Ways to solve the problem

Although a tool such as a screwdriver is the most popular, not every home craftsman uses it every day. Every day the battery is subject to spontaneous discharge, as a result of which the internal structure of the product is destroyed.

After the battery does not last for several minutes, the question arises, what to do with the screwdriver now? You can buy a new battery, but first you need to find it, because you can only find the exact design of the power element from official dealers. The second option is to throw away the screwdriver and buy a new one, the cost of which is at least 2-3 thousand rubles (this is an average quality product). The third option is the simplest, but at the same time it requires effort - to convert the product to be powered by alternating voltage.

The advantages of the latter option are the following factors:

- There is no need to constantly recharge the battery, which is very annoying during the work process;

- Now the screwdriver can be stored as long as you like, without thinking that the battery spontaneously discharges every day;

- Constant torque, which will provide voltage from the mains.

Among all the advantages, there will be only one drawback, which is due to the need to connect the device to an outlet, so the product must be connected to the electrical network during operation.

Other power supply methods

Block inside

The solution to the problem “is it possible to connect a screwdriver via a charger” can be an alternative option for powering the screwdriver - installing a power supply in the empty housing of the tool’s power supply unit.

Before starting action, it is necessary to prevent overheating of the unit, for which purpose holes are pre-arranged in the housing that will ensure air movement and heat removal. With this improvement, it is advisable to reduce the time of continuous operation of a screwdriver to 15 minutes.

A ready-made block is purchased and selected according to the body size and technical parameters. The pulse version of the module is most suitable for use; it is small-sized and lightweight. The use of domestically produced modules from the last century is not recommended - they have large volumes and low efficiency.

Unusable batteries are removed from the stock and a power supply is placed in their place. The contacts are energized and the housing is closed. The assembled hybrid gadget is ready to work from the network.

- The wires can be extended for convenience.

- It is necessary to monitor the quality of the assembly: the structure should not be able to touch metal elements, otherwise a short circuit will occur. It is best to leave some space between the transformer and the board, which will have a positive effect on cooling.

- If any parts of the structure become very hot, it is possible to install modules that remove excess heat or install ventilation slots.

On your own

For users with special knowledge and skills, the problem “is it possible to power a screwdriver from a charger without special means” will not be difficult, because Assembly of the nutritional unit is possible with your own hands. Instead of damaged elements, a power module assembled according to the circuit is inserted into the case. The outgoing voltage is monitored, the wires are energized, and the housing is locked.

Advice: the circuit may require additional load; this can be achieved by including a 15W light bulb in the system, which will also provide illumination.

A computer module will also work

Another solution to the problem of powering a screwdriver is to mount it to a computer power supply. This option applies to modules that are equipped with a mechanical switch lever. The positive aspect is that the unit is cooled by a cooler and is protected from exaggerated loads by a built-in special system.

Such an assembly can be arranged only with the use of power modules for 300-350 W and a current of 12 volts, at least 16 A. For tools with a voltage of more than 14 volts, this power supply option does not work.

The user may wish to hide the unsightly unit in a beautiful casing, then it is recommended not to forget to provide ventilation in it.

Car charger

When looking for a solution to the question “is it possible to connect a screwdriver to a charger,” you can stop at charging with a car AK unit. Modules with manually adjustable current and voltage are applicable. The connection is absolutely not complicated - just connect the input channels of the tool’s motor to the contacts of the car charging unit.

General recommendations

All of the above methods include one step that unites them - disassembling the power module housing. If the frame is secured with bolts, then this is not a problem; fastening with glue requires carefully opening the seam by tapping the gap with a hammer and inserting a knife into it.

When installing, observe the direction of the voltage - it should not be applied to the battery. Therefore, the module is mounted parallel to the power contacts, and a diode illuminator with a certain power is built into the positive line.

Summary: to the question “can a screwdriver work from a charger” there is a positive answer, and several solutions, but caution, some scientific knowledge and dexterity are required.

A screwdriver with an autonomous power supply is definitely one of the best inventions of mankind, and it makes life much easier for almost all men.

Required materials and tools

For most, the third option may seem difficult, because it is much easier to buy a new device and use it for several more years. In fact, the old screwdriver will last even longer, but for this it is necessary to restore it. This is quite simple to do, and you will need the following tools and materials:

- A charger that previously played an important role in charging the battery.

- Multicore electrical cable.

