The aerosol method brought the painting process to a completely new level of productivity and quality of the applied layer. The operation of a paint sprayer is much simpler than hand tools, however, it has certain design nuances that should be taken into account when choosing a tool for certain types of work. In this publication, we will examine in detail such a topic as the influence of the location of the tank on the ease of painting in various areas, and we will identify which design is more suitable for certain areas of application. As a useful addition, we will analyze common problems and problems associated with the spray gun tank.

How does a pneumatic spray gun work?

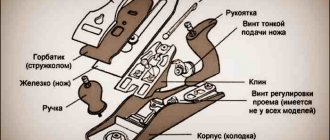

An overview of the advantages and disadvantages of a particular tank location will become more meaningful and clear if you understand the operating principle of the spray gun itself. A general idea of the structure of the spray gun, together with the features of using various containers, will help you form your own opinion and make the best choice for any individual situation.

The main and only driving force that forces the spray gun to spray paint and varnish mixtures is the air coming from the compressor receiver. Coming out of the blower and passing through a sealed hose, the driving flow enters the spray gun through an opening in the handle. Next, the air rests against the damper, which is moved back by pressing the trigger, and passes further into the channels associated with the supply of paint and varnish material.

A metal rod with a cone-shaped tip (needle), which fits tightly to the inside of the nozzle, is responsible for dispensing paint. When the tank is located at the top, the mixture flows down under the force of gravity, but a spray gun with a bottom feed works on a different principle, pulling paint out of the container. In both cases, the paint enters the nozzle, where it is picked up by the air flow and flies out of its hole under pressure. In addition to the channel with the material, part of the air enters the air cap, which gives the spray torch an elongated shape and breaks the mixture into smaller droplets. In this way, spraying occurs in a pneumatic spray gun.

What is a spray gun

A spray gun is a type of pneumatic tool that is used to apply paints and varnishes to various surfaces. This tool works in conjunction with a compressor. Due to its unique design, paint is sprayed and applied to the surface to be painted.

It should be noted right away that the material is about pneumatic spray guns. They are also known as sprayers, atomizers and pneumatic paint and varnish guns. They only work in conjunction with air compressors. In addition to pneumatic spray guns, there are also electric ones that operate from an electric motor. To understand how a paint gun functions, you need to consider its design.

Features of the models

As you know, numerous tool manufacturers today delight us with more and more diverse products, and paint sprayers occupy a decent share of this market. Constant improvement, changes in design, materials and functions have given rise to many unique models with their own characteristics. In this topic, we will find out for which work the lower or upper tank of the spray gun is more suitable, and we will touch on a couple of specific variations of its design.

Spray gun with top tank

As mentioned above, a paint sprayer with an upper tank works on the principle of attraction, where the sprayed mixture itself flows into the material supply channel. The tank is installed using a threaded connection, which can be either internal or external (depending on the model). A “soldier” filter must be installed at the connection point.

The design of a spray gun with an upper tank, the diagram of which is shown above, does not differ from the bottom feed, however, the tank itself has its own characteristics. The container consists of a body with a lid and a ventilation hole to allow air to enter as the volume of paint decreases. The manufacturing material can be metal or plastic. The first one is more reliable and resistant to deformation, but has a decent weight. The plastic tank is light, translucent (the paint level is visible), but with prolonged contact, it can react with solvents and become deformed, losing its seal. This is especially true for the threads on the lid. The average volume of overhead tanks is 600 ml.

The properties of a spray gun with top paint supply allow it to spray thicker mixtures than with a bottom tank. The paint is of the same consistency, sprays more efficiently, applying a thicker layer. Due to their high dispersion, spray guns with an upper tank are used mainly in professional activities, when painting cars, furniture and various structures.

Spray gun with bottom tank

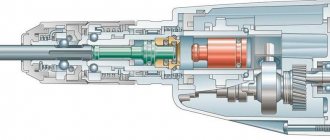

An equally popular design of a pneumatic spray gun, which has great success in certain areas of application, which we will discuss further. The principle of operation of a spray gun with a lower tank is based on the pressure drop in the container due to the passing air flow over its tube. A strong pressure, flying over the outlet of the tank, pushes out the mixture and picks it up and sprays it out of the nozzle. This effect was discovered in the early 19th century and named after the physicist John Venturi.

The design of the lower tank of the spray gun consists of a main container and a lid with a tube. The connection of 2 elements occurs using threads or special lugs installed on the lid. The tube fixed in the lid is bent in the center at an obtuse angle so that its suction end is directed to the side of the bottom of the container. This solution allows you to use the tool in an inclined position and paint horizontal surfaces from above or below. The design of a spray gun with a lower tank requires changing the position of the tube depending on the position of the tool during operation: the tube is forward if the nozzle looks down and back if you want to direct the torch upward.

