Design and principle of operation

The design of a circular saw is quite simple. The device can be manual or stationary, and combined models are also available.

Regardless of the type, the equipment consists of a saw and a base plate. The last element is made of durable steel sheets or aluminum alloys. The main purpose of a circular saw is accurate and high-quality longitudinal cutting of wood.

A circular saw

Cutting boards and bars is carried out by rotating disks, which have special casings that serve as protection against injury during the working process. The cutting part is driven by a trigger mechanism. Circular equipment allows you to process large volumes of wood.

How and with what to cut laminated chipboard without chipping?

The abbreviation LDSP should be understood as a laminated chipboard, which consists of natural wood waste mixed with a polymer adhesive composition, and has lamination in the form of a monolithic film consisting of several layers of paper impregnated with resin. The lamination process is carried out under production conditions under pressure of 28 MPa and at high temperatures reaching 220°C. As a result of this processing, a very durable glossy coating is obtained, which can have various color shades and is highly resistant to mechanical damage and moisture.

READ Why The Chainsaw Constantly Weakens the Chain

Electric milling machine

This is a hand-held type of power tool that is used to cut and drill wood board. Before starting work, a small cut is made in the laminated chipboard using a hand jigsaw, departing from the marking contour by 3–4 mm. During the sawing process, several cutter knives and its bearing device are used, which regulates the depth of cut. Using a cutter is not so easy, so to cut a slab you need to have some skill in working with this tool. The movement of the cutter is quite fast, and there is a possibility of making an uneven cut.

But with the help of a cutter you can get a perfectly smooth cut of the material - the appearance of chips and cracks when using this device is very rare.

The use of hand tools is advisable in the manufacture of single products from laminated chipboard. For mass production, it is advisable to purchase formatting and cutting equipment.

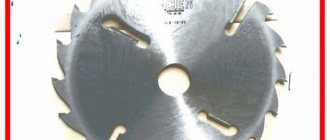

Circular saw

This power tool consists of a small work table and a rotating toothed disc. A circular saw makes cuts on a particle board much faster and better than an electric jigsaw. When performing the sawing process, the saw is turned on at low speed. In this case, chips may appear on the opposite side of the saw teeth.

To prevent this situation, before starting sawing, apply paper adhesive tape to the cut site.

Electric jigsaw

In order to make an even cut without damaging the laminated layer, you will need to take a jigsaw file with the smallest tooth size. It is advisable to use a jigsaw for sawing small sections of chipboard. Jerks and unnecessary pressure during work should be avoided. The cutting blade feed speed of the tool should be set to minimum.

This device is quite capable of performing an even and high-quality cut without chipping the laminated surface.

Hand saw

This hand tool is used in combination with a metal blade, as it has the finest teeth. Before work, paper adhesive tape must be applied to the cut site to protect the lamination layer from damage. The hand saw blade must be held at an angle of 30–35°; this position reduces the likelihood of chipping on the material. The movements of the hacksaw blade should be smooth, without pressing on the blade.

After the cut is completed, the edges of the cut will need to be processed with a file and fine-grained sandpaper.

Classification of types and sizes

Circular saws are divided into two classes - household and professional. The equipment differs in power, size and diameter of the saw blade:

- Household models are small equipment weighing from 4 to 5 kilograms, which is usually used for cutting wood at home. Equipment power – no more than 1800 watts. The size of the blade in such saws is 160 – 200 millimeters.

- Professional circular saws are designed for processing large quantities of wood. They are capable of sawing beams up to 85 millimeters thick. The weight of such equipment exceeds 8 kilograms, and the diameter of the disk is 250 millimeters. Professional saws have higher power - over 1800 watts.

Household model of a circular saw

Several types of circular saws are produced:

- Standard. The model is designed for cutting wooden blocks with a density of up to 85 millimeters.

- Mini saw. A small circular device weighing up to 2 kilograms and a power of up to 800 watts. Used for cutting thin wood.

- Submersible. Equipment is used to cut holes inside the wood. The design of such a saw consists of a mechanism that promotes vertical immersion of the disc.

- Diamond. This type of equipment is designed for cutting hard materials - stone, ceramics or tiles. The working mechanism of the device consists of a diamond disk, which allows cutting to a depth of 55 millimeters.

- Rechargeable. Such a circular tool has low power and fairly compact dimensions. The device runs on a battery and is often used in the construction of wooden houses.