- A battery from a screwdriver that has become unusable.

Tools you will need are a soldering iron, acid, solder and insulating tape.

All these details will allow you to transform the screwdriver so that it can be connected to a 220 Volt network.

Where to start work

- To convert a screwdriver to be powered from a 220 V electrical network, first of all, you will need to solder an electric wire to the contacts of the charger. But since the wire has copper conductors, and the power supply has brass terminals, connecting them will be very difficult. But nothing is impossible in the world, so we use acid as a connector. It is necessary to treat the terminals of the charger with acid, and then solder the wire to the contacts. The connection must be of high quality, since the contact and functioning of the device itself depends on it.

- At the next stage, the old battery is rebuilt. To do this, it must be disassembled and the entire internal part removed from it. Although the manufacturer does not recommend doing this, we will need the battery design. When disassembling the battery, it is important to use protective equipment and not throw the internal contents in the trash, but rather recycle it. A weight should be placed in the battery case, which will act as a counterweight.

- After the inside of the battery has been removed, we begin the process of soldering the free contacts of the electrical cable to the battery terminals located in the inside of the case.

Important! During soldering, it is important to control the polarity, but if it is not observed, then nothing terrible will happen, only the device will function in the other direction. But with the help of a switch this situation can be easily resolved.

The electrical cable is inserted into the battery from the outside, making a special hole in the structure of the required diameter. After this, it is important to ensure that the cable is securely fixed in the battery housing structure. For this, you just need insulating tape, with which you should wrap the cable inside and outside, thereby making a lock. After this, insert the battery case into the screwdriver and use it for its intended purpose.

How to Use a Screwdriver Without a Battery

How to recycle a cordless screwdriver into a corded one at home: notes, tools and materials

A screwdriver is one of the most common types of tools used in everyday life and production. This popular rumor is that the device is needed for performing electrical installation and construction work, as well as for assembling furniture and other items whose design requires the presence of threaded connections. Cordless screwdriver

has such advantages as compactness and mobility. Still, many owners of this tool are often interested in how to convert a cordless screwdriver into a corded one.

What is this connected with? When using it, you have to deal with such a drawback as low energy intensity, which forces you to charge the battery every 40 minutes of intensive use. At the same time, when the device is rarely used, spontaneous discharge of the battery leads to its breakdown due to the destruction of its components. It is unrealistic to repair a battery that has become unusable; there are difficulties in purchasing a new one: often the components are sold only by official representatives of the manufacturer, and the price of a new battery is slightly lower than the cost of a new screwdriver.

Content

What are the benefits of changing your diet?

A household screwdriver with a failed battery can be switched to mains power by making certain changes to its design. This will not require a significant expenditure of finances, time and effort. At the same time, the advantages of such a transformation of the instrument are obvious:

- There will be no need to constantly charge the battery, and along with it the necessary breaks during work, because the duration of such a procedure is 3 hours or more.

- A constant current value, which does not decrease during the gradual discharge of the battery, will ensure constant torque.

- If there is no need to use the tool, its long use will not lead to a deterioration in technical characteristics.

The only drawback when working with a corded screwdriver is the dependence on the availability of an electrical network.

Preparatory stage

Before starting work, our client should prepare the necessary materials. They are all cheap and available on the market. Some structural elements, for example a battery or power supply, are sometimes taken from old, no longer used devices.

READ How to Convert an 18 Volt Screwdriver to 220

Well before you remake the battery

screwdriver in the network, make sure in place:

- charger and battery (from the screwdriver itself);

- soft multicore cable;

- soldering iron;

- acids;

- solder;

- electrical tape.

Selection of power supply

The power supply provides conversion of alternating current, the voltage of which is 220 volts. Screwdrivers consume a constant current with a nominal value of 9–19 V, therefore the connection to the network is made using an electrical transformer; for these purposes it is better to use products from the Toshibra and Feron brands.

Transformers of these brands are reliable in operation, quite small in size, lightweight, and do not complicate the movement of the tool. Their load properties correspond to the characteristics of a screwdriver for home use - decreasing under overload, they protect the tool from damage. The design of the devices has 2.4 input and output wires, they allow you to provide power to halogen lamps and other types of electricity consumers with a voltage of 12 V.

Design features of electronic transformers

Increased leakage inductance ensures a falling characteristic; additional galvanic isolation increases the safety of the power supply

. By changing the number of turns of the primary winding, you can adjust the output voltage, adjusting it to a specific type of screwdriver.

