A necessary companion during construction is drilling work. We will tell you in this article how a drill differs from a brace and what its operating principle is.

Since ancient times, a drill has been used to get a straight hole. To make it more convenient, various devices have been invented. One of these products is a brace, which is a simple tool in the form of a bent handle like a bracket with a chuck for attaching a drill. This ancient drilling device is considered the prototype of the mechanical drill. Looking ahead, we note that a hand drill is not fundamentally different from a brace, and their mechanisms are very similar.

Kolovorot: how it appeared

This name comes from the ancient Slavic terms “kolo” and “gate”. The first means circle, the second means rotation. By the way, according to the principle of this tool, an earth drill or a drill designed for ice works. The latter are used by fishermen when they drill holes for fishing in winter. In common parlance, such a tool is called a brace; in reality, this is the designation for a hand drill.

A rotator, close to the modern one, was invented in the 15th century. Craftsmen came up with hand tools of all kinds, most of which were not used in practice, since they were unproductive and inconvenient to use.

Drills for brace

The rotary chuck jaws are designed for mounting special drills with square shanks. Some hammers are made with universal chucks that can also hold round drill bits for hand drills.

Center drills

Used for drilling shallow holes. A single sharp protrusion (spur) on one edge of the drill first cuts the edge of the hole, and then the cutting edge on the other side of the drill carefully selects the waste material. Center drills are available in the range from 6 to 500 mm.

Screw drill

A screw, or auger, drill is in principle similar to a center drill, but a screw protrusion, or auger, runs along its body, which maintains the required direction when drilling deep holes and removes waste material.

It has two spurs (sharp protrusions) and two cutting edges. The Jennings screw drill model uses a double helix. These drills are available in diameters from 6 to 38 mm; Jennings drills have a smaller range of diameters - only up to 25 mm.

Variable diameter drills

For such drills, the drilling diameter is adjustable within established limits. The blade with a diameter scale is held in position by a spring-loaded clamp or, in some models, by a toothed wheel. There are usually two types of knives - for holes with a diameter of 1 2-38 and 22-75 mm.

Countersink drills

Similar to the same drill bits for hand drills, but with a square shank for a standard brace chuck.

Screwdriver

This attachment turns the brace into a powerful screwdriver that can generate significant torque when driving large screws.

Positive and negative sides of the brace

Any toolkit has both advantages and disadvantages.

- The main positive aspect of such a device as a hand drill is considered to be simplicity, due to which the device is reliable and has a long service life.

- The minimum of components in the mechanism and the absence of connection to power sources make it possible to use the brace everywhere, moreover, at any temperature conditions, because there is nothing in the device to freeze or overheat.

- Due to the low rotation speed, it is possible to carry out work as accurately and accurately as possible, making the required recess exactly to the millimeter, while changing the drilling angle.

- In addition, the process is simplified if you have thin drills, because on a high-speed unit they often break due to collateral vibration.

- An important advantage of the brace is the cost, which is significantly lower than the price tag for any electric tool.

Noting the shortcomings, we note that they are minor:

- The rotor is very outdated and has low speed.

- It is not always possible to replace the chuck in order to secure a working part that has a non-standard shank. For this you need to have tools with different types of clamps, or you need replacement clamps for a specific shank.

What is the working principle

The simplest solid tool, consisting of bent metal, is threaded on one edge to make a hole. In more complex samples, it is quite possible to replace the drill, since the shank of the cutting component is secured inside the hollow tube. Thus, in improved modifications, the working device is fastened using a chuck. The cavity of the latter has a cross-section in the form of a square, rectangle or Morse cone.

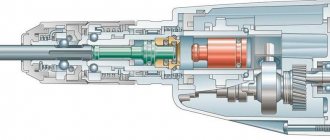

The mechanism of a modern brace

Regarding the rotation mechanism, we note that the components are quite simple. It includes:

- a push handle shaped like a mushroom, fixed on a bearing for immobility during operation;

- crankshaft and handle, which is located on a curved section for convenient rotation;

- a cartridge that secures the cutting part;

- a ratchet that distributes pressure, allowing you to work in areas where it is not possible to complete a full rotation.

Design and principle of operation

The hand crank is a simple but reliable device. It consists of a metal rod bent into a bracket or shaft. At its upper end there is a round handle mounted on a bearing. This ensures her immobility while working. It is shaped like a mushroom. It is pressed by hand during operation. In the central part of the bracket there is another handle that rotates freely. At the lower end there is a chuck for securing the drill.

There are also simple designs, without a cartridge. They have a small recess intended for the drill shank. On the side there is a socket for screwing in a bolt that clamps and holds the drill. In the simplest models, the lower end is sharpened, and it is used for drilling.

