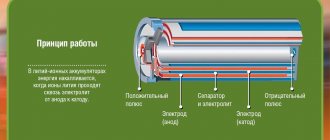

Principle of operation

When deciding which soldering iron to choose for polypropylene pipes, first of all, you need the equipment to allow them to be used quickly and easily. The owner of the welding machine should not feel discomfort during operation and the equipment should not fail at the most unexpected time.

The design of the unit itself is quite simple. The main elements are 3 – body, handle, heating plate.

The operating principle of soldering plastic pipes is based on a diffusion process and consists of the following steps:

- The iron heats the seam, along which welding will subsequently take place.

- After the edges of the pipes are applied to the heating element.

- The ends heated to the required temperature are connected. After cooling, a sealed joint is obtained with excellent elasticity and reliability.

Different types of welding machines are used for soldering pipes; they all have certain features and also differ in functionality and additional accessories.

When choosing a welding machine for soldering plastic pipes, you should give preference to a tool with the maximum configuration Source specinstrumenta.ru

Connecting PVC pipes without a soldering iron

If necessary, polypropylene pipes can be connected without a soldering iron, for which you should use the following methods:

- Socket connection . Such a connection can most often be found in areas of drain pipelines in which liquid is transported under the influence of natural forces. In addition, the socket connection is suitable for all water lines operating without pressure.

- Cold connection . To implement the cold method, compression fittings are used, which make it possible to do without a soldering iron - but instead you will need a crimp wrench, often sold along with the fittings. The main disadvantage of this method is that it takes a lot of time.

- Adhesive connection . This method is quite good - it takes little time, and the quality of the connection is quite acceptable. For connection, a special glue is used, which dissolves the surface of polypropylene, due to which the individual parts are glued to each other at the molecular level.

- Push fitting connection . A push fitting is a simple device consisting of an O-ring and a retaining ring (the latter prevents the fixed pipes from coming apart). The final fixation of the parts is carried out using a union nut, the inner part of which is made in the shape of a cone.

Methods for connecting pipes without a soldering iron are quite varied, but have their pitfalls, so before installation you should carefully study all aspects - for example, whether the chosen method is suitable for a particular situation.

Conclusion

A soldering iron for PVC pipes is a device that greatly simplifies the installation of plastic pipes. Choosing the right soldering iron will allow you to create the most reliable connection, which will not cause problems throughout the entire period of operation of the pipeline.

Types of soldering irons

Before choosing a soldering iron for polypropylene pipes, you need to know that there are 2 main types of devices, most often used in construction or repair:

- Manual.

The equipment has small dimensions, which makes it possible to use it in limited space. The soldering iron makes the most airtight connections if the pipeline cross-section is no more than 50 mm. Therefore, this equipment is not suitable for working with pipes of larger diameter, which must be taken into account when choosing.

The advantages include ease of maintenance and long service life.

- Mechanical.

More professional soldering irons that can work with large-section plastic pipes, creating high-quality sealed connections. Some welding machines can solder pipes with a diameter of about 2 meters.

This type of equipment is characterized by versatility, since it allows you to work with various plastic materials, as well as metal. The main disadvantage is that it requires a lot of experience, since the device is quite complex to operate.

Professional welding machines will require skills to work with them, so they are not suitable for home use Source ytimg.com

Before making the final choice of a soldering iron for polypropylene pipes, you need to decide for what purposes it is required. If this is only a tool for household use, then you should not make special demands on the unit. Middle-class equipment will be sufficient; it will satisfy the cost and will not be very large.

Reviews of soldering irons for polypropylene

KERN Welder R63

Soldering iron for connecting polypropylene pipes KERN Welder R63, a reliable assistant in repairs!

Advantages: the price justifies the quality, rich equipment, easy to learn, convenient to use, compact size.

Disadvantages: I did not notice any significant disadvantages, except that in domestic conditions it is rarely required for use

Yuri Naumovich

High quality tool.

Advantages: convenient temperature control function that protects the device from overheating, easy-to-use manual unit.

