Installation of electric winches

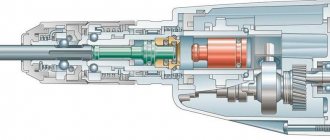

The main components of an electric winch are:

- Electric motor. The main task of the power unit is to drive lifting equipment. When calculating the traction force of an electric winch, the power of the motor is taken into account;

- Drum. In the electric winch model, the drum is connected to a gearbox. A cable is wound around the drum, with its help the chain is pulled;

- Frame. Support welded structure, on which the reliability of the entire mechanism depends;

- Brake system. Provides fixation of the cable and prevents its spontaneous movement;

- Cable. The purpose of the product is to secure and move the load. The lifting capacity of the winch depends on the strength characteristics and diameter of the cable. The quality of the cable directly affects the safety of working with load-lifting mechanisms (HLM);

- Launch equipment. The control panel provides convenient operation and precise control from a safe distance;

- Reduction gear. Responsible for smooth rotation of the drum and uniform pulling of the rope, forward movement of the load. The gearbox allows you to adjust the operating speed of the equipment.

Winches. Types of winches and their applications.

Winch

- a mechanism whose traction force is transmitted by means of a rope, chain, cable or other flexible element from the drive drum. The winch drive can be manual, electric, or from an internal combustion engine. It is intended mainly for lifting loads vertically, but is sometimes used to move loads horizontally. A conventional electric winch consists of an electric motor, gearbox, drum, frame, and braking system. If necessary, some winches are combined with a chain hoist. Depending on the design, winches can be divided: according to the type of traction element - into rope and chain; by type of installation - fixed (fixed to the floor, wall, ceiling) and mobile (on trolleys moving on the floor or on overhead tracks); by the number of drums - for one-, two- and multi-drum winches; by type of drum - rifled, smooth and friction.

Types of winches and their application

Manual winches Manual lever winches

Lever manual winches are designed for moving loads when performing repair, installation and dismantling and other various works in production and at home. They are very compact and can function without being rigidly attached to a supporting surface. Thanks to their small size, hand lever winches can be used in the most difficult to reach places. Many of these winches are equipped with a telescopic handle with a locking mechanism, which allows you to significantly increase the pulling force. If it is necessary to lengthen the rope, additional slings are used in these winches.

Hand Drum Winches

These are the most common type of hand winches.

The principle of their operation is absolutely simple - a person turns the handle, winding the cable onto the drum. The simplest version of such a winch consists of a main body, two bearings, a toothed drum for winding the cable and a handle. Manual drum winches allow you to increase the traction force by a maximum of 2 times, and work can be carried out only at a height of human height. Therefore, these hand winches are used in simple work areas. Manual worm winches

The main difference between worm and drum winches is that they are driven by an “endless screw”, an “Archimedes screw”. The advantages of these winches are their miniature size, as well as the low effort required. However, in order to move a load using manual worm winches, significant force must be applied. In addition, due to the large number of mating parts between which friction occurs, they fail much more often.

Mounting and traction mechanism

These devices are similar to lever winches, but they do not have a drum. In their design, mounting and traction mechanisms use “cams” that move the cable, so, unlike lever winches, it does not depend on the capacity of the drum; when using these mechanisms, there is no need to tension the cable, so it can be used of any length. When working with this type of winch, the cable must not become dirty.

Electric winches

help to minimize the physical effort applied to the handle in manual winches, increasing labor productivity, and provide much greater speed of work. Many electric winches are universal; they can be used not only for horizontal movement of cargo, but also for vertical lifting. The electric winch is controlled from a push-button remote control; its design is completely safe and easy to use. Depending on the model, the lifting capacity of electric winches can reach 20 tons.

Mobile electric winches (Construction winches)

These mechanisms are distinguished by their low weight, which does not exceed 50 kg, ease of transportation, they are not difficult to install, and operate on a 220V electrical network.

Also, the advantages of these winches include the convenience of controlling them from a remote control, the ability to install them permanently on a beam, or movably on a separate carriage. The disadvantages of these mechanisms include their low load capacity, which does not exceed one and a half tons, and the low speed of lifting the load. Electric installation winches

These winches are designed for lifting and moving large loads at construction and industrial sites. Mounting winches have a large mass (from 600 kg), are mounted on a reliable metal base (frame), and are permanently installed on a horizontal surface. They are designed for independent lifting of loads, have a large supply of cable, however, they have a low load lifting speed - no more than 12 meters per minute.

Traction winches

These winches are used as a traction mechanism during loading and unloading operations; they are equipped with various lifting devices. Traction winches are not designed to independently lift loads, but only provide traction force, for example, to move crane trolleys. Therefore, unlike installation winches, they have a higher lifting speed (up to 35 meters per second) and a smaller cable reserve.

