Models and prices

A pipe cutter for steel pipes has different technical and user characteristics, which ultimately affects its price. The table provides an overview of some manual models with their parameters and prices.

| Model | Characteristics | Price, rub |

| RIDGID 35S | has 6 roller bearings for high-quality cutting of pipes (from 6 to 35 mm) made of stainless steel | 3 700 |

| SUPER 1 1/4 | has wide rollers and a hardened disc for long service life (pipes 10-42 mm) | 4 400 |

| INOX SUPER 1 1/4 | high-quality cutting ensuring a smooth surface of pipes (10-42 mm) | 7 500 |

| RIDGID 65S | has 12 roller bearings for high-quality cutting of pipes (from 6 to 65 mm) made of stainless steel | 6 500 |

| REMS PAC CT | has hardened cutting discs for long service life, precise and high-quality cuts (10-60 mm) | 11 600 |

| Kopco St | strong and durable disc for working with a wide variety of pipes (3-120 mm) | 23 000 |

As you can see, the pricing policy is determined by the functionality of the pipe cutter, the range of pipes it can work with, the angle of the cut and its accuracy.

Video review of the RIDGID 65S model and rules for working with it.

Purpose

PVC pipes are easy to cut, but it is impossible to obtain a tight connection between two pipeline elements if the cuts are uneven. Therefore, a specialized tool is used. Pipe cutters are used for various jobs:

- Repair. The tool is needed when replacing individual parts of the pipeline.

- Assembling a new pipeline. The tool is used when cutting individual pipes to the required sizes.

- Dismantling damaged or old water supply circuits.

The pipe cutter is suitable for working with different types of plastic pipes.

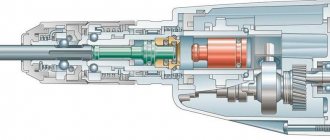

Pipe cutter for steel pipes - device and principle of operation

This device is the best tool for precise cutting of pipes at right angles.

The simplest pipe cutter for steel pipes consists of the following elements:

- A cutting roller, which can be of different types depending on the characteristics of the pipe that is supposed to be cut.

- A clamp for rigidly attaching the roller to the frame and a housing for its placement.

- The frame is the base in which the roller is placed.

- Feed handle - it is used to rotate and cut the pipe.

The device is shown schematically in the figure below (disassembled).

The steel pipe cutter works by applying the mechanical force of rotation of the feed screw. The pipe is fixed in the frame and secured with clamps on both sides. The screw begins to rotate, as a result of which a groove is formed in the pipe wall, which deepens until the pipe is completely cut. In this case, the screw of pipe cutters with one roller is turned a full turn (360 degrees), and devices with 4 rollers are rotated 120 degrees, since each of them cuts off its own piece of pipe.

IMPORTANT. In some cases, special metal hacksaws are used to cut pipes. This is especially convenient when you just need to get 2 or more pieces from one product. However, if smooth edges and right angles are required (this is especially true for subsequent threading), then a pipe cutter for steel pipes is the only tool that can do such a job.

Scope of application

The device is used for mechanical cutting of pipes made of any materials (steel, copper, cast iron, ceramics, plastic, metal-plastic). However, in most cases, it cuts pipes only from a specific material (although there are also devices that can cope with both steel and plastic pipes).

However, some pipe cutters only cut at right angles, while others can handle any cuts (mostly from 45 to 90 degrees).

IMPORTANT. Pipe cutters of any kind are used only for cutting round classic pipes and are not suitable for working with profile pipes. The reason is that the design of their mechanism involves performing rotational movements around the surface of the pipe. The profile has a square and rectangular shape, so it is cut using a grinder or a hacksaw.

Kinds

Varieties of pipe cutters are classified depending on the objects being cut and the characteristics of the cutting element. Accordingly, the following types of tools are distinguished:

- The cutter cuts pipes up to 100 mm in diameter. Suitable not only for steel, but also for plastic pipes, Has several steel discs.

- The chain one is distinguished by the fact that it can cut pipes made of dense materials (cast iron, concrete, ceramics), since it has a mechanism for tightly fixing the cutting object, made on the basis of a conventional chain and rotary levers.

