Pneumatic jackhammer: technical characteristics

It is extremely important to consider the technical characteristics when choosing a fender. This instrument is divided (depending on the impact energy) into several groups:

- Equipment with an energy of 30 J is well suited for work in cramped conditions or at heights. This is facilitated by the low weight of the unit.

- A tool with an impact energy of 40 Joules is good for general construction work.

- 50 Joules and above are suitable for very hard material. Moreover, it is necessary to understand that the harder it is to process the surface, the greater the impact energy should be.

It’s worth saying a few more words about the fact that there is a large selection of attachments. In the standard version, a peak is installed, but if necessary, it can be replaced with a chisel or crowbar

It is extremely important that the pneumatic jackhammer, the technical characteristics of which we have already partially reviewed, be light in weight. Typically it ranges from 1.5 to 10 kg

Such equipment is convenient and easy to hold for a long time.

Important criteria for choosing an electric jackhammer

Depending on the weight, a jackhammer performs different functions.

If everything is clear with the main features of the device and the operating principle of an electric jackhammer, then what functions the lance performs, as well as what you need to pay attention to when choosing a unit, you need to understand in a separate order. Electric jackhammers are equipped with different types of picks. Each of them is designed to perform a specific job. The main varieties are as follows:

- Pike-crowbar - allows you to dismantle brick and concrete structures, loosen the ground, remove old road surfaces, and process rocks.

- Shovel - mainly used when it is necessary to level the edge of asphalt and chip off ice.

- Chisel - such a peak will help cut various materials.

The weight of a jackhammer is as important as its design. Depending on the weight of the device, the tool belongs to different classes:

- lung;

- average;

- heavy.

Lightweight devices weigh up to 5-6 kg. They are used primarily for work at heights and finishing work. Average jackhammers weigh up to 10 kg. Used to perform work in a horizontal plane. The weight of heavy units reaches 30 kg. They are necessary for performing various soil and foundation work. Before purchasing a jackhammer, carefully consider the type of work you plan to do with it, and make your choice based on this information.

DEVICE AND OPERATION OF THE HAMMER

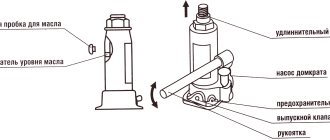

7.1. The hammer (Figure 1) is a piston pneumatic impact machine with valve air distribution, operating under the influence of compressed air. The hammer consists of an air distribution and impact mechanism, a handle with a starting device assembled in it, and a muffler casing.

7.2. The air distribution-shock mechanism consists of a barrel 2 with an axle box, a jumper, a hammer 13, a valve box 5, a valve 10, a pin 8, a seat 6 and a cover 7 pressed into the barrel.

The air distribution-percussion mechanism carries out: a) the intake of compressed air into the barrel cylinder, alternately into the forward and reverse stroke chambers of the striker and the release of exhaust air into the atmosphere; b) converts the energy of compressed air into mechanical work of a moving striker.

Figure 1. Pneumatic jackhammer MOP-2

7.3. The starting device consists of a handle 3, an intermediate link 1, a plug, a valve, a spring 11, a nipple 17, a union nut 18.

7.4. To prevent self-loosening of the threaded connection of the barrel and the link when the barrel hole is aligned with the slots of the intermediate link, a lock 19 is installed.

7.5. Valve cover 7 serves to press the air distribution unit to the end of the barrel.

7.6. The hose supplying air to the hammer is connected using nipple 17 and union nut 18.

7.7. To keep the lance from falling out, an end spring 16 is screwed onto the hammer barrel, and a rubber bushing 20 is installed on the tool between the barrel and the end spring.

Depending on the working conditions, a pike, spatula, hatchet or other tool with the required design of the working end can be used in the hammer. The shank dimensions are shown in Figure 2.

Figure 2. Tool shank for hammers MOP-2, MOP-3, MOP-4.

7.8. The hammer is started by pressing the handle. The pressing force when turning on must overcome the resistance of the spring and the valve, supported by compressed air. To start the hammer, it is necessary to apply a force of 68.6–97.6 N, depending on the air pressure. The hammer turns off automatically when the force is removed from the handle. The hammer handle is made of aluminum casting, the thermal conductivity of which is 0.4 W/(m-K) and has a surface roughness of 0.8 mm.