Disadvantages: none found.

Dmitry Tikhonovich

The combination of price, ease of use and quality is optimal.

Advantages: for its price, it’s a convenient and high-quality device that you won’t mind spending money on.

Disadvantages: none.

Konstantin Savvevich

Criterias of choice

When choosing which soldering iron is best for polypropylene pipes, you need to pay attention to the following criteria:

- Teflon coating . This will reliably protect the surfaces of the equipment and prevent plastic from sticking to the iron.

- Type of welding machine . The device must be purchased taking into account certain needs. If this is a specialist who earns money by soldering pipes and installing water distribution systems, then it is worth taking a closer look at mechanical equipment. Manual devices, on the contrary, are easier to operate, have small sizes and almost the same performance as mechanics. They are best suited for home use in terms of capabilities and ease of use.

Mechanical soldering irons are complex in design and are most often intended only for narrowly focused work. Source ytimg.com

- The power of the welding machine should be enough to cope with pipes of the required diameter. It is advisable to choose equipment of medium power for soldering polypropylene pipes. For a pipeline with a cross-section of 25-70 mm, this figure is about 800 watts.

- The country of manufacture and reputation in the construction market are one of the main criteria with which you can choose a truly high-quality unit. Before deciding which is the best soldering iron for plastic pipes, it is worth getting acquainted with the reviews and reviews of a specific model.

- Many different attachments and additional functions indicate the versatility of the soldering iron and its ability to perform several manipulations with pipes during soldering. It is necessary to pay attention to the real benefits of attachments, since it is not uncommon for product manufacturers to equip it with useless functions and devices, thereby increasing the price of the product. The most popular additions for soldering irons are adapters for working with pipelines of different cross-sections.

If soldering of sewer pipes is required, then for this you need to choose a special welding machine Source ytimg.com

Before you buy a soldering iron for soldering polypropylene pipes, you need to read the instructions, which must be in the box with the device. It certainly indicates all the required information - the manufacturer, the power of the device and the basic equipment.

Attention! Before using a new tool for the first time for real work, it is best to first test it on some excess plastic products.

All welding units are slightly different in use, that is, this testing will help you get used to certain features of the soldering iron, find out the required temperature and holding time for pipes when soldering.

Soldering iron for polypropylene pipes - operating principle and design

The principle of connecting polypropylene pipe products is the mutual diffusion of molten materials of their shells in close contact. As a result of the interpenetration of semi-liquid masses, a single monolithic compound is formed, which is not much inferior in strength to solid material.

The melting point of polypropylene, from which almost all pipes and fittings are made, is 176 °C; when it is heated above 300 °C, partial destruction of the material is observed (complete destruction occurs at 415 °C), while the PP darkens. Based on the temperature characteristics given, a method of connecting polypropylene pipes with an optimal heating temperature of 260 °C is used.

This temperature regime was not chosen by chance - when PP shells are heated to 260 °C, installation time takes a matter of seconds and irreversible destruction of the material does not occur.

For soldering polypropylene, an electric heating tool is used, onto which heating nozzles with diameters corresponding to the dimensions of the outer and inner walls of PP pipes are attached. When the aluminum electric heating iron comes into close contact with the screwed couplings, the latter transfer their heat to the pipe sections with which they come into contact, as a result, the shells of the parts melt to a creamy consistency.

The retail network offers three main types of electric soldering irons based on the shape of the heater, the distinctive features of which will be discussed below.

Rice. 2 Main components of a sword-shaped electric soldering iron

Ensiform (flat platform)

A sword-shaped soldering iron for plastic pipes is the most commonly used tool; it consists of a body with a handle to which a heating element (iron) is attached. The device has a step temperature switch and two indicator lights that indicate when voltage is applied and the iron reaches the optimal temperature threshold of 260 °C.

The heat transfer platform of the electrical appliance is equipped with two to three through holes for fixing nozzles of a standard size range in it (measured by the diameter of the outer pipe shell) 20 - 25 - 32 - 40 - 50 - 63 mm, depending on the configuration, their number ranges from 3 to 6 items.