Video instructions: how to work with a pipe cutter.

- The roller is equipped with cutting rollers (from 1 to 3) and guide elements, and the diameter of the pipes that it can cut directly depends on the number of rollers: a device with 1 roller cuts pipes up to 50 mm, and with 3 rollers – up to 100 mm and even more .

- The telescopic one has a carriage, roller and guides that can optimally fix the pipe depending on the required cutting angle. It copes well with cutting thick pipes or made of durable materials, since due to the configuration it can create strong pressure on the surface of the cutting object.

- The ratchet pipe cutter is portable and can cut thin pipes. Its design is the simplest among devices of this class - 2 handles and a cutting blade.

- Electric is equipped with an electric motor. Thanks to this, the worker’s effort in cutting the pipe is minimal - it is only important to configure the tool correctly, and he will do the rest of the work almost independently.

- Guillotine got its name because of the design of the cutting mechanism. Its knife makes a perpendicular cut in pipes of small diameters (up to 30 mm). The pipe is fixed in the frame, and the screw pushes the guillotine and makes a clear cut at an angle of 9 degrees. The tool is suitable for cutting pipes of different thicknesses and structures (single-layer, multi-layer, reinforced).

- A pneumatic pipe cutter is driven by rarefied air pressure. This device is used in production for cutting pipes with very large diameters (up to 1500 mm). At the same time, it copes well with cutting dense materials (cast iron) and light plastic.

- Orbital pipe cutters are designed not only for mechanical cutting of pipes, but also for chamfering thin-walled pipes. For this purpose, they are equipped with special chamfer cutters.

At the same time, it is a universal tool - it cuts pipes of any diameter and from any material. Application is limited only by engine power. However, such a pipe cutter also has a significant drawback - it will be inconvenient to use in hard-to-reach areas of work (for example, sewer pipes).

With its help, you can not only carry out mechanical cutting of pipes, but also carry out work on their trimming, chamfering with blunting, as well as from the outer surface of the pipe.

Video overview of one of the models

Often, add-ons are offered for various types of pipe cutters to ensure the safest conditions for working with pipes. Thus, using the quick crimping mechanism, you can quickly secure large pipes in the device without using a special screw. The pipe cutter can also be equipped with additional removable cutting elements designed for pipes of various thicknesses, and rollers that move the device around the pipe.

Types of plastic pipes

In household communications there are all types of polymer and combined pipe materials that the modern market offers. Their purpose is limited by the technical characteristics of the materials. Depending on the conditions under which (temperature, pressure, location) the system will be operated, the material is selected.

Metal-plastic

Metal-plastic pipes are multifunctional pipes used for the construction of plumbing, heating, and installation of heated floors. They have a multilayer structure (5 layers) and are combined. The middle (3rd) layer is aluminum foil, which is firmly bonded with an adhesive base to the polymer.

Installation of metal-plastic pipes is carried out using metal fittings. The requirements for cutting are strict, since the quality and durability of the connection depends on this.

Polypropylene

Polypropylene materials are widely used for the installation of household water supply networks. These plastic pipes are assembled using special fittings and diffusion welding. The throughput of the future water supply system, the number of fittings used, and service life directly depend on the quality of the cut of the polypropylene pipe.

Cutting polypropylene pipes with improvised tools leads to microcracks in the pipe itself. This is especially critical if the pipeline is planned to be installed in a closed manner.

Polyethylene

There are two types of polyethylene pipes - high and low pressure. High-pressure polyethylene materials (HDPE) are used for the construction of non-pressure communications, such as sewerage, drainage, and channels for laying electrical wires.

HDPE - low-density polyethylene is a material for the construction of pressure water and gas networks. Installation of polyethylene pipelines is carried out using fittings and welding. The requirements for the quality of the cut are high, and the material cannot be called pliable for cutting.

Polyvinyl chloride

Polyvinyl chloride (PVC) pipes are a reliable material for the installation of industrial and household communications that are operated without heating. PVC is a rigid material that can withstand significant external pressure. The main areas of application are water supply, sewerage, electrical networks and the construction of artesian wells.

