, or better yet, further away.

- It is strictly prohibited to allow people under the influence of drugs, alcohol, or psychotropic drugs to work.

It should be taken into account that the higher the center of gravity of the vibration equipment (and the smaller the support area), the easier it can tip over. This is very dangerous for the operator

You should also be very careful when turning on equipment that is not equipped with a soft start function.

The use of a vibrating plate is required when carrying out all construction activities that involve compacting loose soils. It is necessary to take into account the characteristics of the materials being rammed in order to achieve a high-quality result. It is necessary that the maximum depth of the poured layer corresponds to the thickness that the operating unit is capable of compacting. In any case, safety must come first. Failure to follow these simple rules along with inattention can result in serious injury.

To give the building maximum stability, you need to carefully compact the sand at the base of the foundation - this will protect the building from water and shrinkage.

Such a cushion can be made of concrete or crushed stone, but most builders choose sand.

High-quality sand compaction is a guarantee of a durable foundation.

Before compacting begins, the thickness of the future cushion, which will be necessary for the foundation of the building, is determined. The sand layer can be from 10 to 30 mm, but this factor completely depends on the weight of the future building - the greater the weight, the thicker the layer should be. If the sand base is made for a road or site, the thickness should be about 150 mm.

Civil and Environmental Engineering - College of Engineering

CIVIL AND ENVIRONMENTAL ENGINEERING

CIVIL AND ENVIRONMENTAL ENGINEERING

- Branch

- Near

- Meet the head of the department

- CEE department code

- calendar of events

- Employment Opportunities

- Professional coverage

- Conferences and short courses

- Engineering software

- Advanced training programs

- Archival media

- Video

- Newsletters

- Bachelor's program

- ABET

- What is civil engineering?

- What is environmental engineering?

- Admission Information

- Schedule a visit

- Curriculum and consultations

- SUCCESS program

- Academic village

- Request information

- News and notes

- Graduation program

- Research activities

- Faculty

- Traditional subdisciplines

- Admission Requirements

- Application information

- Non-Citizen Candidates for Bachelor's Degree in Certification

- Applicants for Bachelor's Degree in Engineering

- Degree Information

- Graduate Forms

- Features of Grad Assistant

- Distance learning

- Request information

- News and notes

- Student Resources

- Course Descriptions

- Scholarships and funding

- Student associations and clubs

- Available student vacancies

- Research

- Areas of research Research centers and institutes

- Research laboratories

- International programs

- Human

- Directory

- Regular Faculty

- United Faculty

- Research staff

- Instructors

- Honorary Faculty

- In Memoriam

- Administrative staff

- Faculty recognition

- Faculty Awards

- Faculty editorial positions

- Resources of the Republic of Belarus

- Department Resources

- Alumni and friends

- Meet our alumni

- 1930s - 1940s

- 1950s - 1960s

- 1970s - 1980s

- 1990s - 2000s

- 2001 - PRESENT

- stay in touch

- for complete leveling and increasing the degree of rigidity of the surface of the base of the future structure being built;

- to prevent the destruction of the foundation structure under the influence of moisture or low temperatures, when the soil begins to swell from excess water;

- to prevent distortion of the structure from the action of bending and compressive loads on it during soil shrinkage processes;

- in order to eliminate hidden voids filled with air;

- for the construction of an intermediate stable layer formed between the soil and the foundation structure.

What is it and what is it for?

When building a house under a foundation or screed, it is necessary to make a hard layer in the form of a lining of sand or gravel with a fine dispersion. The tamping technique allows such a base to provide the necessary density. To compact bulk materials, specialized equipment is used, and if the coverage area is small, a manual method of performing the work is used. A dense sand cushion is necessary before starting construction work for the following reasons:

Compacted sand creates a dense and durable layer, which is a reliable base for laying asphalt pavement, paving slabs, and building foundations. A properly formed sand layer is not subject to deformation and does not fall through if you step on it. Tamping technology involves performing this work in multiple passes over the entire surface of the sand layer.

READ How to Properly Sand Wood with a Sander

Upon completion of these actions, quality is assessed not only visually, but also with the help of special devices.

Safety precautions for work

When compacting soil with a pneumatic primer and using it for other materials, you should first go through the safety regulations.

Of the recommendations that already exist, remember the following:

- For safe operation, the operator must cover his body and face with personal protective equipment, namely headphones, glasses, hard hats, durable clothing and shoes.