7.9. The hammer works as follows: when you press the handle, the valve moves down and opens a hole communicating with the annular chamber of the valve distribution. With the help of a valve distribution, firing pin and barrel, compressed air is supplied alternately to the forward and reverse chambers of the firing pin, thereby forcing it to perform reciprocating movements. Thus, the working process of the hammer is not fundamentally different from the working process of any hammers with valve distribution.

Jackhammer Maintenance

Due to its simplicity of design and purpose, this is a fairly reliable and “indestructible” tool. Equipment repair specialists note that 70% of breakdowns are associated with overloads and dishonest attitude towards operating standards.

Only trained personnel are allowed to operate the equipment

Simple rules will help you avoid premature wear.

- Timely lubrication. Before installing the chisel (or other attachments), it is necessary to lubricate the shank with lithol, grease or other heavy lubricant. Reducing friction inside the chuck prevents overheating and wear on the jackhammer barrel.

- Compliance with operating hours. Every 35–40 minutes you need to take a break for 5–10 minutes. This is necessary so that the hammer cools down and the lubricant does not boil.

- Carrying out routine maintenance work. The manufacturer's recommendations must be included in this paragraph. After 100–150 hours of operation (depending on the model), the lubricant coating must be changed. Make sure that no oil leaks from the impact mechanism. If the leak is “chronic”, it is necessary to replace the gasket.

- Proper storage.

A dry room, with a positive temperature and relative air humidity of no more than 80% will be the optimal condition for the safety of all the mechanisms of the unit. Do not leave the hammer outdoors during rain or severe frosts. If you have a transport case, it must be packed after completion of work. Proper storage of the tool is the key to its safety

It must be remembered that a new tool received from the factory must be disassembled, cleaned of grease, and thoroughly rinsed all components in kerosene. Only after this is assembly done and the hammer is ready for work. The vast majority of manufacturers provide for a certain period of storage of the product and protect the instrument from corrosion by covering it with protective compounds that need to be removed.

Maintenance includes the following two types:

- shift, which is carried out every day before starting work;

- monthly, performed once a month in stationary workshops and involving complete disassembly, washing and lubrication.

Consumables that wear out constantly need to be replaced when they expire. You can sharpen the chisel and lance yourself. To do this, use a grinder or a stationary sharpening machine.

It is important to maintain the correct sharpening angle. It is forbidden to “edit” the shank with a sharpener - this leads to an increase in technological gaps with all the ensuing consequences

Electric jackhammer - how does the unit work?

In principle, jackhammers are not divided into household and professional, since the tool itself is professional. Fenders are grouped according to different criteria. For example, weight - light jackhammers include units that weigh no more than 5 kilograms. Such devices are universal and especially convenient when working in a horizontal position.

Most often, it is these devices that are purchased by repair teams, because with their help you can easily knock off old plaster on the walls, make a niche for a transformer, or get rid of a wall altogether by connecting two rooms into one. Along with the chippers, we recommend buying different chisels for the hammer drill - they will also fit the chipper. They can also solve more complex problems, although it will take much longer than when working with fenders weighing over 10 kilograms, which belong to the average category.

Heavy hammers weighing from 30 kilograms cope with the most difficult jobs, for example, dismantling concrete structures. True, it is most convenient to work with such units in a vertical position; in a horizontal position it is almost impossible, because the operator needs to cope not only with the weight of the tool, but also with vibration. Medium and heavy devices are highly specialized - weight, while being their advantage, is at the same time their main disadvantage.

Gasoline jackhammers and their varieties

The principle of operation of jackhammers, which are powered by internal combustion engines, is almost completely identical to electrical devices. Instead of an electric motor, an internal combustion engine is used to drive the piston. With its help, the air pressure acting on the firing pin increases in the chamber. The firing pin, in turn, hits the heel of the firing pin, transmitting a shock wave to the nozzle fixed in the tool chuck.