Each soldering iron for pipes is equipped with a stand of various designs, in which the electrical device is fixed during installation work.

With round flat iron

For welding pipelines of large diameters, nozzles with dimensions of 75, 90 and 110 mm, less often 125, 140, 160 mm in circumference, are used. To ensure better contact of their surface with the platform, the latter is made round. Typical devices in this category have large overall dimensions, two electric heaters and a fairly high average total power of 1000 W, depending on the model. The main area of application of disk devices is conventional socket and butt soldering of large-sized PP pipes.

Rice. 3 Models with disc heaters

Related article:

Polypropylene pipes - types and technical characteristics . It is possible that while reading about a soldering iron for polypropylene pipes, it will also be interesting to learn about polypropylene pipes used for laying plumbing and heating systems. Types, sizes, connection and installation options, all this is in a separate article.

Pin type (with cylindrical heater)

A soldering iron for polypropylene pipes with a cylindrical electric heater is less popular than its previous analogues; the device is usually purchased for working in hard-to-reach or inconvenient places.

The pin-type heater is fitted with block heating nozzles made in the form of couplings consisting of two parts and equipped with side pipes for inserting PP pipes. The nozzles are pressed against the cylindrical surface of the heater using bolts; usually a typical kit includes no more than four couplings.

Since the device is intended for use in confined spaces and for work on weight, it is equipped with a compact retractable leg, which is not very suitable for using an electric soldering iron on a stationary surface.

Rice. 4 Soldering irons with cylindrical heaters

Rating of welding machine manufacturers

When choosing a machine for welding polypropylene pipes, the rating of the best manufacturers is presented by the following companies: Rothenberger, Candan, Dytron Polys Sturm, Denzel. All of them showed excellent performance and demonstrated excellent ability to work with plastic products.

All soldering irons are similar in appearance, but have different characteristics that you need to pay attention to Source dnipro-m.ua

Rothenberger Roweld P63T

The rating of machines for welding polypropylene pipes opens with the company Rothenberger, which is a recognized leader in this field. In appearance, this professional iron may seem simple, but the equipment of this brand is distinguished not by its beauty, but by its convenience and long service life.

The heating element of the welding machine is sword-shaped, has a thermostat that maintains the temperature at a given level and a power of 800 watts. Unlike soldering irons marked “E”, which indicates the installation of an electronic thermostat, this device is simpler and, accordingly, not so expensive, and this does not affect performance at all.

The device is designed for soldering pipes with a cross-section of 20-63 millimeters - this particular set of Teflon nozzles is included in the kit. The device is easy to use - although it does not heat up the fastest, if you consider large cross-section pipes, it melts plastic quite accurately. It has a light weight - 8 kg.

Soldering iron for plastic pipes Rothenberger Roweld P63T is one of the best for professional use Source storgom.ua

The iron is installed either on a stand or on a clamp screwed to a hard surface. Heated nozzles and pipes can be easily removed after soldering.

Advantages:

- high quality workmanship;

- easy to carry;

- ease of use;

- reliability.

Flaws:

- relatively slow heating;

- high price.

See also: Catalog of companies that specialize in water supply, sewerage and related work

Dytron Polys P4a 1200 W Trace Weld Solo blue

The rating of soldering irons for polypropylene pipes is continued by the Czech device. It looks more interesting than Rothenberger, and the cost is lower. But one point needs to be taken into account - the word “solo” in the name indicates that we are considering a “bare” device without attachments and a box for transportation. So, the initial cheapness, unlike the complete Rothenberger, is not so cheap. With a case and attachments, the equipment is more expensive.

Soldering iron for plastic water pipe Dytron Polys P4a 1200 W Trace Weld Solo blue, fully equipped with the same quality of work, will cost more than Rothenberger Roweld P63T Source ytimg.com

Teflon nozzles for Dytron Polys are offered in a huge range, their diameter ranges from 16-125 millimeters. Due to the powerful heater, the device quickly copes with thick pipes. The temperature is adjustable within 180-280C. The regulator itself is not very convenient - it is made to look like a screwdriver.