- If work will be carried out on a small hill, then the operator and other workers must be above the device. The work should be done from top to bottom.

If for some reason the vibrating plate encounters an obstacle, you should immediately turn it off. After this, remove the obstacle, and the tool should be inspected to ensure that it does not have any malfunctions.

Please note that the higher the center of gravity of the device, the easier it is to tip over. In addition, the master should be careful when working with equipment that has a small support area.

Work especially carefully with a vibrating plate that has a soft start button, since if the work is done in a confined space, then it will be much safer for a person to use remote-controlled models. Naturally, such devices are more expensive, but they fully justify their cost. Compaction with a vibrating plate helps to cope with any tasks that involve compacting bulk materials. To get a high-quality result, you should take into account the characteristics of specific surfaces, and also calculate the appropriate thickness for the layer. The main attention should be paid to safety precautions. Failure to follow these basic rules can result in serious injury and tool failure.

How to compact sand under tiles: features of installing sand under paving slabs

Compacting sand during the process of laying paving slabs is necessary in order to obtain a dense layer that is not subject to shrinkage, heaving and compression, which will become a reliable support for taking the load from the tiles.

Carefully compacted sand is not subject to processes such as compression or stretching. In addition, the sand cushion prevents water from reaching the tiles from under the lower layers of soil. To achieve painstaking compaction of sand, it is necessary to pour it onto the base in small portions, which are constantly moistened with water.

In addition, the work to begin begins with clearing the earth of its grass layer. Later comes the painstaking compaction of the soil itself using a special roller or hand tool. Only then does the sand cushion begin to be refined, every three cm of which is very carefully compacted. To check the compaction density, put on boots and walk on the sand; the absence of traces indicates high-quality work.

To compact sand, a hand tool or a special vibrator is used. The use of a vibration plate can significantly speed up this process. But, if you don’t have a tool for compacting sand on your site, it’s enough to take an ordinary beam and attach handles to it. The tool allows you to carefully compact the sand under the tiles, despite the fact that this process does not take much longer in terms of time.

Sand is laid on the base in layers of 20-30 mm, while the next layer is poured only after the painstaking and complete compaction of the previous one has been completed. Use a building level to control the horizontalness of the backfill. We recommend constructing a sand cushion using coarse-grained sand, which has excellent resistance to compression.

Later, it is recommended to lay geotextile-based materials and lay a gravel cushion on them. The thickness of the layer of such a pillow is about 100-50 mm. Then, the base is again covered with sand and carefully compacted. Later the tiles are laid. The tile should be immersed in the sand a third of the way; to check its correct placement, use a rubber mallet. At the end of laying each row of tiles, check the horizontal position using a level.

Installation of the edges and water drainage system is done before laying the tiles on the sand .

Fixation of these parts is ensured by laying them on cement mortar. Lay the tiles away from you. Upon completion of installation work, all cracks between the tiles are filled with sand. Later, the surface is filled with water and waited for three days. Then, the tile is ready for use.

Homemade vibrating plate

Factory installations for tamping cost a lot. Therefore, some craftsmen prefer to make a vibration compactor themselves. This process will require welding skills and a small set of tools.

Advantages of homemade products

The cost of a device made independently is much lower than that of ready-made equipment. In appearance, it resembles a walk-behind tractor with a vibration motor. Quality and durability are ensured by the simplicity of the design. The efficiency of such a vibrator is no lower than that of a purchased one, and sometimes even higher. Advantages of a homemade vibrating plate:

- Full compliance with the operating conditions for which it is manufactured allows you to perform the assigned functions with high quality.

- The owner chooses which vibrating plate to make: with an electric motor or an internal combustion engine.

- Everyone also worries about their own safety. Therefore, all the necessary protection systems will be provided and installed.

- Having your own device will allow you to choose the time and place of work according to your circumstances.

Selecting a traction device

First of all, it is necessary to decide what type of fuel to prefer. This could be a self-made 220 V vibrating plate, but its use will be limited. The diesel engine is too noisy and heavy, so it is preferable to go with a gasoline engine. Such a drive will allow compaction of earth, sand, bulk building materials, tiles and asphalt surfaces.

To ensure acceptable seal quality, a single or two-cylinder engine is suitable. There are many of them on the market. In the more expensive category, the most popular models are from Honda and Kipor, as well as cheap Lifan, DDE and Champion.

