Types of pistols

Selecting the correct barrel length will ensure efficient delivery of the insulator to remote locations.

If difficult areas are not expected, purchase devices with short tubes:

- 100 – 150 mm - for easily accessible seams, open surfaces;

- 150 – 200 mm – standard universal size for all types of work;

- over 200 mm - for semi-closed places.

Valera

The voice of the construction guru

Ask a Question

Plastic guns are an economical option with a short warranty period. The nozzle often gets clogged and requires regular cleaning. The supply pressure is low, so the control valve is not functional enough. Some manufacturers use high-strength plastic - such devices are not much inferior to steel structures. There are metal tools and steel ones with Teflon coating.

Criterias of choice

When purchasing, pay attention to the material of the tool . The trigger and handle are allowed to be made of plastic; metal is recommended for other parts. The Teflon layer prevents foam from sticking and prolongs service life.

Factors taken into account:

- possibility of disassembly;

- barrel length, its internal coating;

- handle shape (for comfortable work);

- smooth starting mechanism for effective output adjustment;

- pistol weight;

- presence of nozzles, regulator;

- dispenser cycle unit;

- integrity of the gearbox.

A quality product has clear joints between parts. There is no grease on the body, there are no defects.

Terms of use

The installation or insulation process will be more efficient if you use the gun correctly. Skillful handling will extend the operating time of the mechanism. After purchase, specialists check the foam gun to ensure that the valves are working properly . They do not use foam, but a cleaning liquid. The cleaner canister is equipped with a mounting part for the gun, as is the container with polyurethane foam.

Make several presses so that the composition fills the internal capacity of the gun. The container with liquid is removed from the device, and the instrument is left for 2 days. After this time, press start. A characteristic pop should be heard. This means that the cleaning liquid has not escaped from the compartment thanks to reliable valves. Air does not penetrate inside, the required pressure is maintained. If everything is wrong, the gun is returned to the seller.

How to insert a foam canister

Before charging, shake the container for 30 seconds to mix all components. The container is screwed onto the adapter to the gun until a hissing sound appears.

Remove the retaining ring and screw the cylinder into the thread until it stops. Further actions:

- the cylinder is positioned bottom up;

- turn the adjusting screw counterclockwise a quarter of a turn and pull the trigger;

- make a test release of foam, look at its consistency, press again to adjust.

Valera

The voice of the construction guru

Ask a Question

After screwing the container with polyurethane foam, the composition moves through the valve into the supply tube. By pressing the start button, the valve opens and the foam comes out. The supply of foamy mass is shut off with a regulator on the rear surface of the housing. In this position, without twisting the cylinder, you can store the gun for up to six months without the composition hardening. If you disconnect the bottle, the foam will dry out.

How to apply foam or sealant

to be treated is cleaned of dust and moistened with water for better adhesion and setting of the polyurethane foam.

Work process:

- The barrel of the tool is brought to the seam, the trigger is pulled;

- the composition is applied in layers so that the tip of the barrel is immersed in the foamy mass;

- the volume of foam is coordinated by the stroke of the trigger;

- After completion of application, close the adjusting bolt.

Before use, check the serviceability of the tool. When applying, position the barrel of the gun at an angle of 90° so as not to block the view of the treated area. The foam is applied smoothly, taking into account the increase in volume. In the gaps, the space is filled halfway.

To use foam, you need to wear gloves and goggles, and it is recommended to ensure the room is ventilated. Do not point the gun at animals or people.

How to replace a cylinder

Unscrew the cylinder in the reverse order if you need to replace it.

Operating procedure:

- turn the pistol over with the handle up;

- open the adjusting screw clockwise;

- pull the trigger;

- unscrew the empty container;

- Place a container with rinsing and clean it.

After this, you can screw on another balloon with polyurethane foam. The gun is shaken together with the installed cylinder (30 seconds). Remove the frozen foam from the tip of the barrel with a knife. Then unscrew the control bolt and release the foam until a uniform flow is obtained.

How to clean a gun

Cleaning is carried out if the tool has not been used for a long time. To do this, temporarily remove the foam container and screw on a container with cleaning liquid . Press the trigger and clean the inside of the gun cavities. Experts recommend leaving the gun filled with cleaner for 10 minutes.

If there is dried composition , unscrew the cleaner and treat the outside of the body. Put on a cylinder with an insulator and continue working.

The flushing composition is sold together with the gun or separately. The liquid is packaged in cylinders similar to containers with foam. If, after washing, parts of the foam remain inside the instrument, the procedure is repeated until completely cleaned.

Care instructions

According to the instructions, store the device with a screwed-on cylinder so that the foam in the tool is always ready for application (under pressure). If you remove the container, the foam or sealant hardens in the barrel, you will have to further disassemble and clean the device.