The “solo” package is simple – the welding machine itself, a hex key for attachments, and a stand. The latter, by the way, is not as convenient due to its short “paws”, unlike the Rothenberger, so in the category “soldering iron for polypropylene pipes” the rating of the best takes only second place.

Advantages:

- accurately maintains the set temperature;

- powerful heating element.

Flaws:

- the stand is inconvenient to use;

- minimal set.

Which country of origin is better?

I started working with an expensive Czech welding machine, then switched to cheap Turkish and Chinese machines. Over the past 10 years, I have owned more than 20 different soldering irons for soldering polypropylene pipes. Below I will talk about each of them, and then I will summarize and justify in which case you need to buy this or that device.

For ease of understanding, I will explain in simple language and say: PPR soldering, soldering iron. Although it should be said correctly: welding and welding machine for PPR pipes. After all, polypropylene pipes are welded, not soldered. But I’m a simple person, so I’ll speak as people at the construction site understand me. Philologists, sorry.

Turkish

All the Turkish welding machines for plastic pipes that I came across had 2 problems: poor quality, bad nozzles and a bad thermostat. When I didn’t have money for a good soldering iron, I bought a Turkish welder and immediately bought good Czech attachments for it.

The Teflon layer peeled off from the Turkish attachments that came with it literally within a week. When there are problems with Teflon on the nozzles, it is very difficult to weld the pipes: they do not fit into the nozzle well and the welded joint in most cases will turn out to be of poor quality and, most likely, will leak.

The exception is the VALTEC socket welding machine.

After purchasing this soldering iron, the Teflon came off the tips after 2 hours of use. The heating element became loose and the insulators fell out. I only worked with it for 2 hours after purchase. Welded polypropylene pipes with a diameter of 25 mm. I do not recommend purchasing!

Of the Turkish welders for propylene pipes, I liked the CANDAN socket welding machine the most. I can’t say that this soldering iron is good, but it is quite durable and durable.

Chinese

Of the Chinese soldering irons for soldering pipes, I only had welders with an unusual heater shape. At a construction site, such soldering irons are usually called “ushastik”. I had machines for welding PPR pipes from the following companies: Kalibr, Fora, Denzel. In terms of quality, they are all more or less the same, as well as in price.

The main advantage is the unusual shape of the heating element.

On conventional welders, the nozzles are placed one after the other, and if you need to weld first 20 mm and then 25 mm plastic pipes in a hard-to-reach place, you have to swap the nozzles. Otherwise, you won’t get close. And this soldering iron is convenient to work with: turn it over and work with the 20 nozzle, turn it over again and solder with the 25 nozzle.

But this soldering iron has a heating element made in such a way that it is better not to place nozzles larger than 40 mm on it. I worked with it for quite a long time, and it seems to me that for 20 and 25 mm pipes this is what is needed. For larger diameters it is better to use other welding units.

Some installers think this is a household model, but I worked with it on construction sites for 8-10 hours a day for several weeks in a row and it worked fine.

Czech

Of the Czech welders for plastic pipes, I only had Ecoplastic and Dytron. Although, in essence, these are the same soldering iron. Dytron has been producing its polypropylene pipe welders for the Ecoplastic brand for many years.

Only for Ecoplastic they made a green handle, and all welders under the Ditron brand received a blue handle.

This soldering iron is the best I've ever owned.

Firstly, the kit comes with good unpaired attachments. They are also sometimes called block type. Secondly, good equipment: I have included nozzles from 20 to 63 diameters, a nozzle for butt soldering of pipes, and a very convenient stand. Which you can hold with your foot.

A clamping vice that can be screwed onto a soldering iron and then secured almost anywhere for easy welding. This welder has a melt-proof electrical cable that will not melt if the nozzle touches it.

