The modern range of tools for working with fasteners is very diverse. The most popular is the adjustable wrench. Its unique features and versatility make it a popular tool. The cost depends on a number of parameters that you need to know and be able to choose the appropriate option.

What is an adjustable wrench

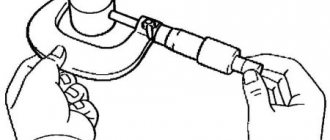

An adjustable wrench is an adjustable tool with movable and fixed jaws.

It is adjustable thanks to a rotating mechanism that allows it to be used with nuts, bolts, etc. of different sizes, so they are more versatile than fixed wrenches.

Classification of adjustable wrenches depending on their size

It is customary to divide distribution equipment based on its size. The dimensions of the adjustable wrenches are as follows:

- Small size (0-19 mm). Area of use: minor repairs.

- Medium (up to 30 mm). Area of application: plumbing work.

- Large (up to 46 mm). Purpose – work with mechanisms and devices of large dimensions.

Benefits of having a universal tool

With an adjustable wrench, you can take advantage of the tool's capabilities to tighten or loosen different types of fasteners.

- It is very useful as it can be adjusted to fit any nut or bolt so you don't always have to worry about choosing the right size of wrenches for different fasteners.

- One adjustable wrench can replace all different size wrenches, saving space in your tool cart, weight less and saving money.

- Some are better suited for the intensive use associated with general vehicle assembly, repair and maintenance, while others are better suited for household and everyday tasks.

Small keys are ideal for DIYers. They're also good for hard-to-reach corners where large keys won't fit.

So before making a decision, it is good to know its characteristics and become more familiar with this topic.

The best classic adjustable wrenches

Models of this type are the most common; they have a worm or screw adjustment mechanism and smooth jaws. They are convenient when working with connecting elements of various types, installing flexible plumbing hoses, etc. Classic adjustable wrenches have small dimensions and weight, which makes them convenient to work with one hand.

Kraftool SlimWide PRO 27258-20

5

★★★★★

editorial assessment

100%

buyers recommend this product

The tool is made of high-quality chrome vanadium steel and reinforced with a phosphated coating. This ensures high strength and durability of the key. The increased maximum gap width ensures ease of use when working with large fasteners.

The length of the model is 200 millimeters, weight - 280 grams. The jaws are angled at 15 degrees for a secure grip on parts. The ergonomic handle has an anti-slip pad. If necessary, the adjustable wrench can be hung from a special ring.

Advantages:

- high strength;

- reliable grip of fasteners;

- ease of holding;

- quick adjustment.

Flaws:

- price.

The Kraftool SlimWide PRO wrench is convenient for working in hard-to-reach places. It is suitable for both professional and home use.

Gross 15569

4.9

★★★★★

editorial assessment

94%

buyers recommend this product

This wrench comes with protective attachments that prevent damage to working parts during storage or transportation. The main manufacturing material is high-strength chrome vanadium steel.

The maximum working width is 50 millimeters, the total length is 250 mm. Thin jaws make the tool easy to use in hard-to-reach places.

The thoughtful shape of the handle allows you to create more force, while the relief coating reduces the likelihood of the tool slipping. A special hole is used to hang the key on a cord.

Advantages:

- durable metal;

- thin sponges with removable protective attachments;

- non-slip handles;

- durability.

Flaws:

- the handle is quite thick.

The Gross adjustable wrench is designed to work with the most stubborn fasteners. This is the tool chosen by professionals.

Bahco 9031

4.8

★★★★★

editorial assessment

89%

buyers recommend this product

The special measuring scale in this model ensures accurate size adjustment. The handle with a thermoplastic pad has an ergonomic design, is not afraid of sharp impacts and does not slip during operation.

The length of the key is 218 millimeters, the grip width is 38 mm. The main elements are made of high-quality alloy steel. To increase strength and durability, they are precision hardened and multi-stage anti-corrosion treatment.