If the device is used regularly, cleaning is expected every three months;

A device with a screwed-on cylinder must not be left near heat sources or exposed to the sun.

Some users prefer manual cleaning . To do this, the gun is disassembled into parts and dried residues of the composition are removed. Use rags and solvent. Use a wire or a thin screwdriver for the nozzle, where it is difficult to push the rag through. Clean carefully so as not to damage structural elements.

Valera

The voice of the construction guru

Ask a Question

If you need to foam around a door frame, and you purchased foam with a removable tube, is it possible to get the job done without purchasing a gun? Such cylinders are suitable for small volumes. The container is shaken for 30 seconds to ensure homogeneity. Remove the protective cap and attach the plastic tube. Such parts are sold with household containers, but professional ones are not equipped with them. The nozzle of the tube is brought to the application site and the valve is pressed.

How to choose the right foam gun

1. Packaging for polyurethane foam. “Amateur” or “professional” 2. Choosing the right gun 3. Using a gun and rules for working with foam

Packaging for polyurethane foam

Polyurethane foam (polyurethane sealant) has proven itself to be an excellent material for construction and installation work. It is indispensable when installing windows, doors, repairs, remodeling, etc. Like any building material, work with polyurethane foam is carried out using special tools.

Initially, polyurethane foam is sold packaged in cylinders, which can be divided into two types: “amateur” and “professional”. The composition of both types of cylinders is identical; they differ in the design of the cylinders themselves. In the amateur version, the valve is made in the form of a plastic beak with a tube placed on it. When opening such a cylinder, it is worth remembering that it must be completely used up within an hour, otherwise the foam will simply harden in the outlet valve and the entire cylinder will become unsuitable for further use.

For a professional cylinder, a special thread is provided for mounting on a gun for polyurethane foam. You can distinguish such a cylinder from an amateur one by its special cap, as well as its price, which is approximately 15-20% higher.

The tool for applying polyurethane foam is a special gun . This is a device that allows you to dose foam very economically and apply it with great precision. To perform large volumes of work with polyurethane foam on an open surface, amateur cylinders are perfect for you, which will save a certain amount of money. But, if it is necessary to perform delicate and accurate work, professional foam cylinders and guns are simply necessary.

How to choose the right gun

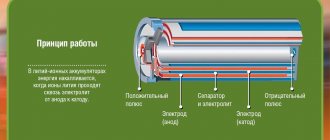

There are many guns for polyurethane foam. Despite their simple design, they have their differences. The gun itself is a tube with valves on both sides. Based on considerations of ease of use, a handle similar to a pistol handle and a trigger drive are installed on the pistol. The actuator is connected to the outlet valve by a rod passing through a tube.

The standard valve design is a ball valve and the valve is positioned perpendicular to the supply tube. There is a ring on the drive into which the cylinder is installed. To charge the pistol, we move the holder ring up until it stops, and screw the cylinder along the thread. Then we screw the ring and the balloon onto the valve until it opens. The signal for the valve to open will be a characteristic hissing sound, which indicates that the tube has begun to fill with foam. After completing the described steps, when the foam reaches the tip of the tube and fills the cavity of the outlet valve, the gun is ready for use.

When choosing a pistol, you need to pay attention to several design features. Absolutely all parts of your pistol must be made of metal. Of course, there are good models from well-known manufacturers with plastic holders, but such pistols are rather the exception to the rule. It is usually not recommended to buy a pistol from a little-known company with a lot of plastic parts.

For permanent work, it is recommended to spend more money and buy a reliable collapsible pistol. Having such a tool, you can always disassemble and clean it, or simply replace a failed part. This investment will significantly reduce your costs in the future. When purchasing, pay special attention to the quality and reliability of both gun valves. They are easy to check, but verification can only take place during operation.

To work, you will definitely need washing liquid , as a rule, this is ordinary acetone, packaged in special pressure cans. The test itself is quite simple: you need to screw a can of acetone onto the gun, and press the trigger several times so that the liquid fills the gun tube. Then we leave the gun alone for 2-3 days. After this period has expired, when you press the trigger, the acetone that has been there under pressure all this time should shoot out of the valve. In cases where the pressure is released, such a pistol should be returned back to the store, because it will be very inconvenient for work, due to the need for constant washing, even at short intervals of 15-30 minutes.