Shunting winches

Shunting winches are a special type of winches that are used in various areas, in particular at loading and unloading units.

This mechanism can often be found at mobile loading stations when it is necessary to pull up trains when filling wagons and trolleys, as well as for exchanging loaded trains for empty ones. Cable winches

Cable winches are a tool for quickly and conveniently pulling cables. They are used in the case of installation of heavy power or multi-pair communication cables, as well as in the case of an insufficient number of installation personnel. Electric cable winches are designed for horizontal pulling of cables along trays, in pipes and cable ducts.

Scraper winches

Scraper winches are designed for transporting rock mass separated from the massif using a scraper along horizontal and inclined mine workings (with an inclination angle of up to 35°) during underground mining.

All winches have a standard design, consist of separate transportable units and differ from each other in overall dimensions, weight, layout and power of electric motors. Mine winches

Mine winches have a specific design, consisting of so-called individual transpontable units, the main ones of which are the following elements: electric or pneumatic motor, drive gearbox, working and idle drum units, brakes, etc. Mine winches differ in dimensions, specific purpose, operating characteristics, type drive, layout, power. Mine winches have a wide range of applications: they are used in underground and open-pit mining, for transporting rock mass separated from the massif through horizontal and inclined mine workings, for moving cargo and equipment, i.e. as an electric lifting and traction mechanism.

Types of automobile winches:

Separately, we can highlight automobile winches designed for pulling out a car, which are rigidly attached to the car body. They are available in three types.

Electric car winch

The electric motor of such a winch is powered from the vehicle’s on-board electrical network. They are distinguished by their simple design, ease of installation, ease of use, and the ability to work autonomously even when the engine is turned off. However, they consume a large amount of energy from the on-board network.

Mechanical car winch

This winch is powered by the car's engine, from which it receives torque. Mechanical winches are distinguished by high power, unpretentiousness and reliability. You can regulate the speed of winding the cable on them by changing the engine speed. The main disadvantage of these mechanisms is that they can only be installed on SUVs on which the transfer case allows the connection of a power take-off.

Hydraulic car winch

This type of winch is driven by a hydraulic motor driven by a power steering pump. A hydraulic winch has many advantages: high reliability of the hydraulic motor, it is resistant to overloads, under which the hydraulic motor does not break but stops, it can work underwater, thanks to the sealed housing. The disadvantage of such a winch is the low speed of winding the cable and the inability to work with the engine turned off.

You can find all types of winches on our website, all you need to do is follow the link: https://www.eosn.ru/catalog/pto/lebedki/

We are waiting for your questions on the Questions and Answers page: or by phone

The next article will be about “How to choose the right winch?” do not miss))))

Operating principle of electric winches

The operating principle of an electric winch is quite simple. The device contains a transmission mechanism with a drum on which a cable, rope or chain is fixed. The drum drive puts it into action and ensures winding of the cable. Thanks to the presence of a durable body and reliable fastening, the winch is able to withstand significant weight of the object being lifted. Due to the large traction force of the equipment, the actual force required to operate the drum is greatly reduced. Winches are capable of lifting loads weighing several tons.

Advantages of electric winches

Electric winches have a number of advantages over traditional hand-held devices. Of course, this is a more advanced, functional, effective technique.

The main advantages of electrical engineering:

- increased efficiency - the electric drive significantly increases the efficiency, it becomes possible to move loads faster under a higher load;

- remote control - if necessary, you can organize remote adjustment of the device’s operation;

- the ability to start under load, which is impossible in primitive models;

- ease of setup.

Functional advantages

In addition to starting under load, the electric winch also has a function such as reverse. If necessary, you can reverse the mechanism - that is, provide reverse movement. Moreover, this movement is controlled. To prevent spontaneous unwinding of the cable, the devices are equipped with special brakes.

Classification of cargo winches

Lifting equipment is distinguished according to the following criteria:

- Type of food. The devices can operate from an electrical network of 220V and 380V. 12 V devices are also available that can operate on battery power;

- Installation method. The choice of installation type depends on the type of device - portable electric or stationary winch. Mobile devices weigh up to 50 kg, so they do not require complex installation work. They can be moved from place to place. Stationary models are highly powerful and cope well with increased loads, suitable for intensive work. Their installation must be carried out in strict accordance with the installation instructions;

- Operating principle. Lifting equipment is divided into hydraulic, worm, etc.;

- Type of traction element of the system. There are chain and cable winches, single and multi-drum, with one or several speeds.

Small winches

The advantages of the devices include light weight (does not exceed 40 kg), the presence of a 200V or 12V electric motor and low cost. Such electric winches are popular in small workshops and at home. The lifting capacity of the mechanisms is on average 1-2 tons, the speed of lifting loads is low. Small-sized winches can be mounted on a beam equipped with a movable carriage.

