Features of application

A device such as a hydraulic wood splitter is widely used in production workshops and private households. The machines are responsible for bucking and splitting logs. Those who have had to collect firewood by hand know how much free time this work takes. Non-hydraulic installations are significantly inferior in terms of reliability and durability. Uneven loads often lead to premature equipment failures.

Another thing is a hydraulic wood splitter, made by yourself or assembled at a factory. Such designs are gaining popularity among consumers. Even if the load reaches ten tons, it is applied gradually. Therefore, the oil pump and engine can withstand it without breaking. If there is not enough force, the cylinder will simply stop rotating. And the oil pump will not break down.

DIY hydraulic wood splitter

Working principle and application

Hydraulic and mechanical tools for splitting firewood are used in small woodworking shops and private farms. Regardless of location, all machines operate on the principle of mechanical bucking and splitting of wood .

Manual models of wood splitters often become unusable. In addition, preparing firewood with their help requires a lot of time, effort and skill. Non-hydraulic equipment breaks down periodically because the load is distributed unevenly.

Hydraulic splitting axes continue to gain popularity not because of clever advertising. The point is that the tool takes on the load gradually as the force increases. That is, the oil pump and engine will not be subject to overload and, as a result, malfunctions.

Types of hydraulic wood splitter

There are dozens of models on the construction equipment market, the cost of which varies from 15 to 250 thousand rubles.

The price of the device is determined based on the following important criteria:

- Power. The higher it is, the more expensive the equipment.

- Engine's type.

- Weight.

- Maximum log length.

- If you buy a model with an electric motor, you need to look at the declared voltage.

The power source can be electric or gasoline.

Let's look at the features of each type:

- Electric motor. Inexpensive machines intended for use at home have an electric motor. The model is extremely simple and environmentally friendly. Suitable for daily work, even in a garage. And if you made the wood splitter yourself, and the model turned out to be quite compact, you can easily move it by hand. Perhaps the main disadvantage of such a device is the inability to work without power supply.

- Gasoline engine. As a rule, they bet on powerful models. It will no longer be possible to transport it to the place where firewood is collected manually. The gasoline-powered device has an impressive weight and costs much more. But the efficiency of such a device is much higher.

Electric wood splitter Sadko

Depending on the method of laying firewood, the following types of splitters are distinguished:

- Vertical. Differs in compact sizes. The movement of the cutter is carried out from top to bottom. The log is installed below in a vertical position. There are models on sale in which everything happens the other way around. The knife is motionless, the tree moves towards it.

- Horizontal. The most popular type of wood splitter. The wood is laid horizontally and moves towards the knife.

- Mixed. It is almost impossible to buy equipment; it is considered very rare. As a rule, only professional models have two types of bookmarks. Versatility is an important advantage. Thanks to it, the processing process speeds up significantly. Most often, mixed mechanical splitters are installed at large enterprises and sawmills.

Since not everyone can afford the purchase of equipment, a homemade hydraulic wood splitter with your own hands becomes the most effective and cost-effective solution. It all depends on the knowledge of the master, his skill and budget. With good effort, you can assemble almost professional equipment. And even put the machine “in line” to perform automatic trimming. If you intend to create a hydraulic wood splitter with your own hands, the necessary drawings and recommendations can be easily found on the Internet.

The most popular type of wood splitter is horizontal

General classification

All types of wood splitters differ in the method of stacking logs, the volume of processed wood, mobility and type of drive.

Horizontal

In horizontal models, the log is laid inside a horizontal groove, after which the laid element is pushed towards the knife. In some tools, the log may lie motionless inside the groove, and the knife itself moves towards it. Horizontal models can have short legs (desktop) and long legs (for full-length work).

The machine is a strong horizontal frame on which a splitting chute with a dividing knife is installed

Vertical

In vertical models, the log is installed vertically, and the knife is pushed from above by means of a hydraulic cylinder. The efficiency of this machine is higher than that of horizontal models, which is due to the lack of movement of the log during the splitting process without creating additional friction. However, working with crookedly sawn elements requires holding them manually, which goes against the safety precautions for operating this equipment.

The machine has a robust vertical structure

Industrial

Industrial log splitters, most often equipped with an electric motor, are used with a 220 or 380 V motor with a power of 3 kW or more.

Industrial wood splitters are very powerful and can cope with huge volumes of firewood.

Household wood splitters

Household models are distinguished by maximum structural simplicity, extreme ease of operation and absolute unpretentiousness in terms of maintenance.

The design of the simplest mechanical wood splitter resembles a well crane

Types by drive type

With an electric, gasoline engine, with a power take-off shaft or with a hydraulic system and a combined type of drive (according to the type of drive).

Gasoline log splitters are suitable for medium-sized businesses

A small electric wood splitter is perfect for home use.