Circular saws are divided into four types depending on the depth of the blade:

- professional - from 65 to 140 millimeters;

- large - from 70 millimeters;

- medium - 55 millimeters;

- small - from 40 to 46 millimeters.

The number of teeth on the disk is of no small importance for the quality of the cut. The fewer there are, the lower the productivity of circular equipment. For large-scale processing of wood, special cutting devices with carbide tips are used.

Review of models and manufacturers

It is perhaps difficult to make a specific rating of models, since it is constantly changing, and the leading positions are occupied by one or another brand. However, the main manufacturers are always in the TOP 10. The products of some of them are presented in the table below.

Table. Characteristics and prices of some models of hand-held electric circular saws.

| Name, photo | Short description | Average market value, in rubles |

| 1. Makita SP6000 Set | A high-quality unit with a power of 1.3 kilowatts, a disc diameter of 16.5 centimeters and a maximum cutting depth of 5.6 centimeters. As for the rotation speed, it is 5,200 rpm. Finally, such a saw weighs 4.1 kilograms. | From 6 840 |

| 2. Makita HS7601 | The unit is from the same manufacturer, but the power in this case is already 1.2 kilowatts. The cutting depth is 6.6 centimeters, the rotation speed is the same, and the disc diameter is 19 centimeters. The saw weighs 4 kilograms. | From 3 230 |

| 3. Bosch GKS 190 | A high-quality device with a power of 1.4 kilowatts and a cutting depth of 7 centimeters. The rotation speed reaches 5.5 thousand revolutions per minute, while the diameter of the disk is 19 centimeters. The unit weighs 4.2 kilograms. | From 3 180 |

| 4. Bosch PKS 55 | Another model from the same manufacturer. The power indicator reaches 1.2 kilowatts, the diameter of the disk is 16 centimeters. The cut reaches a depth of 5.5 centimeters. The disk rotates at a speed of 5.6 thousand revolutions per minute. Weight – 3.9 kilograms. | From 2 390 |

| 5. DeWALT DWE560 | Another good circular saw powered by electricity with a power of 1.35 kilowatts and a blade diameter of 18.4 centimeters. The depth of the cut in this case reaches 6.5 centimeters, and the rotation speed is 5.5 thousand revolutions. The model weighs only 3.7 kilograms. | From 3 100 |

| 6. Interskol DP-165/1200 | A cheaper hand saw, the power of which reaches 1.2 kilowatts. The disc has a diameter of 16.5 centimeters, while the cutting depth is 5.5 centimeters. The disk rotates at a speed of 4.7 thousand revolutions per minute. The unit itself weighs 4.5 kilograms. | From 1 760 |

Read also: Laying heating cable under tiles

These are not all popular models. You can find the characteristics of some more of them in the table below.

Table. Characteristics of some more popular circular saws.

We sincerely hope that our practical advice will help you choose the appropriate saw model. But to make all this more useful, we advise you to familiarize yourself with the technical characteristics of the models you like in advance, and only then go for the purchase itself. And in conclusion, some rules for operating the equipment described above.

Types of jobs

The area of application of a circular saw depends on its size and type.

Hand circular saw

These electric saws are designed for precise straight cutting of thin wood materials. The manual circular device is small in size and is most often used for work at home.

Small-sized equipment for cutting wood is necessary for interior decoration of houses. Hand-held circular saws are often used during renovations to cut laminate flooring or wall finishing material.

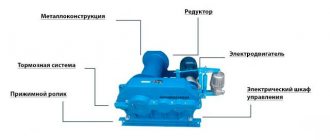

Circular machine

Stationary circular saws are equipment for daily use. Such professional machines are capable of processing a large amount of wood in a day. They have quite a large weight - more than 10 kilograms and high power of up to 2500 watts.

Circular machine

Circular machines are used mainly in production for industrial purposes. The cost of such a device is quite high. Some small models of circular equipment also have the function of stationary use. They are successfully used in home workshops.

Operation algorithm

Hand-held and stationary circular saws have a similar operating principle. But equipment management has some differences.

Manual models

A circular hand saw is an effective and safe tool. But still, the use of such equipment requires compliance with certain operating rules:

- Electrical connection. When using a saw in areas remote from the power supply, an extension cord is often used. It must fully match the power of the circular tool. Before connecting it, you should check the integrity of the cable insulation. When connecting the saw to the network, you should check that the switch on the device is turned off.

