So, your drill sparks on the brushes and you don’t know what to do in this situation. This article will tell you why this happens, whether it needs to be fixed, and if so, how.

It is immediately worth noting that the presence of the specified sparking during operation is a completely acceptable phenomenon. This is true only if the sparks are small and there are not so many of them. If they just fall out, this may indicate a malfunction.

Note that on a new, working power tool, the brushes may also spark strongly at first, since they need to first get used to. Grinding in usually takes 10-15 minutes of work. If after this everything remains as it was, then it is better to take the instrument back to the store with a claim.

If your drill is no longer under warranty, you can try to fix it yourself.

But first we will describe the reasons for this phenomenon.

Why do brushes spark in an electric motor?

Sparks, including on a working engine, appear due to mechanical action between the brushes and the commutator. The brush, moving along the commutator from one of its contacts to another, alternately forms and breaks a connection with each of them. Now remember what happens if you unplug any working electrical appliance from the socket - usually at such a moment a spark jumps between the plug and the socket. In the case of a brushed motor, this is the same phenomenon.

The largest selection of power tools and gas-powered equipment at the best prices. Free delivery to your region. Payment online or upon receipt.

Therefore, a small spark even on a working electric motor is acceptable, since connections and ruptures constantly occur here.

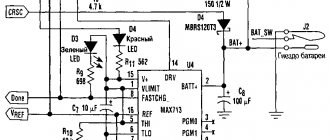

Battery sparks

Cordless electric drills use batteries for portability. They can create an internal spark, so if the drill sparks internally , this is part of normal use. However, they should never spark around the battery compartment. If the battery sparks when installed in a drill , or sparks even when not connected, it is likely a short circuit. Cleaning the battery contacts may solve the problem, but in other cases the sparking is not safe and the battery needs to be replaced.

READ Drill Won't Drill Wall

Brushes not installed correctly

If the brushes are deviated from the norm towards the commutator surface, a significantly larger amount of graphite dust is generated during operation. Misaligned brushes must be corrected.

Causes of severe sparking and how to eliminate them

Now let's move on to strong sparking. It occurs mainly for the following reasons:

- contamination of collector contacts with carbon deposits

- graphite dust getting between the collector contacts

- interturn short circuit in the armature winding

Let's go through each point separately.

1) Soot contamination occurs as a result of engine overheating. The presence of carbon deposits leads to even more friction, which leads to even faster overheating and even more carbon deposits. Which very quickly leads to breakdown.

Excessive sparking here results from the fact that carbon deposits form additional resistance, which causes the spark to break when it breaks, becoming larger and more powerful.

In general, carbon deposits should be removed immediately.

This is done with zero grade sandpaper. That is, you need to remove the collector along with the armature and carefully clean it. Ideally, it is advisable to carry out the grinding on a lathe so as not to disturb the correctness of the circle. But, as a rule, this is not possible, so you can get by with manual stripping. The main thing is not to overdo it.

2) When using a drill, the brushes wear out, which causes the formation of graphite dust. It can easily accumulate between the collector contacts and lead to short circuits between them, since it is a conductor of electricity and has its own resistance. Because of this, the current is distributed unevenly, which leads to large sparks in some places.

In a working drill, wear occurs quite slowly, so graphite dust hardly accumulates. Accordingly, its accumulation signals that the brushes are in the wrong position during operation. This usually happens when they do not stand tightly in their groove, but, on the contrary, have some play.

This often happens when replacing brushes, when they are selected to be not quite suitable in size. Therefore, when replacing this point, you should pay close attention.

Repair of such a malfunction is carried out by removing dust with some pointed tool and replacing the brushes with more suitable ones.

3) In the event of an interturn short circuit in the armature, the current flows in a larger value to some contacts and a smaller value to others. Because of this, more current flows in some places than necessary, resulting in large sparks.

Identifying such a short circuit should be done when the two previous points did not give much effect. It is produced using a special device that creates an alternating magnetic field. When an armature is placed in this field, it begins to rattle, as induced currents appear in it.

Some people make such a device themselves from a power transformer, in the core of which a cutout is made where the armature is placed.

If the reason turns out to be an interturn short circuit, then you need to rewind the winding or completely replace the armature.

These are the causes of excessive sparking on the drill brushes. Remember, if you don't do anything about it, the engine will most likely break down soon. Therefore, do not be lazy and follow the recommendations indicated in the article.

Drill sparks

Commutator electric motors differ from other types of motors by the presence of a commutator-brush assembly. The unit provides an electrical connection between the rotor circuit and circuits located in the stationary part of the motor, and includes a commutator (a set of contacts located directly on the rotor) and brushes (sliding contacts located outside the rotor and pressed against the commutator).

When operating a commutator motor in a power tool, you can sometimes observe sparking of the brushes. In some cases, this symptom leads to rapid breakdown of the power tool, and in others it does not bode well. One way or another, it is useful in each case to understand the cause of the sparking, so that, if necessary, the correct measures can be taken in a timely manner. In this article we will look at the causes of sparking brushes, as well as measures to combat the problems that cause this phenomenon.

It is obvious that intermittent mechanical contact of the brushes with the commutator cannot but lead to sparking, because in fact, the electrical circuit of the rotor is broken and closed again many times per second.

READ Screwdriver Operation From Network 220

The rotor contains a winding, which is a predominantly inductive load. The rupture of such a circuit is inevitably accompanied by a transient process, which is associated with the appearance of small arcs from the self-induction of the rotor winding or the rotor and stator windings. Of course, brushes wear out over time, as do commutator plates, but sometimes problems arise even before they wear out.