The handle of the hand rotator rotates around its axis. This type of rotation is called swing or takeoff. Its diameter depends on the size of the device: from 14 to 30 cm. Models with a span of 25 cm are common. In cases where it is impossible to make a full swing, a ratchet is installed above the cartridge. After the maximum possible revolution, the handle is returned back and the movement is repeated. The ratchet prevents the drill from moving in the opposite direction. Drills are selected taking into account the purpose of the work. Their diameter is up to six mm.

This device is easy to operate. The tip of the drill is placed at the selected point and fixed by pressing the upper handle. Drilling is carried out by rotating the shaft. The drill penetrates the surface, forming a hole of the required depth and diameter. The direction of drilling is regulated by the position of the axis of the hand rotator: you need to hold it at the desired angle and make sure that the channel does not go to the side. Before finishing drilling, the pressure on the upper handle must be released so that chips do not appear on the outer edge of the hole.

Hand drill and brace: what's the difference?

Despite the fact that the brace is considered a prototype of a hand drill, and besides, the functionality of this toolkit is identical, they differ from each other.

Thus, a hand drill, like a brace, is presented in the form of a device that is simple in its method of use and design, and is also reliable in operation. The tool differs as follows:

- Appearance. The rotator is presented in the form of a crankshaft with a handle and a chuck for securing the cutting part, while a hand drill has a gear gear. The latter has a rod (shaft, spindle) and a cartridge.

- Number of speeds. The rotator is characterized by one rotation speed, depending on the efforts of the worker. A hand drill can be 1-speed or 2-speed (based on the absence/presence of a 2-speed multiplier). This device is presented in the form of a mechanical gearbox, which includes a set of gears concentrated on different axes of one housing. Switching speeds occurs due to a change in the transmission speed.

Among the types of work carried out, a rotary hammer and a drill have no obvious differences.

Where is a hand drill used?

The main value and uniqueness of this tool is complete control over the process, if we mean its main purpose - making holes. With it, unlike an electric drill, we can instantly stop working at any time, strictly controlling (down to fractions of a millimeter) the depth of the hole. This is especially important when there are high requirements for dimensional accuracy.

First of all, the brace is used for drilling holes in wood, but this is not its only function. It can also be used to:

- screwing in and out screws, self-tapping screws and self-tapping screws;

- cutting internal threads with taps and external small diameter threads with dies, using a device clamped in a chuck;

- countersinking (processing of parts to create holes for the countersunk head of bolts and screws) and countersinking (processing of holes in a part to increase the diameter);

- work in conjunction with various locksmith sets of heads, often complete with an adapter - cardan;

- grinding valves into seats in car engine heads.

The list of materials for working with a brace is not limited to wood. It is used to make holes in both plastics and soft metals. For example, for aluminum, and sometimes brass, its “low speed” is more beneficial. And if you use a high-speed electric drill when drilling large-diameter holes in thin steel workpieces, you can rarely avoid breaking their shape due to drill beating. But with the help of a rotator - slowly but surely, you can do this work with higher accuracy.

Application of a brace

If previously the brace was used for drilling exclusively in wood, then over time the need arose to obtain even holes in products made of metal, plastic, and other materials. Today, thanks to a low-speed device, you can easily drill through plastic or metal, obtaining a neat hole without dents/chips along the edges. When using a brace, it is possible to make an even hole of large diameter without damaging the mold if, for example, the product is thin-sheet steel.

For safety reasons, when working, you need to use only a high-quality drill without chips/cracks. Using a dull or improperly sharpened drill for a hand drill will result in a torn surface. If you install the drill incorrectly, you may end up with a different diameter due to runout of the cutting component.

Note. It is forbidden to hold a hand drill with the drill in the direction of the worker. The handle should be pressed with your exclusive hand.

Despite modern technologies, a reliable tool will be in demand for a long time, helping owners produce high-quality work.

Advantages and disadvantages

Like other tools and devices for construction, a hand brace has a number of advantages and disadvantages. When choosing a device, you need to take them into account. The disadvantages of this device include the following.

- The need to use physical force. This requires a lot of effort.

- Heaviness. Such a hand-held device weighs more than an electric and mechanical drill.

- Dimensions. Its length is significant, which makes transportation difficult.

- Low operating speed. Drilling takes a long time. It will take extra effort to speed things up.

The positive aspects of using a hand rotator are as follows.

- No need for energy resources. Thanks to this, it is possible to use it without connecting to an electrical outlet or refueling, using mechanical rotation of the handle.

- Accuracy. It is possible to direct the drill as required, at the desired angle. The hole will meet the requirements down to the millimeter.

- The ability to use a small drill without the risk of breaking it, as happens when working with an electric drill.