We recommend that you read: Do-it-yourself installation of various types of plastic pipes for water supply lines

Note! When cutting polymer materials with a jigsaw or grinder, they can not only be mechanically damaged, but also deformed from overheating.

Pipe cutting methods

Pipe cutters for steel pipes have different technical designs (in the form of manual devices, machine tools, automatic mechanisms) depending on several factors:

- parameters of the pipe that needs to be cut (wall thickness and outer diameter are taken into account);

- required cutting accuracy (especially relevant for the further use of pipes in water supply systems);

- quality of the pipe surface after cutting (a smooth surface is required in cases of threading the pipe in the future);

- production volumes (home conditions or industrial scale).

Accordingly, the following methods of cutting steel pipes are distinguished:

- Laser cutting;

- Cutting on disc machines;

- Cutting with circular saws;

- Use of professional cutting machines;

- Cutting on band saws.

Laser cutting

The laser pipe cutter for steel pipes cuts using a laser. In this case, the surface of the pipe does not receive mechanical damage due to the lack of direct contact with the cutting element. The pipe is fixed with clamps on a special table (using equipment), on which the laser head is located. The pipe is rotated by a special mechanism, and the laser precisely cuts the steel according to predetermined parameters. In this case, it is possible not only to mechanically divide the pipe into several parts, but also to cut out any elements in its body (for example, a mesh, as shown in the figure below).

The advantages of such production are obvious:

- this is a safe cutting method, since all work is automated;

- they are quite simple to carry out even for low-skilled specialists;

- the surface is cut perfectly smooth along the contour, there are no scratches or other mechanical defects;

- You can make cuts of any size;

- production is fast and waste-free (used for professional purposes).

Cutting on a disc machine

Perpendicular cuts of pipes are made on it. The product itself remains flat, which is of great importance for further work with it. The machine can also make cuts at various angles (up to 45 degrees).

Video about cutting on a disc machine

Cutting with circular saws

A pipe cutter for steel pipes based on a circular saw is used in cases where production volumes are small and the final product must be of high quality. The circular saw cuts the pipe by rotating 360 degrees. In this case, you can get a cut at any angle.

Manual and automatic circular saws are used. At the same time, the latter perform cuts an order of magnitude more accurately. Most often, this cutting method is used only at home.

Video review of one of the circular saw models.

Cutting tools: classification and application features

Pipe cutters for plastic pipes can be divided into hand tools and power tools. Regardless of how the tool is driven, all pipe cutters are classified according to their mechanism of action.

Pipe cutters for polymer materials are divided into several types according to configuration, operating principle, and cutting tool:

- guillotine;

- roller;

- scissors (ratchet pipe cutter);

- chain

In addition to the principle of operation, instruments differ in size.

Note! When talking about size, we do not mean the size of the pipe cutter itself, but the maximum and minimum diameter of the pipe that the tool is capable of cutting.

Most hand tools are limited to a maximum diameter of 110-150 mm, which is sufficient for installing any household communications.

Pipe cutters for larger pipelines are professional tools and are produced with an electric drive. Such equipment is expensive, and purchasing it for one-time installation is impractical.

Pipe cutters differ in the material used to make the tool itself. The cutting part is made of alloy steel. The thicker the blade, the longer the device will last. The handles and body can be made of metal, or metal and plastic can be combined. It is preferable to choose a manual pipe cutter with aluminum handles. Such scissors will be lighter and more convenient to use than steel ones.

Guillotine pipe cutters

A guillotine pipe cutter is a fixed frame along which the blade runs. The manual version involves smoothly lowering the blade into the body of the pipe by screwing the rod into the thread to which the blade is attached. A professional guillotine pipe cutter with hydraulic drive works like a pistol.

Guillotine pipe cutter

The advantage of this type of pipe cutter is that the blade enters the pipe strictly perpendicular to its guide axis and applies pressure evenly. The guillotine blade has the shape of an obtuse angle, which eliminates forceful blows. The cut is smooth, without cracks, chips, or burrs. A significant plus is the low price of a manual guillotine and the simplicity of its design.