It also has a sound function for sound notification of welding time, which few people use. The main thing is that it accurately (plus minus 1.5°C) maintains the set temperature. Few other soldering irons can do this. And for welding quality this is the most important parameter.

German

I once saw colleagues with Rothenberger polypropylene welding machines.

The guys boasted about what a wonderful soldering iron they had, but I noticed that it looked suspiciously like a soldering iron that costs 3 times less. I’ll tell you about it now.

Best of the budget

I had another soldering iron, which I liked for its quality and reliability. This is a Heisskraft PPR welding machine.

Both I and other crews worked with them quite a lot on construction sites. It didn’t come loose and there were no gaps. The attachments included are quite good. I don’t know where they make it, so I took it to a separate point.

Video description

A short review of the Dytron Polys P4a 1200 W Trace Weld Solo blue is presented in this video:

CANDAN SM-04

The equipment for welding plastic pipes is replenished with the Turkish model CANDAN SM-04. The equipment can work with polypropylene products with a cross-section of 50-110 millimeters. The heater has 2 independent sections, that is, taking into account the need, you can select an operating mode of 1 or 2 kilowatts.

The CANDAN SM-04 welding machine can be classified as a type of tool where the price corresponds to the quality Source ventorus.rf

The thermostat maintains a stable temperature regime, the equipment is not prone to overheating. The stand that is included in the kit is universal - it can be installed either on the floor or used as a clamp for fastening on a table. But the device is equipped with only three attachments; other necessary ones will need to be purchased separately.

The welding machine looks a little rough, but it works well. That’s why it gained its popularity - an excellent soldering iron for propylene pipes at an affordable price finds its consumer.

Advantages:

- convenient stand, which is included in the kit;

- switching power modes;

- Teflon coating;

- affordable price taking into account its configuration.

Flaws:

- The set contains only 3 nozzles;

- inconvenient to transport.

The principle of welding polypropylene pipes

Welding polypropylene pipes with a soldering iron is as follows: the contacting parts of the pipe and fitting quickly heat up, after which they are instantly connected to each other and cooled in air. A soldering iron helps to firmly connect parts (if the work is carried out correctly, taking into account all the subtleties of the technology).

Description of welding procedure

- Before work, be sure to prepare the working surfaces of the soldering iron and polypropylene products. If necessary, pipes are cut with special scissors (roller pipe cutter), which prevents the edges of the pipes from being crushed.

Cutting polypropylene pipes

- After preparation, the soldering iron is fixed on the working surface, the coupling and mandrel are fixed on the heating element, the temperature is set on the thermostat, the soldering iron is plugged in and wait for it to warm up (which will be indicated by an audible alarm).

- The polypropylene pipe and fitting are forcefully inserted into the soldering iron nozzles and held for 3-4 seconds until the parts are completely heated.

The polypropylene pipe and fitting are forcefully inserted into the soldering iron nozzles and held for 3-4 seconds until the parts are completely heated

- After heating, the polypropylene parts are removed from the soldering iron and connected to each other in the required position, strictly excluding rotation of the parts being connected. It will take about 15 seconds until the surfaces are completely “sintered”.

- To connect the pipe and coupling without distortions, it is recommended to make pencil marks on the parts before the welding process.

- If unevenness occurs, the fitting should be cut off and the soldering procedure should be repeated using new parts.

- If pipes need to be soldered vertically, have an assistant hold the pipe in position.

Nuances of welding polypropylene pipes

- To connect the pipe and coupling without distortions, it is recommended to make pencil marks on the parts before the welding process.

- If unevenness occurs, the fitting should be cut off and the soldering procedure should be repeated using new parts.

- If pipes need to be soldered vertically, have an assistant hold the pipe in position.

How to prepare fittings and pipes for welding

One of the stages in preparing fittings and polypropylene pipes for welding is degreasing the contacting surfaces of the parts.