Gasoline jackhammers are classified into types according to the type of engine used. They come in two-stroke and four-stroke types. Jackhammers with two-stroke engines have such advantages as compact dimensions and low cost.

Design of a gasoline jackhammer

Units with four-stroke engines have a large reserve of power and performance. They weigh quite a lot, which allows them to be used not only for crushing material, but also for the purpose of compacting soil or bulk substances.

This is interesting! The main advantage of a jackhammer, which is powered by an internal combustion engine, is mobility. This eliminates the need to connect them to an electrical network or a compressor, as is typical for electric and pneumatic units.

How to use the device, safety precautions

Working with a jackhammer has a number of features associated with the impact of negative factors on the operator.

- increased vibration during operation;

- increased level of dust in the chiselling area;

- high noise intensity, hazardous to health;

- an abundance of small particles of solid material flying at high speed from under the bit.

When working with a chipper, protective equipment is required

Therefore, safety requirements include the following points:

It is prohibited to carry out work without the use of personal safety equipment - earplugs or headphones, a respirator, safety glasses, as well as to work without gloves and a protective suit made of thick fabric. It is prohibited to use a jackhammer that is known to be faulty.

Before turning on, it is necessary to check the fastening of the chisel and the tightness of the bolts on the housing. During operation, following the safety rules, it is necessary to hold the bump stop only by the standard handles. It is unacceptable to work with one hand. If there is an additional holder, use it for its intended purpose.

The body position must be stable. It is prohibited to entrust the instrument to minor children and to leave it turned on unattended. It is unacceptable to point the tip of the chisel towards other people. After completing work, do not touch the metal part of the housing with bare hands. This may cause severe burns. It is unacceptable to use the tool for purposes other than its intended purpose, such as a crowbar or a shovel when the drive is turned off. The maximum operating period of a jackhammer is limited to 6 hours. Resumption of work is permissible only after a 1-hour break. When using the tool in the cold season outdoors, the lubricant needs to be warmed up. To do this, you need to turn on the device, and for 2-3 minutes. warm up at idle speed.

Following these simple rules will protect the user from injury and the bump stop from premature wear.

Often, when using a pneumatic jackhammer, some users increase the pressure of the compressor supplying compressed air to the tool. They proceed from the simple reasoning that the greater the pressure on the piston, the greater the impact force. This is true. But, unfortunately, for a very short time.

The compression level must correspond to the set nominal pressure of the unit

All rating parameters of the hammer are indicated taking into account the nominal pressure - this is, as a rule, 0.5–0.6 MPa. (or 5–6 atm.). When the pressure increases to 7–8 atmospheres, the load on the piston increases sharply (by 40–60%), and this leads to a halving of the service life of the parts. Therefore, the conclusion is simple - instead of “squeezing” unusual power out of a hammer, it is better to choose a tool with increased impact strength.

During operation of an electric jackhammer, sparks occur on the electric motor commutator. This must be remembered when performing work near combustible and flammable materials. In such a situation, it is safer to use pneumatically driven devices.

Bosch jackhammer

Bosch jackhammer

For some, choosing a jackhammer is a very simple operation, since they are accustomed to trusting the famous Bosch brand. The specialists of this company recently released a fender, which is a tandem of high power and fairly low weight. The device has the following advantages:

- powerful motor that runs on electricity;

- the impact force is 23 Joules;

- weight is about 11 kilograms;

- The device operates for a fairly long period of time without stopping, even under high loads.

All characteristics are indicated by the manufacturer on the packaging, so choosing the right one will not be difficult.

Main characteristics of a pneumatic jackhammer

Pneumatic jackhammers are usually divided into several subcategories based on indicators such as impact energy. Each type of work requires its own energy. For example, if the impact energy of a tool is 30 J, it will be convenient to use it in suspended and constrained conditions. A tool with an energy of 40 J will be sufficient for general work. And so on in increasing order. If it is necessary to destroy particularly strong and rigid materials, it is best to use bumpers with a rating of 50 J or more.

Pneumatic devices have a fairly simple design. Their main working element is also the so-called. peak, thanks to which shock work is carried out. If necessary, this element is changed to a more suitable one, in accordance with the specific situation. For example, instead of a regular peak, you can install the previously mentioned chisel, crowbar, etc.