Planetary winches

The gearbox of the device contains, instead of one, several driven gears. Due to the planetary design, high gear ratios are ensured with compact dimensions of the lifting mechanism (HLM). Planetary winches are lightweight, have a load capacity of up to 500 kg, and operate on a 220V network (industrial models - from 380V).

Mounting winches

The equipment contains an electric motor with a power of 7 kW, lifts loads weighing over 600 kg, and the lifting speed is up to 12 m/min. The device has a drum with increased rope capacity. The significant weight of the winch does not allow it to be suspended; installation on horizontal surfaces is only possible. The main tasks of installation electric winches are lowering and lifting loads.

Traction winches

The task of the traction mechanism is to provide traction force. Winches of this type are not used for lifting loads. For example, a car winch can move a loaded pallet or pull out a stuck vehicle. The equipment is characterized by an increased speed of cargo movement up to 35 m/min, but at the same time has a reduced rope capacity.

Shunting winches

The device is designed for moving platforms, tanks, railway cars, gondola cars, and performing auxiliary work on moving cargo in the horizontal direction located on rail tracks. Powerful models are capable of moving up to 17 loaded cars with a total weight of 1,200 tons. Shunting winches are installed near rail warehouses, which makes it possible to abandon shunting diesel and electric locomotives.

What is a manual winch?

First of all, let's draw a clear dividing line between winches and hoists; these are similar mechanisms that have completely different purposes. The former are necessary to move loads in a horizontal plane, and the latter – in a vertical plane. Based on this difference, we will consider the devices sequentially and start with those that interest us in the first place, namely winches. They are divided into manual and electric, and for the latter the source of energy can be a gasoline engine, which, by rotating the generator, provides the electric motor of the traction mechanism with energy.

The operating principle of both types of traction devices is almost the same. At the heart of everything is a drum with a cable wound around it and a gear that reduces the load. This can be a regular gear drive, a worm (screw), or a lever with a ratchet. All this is mounted on a special frame, which is equipped with either grooves for bolted connection to any surface, or eyes for attaching a chain, which is used to secure it to a fixed support. There are wall-mounted and floor-mounted options, the former are designed for loads in the range of 700-800 kilograms, the latter are capable of moving up to 10 tons, depending on power.

If there is no source of electricity, the best choice is a manual worm winch; it is more difficult to pull the load with your own hands, but the advantage is complete autonomy. The most commonly used are gear-driven drum mechanisms. These can be traction or mounting devices, the only difference between them is that the former wind the cable on a drum, and for the latter a cable or belt of any length can be used, since they pass it through themselves. Vehicle owners often choose lever winches if it is not possible to install a stationary electric one on the hood. Almost without exception, manual traction mechanisms are equipped with ratchets in order to stop the movement of the cable at the right time.

Key factors for choosing winches

In addition to carrying capacity, important criteria for choosing equipment are:

- Traction force. Determines the maximum permissible weight load. This parameter is influenced not only by the weight of the load, but also by the friction factor (resistance to movement), the lifting factor (the load is pulled up or forward). For different models, the traction force can range from 0.2 to 5 tons;

- Voltage. Engine power can vary between 0.28-20 kW. This characteristic has a direct impact on performance. For stationary use, it is better to choose devices operating from a 200V and 380V network, with the ability to connect to a single- or three-phase network, respectively. Automotive models can operate from the on-board vehicle network with a voltage of 12-24V;

- Rope length. The cable can have a length from 5 to 100 m. This parameter determines the height to which heavy loads can be carried;

- Winding speed. The parameter depends on the power of the device. For example, an electric winch with a power of 1.6 kW is capable of mixing 500 kg of cargo at a speed of 10 m/min.

Also, when choosing a device, it is important to pay attention to its weight and dimensions.

The subtleties of working with a lever winch

In lever-type lifting manual mechanisms, the main factor for achieving the required torque value is the greatest working force on the handle. It is determined by the duration of continuous operation of the lever winch. If the lever winch is operated for a long time, the force on the handle cannot exceed 10 kg. For short-term work (5 minutes or less), this force can be 16 kg.

If a manual lever winch is equipped with a pulley, the force on the handle is reduced, but at the same time the number of turns of the handle that must be performed to move the load the same distance increases.

In modern designs of these mechanisms, the test force on the handle is usually at least 80 kg, which must be indicated by the manufacturer in the winch data sheet.

The size of a manual cable winch also depends on the force on the handle. The main ones are:

- The arm (radius of rotation) of the handle, which should not be less than 400 mm.

- The center of rotation of the handle should be located at a height convenient for working with a lever winch.