Almost all models of lower containers are made of polished metal and on average hold 1 liter of mixture. Such devices are convenient to use for performing large volumes of work, but with weak muscles, the hand may periodically get tired.

An undoubted advantage of the work is the open view, which is provided by the special design of the spray gun with a lower tank. The diagram presented below clearly demonstrates the principle of using a pneumatic spray gun with a pressure tank installed in place of a standard container. This approach allows you to significantly increase the ease and productivity of work, without being distracted by constantly adding paint.

Sprayers with a lower tank are effective in finishing work, when painting rooms, gates, facades and other elements. Less often, but no less successfully, they are used in car services and various industries. They are considered less professional than top-mount devices, but still provide very decent coverage.

With side tank

A relatively new type of container arrangement for painting, which appeared not so long ago, but is rapidly gaining popularity. Spray guns with a side tank, called “adjustable” or “rotary”, operate on the same principle as with the top one. The mixture enters the nozzle under the influence of gravity, but not from the top, but from the side of the gun.

The side tank of the spray gun is made primarily of metal and is connected to the body using a threaded connection that is tightened by hand. Like the standard top tank, the rotary lid has a small vent to allow air to flow in while painting. The capacity of the container is not large and averages 300 ml. The compact size is due to the need to rotate the tank 360° so as not to touch it with paint even when tilted towards the nozzle.

A spray gun with an adjustable tank is classified as professional and is used primarily for painting cars or decorating furniture.

Vacuum tanks for paint sprayers

A modern type of container for a pneumatic spray gun, which allows you to spray paint in any position of the tool (even upside down). It is installed mainly in the upper mounts using an adapter. The vacuum tank consists of a durable body without a bottom, inside of which a soft container is inserted, on top of which a lid with a filter is installed.

The principle of operation of a tank of this type is a deformable container, completely filled with paint and varnish composition. If, when pouring, there is air left in the container, it is released by turning the spray gun upside down and pressing the trigger until all the empty space is gone and only the sprayed mixture remains. The vacuum created in the tank will ensure the supply of paint to the nozzle in any position of the spray gun. The volume of these containers starts from 90 ml and reaches 850 ml. In theory, the soft tank is positioned as a consumable material for one-time use. In practice, it can be carefully washed and reused several times.

The most optimal area for using vacuum tanks is car painting, where the painter is forced to frequently change the position of the tool. Can also be used for other objects with complex surfaces and small areas.

How does a modern airbrush work?

The spray gun device consists of the following main elements:

- glasses for coloring matter;

- housings;

- needle springs;

- needle regulator;

- fitting;

- valve with spring;

- rod;

- trigger;

- the needle itself;

- nozzles;

- heads;

- adapter;

- union nut.

Correct position of the spray gun when painting the surface.

If we deal with modern models, they have a special pump that supplies paint from the tank to the nozzle. To be able to regulate the amount of substance, the body of the spray gun has a special adjusting screw. There are instruments that have an electronic system that performs the same function.

Nozzles with a narrow jet or flat jet shape allow you to apply paint to the surface in strips, the width of which can be set in advance. The spray gun is used for painting work on many objects: cars, walls, furniture, or even to create graffiti. Therefore, a separate nozzle is selected for each case.

In order to be able to control the consumption of material during use, the paint cup is made of a translucent material, most often plastic.

Tips and possible tank malfunctions

The operation of a spray gun with a tank is quite simple and intuitive, but has certain nuances.

In this topic, we will not analyze all the subtleties and tricks of using a pneumatic spray gun, but will focus only on its paint container. Let's start with some advice. Cleaning the tank after work.

Should be done as soon as possible. Preferably before the paint has had time to dry. It is recommended to use a comfortable brush with nylon bristles. It is not advisable to use metal brushes, sandpaper or pick at the dried mixture with a knife. This aggressive cleaning method scratches the surface of the container, making subsequent cleaning more difficult.

Leak in the lid area.

If the connection between the lid and the tank is not tight enough and allows drops of the mixture to pass through, the best option would be to install a new gasket. If one is not available, you can put a piece of fabric or a nylon stocking between the container and the lid, which can also serve as a filter for the mixture being poured.

The air goes into the spray gun tank.

A fairly common problem associated with insufficient tightening of the air cap or its deformation. Also, this phenomenon may be a consequence of a torn gasket between the nozzle and the head of the tool. The problem is eliminated by replacing the damaged head, gasket or nozzle.

article from the Rating section

- 100

Pneumatic tools Painting tools

Save this page on your social media. network and return to it at any time.

ADD A COMMENT