- Reliability. The simplicity of the design ensures that there is no risk of tool breakage.

- Low cost. The price of such a device will allow you to purchase it if necessary at any time.

Despite the wide selection of electrical tools that allow you to perform work quickly and effortlessly, during construction there is a need to use simple and reliable devices.

BRAND

GATE , GATE , GATE stagnation. lesson, VORITTYA dial.; KOVOROT frozen, KOVOROTO frozen. (gate on the exit streets of the village). Zinka escaped the gate (A. Golovko); The good brook highway led them to a slick gate in front of a clean, splendid dacha (M. Trublain); No one is visible in Jerusalem, Gates are locked (T. Shevchenko); Without the light of a dark time, No one can tell a crock for stealing (P. Grabovsky); The girl keeps crying. She got up after the window, drove both the whips and the calf into the gate, and packed everything up (S. Rudansky); The stench goes into the whirlpool, As soon as the goose gets lost, the goose goes into the bin: It’s already a snack... (S. Rudansky).

II. WINCH tech. (device for holding and moving vanities), ROLLER , CABESTAN (with a vertical shaft). You worked as you might, in front of the swan, and shaved your breasts (Ya. Shporta); The need was to transport it (the cable) across the river, securing it at one point, securing it at the other, tightening it with a rotator (M. Trublaini).

VIR (place in the river, sea, then with a circular flow of water), KOLOVOROT , NURT , CHORTORIY force., KRUTIZH , KRUGOVERT , WATER Whirl , KOLOVERT REDSH, KRUTOVERT ri dshe, NURTA r_dshe, NURTINA r_dshe, NURTOVISCHE r_dshe, CIRCLE r_dshe, KRUTOVIR'YA rіdshe, NOISE rіdko, WATER ROCK size. next, KRUTIL dial., OMUT dial. On the fairway I got (Tamila) from Vir. There are plenty of them on the Dnieper, many of them are chortoirs (L. Dmiterko); The engineer fell from the forest steep just into the whirlpool Dar'i (I. Le); You (vodyanikov) have nothing to do with tightening the chovna at the nurt (M. Stelmakh); No matter how hard I tried, I couldn’t get through all the twists and turns (I. Golovchenko, O. Musienko); - Pilot, pantrui! Bistrina. Whirlwind (M. Sheremet); Gude, the black water swirls (L. Pervomaisky); There, where the waters of two rivers converge, such steep turns arise that they can easily get wet (M. Chabanivsky); The fisherman is sitting above the shore, fishing, The floating float is floating,... Chi is nurturing in the water (P. Kulish); The great one overcomes the restless steepness, goes straight to his pier (I. Tsyupa); Chauvin rushed to the bistrina in the noise; the water flowed like a yogo, otherwise a trisochka (I. Nechuy-Levytsky); Andriyko’s squad (N. Ribak) drowned in that whirlpool; Vіn gurgling u viruchu krіl (I. Chendei); Below the waterfall is a deep, blue, vast pool (I. Franko).

VIR of what, what (a turbulent, rapid flow of the flow and so on, which snorts, pulls with it), KOLOVOROT , NURT , VIKHOR , VEREMIYA , KOLOVERT rіdshe, NURTOVISCHE rіdshe, CIRCLE r Come on. Having arrived in St. Petersburg, Shevchenko is plunged into the world itself (P. Kolesnik); How many talents are lost in the whirlwind of everyday life through those that they sometimes do not have the opportunity to reveal to themselves!.. (I. Golovchenko, O. Musienko); — Now bring your affairs in Kovalivtsi to order, and don’t rush headlong into a new deep hole (V. Kucher); Whirlwind of war; I told (my mother) what was going on here, as I realized today’s morning faith (O. Gonchar); On the hump there is a bliskavka shabel, a terrible circle of cinematographers (Y. Kravchenko); Oh, how scared you are (conscience).. to ruin your life in peace (V. Korotich); The mood of the dance was transmitted to the spectators, who squealed them in their whirlpool (Ya. Galan).

DRILL SHARPENING

Rotary drills

To sharpen both screw and center drills, use a small flat or triangular needle file. Sharpen each spur by filing it from the inside with a file. Never grind the outside of it. With the lead screw resting the drill on the workbench, sharpen the cutting edges. Drills with variable diameters are sharpened in the same way.

Twist drills

There are special electric machines for sharpening drills. All you have to do is insert the drill bit into the machine, tip first, and turn it on. There are also special templates into which a drill is inserted at the desired angle, and the template itself is moved over sandpaper. Most woodworkers sharpen drill bits by rotating the tips while holding them against a rotating sharpening wheel. Do not press too hard and try to sharpen both cutting edges evenly so that the center of the drill does not move.