- Fastening the material. Wood intended for cutting should be well fixed on a flat surface. To do this, the material is placed on a workbench and secured until it is completely stable.

- Setting the cutting depth. The required indicator is determined using a special scale on the instrument. When cutting a block, the disc should not protrude beyond the boundaries of the material, otherwise the workbench may be damaged. Therefore, it is recommended to fix the cutting depth slightly less than the required value.

- After setting all the necessary parameters, the cutting mechanism should be set in motion. Start cutting only with the disc rotating. The movement of the saw along the material should be smooth and even.

At the end of the work process, the hand-held circular tool must be disconnected from the network.

Stationary models

The use of circular machines has its own operational characteristics. To cut wood you need:

- Set the switch on the equipment to the “off” position. Only after this can you connect the cable to the electrical network.

- Raise the handle to adjust and fix the cutting height of the disk according to the dimensions of the material prepared for cutting.

- Check the position of the guide bar and saw blade. Their arrangement must be parallel to each other.

- Start the circular saw and make a longitudinal cut of the wood material. Cutting one board should be done in a single approach.

Using a stationary circular saw

After processing all the material, turn off the switch on the equipment that stops the rotation of the blade and disconnect the tool from the electrical outlet.

Nuances of additional functions

Modern models of circular saws are safe equipment with high technical parameters. Many devices are equipped with additional functions that make the work process much easier:

- Slip clutch. This device allows you to avoid injury when the disk jams. Using a clutch, you can significantly reduce the shock when stopping the rotating mechanism.

- Smooth start. This function allows the disc to gain speed without jerking. A smooth start protects the mechanism from shocks, which has a positive effect on the service life of the engine.

- Overload protection. When the engine reaches critical indicators, the mechanism is automatically switched off.

- Supports the required disk rotation speed. When under load while cutting dense materials, power is automatically added. This function protects against a decrease in the disk speed.

- Accelerated braking. When you press the power off button on the device, the drive suddenly stops.

- Locking the start buttons. This feature prevents the tool from turning on if the switch is accidentally pressed. It is usually installed by pressing two keys simultaneously.

All models of circular saws have a function for setting the depth of cut. When purchasing equipment, it is recommended to pay attention to the convenience and accuracy of fixing such adjustments.

Safety precautions

Using a circular saw requires caution. To prevent accidents from occurring during the operation of electrical equipment for cutting wood, basic safety rules should be followed:

- Before connecting the device to the network, you must make sure that the equipment is turned off;

- While working, use protective equipment - gloves, glasses, clothing;

- do not allow water to come into contact with the instrument;

- do not use the circular device in places with high levels of humidity;

- equipment can be moved or lowered to the floor after shutdown only when the disk is completely stopped;

- prevent engine overheating;

- exclude access to the instrument for children;

- cutting boards should not contain foreign objects - bolts or nails;

- Before work, check the reliability of fixation of the material.

Proper use of a circular saw will allow you to accurately cut any number of boards with high quality. And compliance with all operational requirements will completely secure the work process.

What can you do with a hand-held circular saw?

Manual circular saws are suitable for performing a whole list of jobs:

- trimming several wooden blanks at once that lie in the same plane;

- trimming wide boards for which you cannot use a pendulum saw (you will need a rip fence);

- trimming boards when laying floors;

- trimming workpieces at an angle ( you can use a guide or do without it);

- longitudinal cutting of workpieces at an angle;

- sampling a quarter in a board or beam;

- cutting sheet materials using a guide;

- cutting organic glass and plastic;

- using a hand saw as a stationary one by mounting it to a table.

Preparing the workplace for work

You need to remove all unnecessary items from your desktop. There should be no tools, keys or consumables. In addition, you need to ensure a free approach to the table. The floor in the work area must be dry to avoid accidental slipping. The machine must be grounded.

READ Lawn Mower Electric Circular Saw Select For Home

There are also requirements for the operator’s work clothes. Clothes need to be tucked in so that there are no flapping ends. If you have long hair, tie it up and hide it under a hat. Wear safety glasses and a respirator. It is recommended to use hearing protection as the noise level can be quite high when using a circular saw.

Before starting the saw, you need to check it for defects in the saw blade and make sure that it is securely fastened. Check to see if the riving knife is installed correctly and then check that the guard is working properly.

If your saw has a short cord, you may need an extension cord to help you move comfortably around your work area. It is advisable to use a circular saw with a soft start feature so that the tool does not jerk when starting.