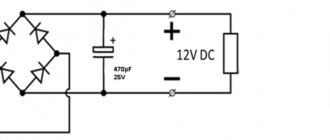

By tapping the secondary winding from the midpoint, it is possible to use not a diode bridge, but a full-wave rectifier equipped with only 2 diodes instead of 4. This will reduce power losses by 2 times.

Capacitors C1 and C2 smooth out low-frequency and high-frequency ripples; LED HL1 can be used to check the operation of the unit. Resistor R1 limits the amount of charging current supplied by the capacitor, load resistors R2–R7 ensure the start of the power supply.

Connecting the cable to the charger and battery terminals

Converting a cordless screwdriver to a corded one requires creating a strong connection between the wire and the charging and battery contacts. When performing an operation on a charger, the cable and terminals are usually connected using soldering, but this can be replaced by using alligator clips. Before starting work, the surface of the parts to be soldered is treated with acid. You can also use special solder.

Converting a screwdriver to a network one

When the batteries do not hold a charge and have exhausted their service life, and the screwdriver

still in good condition.

How to convert a screwdriver to work from a 220 V network

I’ll share a practical example of how I remade my screwdriver

. Is it possible to connect a power supply from this screwdriver?

When connecting the cable to the battery terminals, use

not recommended - such fastening will come apart during operation.

The only reliable solution is to solder the ends of the copper wire to the contacts. It is most convenient to use the battery of the screwdriver itself.

It is first disassembled to remove spent batteries. It is advisable to protect the skin of your hands and respiratory tract from harmful substances contained in the old battery filling. READ Screwdriver Makita 14 4 Volt Repair

Inserting and securing the cable into the battery housing

Then you need to clean the tool. The screwdriver at the location of the used elements is treated with a rag moistened with a weak alkaline solution, then with ordinary water. To dry the body, wipe it with a clean cloth. After complete evaporation of moisture, the ends of the cable are soldered to the contacts located on the inner wall, observing polarity.

If it is violated, the direction of rotation of the screwdriver will change, and therefore the position of the button that switches reverse. To insert the wire into the battery case, a hole is drilled in it. On the inside of the device wall, the cable is fixed using electrical tape and insulation removed from a larger diameter wire.

To prevent tension and breakage of the wiring, an insulating sheath is put on it and secured to the surface with several layers of insulating tape. To prevent a shift in the center of gravity, you should compensate for the change in the mass of the device handle by adding a counterweight. You can use a piece of pressed rubber as it.

What to do if you don't have a charger

It is also possible that the charger is lost or broken. How to convert a cordless screwdriver into a corded one with your own hands in this case? Use a battery designed for use with another technical device.

The main condition for this: a household screwdriver must have characteristics corresponding to its parameters - not only voltage, but also current. For example, when using a car battery, increased values of this indicator contribute to overheating and rapid breakdown of the electric motor.

When wondering how to convert a cordless screwdriver into a corded one, you can use a car battery. But this option is only suitable for cases where a small amount of work needs to be done. The connection is made in the same way as the connection to the charger terminals described above.

Combination of car battery with portable power supply

This is one of the possible solutions to the problem. Let's look at how to convert a cordless screwdriver into a mains-powered one using a power supply . A soft cable is connected to the instrument terminals, and an electrical plug is attached to the other end. In order to make a power supply, it is enough to connect a rectifier to any transformer with parameters corresponding to the screwdriver data. Its task is to convert alternating current with a voltage of 220 volts. Screwdrivers of different brands require a certain amount of direct current, which can be adjusted by increasing or decreasing the number of turns on the transformer coil.

READ Cordless Drill Screwdriver Bosch Easydrill

If you lack experience in this area, it is better to use a ready-made transformer with the required characteristics and equip it with a rectifier. The diodes of the rectifier bridge must match the model of screwdriver you have. Its connection is made according to the standard scheme.

How to avoid unnecessary operations using a computer power supply

The method described above has a significant drawback - its implementation is associated with certain difficulties. But there is an easier way out. To do this, you will need a power supply from any computer. Let's figure out how to convert a cordless screwdriver into a corded one using it.

The main advantage of a computer power supply is its versatility. With the correct connection of the wires, you can obtain currents of any value - it doesn’t matter what parameters your instrument has. Screwdriver use

when using such a transformer it will be as convenient as possible.