Gun for polyurethane foam Gun for polyurethane foam, reinforced Gun for polyurethane foam, metal body

Using a foam gun

When using a gun, you should remember the usual rules for applying foam . To achieve the maximum effect from using polyurethane foam, it is necessary to first spray the surface to be treated with plain water, for example, from a spray bottle, because For high-quality expansion, the foam needs moisture. It is also very important to consider the expansion coefficient of polyurethane foam. Therefore, the cavities to be treated must be filled to ¼ or 1/3 of the total volume. This principle of operation is due to the fact that you can always finish foaming, but removing excess foam is quite problematic. Do not forget to secure small parts so that the expansion of the foam does not dislodge them and thereby damage the structure.

Another very important feature of using a high-quality gun is the fact that a properly wound cylinder can not be removed for several months, and the foam will not lose its properties. This method is good when you use foam frequently, but in small quantities. This method will significantly reduce your financial costs. True, you need to be very careful; leaving an empty or almost empty cylinder on the gun is strictly not recommended. When the cylinder is emptied, the gun is immediately washed with flushing liquid or, if it is not available, it must be disassembled and treated with acetone from a syringe.

Malfunctions and methods for their elimination

If the tool is of high quality, breakdowns are rare, and there is no need to be distracted from work by regularly cleaning the device.

The main malfunctions of the tool when clogged with foam:

- blockage appears at the exit from the barrel;

- the foam dries inside the valve to which the cylinder is fixed.

Valera

The voice of the construction guru

Ask a Question

Do not press the trigger if there is a suspicion that it is blocked by dried mass - you can break the part. The outer surface of the barrel is cleaned mechanically, trying to do it without damage. The nozzle is lowered and the solvent is poured into it. After 10 - 15 minutes, carefully press the trigger to squeeze out the liquefied composition.

Instructions for using a foam gun

Instructions for use are included with each tool. It contains several sections:

[ot-video type=”youtube” url=”https://www.youtube.com/watch?v=gkIfztU1VKw&feature”]

- Introduction. It is recommended to tighten all threaded connections, as they may become loose during transportation.

- Connecting a foam bottle. Before winding it must be shaken for 1-2 minutes.

- Replacing the cylinder. When replacing, you must hold the gun with the cylinder facing down.

- Storing a pistol with a cylinder. Must be stored with the container facing down.

- Storing a pistol without a cylinder. Be sure to store it cleaned and washed after use. Never store a gun without cleaning it.

Features of the work

Before starting work, the foaming areas must be cleared of dirt and dust.

Be sure to moisten them with water. It is advisable to carry out work not in hot weather, in which moisture evaporates more slowly. The optimal temperature for foam is + 20 degrees. When working with a foam gun, you should always hold it with the canister facing up. If the cylinder is lowered down, only gas can come out of the barrel. Therefore, the upper seams are foamed first while the balloon is full, and then the distribution of foam continues from top to bottom. Lastly, foam is applied to the bottom seams.

If at the beginning of work the cylinder is not full, you should start foaming from the middle, for example, a door frame, and move down. After producing foam and replacing it with a full cylinder, foam the upper part. When working under the ceiling and in deep seams, you can use a flexible extension.

Caring for your pistol

[ot-video type=”youtube” url=”https://www.youtube.com/watch?v=2UAnGM74g8U&feature”]

After the foaming work has been completed, it is necessary to determine the approximate amount of foam remaining in the cylinder. If its amount is more than half, then it is necessary to remove the remaining foam from the spout with a cloth moistened with acetone. After this, place the gun with the cylinder on the rack. In this form, the foam can be stored for up to 5 months, always with the container facing down. And if necessary, you can immediately foam it by shaking the container several times.

If the foam in the cylinder runs out, then it is removed and the internal parts are washed by attaching a cylinder with washing liquid. The outside of the gun is wiped with a rag moistened with acetone.

If, when carrying out construction or repair work, it is necessary to perform foaming with good quality and precise dosage of foam, then it is necessary to purchase a foam gun with professional cylinders.

Rating of manufacturers and models

The first positions are occupied by the brands Biber, PIT, Blast and Stayer.

Brief characteristics of the models:

- Biber Master 60.111. It is characterized by good quality at low cost and can withstand heavy loads. The model is collapsible, the box can be plastic or metal. The pistol weighs 670 g.

- PIT R 7000.003. Chinese brand of low quality for one-time use. In the model, the barrel and valve are made of steel, the rest of the parts are made of plastic. The case cannot be disassembled; the instrument weighs 400 grams.

- Stayer Master Economy Max 06/861. It is a simple model with a non-separable body made of metal and high-quality PVC. The instrument weighs 410 g.

- Blast Extra Lite 59.0024 . The non-separable plastic version is inexpensive. Users purchase a model for one-time use in small quantities. Weight 510 gr.

Other brands are also popular in the Russian market: Matrix, Zubr, Hilti, Finch Industrial Tools . The models from these manufacturers are high quality and not expensive.

Cost of spray foam guns