The disadvantages include the labor intensity when working with hand tools. Here you need to first completely tighten the rod, then completely unscrew it. If you have to cut a large number of pipes, then you should think about a more convenient option.

Roller tool

Roller pipe cutters for plastic pipes are a hook-shaped tool with a wide pipe bed and movable cutting metal discs or rollers. The configuration may vary depending on the manufacturer, but the principle of operation is the same.

We recommend that you read: What is the difference between HDPE corrugation and PVC and which is better to choose?

Note! Disc pipe cutters (with a cutting part in the form of a metal disc) are designed for cutting plastic pipes only. Roller (cutting part rollers) pipe cutters are a universal tool.

To cut, a plastic pipe is placed on the bed of a pipe cutter, the roller knives are lowered and the cutting is carried out using rotational movements around the pipe. The process is carried out by uniform pressure from several points, depending on the number of rollers. For metal-plastic pipes with a diameter of up to 50 mm, one cutting roller is sufficient.

On an inexpensive tool, after each circle, the immersion depth of the cutting rollers is increased manually. This creates jerks in the pressure on the pipe, and each time moves it a little. The steps are repeated until separation. The cut may have burrs, so additional chamfering will be required. Many models of manual roller pipe cutters are equipped with a chamfer. However, the operations are performed one after another - first they cut, then they chamfer.

Ratchet pipe cutter or scissors

Plastic shears are pruning shears with a single blade and a semi-circular stop, which is equipped with a ratchet mechanism to prevent backlash. Using a ratchet pipe cutter is convenient because you only need one hand.

Cutting is carried out by repeatedly pressing the handles, and no return action occurs. The operating principle of shears for plastic pipes is similar to a guillotine pipe cutter, but the blade here exerts a lateral, less uniform action. A ratchet manual pipe cutter is used for installation of communications with a diameter of up to 32-50 mm. Thicker plastic pipes are cut with a power tool.

Chain pipe cutter

A chain pipe cutter is a pliers with an attached flexible chain of cutting rollers. To secure the chain, there is a special clamp on the movable handle. Cutting is carried out using rotational and return movements with gradual tightening of the chain until the segments are completely separated. This type of pipe cutter is suitable for cutting large diameter plastic materials or fixed areas in hard-to-reach places.

Chain pipe cutter

Note! Chain pipe cutters are divided into tools with moving rollers (for plastic materials) and tools for metal pipes. In these pipe cutters, the rollers do not rotate, and cutting is carried out only due to clamping force.

Reciprocating saw

The reciprocating electric saw is a professional tool. Used for installation of large diameter communications. In domestic pipelines, its area of application is sewer networks.

Battery-powered reciprocating saw from Bosch

A reciprocating saw resembles a jigsaw, but has a quieter action and teeth for plastic materials. It has a flexible blade that allows you to cut areas embedded in walls flush. The big advantage of this tool is the unlimited size of communications and high speed of work.

We recommend that you read: How to properly install corrugation on a toilet?

Professional pipe cutters

A pipe cutter for steel pipes, which is used for high-quality cutting, is a professional device with which you can cut pipes of any diameter (including large ones) and at almost any angle, depending on their further use. To do this, the mechanism is equipped with clamps that regulate the position of the axis that rotates the knives. The disk that cuts metal is equipped with a special cap that protects it from mechanical stress and allows it to be used for a long time. Moreover, the set contains several disks with diameters from 1 to 12 cm (thickness up to 8 mm).

At the same time, the worker’s efforts are minimal - often the devices are equipped with a special mechanical drive that starts the mechanism by simply pressing a pedal.

Features of pipe cutting work can be seen here.

Cutting on a band saw

Such machines allow you to cut fairly large pipes (up to 32-34 cm in diameter) and operate with high productivity, which allows them to be used in production.