It is also important to pay attention to such an indicator as the weight of the pneumatic bump stop. Keep in mind that while working you will have to constantly hold the chipper in your hands, and if its weight is too large, you are unlikely to be able to complete the job efficiently in the shortest possible time. In view of this, pneumatic type bumpers, as a rule, have a low weight, on average from 1.5 to 10 kg

In view of this, pneumatic type bumpers, as a rule, have a low weight, on average from 1.5 to 10 kg.

The pneumatic type jackhammer is started in the following order. First, the bumper is connected to the compressor using a cord specially designed for this purpose. After turning on the compressor, compressed air is supplied and the battle begins.

Among the distinctive characteristics that must be taken into account when choosing a pneumatic jackhammer are:

- The number of blows performed in 1 minute.

- Air consumption for work.

- The pressure required to carry out the work.

- The strength of the blows.

Main features of electric jackhammers

A device such as a jackhammer has a very powerful impact force. It is the impact energy that is the most basic characteristic of this device. It is determined by the number of blows that the jackhammer in question is capable of making within a minute, and the energy generated by the device during the same time. The design of such instruments is extremely simple. Inside the body of the jackhammer there is a firing pin. It is driven by the drive. The striker has a mechanical effect on the lance, which is the executive body of the jackhammer. The lance makes very frequent movements of a reciprocating nature, due to which the destruction of the material being processed occurs.

Electric jackhammer device.

It must be remembered that when the device operates, very crude energy is generated. The operator is constantly exposed to loud noise and strong vibration. Therefore, you can start working with a jackhammer only if you follow safety regulations and use appropriate protective measures.

As for the design of an electric jackhammer, such a unit is equipped with an electric motor. Thanks to it, the rotor is driven. It affects the firing pin. The latter sends mechanical impulses to the peak. Devices of this type are very popular, but have a number of different disadvantages. Due to the fact that the motor sparks during operation, the use of this jackhammer is impossible in areas with a fire hazard. In addition, one of the disadvantages is that the device depends on the electrical network. Without it, it simply won't work.

The main characteristic of an electric jackhammer is the impact energy.

The user needs to understand the features of supplying electricity to the device drive. This information will be useful when performing various minor repairs. A fairly common reason for the failure of an electric jackhammer is trivial and simple electrical circuit violations: brushes wear out or a button breaks. Most often the problem lies in the brushes. The design of the tool is such that, due to the brushes, electrical energy is transferred to the motor. If they are erased, the bump stop simply will not turn on.

You can see a pair of plastic plugs at the installation site of the electric motor. To fix the breakdown, just unscrew the plugs, remove the remnants of the used brushes, replace them with new ones and return the plugs to their place.

In the case of replacing the start button, everything happens almost the same. But in this case, you will need to disassemble almost the entire body of the device. However, modern manufacturers try to provide for such breakdowns and assemble the devices so that the start button has a separate cover. This greatly simplifies the replacement of this element.

General criteria and characteristics of jackhammers

Now you know the design features of electric and pneumatic jackhammers. To complete the picture, you need to familiarize yourself with the main characteristics of such tools, which will allow you to choose the most suitable model.

The most important characteristics of any bumper are the number of impacts and their strength. The performance of the fender directly depends on these parameters.

In the case of an electric model, it is necessary to take into account such a moment as engine power

Pay attention to the weight of the tool. This has already been mentioned before

If the jackhammer weighs too much, this will create certain difficulties during its operation. Everything very much depends on the nature of the work to be done. For example, if you need to get rid of old floor screed, a heavy jackhammer will come in handy. If you need to destroy the walls, the weight of the unit will work against you.

The manufacturer of the instrument should not be overlooked. No lengthy explanation is needed here. Everyone knows that there are responsible manufacturers, under whose name truly high-quality goods are produced, and there are companies engaged in the production of so-called. consumer goods. If you are planning to buy a jackhammer, it is better to choose a tool from a good brand. There are quite a few companies that are not yet very popular worldwide, but produce high-quality products.