Materials and accessories

Everything you need to build a vibrating plate with a gasoline engine is usually available nearby or can be purchased inexpensively on the market. Materials to be used:

- Gasoline engine.

- A metal sheet measuring 0.80 by 0.45 meters and 8-0 millimeters thick.

- Two pieces of channel.

- 4 bolts for 12.

- The tube for the handle is selected according to the size of the palm.

- Shock absorbers from a car engine.

- 2 wheels.

As a last resort, there is a service such as tool rental. Renting the necessary equipment will be inexpensive. Equipment needed for work:

- Welding apparatus and electrodes.

- Angle grinder and discs for it.

- Drilling device (drill or machine).

- Hammer or small sledgehammer.

- Ruler, chalk or scriber, tape measure.

- Protective equipment: welder's mask, goggles, gloves.

Making a vibrating table

First of all, the working platform is made. The edges of the sheet metal must be bent 30-40 degrees relative to the ground. To do this, the surface of the plate must be sawed 10 centimeters from the edge, with a depth of no more than half its thickness. Then bend along the cut line with a hammer. The seams at the bends must be scalded for rigid fixation. This design of the sole will allow the future vibrating plate to slide along the surface rather than bury itself in it.

The most crucial moment is welding the channels to the sole. They need to be measured exactly according to the size of the slab and welded, focusing on the center - so that there is 70-00 millimeters between them. To prevent the stove from leading, you should not overheat the material being welded. To mount it, you need to mark the channel along the motor mount. You can simply attach it to the channel runners and mark the points with chalk or a marker. You can also measure these distances with a tape measure. After drilling the hole, the engine is placed in place and bolted.

Peculiarities

Mechanized soil laying is not always possible. Before you start making a tamper, you should study the features of how the tool works with crushed stone and sand. Novice builders do not always understand why it is necessary to compact crushed stone, but there are several nuances here.

- Because crushed stone is produced by crushing larger stones, the resulting particles have different shapes and sizes. In this regard, during the laying of the underlying layer, the elements do not adhere tightly to each other. Thus, to achieve the required layer strength, another compaction is required.

- When compaction is completed, the thickness of the lined crushed stone is reduced. The preliminary thickness of such a base is determined by calculation, which takes into account the required loads.

- Compaction of crushed stone provides a stronger base that can withstand impressive loads. Interestingly, if the material is laid on rocky soil, compaction is not required - it is enough to level the gravel in places inaccessible to compaction.

Additionally, in the process of processing crushed stone material, declinging should be carried out - dividing the gravel into fractions. To do this, you will first need to lay out a layer of larger stones and compact it manually, then - material of the middle fraction, which will also need to be compacted. The topmost crushed stone layer should include fine particles. It needs to be leveled and tamped.

As for the specifics of using a tamper to compact sand, the procedure has a number of nuances that must be taken into account. To create a strong and durable foundation, it is recommended to use gravel-type material of medium or fine fraction. However, when constructing a monolithic structure, it is worth choosing river sand, which will also need to be compacted later.

To prevent erosion of the future foundation, it is necessary to line the bottom with geotextiles before filling the sand. The sand itself needs to be sifted to get rid of foreign impurities that could negatively affect the composition of the base.

How to lay tiles with a vibrating plate

Laying paving slabs using a vibrating plate is not much different from the usual compaction procedure. The only mandatory condition is the presence of a special polyurethane or rubber mat attached to the working part of the equipment. The mat is necessary to avoid unnecessary damage to the tiles. Polyurethane plates are preferable because they are more wear-resistant and do not leave black stripes on the surface of the sidewalk.

When building foundations for houses, garages, country paths and much more, great attention is paid to the substrate, consisting of gravel and sand. To ensure that the concrete monolith is laid evenly and does not begin to move over time, it is important to carefully level the underlying layer. For these purposes, you can use specialized vibratory tamping machines or rolling equipment, but manual tamping will be much cheaper.

The principle of do-it-yourself processing is that with the help of a homemade tool, blows are applied to the surface, due to which the sand and crushed stone are compacted. In this case, compaction is performed after laying each of these layers.

Making blanks

We will prepare the structure according to the drawing shown below.

After preparing everything you need, saw off the ends of the timber at a right, even angle, according to the dimensions. After this, it is necessary to use a plane to level the plane of the lower end of the block and remove chamfers of about 5 mm from the edges of the workpiece.

To avoid getting numerous splinters during the work, it is recommended to sand and polish the surface of the block.