In fairness, we note that for the reason mentioned above, even a serviceable commutator engine cannot operate without sparks at all; there is always a small spark on the commutator. A fully functional device normally reaches full power, develops operating speeds and still sparks a little. It’s another matter if the sparking is strong - there is a reasonable concern here.

Sparking brushes as a sign of wear

If the brushes are already badly worn, simply due to the age of the engine, then the engine will not be able to reach full speed and reach full power. In this case, the sparking will be very strong, and the engine will not start the first time.

How to check that this is exactly the case? If the worn brushes are pressed against the commutator with a screwdriver, the contact will become tight and the engine will start working. But as soon as the clamp is loosened, sparks will appear again - the distance between the plates and brushes will become filled with small arcs. The brushes are clearly worn out and should be replaced with new ones. Sometimes replacement is only possible together - with brush holders and springs.

There may be a short circuit in the rotor winding

The armature (rotor) winding of a commutator motor traditionally contains several sections. If at least one is damaged, if there is an interturn short circuit, then more current will be supplied to one section than to the others. This will lead to overheating of the winding in one place, and to uneven sparking on the collector - sparks will be stronger at certain transitions on the plates than at others. This requires rewinding the anchor or a completely new anchor.

Is the stator winding OK?

A similar malfunction is possible inside the stator when part of the winding overheats and strong sparking is observed near one of the brushes. Check the resistance of both halves of the stator winding, they should be the same. If one part of the stator winding has a resistance much lower than the other, then rewinding or replacement of the stator is required.

See also: How to check the condition of an electric motor winding

Drill repair: sparks, smells burnt, vibrates. Do it yourself.

A dirty collector causes an unnecessary short circuit on it, resulting in unnecessary sparks

Dust on the commutator is formed as a result of gradual wear of the brushes - this is graphite dust. It accumulates between the plates (lamellas) of the collector and creates “unauthorized” short circuits. Sparks appear due to short circuits. Simply clean the collector with sandpaper, removing dirt between the lamellas.

Be sure to check how the brushes are located, whether one of them is displaced relative to its normal position, and adjust the brushes if necessary. When the brushes are positioned crookedly, graphite dust is formed in disproportionately large quantities than when the brushes are positioned correctly.

Another cause of contamination is carbon deposits on the manifold due to overheating. When all other causes of sparking have been eliminated, it is necessary to clean the contacts from carbon deposits to improve the contact of the brushes with them.

If the contact is good, the resistance does not increase beyond the nominal value, and unnecessary sparks do not occur. You can clean off carbon deposits like graphite dust - with sandpaper, only by rotating the rotor with the commutator clamped in special pads.

Electric motor design and operating principle

The operating principle of an electric motor is based on the interaction of a conductor with a current located in a magnetic field.

The main element of its design for a DC motor is a permanent magnet, for alternating current it is an excitation winding. The rotor (armature) has its own winding, to which voltage is supplied using a brush-commutator unit. The interaction of magnetic fields causes the rotor to rotate.

The collector consists of a set of contacts, which are copper plates located directly on the rotor. Micanite or mica cuffs act as insulators for each individual contact. Graphite brushes are sliding contacts pressed against the commutator.

Pollution

The product of brush wear is graphite dust, which is an additional source of increased sparking. Dust accumulates between the plates, which creates additional conditions for the formation of sparks. Preventive cleaning of the commutator with sandpaper and removing dirt between the plates will keep it clean.

Poor contact between brushes and commutator

The electric motor spends part of its operating time in overheating mode. Under such conditions, carbon deposits form on the collector. Poor contact leads to increased brush sparking and even more carbon deposits.

You need to use fine-grain sandpaper to clean the surface of the commutator. To increase the stripping effect, use a screwdriver. Clamp the engine rotor into the chuck and remove carbon deposits with sandpaper at low speeds. Afterwards you need to finally polish it on a felt wheel.

Short circuit in the armature winding

The consequence of such a defect is uneven sparking on the collector. It will be stronger on some plates than others. Due to the presence of an interturn short circuit, the current in certain sections of the rotor winding will be stronger than in others.

Rewinding the rotor or replacing it will eliminate the problem.

Mechanical problems

Mechanical reasons are caused by non-compliance with the requirements of design and technological documentation. Most mechanical causes can be eliminated by turning the manifold on a lathe. Refer this repair operation to a qualified technician. Here are some types of faults that may indicate a breakdown:

- The surface of the collector is uneven;

- The shaft runout exceeds the value specified in the technical documentation;

- Individual collector plates protrude beyond a common level for all;

- Insulation protrusion (mica);

- The brushes in the brush holders move with jamming;

- On the contrary, the brushes are inserted into the brush holders with a large gap, which creates vibration during operation;

- The brush holders are installed far from the commutator;

- Uneven tension of the springs, resulting in a difference in the pressure applied to the brushes.

READ Pneumatic Jack Hammer Device And Work

Integrity of rotor and stator windings

More serious problems that cause strong sparking of an electric motor are interturn short circuits of the rotor or stator windings. It is difficult to fix such a breakdown on your own. Signs of a problem with the winding are:

- operation is accompanied by popping noises;

- sparks fly around;

- blackening is observed on the collector lamellas;

- The electric motor speed has dropped.

It will not be difficult for experienced electricians to figure out how to carry out electrical measurements:

- on paired winding outputs to the collector plates;

- between the collector and the rotor (armature) housing;

- between the stator housing and the winding output;

- test the integrity of the stator winding.

For home craftsmen without special equipment, rewinding a faulty electric motor element is very problematic. Therefore, it is necessary to contact a service workshop. When you contact a repair center, for example, with a Samsung vacuum cleaner, they may offer to replace its windings or purchase a new motor.