Jackhammers are usually divided into professional and household. Professional-grade units have higher power and, as a rule, can cope with a larger list of tasks. Therefore, before purchasing, you must definitely plan the scope of the upcoming work so as not to overpay for unnecessary functions.

In addition to the basic characteristics discussed, jackhammers also have additional features that must also be taken into account. First, make sure that the jackhammer, if it is an electric model, is equipped with a button lock, which will ensure uninterrupted and long-term operation of the unit

This lock eliminates the need for the operator to constantly hold the jackhammer start button.

First, make sure that the jackhammer, if it is an electric model, is equipped with a button lock, which will ensure uninterrupted and long-term operation of the unit. This lock eliminates the need for the operator to constantly hold the jackhammer start button.

Secondly, an addition such as an idle frequency limiter will be useful. This feature improves the performance properties of the chipper and ensures longer tool life. The limiter works according to an extremely simple scheme: if the tool receives a less intense load, the engine speed is reduced automatically. Once the load increases again, the engine speed will also increase.

Thus, there is nothing complicated in the design of modern jackhammers. These are simple and functional tools that allow you to cope with a wide variety of repair, finishing and construction work. Knowing the main features of the device and the most important characteristics of a jackhammer, you can choose and buy the most suitable tool for you without any difficulty.

Hydraulic jackhammer: operating principle and application advantages

Another type of jackhammer that should also be given attention is hydraulic. They are close relatives of pneumatic units, only instead of compressed air energy, they use oil pressure.

The principle of their operation is based on a distributor, through which the direction of the oil fluid supplied to the tool from the oil pump changes. Below is a diagram of the working principle of a hydraulic breaker.

The diagram shows that the main structural elements are a piston with a striker, as well as a plunger, which is responsible for the timely opening of the corresponding oil channels. In order not to delve into details, it is necessary to note the main stages of operation of hydraulic jackhammers:

- Oil is supplied under pressure into the chamber in which the piston is acted upon.

- The piston creates oil pressure in the adjacent chamber and acts on the striker, which impacts the nozzle fixed in the tool chuck.

- The reverse action of the nozzle is carried out by changing the direction of oil movement.

A more detailed operating principle of hydraulic jackhammers is presented in the video below.

The operating principle of hydraulic fenders is simple, which has a positive effect on the cost of the tool. An additional advantage is the absence of heating effect on internal parts, which increases their service life. Oil is not only a working material, but also a coolant, thanks to which the service life of such a tool increases tens of times.

The disadvantage of their use is the need to use an oil station. This equipment is expensive, so it is not rational to buy this type of tool for use in the household. Not many construction companies can afford to purchase such tools. Their main advantage is high performance and reliability, but in addition, the advantages of such tools include:

- Effective work for a long time without interruption.

- There is no possibility of power loss, since the tool parts are not exposed to heat and last a long time.

- High speed of dismantling work. Compared to pneumatic ones, hydraulic fenders do the job 2-3 times faster.

- Easy to use. To get started, you need to start the engine of the oil station and connect two hydraulic hoses to the fender.

- Compact equipment. The weight of the hammer is no more than 20 kg, and the weight of the station is up to 60 kg. This allows you to transport the equipment in a passenger car with a large luggage compartment.

If there is a need to perform a large amount of work, you can contact companies that provide hydraulic breakers for rent.

Design and principle of operation of a pneumatic hammer

According to its design features, such a tool falls into the category of piston pneumatic systems equipped with an air distributor with an impact operating principle. The pneumatic hammer is powered by the action of a stream of compressed air supplied by a compressor.

The main structural elements of the tool are:

- Lever.

- Shock absorber.

- Spring

- Valve

- Fixing ring

- Hull part

- Impact part or striker - air distribution impact mechanism

- Buffer spring

- Nozzle

- Nipple.

In general, pneumatic hammers consist of several main components:

- body-handle – includes the trigger, muffler and housing. The muffler is used to suppress aerodynamic noise that occurs when the air exhausted by the hammer is released;

- vibration protection of the handle - involves equipping the tool with a glass with two sealing bushings;

- anti-vibration protection against chisels – includes a spring-loaded bushing and manipulator;

- impact unit (launching device) – consists of a barrel, an air distribution system and a firing pin.