Aluminum-reinforced pipes are prepared for welding as follows:

- if the aluminum layer is close to the surface, that is, directly under the decorative layer of plastic, then in preparation for soldering, the reinforcing layer is removed from the ends of the pipe with a shaver (stripping device) in order to ensure a proper strong connection;

if the aluminum layer is close to the surface, that is, directly under the decorative layer of plastic, then in preparation for soldering the reinforcing layer is removed from the ends of the pipe with a shaver (stripping device) in order to ensure a proper strong connection

- in the case when the reinforcing layer is located in the center of the walls of polypropylene pipes, then preparation is carried out with a special tool that allows you to cut off the ends of pipes with a protruding layer of aluminum;

- Sometimes, to prepare pipes for soldering, I use couplings that envelop the edges of the pipe with polypropylene, which ensures a tight connection between the parts.

How to prepare a soldering iron for use

Preparing the soldering iron for use involves removing polypropylene residues from the working surfaces of the nozzles. After cleaning, the device is ready for use.

Video description

How to choose an original CANDAN soldering iron, watch the video:

DIOLD ASPT-4

Sword-shaped welding machine 1.5 kW. The kit includes a metal case, 6 nozzles with a cross-section of 20-63 mm, gloves, a tape measure, and a pipe cutter. Up to 3 pairs of nozzles can be installed on the heater at the same time; it heats up quite quickly.

The main advantage of the Diold ASPT-4 welding machine is its maximum configuration Source gadgetok.ru

Attention! When purchasing, check the calibration of the temperature setting regulator with a pyrometer.

The stand is made of plastic, it is not attached firmly enough, that is, it needs to be modified. The Chinese pipe cutter included in the kit also does not work effectively. But, in general, this soldering iron for polypropylene pipes is worth the money; with minor shortcomings, it works great.

Advantages:

- high-quality complete nozzles;

- ease of use;

- reliable case with durable fastenings;

- fast heating.

Flaws:

- the pipe cutter included in the kit is not suitable for the job;

- poor quality stand.

Video description

For a brief overview of the Denzel DWP-2000 soldering station, watch this video:

ELITECH SPT1500

A simple welding machine with a universal stand similar to the one that comes with Candan. Working with a soldering iron in weight is not very convenient, since it is quite heavy and has a rigid handle. Best suited for working on the floor or table. A power of 1.5 kW is enough for quick heating and soldering of pipes with a cross-section of up to 63 millimeters.

The manufacturer of the soldering iron ELITECH SPT1500, among other things, equipped its tool with a bubble level Source svarochnye-apparaty.kz

The case is not very successful - the thin metal deforms quite quickly. The supplied pipe cutter also needs to be replaced.

Advantages:

- can be mounted on a workbench;

- quality nozzles.

Flaws:

- inconvenient to use when suspended;

- poor quality case.

Thermal power and design features of the welding machine

High power ratings of equipment are not an indicator of its high-quality soldering. It is necessary to decide what power will be optimal during operation. In order to choose a soldering iron with the required power, you should first become familiar with the diameter of the pipes that need to be soldered. The higher the pipe diameter, the higher the soldering iron power required. When purchasing an iron for soldering polypropylene pipes, do not forget about the recommended gradation:

- pipe diameter from 16 to 63 mm - soldering iron power should be 680 W;

- pipe diameter from 16 to 75 mm - soldering iron power should be 850 W;

- pipe diameter from 125 mm - soldering iron power should not be lower than 1200W.

To install a propylene pipeline for heating in a private house, with a diameter of the pipes themselves of 50 mm, using a welding machine with a power of 700 W is quite sufficient.

Advice! When working in hard-to-reach places, it is necessary to work using one nozzle, so a cylindrical soldering iron will help in such situations. This design will allow you to attach the nozzle to the very edge of the heating element.

When choosing a device, do not forget about its weight. Since all work is carried out in far from the most comfortable conditions, the soldering iron must be kept suspended, while regularly removing and putting on various parts. In this position, beginners’ hands quickly become numb and the possibility of getting burned increases significantly. It is worth remembering this, then the question is: “How to use soldering irons for polypropylene pipes?” will not torment you.