Making a “shoe”

The next stage of creating a tamping tool with your own hands is making a metal “shoe” from a sheet of steel. To cut the plate we use the following template.

Or, you can simply install the beam with its lower end on a sheet of metal and trace it with a pencil.

After this you need:

- Cut the workpiece, as in the picture, using special metal scissors or using a grinder.

- Remove metal burrs from the shoe. To do this, it is most convenient to clamp the workpiece in a vice and remove the excess with a file.

- Without removing the “shoe” from the vice, drill holes for the screws at the previously marked points.

- Clean the surface with sandpaper.

- Bend the “wings” of the workpiece and install the beam into the “shoe”. If the workpiece is a little wider, you need to knock out the “wings” with a hammer.

- Place the drill bit into the screw holes and drill through the wood at a slight angle.

- Secure the screws on all sides.

READ How to Compact Sand Without a Vibrating Plate

Purchasing a unit

If you still decide to purchase a unit, you need to take into account both the main criteria and minor nuances that will make the work easier or increase its service life. However, we cannot fail to mention the manufacturers of vibratory ramming devices.

Equipment from European manufacturers is especially important. German technology is distinguished by its reliability and long service life. Even rental samples show good quality and speed of work. All equipment has a double safety margin. Wacker, Weber, Ammann, Bomag produce professional equipment.

Israeli Shatal and Czech NTC have fewer resources than the Germans, but they also turn out to be good workers at construction sites and on private property.

South Korean equipment from Jeonil Minery is not inferior to products from the Czech Republic or Israel. In the Asian market, this is the best offer among all vibration units.

Russian products from, Motoprom and SZPO are inferior to average European models in terms of convenience and functionality. However, modernization continues, and new, more advanced models appear on sale.

The Chinese, as usual, charge a price. Their products are only suitable for occasional, light-duty work. Among the mass of unknown manufacturers, the companies TEKPACK, MASALTA, DYNAMIC, CIMAR stand out.

Vibrating plates

A vibrating plate is a surface vibrating soil compactor designed for compacting non-cohesive or poorly cohesive soils and fills of insignificant thickness - from 10 to 30 cm. Vibrating plates of various capacities perform compaction of sand, gravel and crushed stone, as well as paving slabs and asphalt. A vibrating plate for soil compaction copes with compacting areas with a slope where the use of a large roller is difficult or impossible. Vibratory plates are rightfully in greatest demand among developers and are gradually replacing vibratory rollers.

Healthy! Sometimes vibrating plates are given an inaccurate name - surface vibrator. This misunderstanding is due to the fact that the operation of a surface vibrator resembles compacting sand with a vibrating plate. However, it has another area of application - compaction of thin-layer concrete pouring during monolithic construction. A surface vibrator is sometimes used to make homemade vibrating plates.

The quality of compaction depends on the level of soil moisture: with sufficient indicators, the soil becomes plastic and the compaction process proceeds faster. If there is a lack of moisture, the compacted layer is additionally shed with water; if there is an excess of it, wait until it dries. The humidity level is controlled by an electronic moisture meter.

| Soil type | Humidity level at maximum compaction, % |

| Sandy | 8 – 14 |

| Sandy loam | 9 – 15 |

| Loamy | 12 – 18 |

| Clayey | 16 – 26 |

Healthy! When compacting loamy and sandy loam bases with a vibrating plate, additional wetting of the working plate of the device is necessary to protect against soil adhesion.

Structure and principle of operation of a vibrating plate

The vibrating plate is equipped with an electromechanical eccentric, inside which unbalanced masses create mechanical vibrations. Using a belt drive, torque is transmitted from the engine to the eccentric shaft. Vibrations propagate to a metal plate (plate), which is in direct contact with the surface of the soil and causes it to vibrate. For convenience, the vibrating plate device is equipped with a handle for the operator.

Types of vibrating plates

Vibrating plates are classified by weight into:

- lightweight (up to 75 kg) – designed for landscape and finishing work, effectively compacting a layer of soil 10-15 cm thick;

- medium-heavy (from 90 to 140 kg) – provide a processing thickness of up to 35 cm; designed for layer-by-layer compaction;

- heavy (from 200 kg) – used as an alternative to vibratory rollers;

- universal (75-90 kg).

Depending on the type of engine, a vibrating plate for soil compaction can be diesel, electric or gasoline.

The most popular are gasoline models. They are economical and provide freedom of movement around the site and the ability to work at subzero temperatures.