The impact system performs a number of basic functions:

- provides air supply to the tool with its further distribution between the striker stroke blocks and removal from the general equipment system after use;

- converts the energy of the used air into the mechanical work of the main working element - the impact unit.

Nozzle – selected depending on the type of task:

- chisel – destruction of reinforced concrete and metal structures;

- sharp peak (pencil) - processing frozen soil, brick or asphalt;

- scrap (cylinder) – brick walls, ice, concrete;

- shovel – suitable for removing ice or working with asphalt.

The pneumatic jackhammer can also be additionally equipped with:

- side handle, which allows you to correctly distribute the applied physical effort, thereby ensuring comfortable operation of the equipment;

- soft start - makes it possible to smoothly accelerate the engine, increasing its service life, and eliminates unnecessary overloads of the device;

- Impact frequency regulator - helps to adjust the hammer to work with materials with different levels of hardness, controlling the intensity of the tool.

The principle of operation of the hammer is as follows: pressure (compressed air) supplied through the hose acts on the handle, operates the tool and overcomes the resistance exerted by the valve spring. In this case, the valve moves and the openings of the air distribution system open. Air begins to alternately enter striker blocks of different types (either into the upper or lower part of the cylinder), as a result of which the impact system begins to make rapid movements of a reciprocating nature.

The main characteristics on which the effectiveness of any type of chipper depends are the force and number of impacts.

Electric jackhammer: design features and operating principle

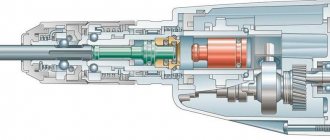

Having learned how an electric jackhammer differs from a rotary hammer, you need to get acquainted with its structure in more detail. Electrical devices are based on powerful electric motors, due to which shock actions are created. However, the electric motor creates only rotational movements, and to convert such energy into impact, a gearbox and a mechanism called a striker are additionally used. Below is a diagram of the internal structure of an electric jackhammer.

Looking at a cross-section of an electric jackhammer, it is not difficult to understand the principle of its operation. The engine drives a shaft to which a connecting rod mechanism is attached, which is connected to the piston. The piston moves inside a sealed chamber. The driven piston (movement frequency is 33 strokes per second) creates high air pressure in the chamber, which acts on the cylindrical firing pin.

The striker acts on the striker, transferring impact energy to the nozzle, which is fixed in the tool chuck. The principle of operation of an electric jackhammer is quite simple, but when studying it, only one question arises - why do we need a sealed chamber in which air pressure is created? Thanks to the air pressure, the possibility of a negative impact on the crank mechanism, gearbox and engine of the tool is eliminated. The air pressure in the chamber acts not only as an impact force, but also as a smoothing element that absorbs the impact when the nozzle moves back.

This is a kind of buffer zone that not only performs the main work, but also protects the important structural mechanisms of the tool from their accelerated destruction. The video below provides a detailed description of the operating principle of an electric jackhammer.

PREPARATION AND OPERATION PROCEDURE

8.1. Hammers received from a factory or warehouse must be disassembled after long-term storage, the parts cleaned of grease and thoroughly washed in kerosene and reassembled.

8.2. Check the freedom of movement of the hammer in the barrel by turning the hammer in a vertical plane.

8.3. Make sure the idler is screwed in tightly and secured with the stopper.

REMEMBER that when this connection is weakened and gaps appear in the air distribution device, the hammer parameters sharply deteriorate.

8.4. Make sure the handle moves freely.

8.5. Before starting work, attach the hammer hose to the filter and lubricant nozzle in the compressed air network. If there is no lubricant nozzle, inject lubricant through the nipple. During the operation of the hammer, periodically fill the hammer with lubricant to ensure constant lubrication of the rubbing parts. Lubricate the new hammer 3-4 times per shift during the first two weeks of use. A worn-out hammer should be lubricated at least twice a shift.

8.6. Clean the lance shank from dirt, put a rubber bushing on the lance, insert the lance into the hammer and secure it with an end spring, screwing it onto the barrel until it stops so that the lock fits into the corresponding groove in the barrel.