The larger the diameter of the pipes, the more powerful the soldering device should be

Video description

What professional builders think about the ELITECH SPT1500 soldering iron, watch the video:

BISON AST-2000

This welding machine is made in a rather original way - a regular piece of profiled pipe is used for mounting on the stand, and the body is a rectangular box. But the unit turned out to be cheap and reliable.

The BISON AST-2000 soldering machine has a fairly simple design, but this does not affect the quality of work in any way Source ytimg.com

It is equipped with 6 nozzles, can be used for pipes with a cross-section of 20-63 millimeters. High-quality Teflon coating, heated pipes can be easily removed. The heater is two-section, quickly reaches the required temperature. Due to its design, the equipment is relatively heavy; when used by weight, your hands get tired quickly.

Advantages:

- reliable soldering;

- fast warm-up;

- high-quality nozzles;

- convenient stand.

Disadvantages: Appearance resembles a homemade design.

Video description

What the BISON AST-2000 is is shown in this video:

Sturm TW-7218

This cylindrical welding machine is used for pipes with a small cross-section - 16-32 millimeters, all attachments for these diameters are in the case. Moreover, despite its small size, the power of this unit is quite high - 1.8 kilowatts, so it heats up to the required temperature quickly.

The Sturm TW-7218 welding unit is an excellent choice for home use Source your-home-and-garden.rf

Video description

For a quick review of the Sturm TW-7218, watch this video:

Wester DWM1000A

The product strongly resembles a Rothenberger sword-shaped welding machine. But at the same time, for all the equipment in a case with 6 nozzles with a diameter of 20-63 millimeters, you need to pay 5 times less.

The Wester DWM1000 A pipe soldering machine is practically a copy of the Rothenberger soldering iron Source 24weld.ru

A 1 kW heater warms up quite quickly, and pipe soldering is quite acceptable. The disadvantage of the welding machine is the electronics - namely the temperature controller. By and large, it is quite possible to repair it, but the equipment is definitely not suitable for professional use.

Advantages:

- digital temperature sensor;

- good quality of soldering;

- Comes with 6 nozzles.

Disadvantages : the temperature regulator breaks down quickly.

Video description

A brief overview of the Wester DWM1000 A soldering iron is presented in this video:

RESANTA ASPT1000

The cheapest sword-shaped welding machine, but it copes with its direct responsibilities quite well. Despite the fact that the heater has 3 seats for attaching nozzles, it will not be possible to install several pairs together: the holes are very close to each other.

The soldering device RESANTA ASPT1000 is the cheapest, but if you need to do one-time work around the house, it is quite suitable Source onlinetrade.ru

A power of 1 kW is not enough for quick heating, but this is quite obvious given the cost of the unit. In general, the equipment performed well.

Advantages:

- high-quality soldering;

- affordable price.

Disadvantages : You cannot put several pairs of attachments together.

Briefly about the main thing

Recommendations from friends and even managers are unlikely to help the store with the question of which welding machine to choose for plastic pipes. Because it requires selectivity and awareness. Main technical parameters that you need to pay attention to:

- Equipment . It must include several attachments and additional tools depending on the model (tape measure, stand, hexagon, cutter). Often the kit is purchased separately, but more expensive products come with everything you need.

- Speed of work . It will depend directly on the power of the equipment. For example, for soldering pipes with a cross-section of over 100 millimeters, it is necessary to select a unit with a power of approximately 1.8-2 kilowatts. If you need to solder standard household plumbing, then it is recommended to choose a welding machine with a power of over 800 watts.

- Temperature . A high-quality and professional tool must clearly withstand the temperature, this will make the work comfortable and the soldering of pipes quick.

If you have already chosen a certain device, it is recommended to study reviews about it in several sources - this way you can form your own opinion about this equipment.

To make the right choice, you need to take into account the amount of work to be done, as well as the amount that can be allocated for the purchase of a welding machine. It is best to choose a complete set, which will include different attachments and tools. This way you can save both time and money.

Ratings 0