The advantages of the device are as follows:

- high quality of the surface of the cut pipe (no burrs, roughness, edges are not melted);

- cuts can be made both at right angles and at other angles (up to 6 degrees);

- cutting exactly corresponds to the initial parameters that are set in advance.

Video overview of the machine using the example of one of the models

Types of pipe cutters

Sometimes pipe cutters are divided into professional, semi-professional and amateur. The boundary between these categories is very blurred. Therefore, it is more correct to systematize them by design features into detachable and non-detachable and by type of drive into:

- pneumatic;

- electrical;

- hydraulic;

- mechanical (manual).

And in order to more clearly differentiate the scope of application, it is necessary to divide them according to design features.

Orbital pipe cutters

The detachable design of the housing, consisting of interchangeable modules, allows the use of an orbital pipe cutter in a minimal working space. Using cutters rotating in a circle, you can cut a pipe and apply both an external and internal chamfer. This is a good pipe cutter for stainless steel, copper and plastic pipes.

Electric orbital pipe cutter

The SS series model from France uses small cutters for cutting. Orbital pipe cutters can handle diameters of 330 mm. These models are inconvenient in that the pipe must be inserted into the holes of the tool. The French orbital pipe cutter has a one-piece body; it cannot be thrown, for example, onto a stationary pipe that sticks out of the ground.

The orbital pipe cutter got its name from the word “orbit”. The removable cutting tool actually moves along guides around the pipe. The mechanism operates from an electric, hydraulic or pneumatic drive. A mechanical vice is used to secure the pipe.

Often an orbital pipe cutter is used not only for mechanical impact on the workpiece. There are models in which the manufacturer also offers devices for orbital welding.

Roller pipe cutters

Manual roller pipe cutter

The hand tool is designed for cutting permanently fixed pipes. Such a roller pipe cutter is simply an indispensable device for working in cramped conditions. For example, a 4-wheel tool has enough space for the handle to rotate only 900 degrees, and for the pipe to be only 3 cm from the wall. An ideal tool for working in corners of rooms.

In such a roller hand tool, the metal is not cut, but is pressed by freely rotating rollers. Therefore, the cut is smooth, neat, without burrs and shavings. The pressure force is adjusted with a handle.

A manual pipe cutter with a ratchet is easy to use. It does not require constant tightening of the screw to reduce the diameter of the roller rotation path. Its design is such that it tightens itself when the roller is advanced with a handle.

Roller pipe cutters for large-diameter steel pipes also include clamp tools. Although working with it requires a lot of physical training, it can be used in conjunction with a special machine that rotates a large diameter pipe around its axis.

Chain pipe cutters

Chain pipe cutter

A chain pipe cutter for steel pipes requires a very minimal working space, since there are no rotating parts or volumetric modules at all. It is a conventional chain of solid, loosely attached disks, which is wrapped around the workpiece. Using a mechanical or hydraulic device, the chain is tensioned and the discs compress the pipeline along its diameter in the desired location. In this case, the metal is not cut, but is, as it were, pressed through and breaks. This tool can be used for cutting metal pipes.

Manual cutting technology using a pipe cutter

Regardless of the technical characteristics of the pipe cutter, the sequence of actions for cutting pipes with its help will look approximately the same:

- Preparatory work - you need to check whether the pipe's characteristics (material, diameter, wall thickness) correspond to the parameters of the pipe cutter, as well as how realistic it is to achieve the desired goal with its help (cut at a specific angle and with a given accuracy).

- Installing a pipe cutter on a pipe. To do this, the handle is rotated counterclockwise to widen the clamps as much as possible, then the pipe cutter is placed on the pipe at a predetermined location of the required cut, and the handle is rotated clockwise until the cutting roller contacts the surface of the pipe.

- Groove formation. At this stage, the cutting roller is slightly pressed into the surface of the pipe. To do this, the pipe cutter is turned a full turn so that the roller makes a small groove in the pipe.

- Cutting. After forming the groove, you need to tighten the screw by turning it 90 degrees, and then begin to rotate the pipe cutter itself. At the same time, it is necessary to gradually tighten the screw until it is completely cut off.