Stationary and mobile

The first version of such mechanisms is usually represented by massive industrial models or entire multifunctional machines. Operating a stationary wood splitter in domestic conditions is most often not at all advisable. Mobile or mobile models are equipped with transport wheels, which greatly facilitate the movement of the device to almost any place of work and are optimally suited for domestic use.

Cleaver "Gorynych". Features of operation

We will not consider all the models on the market, since there are dozens of them. Let's consider one of the most common and successful in terms of price and quality - “Gorynych”. One of the strengths of the cleaver is its speed. As for reliability and durability, Gorynych also breaks all records in these parameters. Recent statistics on the work done by cleavers are truly impressive. In 9 years, one such unit was able to process over 18,000 cubic meters of forest! During this time it was never repaired; all components remained intact. The workers turned it on both in 30-degree heat and in severe frosts down to -20 degrees. The engine and other components coped well with the load at any time of the year.

Among the main achievements of “Gorynych”:

- It takes just 2.5 seconds to complete one cycle.

- The assembly is designed to operate even in extreme temperatures.

- All parts without exception are subject to repair.

- The knife is made of hardened steel. You have to try very hard to dull it even a little.

- Thanks to the special coating, the equipment is resistant to precipitation and other natural influences.

Reliable and durable cleaver Gorynych

In about 3 minutes, the unit splits 26 pieces; in 60 minutes you can process 500 pieces. In the photo you can see what these hydraulic wood splitters look like. The cost starts from 150,000 rubles - for this money you can buy a “Gorynych 220”, model 6T. The first unit is electric. If you calculate the estimate and carefully study the instructions, a DIY hydraulic wood splitter will cost less, but not much. Therefore, it is not so easy to say for sure which option is better.

Self-assembly of a hydraulic splitter

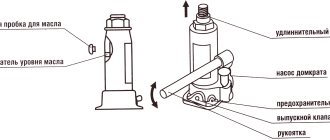

It is best to start assembly by welding the frame attached to the platform. You cannot do without a car jack, which is equipped with the lower part. At the top, the connector required for effective splitting is calculated. After all, the diameter and length of each workpiece are different, so a vertical hydraulic wood splitter must be “omnivorous”.

Homemade mechanical cleaver

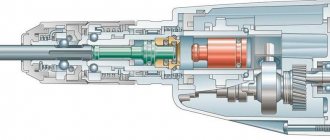

The photograph shows a mechanical cleaver designed for use on an industrial scale. It has a complex design: the jack is hydraulic, and the frame is stationary (non-portable). To create such an installation, you need to have basic plumbing skills and be familiar with basic safety rules. The unit seems simple, but if you neglect it, there is a high risk of an accident.

To save resources, we installed wedge-shaped knives with 4 to 8 blades. If the knife were ordinary, it would simply cut the log into two parts. Due to the wedge-shaped blades, any log is processed in one pass. If you are planning to make your own hydraulic log splitter powered by a tractor, do not forget to equip it with a wedge-shaped knife with four blades.

So, if you are planning to assemble a basic hydraulic wood splitter with your own hands, prepare drawings and use the video and text instructions on our website.

The simplest assembly will consist of:

- Hydraulic pump and drive (motor).

- Hydraulic tank, cylinder and distributor.

- Sleeves.

- You also need to stock up on connecting elements.

Before starting work, it is important to determine specific power indicators and find out the required hydraulic cylinder force. In simple words, you can assemble a wood splitter, but its power is simply not enough to work effectively. Therefore, when large logs or knotty wood come across, the equipment may simply jam.

DIY hydraulic wood splitter

This photo shows the simplest diagram of a cleaver. Pay attention to the hydraulic distributor safety valve. It must be installed without fail, although it does not affect the system parameters.

Homemade devices

“Homemade products” are often used to solve household problems while preparing for the cold season. Some craftsmen manage to make truly “masterpiece” wood splitters - homemade hydraulic ones, using available materials and devices.

If you want to make a high-quality machine yourself, then to speed up the process you can use drawings, video instructions and diagrams.

Making a foot cleaver

It is possible that you belong to the category of people who are not eager to pay huge sums for electricity or buy gasoline. And not everyone has the money to install tractor equipment and other expensive elements of a hydraulic wood splitter with their own hands. In this case, we can offer you drawings of the foot installation. You will have to constantly put in some effort, but you won’t have to pay for light.

First, let's list the tools and components that will be needed for assembly:

- Jack.

- Pipe. The optimal dimensions are 40 by 50.

- Several corners.

- Steel plates. Their thickness is 6-8 mm.

- Durable rubber harness.

- To build a wedge that splits wood, you will need a heavy piece of metal. But keep in mind - its thickness must be at least 30 mm.

- M12 bolts.

- As for additional equipment, you can’t do without a welding machine and an angle grinder, a drill, and a tape measure.