- The length of the control handle for winches with a relatively small load capacity (up to 2 tons) must be at least 300 mm; if the mechanism is of greater power (4 tons or more), then the length of the handle increases to 350...400 mm. Particularly powerful versions of lever winches can be equipped with handles extended to 600 mm; in this case, the mechanism is controlled by two workers. However, for ease of use, a handle length of more than 800 mm is not provided.

- The average operating speed of the user's hand on the handle should not exceed 1 m/s, which corresponds to the angular speed of rotation of the cable on the axis of 60 m/min.

The current rules for the operation of manual lifting mechanisms establish that when two people work on one winch, the non-simultaneous application of working force by them is taken into account. The standard unevenness coefficient φ is 0.8. Thus, the torque on the input shaft can be calculated according to the dependence Min = P×φ×l×m×n, where P is the force developed by the user, l is the length of the handle, m is the number of workers, n is the number of pulley blocks.

Taking into account the fact that almost any lever winch has a gear drive or pulley block, the output torque will be higher: Mout = Mvx×i×η, where i is the gear ratio of the block/gear, and η is the total efficiency of the mechanism drive.

Sometimes, to correctly select the size of a manual lever winch, it is necessary to know the speed of movement of the load v. It can be calculated by the dependence:

v = vp×D/(2×a×i×l), where vp is the speed of the swinging movement of the worker’s hand, D is the diameter of the rope being wound, and is the multiplicity of the pulley (if this device is absent, then a = 1)

Electric winch connection diagram

Working with an electric winch involves certain risks and is classified as a dangerous activity. The device should be operated with the utmost care and attention, strictly following the operating instructions. Before you start using the lifting device, you should carefully study the connection diagram and connect all the wires in the specified sequence. If you plan to connect to a 220V network, 3 wires will be attached to the mounting block (phase, neutral, ground). When connecting an electric hoist to a three-phase system, you will need to connect 4 wires (3 phases and zero). If, after connecting the mechanism, the drum rotates in the other direction, this means that the 2 outermost wires of the existing three, on which the phase is connected, need to be swapped. The correctness of its operation depends on the correct connection of the mechanism.

Particular attention should be paid to the condition of load-handling elements, ropes, cables. If there are deformations, cracks or signs of wear, the cables will have to be replaced. The rope hook must be positioned vertically above the load. Before turning on the device, you need to make sure that there are no strangers in the working area, that the mounting points are secure, and that the power lever is in the non-working position. The serviceability of the braking device is checked at idle speed. It is prohibited to change the direction of travel until the equipment has completely stopped. The load must be unslinged after it has been completely lowered and secured.

It is strictly prohibited to carry out repairs or maintenance on the winch during operation. An electric winch must not be left unattended while it is on. If it is difficult to understand the connection and features of using lifting equipment on your own, you should enlist the help of a more experienced specialist.

Parameters of manual lever winches

The operational parameters of these mechanisms are:

- Method of securing the hook (usually to a fixed base);

- Number of cable branches in the pulley (from two to three);

- Cable length (3...20 m);

- Load capacity (from 0.5 t to 5 t or more).

It should be noted that of all types of hand winches, lever winches have the lowest productivity. Therefore, they are valued mainly for their maximum compactness, ease of operational use (there is no need to fix the winch to any fixed object) and lightness, since the mechanism body is made of high-strength aluminum alloy. The maximum force on the handle of such winches does not exceed 35...40 kg. A number of manufacturers complete devices with additional mounting blocks and hooks, which expands the technological capabilities of the lifting mechanism. Lever winches with a reduced cable length (up to 2...2.5 m) are recommended for use in garages.

The safety of using a manual lever winch largely depends on the rules of its current operation. They boil down to the following:

- Periodically checking the correct reeving of the steel rope.

- Cleaning the internal parts of the mechanism from dirt with a water jet (for this purpose, one or two holes are provided on the body).

- Inspect the cable, which should not have external damage or signs of corrosion.

- Inspection of all components of the device, which should not be deformed, cracked or otherwise damaged.

- Conditions for laying the cable on the axle: before using the device, the number of free turns of the cable must be at least three.

- The moving parts of all winch components must be lubricated.

- The hand lever winch must not be used for lifting persons.

The standard marking of mechanisms is as follows: LR-X, where instead of the letter X the maximum load capacity of the device is indicated in tons.

The price of these devices is determined by the load capacity, the convenience of the handle layout, the diameter of the cable used, and the length of the rope. The price of manual lever winches with a lifting capacity of up to 2 tons is 1000...2000 rubles, from 2 tons to 4 tons - 3000...4500 rubles, more powerful versions, with a double ratchet mechanism - up to 6000 rubles.