IMPORTANT. There is no need to press the cutting roller into the pipe body with great force. This may damage it, resulting in the mechanism having to be replaced with a new one.

Instrument care

The lifespan of a tool largely depends not only on compliance with the basic rules of working with it, but also on proper care. Compliance with the rules presented below will significantly extend the service life of the device and ensure high-quality cutting of pipes with its help.

- You can start working for the first time only after thoroughly reading the operating instructions. Carelessness during operation can damage the device, the workpiece, and even cause injury.

- After a long period of inactivity, the instrument must be inspected for external features and the possibility of its normal functioning (it is better to check it on a test pipe).

- Thorough lubrication of all moving elements is a must. The feed screw and cutting rollers especially need protection.

- The device should be cleaned regularly immediately after use. To do this, use a wire brush, onto which the cleaning agent is applied.

- Periodic checking of all elements and connections of the tool, especially the sharpness of the roller and the accuracy of making the groove in the pipe.

- Compliance with storage conditions - the instrument must be stored in a warm and dry place (mainly at home). An uninsulated balcony and garage will not be suitable in this case, / since temperature changes, direct sunlight and high humidity levels can have a bad effect on the parts of the pipe cutter.

NOTE. Working on a tool that contains even slight visual damage is undesirable. The fact is that the wear of the pipe cutter will go much faster this way, as a result of which the cutting quality will greatly decrease.

How to choose a pipe cutter for plastic pipes

When choosing a pipe cutter, you should rely on the feasibility, volume of work, purpose of the tool and your financial capabilities. A pipe cutter is a professional tool that requires skill.

Which pipe cutters are recommended for certain jobs:

- One-time wiring of metal-plastic - scissors or guillotine pipe cutter.

- Installation of communications with a diameter of up to 50 mm of any plastic networks - scissors or guillotine hand tools.

- Installation of plastic communications from 50 mm in diameter - roller pipe cutter.

- Installation of large diameter networks or areas in hard-to-reach places - chain pipe cutter.

Note! If you choose an expensive tool, without having the qualifications of a 4-5 category mechanic, then if it breaks, the manufacturer will not take responsibility for the damaged pipe cutter.

How to choose the right device

To choose the most suitable pipe cutter for steel pipes, you need to proceed from the following parameters:

- What cutting quality will be acceptable (surface roughness, burrs, degree of melted edges).

- How important is the cutting speed (depends on the total volume of pipe production).

- What are the parameters of the pipes that you will mainly be working with?

- What skills does the worker have to carry out manual cutting?

IMPORTANT. If the steel pipe cutter is not selected correctly, it may not only damage the workpiece and the tool itself, but also cause serious injury. The choice of tool must be approached very responsibly, since such a purchase is made for a long time. In this case, the price factor should come in last place: the main requirement is that the tool fully corresponds to the purpose for which it is purchased.

Making a pipe cutter with your own hands

If for some reason it is not possible to purchase a professional device, then it is quite possible to make it yourself from ordinary materials available to almost everyone. The advantages of this option are as follows:

- such a device will cost less than a store-bought one;

- it can be adapted specifically to your needs (cutting pipes of specified parameters);

- when making it, you can learn new things and gain valuable experience that will be useful in other areas.

NOTE. In this case, before starting work, you need to immediately decide which pipes will be cut. what materials they will be made of (a pipe cutter is not a universal tool - there are pipe cutters only for metal or plastic; devices for universal use are much less common).

What you need for work

To make a tool yourself, you need a small set of tools and materials:

- set of wrenches;

- screwdrivers;

- hacksaw for working on metal;

- square wire rod;

- spring;

- hacksaw blades.

The work will also require a bolt and screws of special sizes, which depend on the parameters of the device itself. Metal rivets are selected in regular sizes (diameter 0.4 cm).

The sequence of work is associated with the stages of manufacturing the left (1), right half (3) of the tool and their assembly. An example drawing is shown below.

The number 2 indicates the cuttings of the canvas, 4 – the clamping screw. Dimensions are indicated in millimeters and can be proportionally recalculated to suit your specific model.