Foot cleaver

The manufacturing process consists of 4 stages:

- Frame assembly. Since the profile pipe can bend under force, it must be strengthened in advance. Or stock up on a thicker element. In the second case everything is clear, in the first we will make a farm. The guide must be welded to the platform by welding a gusset on the back side. Using a corner, make a slider. Sliding along the guide should be free

- Jack base. The unit with a lifting capacity of ten tons comes in handy. In principle, a six-ton truck will be enough to perform basic tasks. To make additional support, take metal strips of 0.6-0.8 cm and weld them under the heel.

- Modernization of the handle. Here we need to make a comfortable bend for the legs. Ideally, weld the pedal to prevent slipping. The presence of an additional spring will return the handle to its original position. Or you can weld the roller and then tie a tourniquet.

- Manufacturing of cutting parts. It is made of thick steel (minimum 3 mm), sharpened into a wedge shape. Fastening is carried out with M12 screws. At this point, the foot device for chopping wood is ready.

Homemade wood splitter

Do you use homemade wood splitters when preparing firewood?

Even for the simplest manual device, the store asks several thousand rubles. You can save money by making a firewood splitter yourself. For clarity, it is worth studying a video with different machines in operation.

Don't miss: Firewood for a summer house and bathhouse: types of designs, step-by-step instructions, the best examples in the photo

There are several variations on how to make a wood splitter. One of them is a rack design. It is popular, because the Internet offers many photo instructions.

The base of the device must be made of thick steel. It must withstand the load and weight of the components attached to it - the wedge, gearbox and motor.

The working algorithm depends on the selected materials and the design of the device. The main steps are as follows:

- The tip is made of sheet steel. Minimum thickness 10 mm, sharpen at right angles.

- If you plan to work with large logs, make a compound blade. Thickness from 50 mm. You can use a steel blank as an amplifier.

- Place the gear 5 cm above the bed. There should be twice the length of the log left before the knife.

- Make the carriage moving along the frame at the height of the installed gear.

- Attach the pusher to the front of the carriage. This is a transverse steel plate, minimum thickness 7 mm.

- Ensure the mobility of the rack with a hinge by installing it on the carriage.

- The movement of the carriage to the gearbox is ensured by a return spring. Attach it so that the rack rises above the gear.

- Install the clamping lever. When you press it, the rack should press against the gear and move forward. Make the length of the rack less than the gap between the blade and the feed plate.

Expert opinion

Igor Lebedev

Ask a Question

Advice! Instead of an electric motor, a gasoline engine is suitable. Its speed is high, so an increase in the gearbox transmission ratio is required.

If you plan to make a hydraulic wood splitter on your own, you need to decide what kind of wood it will be used for.

| Wood species | Average force in kN | ||

| Diameter 200 mm | 300 mm | 400 mm | |

| Birch | 16 | 29 | 48 |

| Elm | 28 | 39 | 65 |

| Oak | 24 | 33 | 51 |

| Spruce | 11 | 18 | 26 |

| Maple | 18 | 10 | 49 |

| Linden | 3 | 4 | 6 |

| Aspen | 10 | 17 | 26 |

| Pine | 8 | 15 | 24 |

The indicators differ significantly. If the logs are very knotty, the load is at least doubled.

For a homemade hydraulic device you need to prepare:

- electric engine (possible with gasoline), minimum 2 kW;

- Control block;

- pump;

- tank for filling oil (you can make it yourself);

- high-pressure hoses;

- hydraulic cylinder;

- beam (metal), U-shaped or I-beam No. 16;

- sheet steel, prepare pieces 5-20 mm thick;

- metal corner, shelf 30-40 mm.

A hydraulic cleaver is made on your own according to the following algorithm:

- Make a bed using a U-shaped beam or I-beam. An important point is the width of the beam. As it increases, the permissible load increases, but the movement of the structure becomes more difficult. The average is 10-15 cm.

- Install a hydraulic cylinder above the beam, height 5-7 cm.

- Complete the rod with a pusher. It is better to use metal, thickness 7-10 mm.

- To move the knife along the bed, make a body.

- To fix the knife in different positions, make 12 mm holes at the bottom of the frame, 50 mm pitch. Similarly, add 2 holes in the blade body, install 2 bolts, and weld them.

Don't miss: How to make fuel briquettes with your own hands?

If you look at photos of homemade wood splitters, you will notice that there are quite a lot of different variations of such equipment.

Crowbar cleaver

This cone splitter consists of a fairly long metal rod and has a pointed cone on one side. At the other end there is a handle.

The performance of such a device is quite low, but at the same time the expenditure of effort is quite high.

The next type of manual wood splitter is cylindrical. This device is very mobile and easy to carry and transport.

The design of such a wood splitter is that on the stand with which it stands, a frame is fixed, the blades of which are directed upward.

The log, which is located in the space of the frame, is struck with a sledgehammer. The upward-facing blades separate the log into several individual logs.

Spring log splitter

The fact is that it is very productive. The prepared log is split using a special working part, which is attached to a crossbar, which works with the help of shock absorbers.

Working with such a device does not require much effort, but with prolonged use a person will get quite tired.