Diesel vibrating plates are reliable and durable. Like gasoline ones, they are independent of the power source. Disadvantages are due to heavy weight, high noise levels and difficult operation in frosty weather.

Electric vibrating plates limit the working area by the length of the power cable, but are the most environmentally friendly. They are used in enclosed spaces with limited access to fresh air, where the use of gasoline models is unacceptable due to the risk of poisoning from exhaust gases.

According to the method of movement, vibrating plates are divided into:

Reversible. Such models are more maneuverable, but have a high price and heavy weight. As a rule, they are equipped with a diesel engine. The advantage of reversible vibrating plates is the possibility of reverse movement without turning the equipment. Therefore, they are indispensable for compacting sand and fill soil in narrow trenches.

The performance of vibrating plates is determined by:

- base area;

- operating frequency;

- vibration force;

- engine volume (for gasoline and diesel cars).

How to tamp correctly?

In order for the frame of the building foundation to be strong, the sand site must be perfectly flat and very dense. This effect is achieved due to the fact that with high-quality compaction, the necessary shrinkage is guaranteed to occur at the substrate. Whether this is true or not, the result must be checked after completion of the work. The quality of work is controlled using a rope pendulum or level.

To perform sand compaction with a vibrating plate correctly and with high quality, the following important nuances should be observed:

- the vibrating plate will show its effectiveness if the thickness of the sand layer does not exceed 0.6 m;

- before starting work, the sand layer is soaked evenly with water, but this must be done evenly and without excess;

- must be made on the working surface in both directions.

Once the layer of sand is securely compacted, the next portion of sand can be poured in to continue work. But the thickness of this layer should not exceed 0.6 m. Layers are added until the result is a dense sand cushion of the required thickness according to the project documentation.

To arrange garden paths, before building a garage, before installing the foundation of a country house, a sand cushion is often prepared manually. Sand compaction can be done with a vibrating plate or manually. Preparing the surface yourself will cost much less than having it done by hired craftsmen.

Let's look at how manual sand compaction is performed.

- Buy a ready-made device or make your own for manual tamping of a T-shape - the horizontal plate is made approximately 30x30 cm in size, and its weight should be at least 15-20 kg. For ease of work, 2 handles are attached to the handle bar on the sides - these grips are needed so that the device can be lifted with both hands at once. If the structure for tamping turns out to be too light, it is additionally weighted with metal or cement.

- Using a self-made tool, uniform and repeated blows are applied to the working surface of the sand mixture . With the help of these blows, it is possible to remove voids and air, as well as compact sand fractions among themselves. Compaction is carried out layer by layer - when 1 layer is compacted, the next portion of sand is poured on top of it.

The process of compacting sand is not so difficult, but quite an important stage in construction. The success of all future work depends on the quality of its implementation, so you need to approach it carefully and conscientiously.

The following video shows sand compaction.

Source

Features of sand compaction

Tamping sand with your own hands has some nuances that should be taken into account when creating a solid foundation for a concrete slab.

First of all, you should decide on the type of sand that is best suited for these purposes. It is better to use gravelly material, but it is not recommended to use fine sand for compaction. The larger the grains, the greater the compression resistance of the base, which will help avoid shrinkage of the future house or parking area.

If you are planning to build a monolithic structure, then it is best to give preference to river or quarry sand of the middle fraction. However, even in this case, the underlying layer will be influenced by groundwater. Therefore, in order to prevent the process of erosion of the base, it is necessary to lay geotextiles at the bottom of the trench, and only after that add sand.

In addition, before adding sand, it must be sifted, since the presence of foreign impurities (especially clay) can affect its properties. Monitor the moisture level of the material; the ideal consistency will be if you can roll the sand into a small ball that will not crumble immediately. Accordingly, the sand moisture level should be in the range of 8-14%.

Accordingly, 50% of the successful laying of a gravel-sand cushion depends on the material itself, the remaining 50% comes from the equipment. As mentioned earlier, specialized machines can be used for these purposes, but it is much cheaper to make a manual rammer yourself.

All about sand compaction

Before installing foundation structures or preparatory work for the screed, as well as for laying paving slabs, it is necessary to compact the sand cushion in order to expel excess air from it and compress the small fractions of sand grains as tightly as possible. After compaction, the sand base becomes very dense, ready for further construction work. To cope with this task, mechanized and manual methods of compacting bulk material are used.