The presence of a cooling system in the power supply guarantees its long service life. It is important to place it in an insulating housing, ensure that the device is grounded and install an electrical outlet on the wall of the rectifier. Emergency shutdown of the power supply is carried out by a toggle switch located on the rear panel of the case.

Using inverter welding

If you have an old inverter device in your house, you can use it to convert a screwdriver. But it is necessary to take into account that the currents produced by welding do not correspond to the required ones, and this forces changes to its design. A secondary coil must be connected to the components included in the device. This work requires analysis and calculations, which cannot be carried out independently without knowledge of radio engineering.

Rules for using a screwdriver that has undergone modernization

We looked at various options for answering the question of how to convert a cordless screwdriver into a corded one. Helpful tips that may come in handy when working with the advanced tool:

- every 20 minutes of using the screwdriver, you need to give the motor about 5 minutes of rest;

- so that the cable does not interfere during operation, it can be fixed at elbow level, leaving some extra length in the arm area;

- periodically you need to clean the power supply from dust that gets inside;

- when using a power supply, it is advisable to limit yourself to a minimum number of extension cords;

- a screwdriver adapted to consume voltage from the mains cannot be used when carrying out work at height - at a distance of 2 or more meters from the ground;

- It is strictly forbidden to work with an ungrounded power supply.

Source

Options on how to do it + (Video)

If the power supply has also become unusable, then do not be upset, since there are other options for how to power the screwdriver:

PC power supply

The power supply for the screwdriver can be provided by a PC unit, which is much easier to find than a new battery for the device. The advantage of a PC power supply is the fact that it is possible to obtain different current values at the output, which is considered very important.

The design of the PC power supply includes a cooler that provides cooling for the transformer and its component elements, so you can immediately note that this type of power supply is durable, and in the next few years you will forget about problems with a screwdriver.

Old inverter welding

You can power a screwdriver using an old inverter welding machine, but this will require some knowledge of electrical engineering theory. After all, in this case it is necessary to add a secondary coil of the transformer, which will make it possible to obtain at the output a completely suitable current for powering the electric motor of the device. Therefore, before connecting the screwdriver to the welding machine, it is necessary to measure the current and voltage at the output, which must correspond to the values of the device.

Car battery

The last option is a car battery that can be connected to a screwdriver and used in places where it is impossible to get 220 Volt power. The disadvantage of such a device is that you won’t be able to work with a screwdriver for a long time, since the car’s power source quickly discharges. Therefore, if the standard UPS of a screwdriver refuses to function, which happens very often, then there is no need to rush to get rid of the device; just spend a few hours and the device will work even better than with a battery.

Self-powered screwdriver

Work with hand tools can also be done in a building where there is no electricity. In such cases, the device is connected to a car battery or to any other power device that has parameters suitable for the operation of a screwdriver.

To connect a car battery, you need to take wires with alligator clips, expose one end and solder directly to the contacts of the tool’s electric motor. The second end is attached to the battery terminals with a clamp, observing polarity.

The principle of connecting a portable battery is similar to a car device. Only the ends of the wires are equipped with copper clamp terminals suitable for fastening.

Read also: What wire cross-section is needed for a welding inverter

An electric tool lasts much longer than a cordless one. Therefore, you should not throw away the screwdriver if the batteries have exhausted their service life. A household man will be able to convert his power tool to mains power, thereby extending its life.

A screwdriver is convenient due to its omnipresence - independence from boundary wires makes it possible to get into hard-to-reach areas. A set of two power modules allows you to power one of them while working with the other. However, each battery pack has a finite number of charge/discharge periods, failing once they are used up. In inexpensive tools, the blocks break faster, and the user receives a gadget with a working motor, but without power. Then the dilemma arises: “is it possible to connect a screwdriver directly to the charger?”

You can power such a screwdriver by connecting it to the network through a power supply, because its motor operates at 220 volts.

Precautionary measures

After remaking a screwdriver, it is important to adhere to the following precautions:

- Provide rest for the device every 20 minutes of operation, which will extend its service life;

- Do not operate the device at a height of more than 2 meters from the ground;

- Periodically clean the power supply from dust;

- Make sure that the electrical cable during operation is not pinched, strained or exposed to negative factors, which can lead to the creation of a short circuit current.

After the alteration, following the safety rules, the old screwdriver will last longer than the new two.