8.7. Blow the sleeve with compressed air and, making sure there is no dirt, attach it to the hammer nipple. Make sure that the hose is securely fastened and that the operating air pressure is not lower than 0.4 - 0.55 MPa.

8.8. Press down the hammer while working the lance.

8.9. When taking breaks from work, store the hammer so that dust, water, etc. do not get into it.

What is a jackhammer, how does it work?

The device is a percussion tool designed to break and split rock sediment, concrete structures, asphalt, etc. The hammer is controlled manually by the operator; the direction of impact, frequency and duration of impact on the surface being treated are regulated. Since the force is transmitted to the working element (pike, blade, chisel, etc.) from the striker driven by an external energy source, the device belongs to the mechanized class of tools. The drive may be

- electrical;

- pneumatic;

- hydraulic;

- gasoline.

The number of beats varies from 15 to 45 Hz. (i.e. 15–45 working movements of the striker per second).

Mobile jackhammer in a mine tunnel

Bumper device

Despite the variety of types, their principle of operation is no different. The working part is a chisel, a peak or a slotting blade.

Various modifications of pneumatically driven jackhammers

What is a jackhammer: in what cases is it impossible to do without it?

A jackhammer is a specialized type of construction tool designed for breaking and loosening hard and durable materials. The device is not only large in size, but also heavy, which is why it is used exclusively for performing complex work. For example, it would not be rational to use it when it is necessary to remove the plaster layer in a house or remove ceramic tiles, since these types of tasks are considered to be an easy type of work, and a classic hammer drill can cope with them. It’s another matter when you need to destroy an old cinder block building, crush a concrete slab or destroy a concrete screed. In this case, you can do without heavy equipment, but you will not only have to put in a lot of effort, but also spend a lot of time.

It is impossible to do without the use of jackhammers in a number of the following cases:

- When dismantling of building structures is carried out: both complete and partial. A hammer drill is quite capable of crushing bricks, but crushing a concrete wall is a task for a jackhammer. In everyday life, there is a need to use a jackhammer when it is necessary to remove an unusable reinforced concrete slab or large boulder. This can be done with the help of special equipment, the calling of which will be very expensive. Using a chipper, you can crush a slab or boulder into small pieces, which ultimately makes it easier to subsequently dispose of the remaining parts.

- Removal of road surfaces from asphalt, concrete and reinforced concrete. Jackhammers are especially popular among workers who repair road surfaces. In the household, such a tool may be needed if it is necessary to destroy the concrete coating in the yard, which is planned to be replaced with paving slabs.

- Emergency rescue work.

- Tamping and compacting soil - in addition to destructive work, the tool is also used when preparing the floor for screed (compacting bulk materials), when installing reinforced concrete pillars and when preparing the area for pouring the foundation. The device is an alternative replacement for vibratory rammers.

- Knocking out window and door openings.

- Excavation of soil for subsequent pouring of the foundation.

- Loosening compacted or frozen soil and bulk building materials.

- Mining.

- Chasing walls for laying communications.

- Chiseling frozen ice.

Based on the presented work, the implementation of which is possible thanks to a jackhammer, you can draw an appropriate conclusion for yourself about the necessity and rationality of using the tool. Due to the fact that the devices have a wide range of applications, and are used not only at a professional level, they are available in two main versions. The first type is professional, characterized by such properties as:

- high performance and power, thanks to which the tool can be used to perform complex and heavy work;

- long service life, which is associated with high quality manufacturing of components;

- high cost, indicating not only the high-quality performance of the instrument, but also its great capabilities.

The second type of jackhammers are household ones, the purpose of which is to perform a certain range of work. For example, if there is a need to use a jackhammer around the house, you can either rent a professional tool or purchase a device and use it when the need arises. The cost of household tools is much lower than professional ones, which actually makes them more popular and in demand, especially among home craftsmen.

This is interesting! It is important to note that household appliances are distinguished not only by the average quality of their components, but also by their low weight. It is precisely due to the reduced weight of the tool that it cannot be used for all types of the above work.