Advantages:

- convenient adjustment;

- non-slip handle;

- reliable grip of the part;

- high strength and corrosion resistance.

Flaws:

- The size scale is quickly erased.

The Bahco 9031 wrench is suitable for working in conditions of high humidity. A reliable tool for professional plumbers and installers.

Stanley MaxSteel 0-90-950

4.8

★★★★★

editorial assessment

87%

buyers recommend this product

The working parts of Stanley MaxSteel have a scale that makes it easier to adjust the size. The handle has a special hole that makes it possible to hang the tool in the required place for quick access. It is equipped with anti-slip pads and protruding elements for a more secure hold.

The maximum working width is 40 millimeters, the tool length is 300 mm. The main material of manufacture is chrome vanadium steel of increased hardness. The phosphated surface provides additional strength and prevents corrosion.

Advantages:

- high strength;

- protective covering;

- reliable grip;

- fine tuning;

- ease of storage.

Flaws:

- a little heavy.

The Stanley MaxSteel adjustable wrench is used for working with nut joints in everyday life and professional work.

READ ALSO

10 Best Torque Wrenches

Have multiple tools in one

With this tool, you can perform different tasks as if you had multiple tools in one. This way, you will not only save money, but you will also save space in your toolbox.

You never know when problems might arise with your pipes, car, or some furniture in your home, so it pays to have an adjustable wrench. It is a very versatile tool with various functions. In addition, some of them include additional functionality.

How to choose an adjustable wrench

As with other products on the market, you will find very different models, which can make the decision a little more difficult. When purchasing, be sure to pay attention to the following characteristics:

Adjustable wrench material

Wrenches, for the most part, are usually made from a steel alloy that will be plated with either chrome metal or some other type of material. Some finishes, such as black phosphate or metallic chrome, are better than others in terms of durability.

It is very important to keep an eye on the finish and polish of your faucet as this will help determine its lifespan. This is especially useful when repairing and servicing cars or motorcycles.

The treated coating makes the key a poor conductor of heat and therefore much safer than traditional keys. So, it is necessary to consider the material depending on the work being performed.

Adjustable wrench size

The first thing to evaluate is whether the adjustable wrench is the right size for the nuts and bolts you need it for.

Since the jaws are adjustable, in most cases you will have no problem adjusting a wide range of mounts.

For general tasks, you can select key sets.

- Today, many brands offer tools of different sizes, features and uses, so you can always choose the model that best suits your job.

- However, you won't need an adjustable wrench for every size, but for a range of sizes.

Adjustable wrench weight

Of course, the weight will be affected by the size and material from which the key is made. Always check whether the model provides ease of handling, as well as comfort and safety. Well, a handle that is too heavy can hinder the job rather than make it easier, and we don't want that to happen.

Lever pipe wrenches

Lever pipe wrenches (gas wrenches) of the entire range of sizes, from number No. 0; No. 1; No. 2; No. 3; No. 4; No. 5; No. 6; No. 7 to No. 8 have the same design, with the exception of the design of the jaws - straight and inclined or “S”-shaped. Two handles (levers) are connected via a lever mechanism. Hence the name of the keys – lever. The lower handle has a trapezoidal thread that allows the adjusting nut to slide one of the two jaws along the guides when adjusting the pipe size. The upper power handle is rigid and usually has a double “T” shaped profile. For normal work, flat hardened straight or inclined jaws are used. To work with “dead” connections, a pipe wrench of the s-shaped lever type is better suited. It can grip the pipe not at two points like a standard gas pipe wrench, but at three, which allows you to create much greater torque with the same lever. The angle of the pipe wrench jaws - 90° or 45 degrees - allows for better access to the pipe in the most difficult situations situations. For ease of searching, the designation of models of foreign manufacturers contains a key size number, which is close to the sizes of keys of domestic manufacturers according to the classification for pipe lever (gas) wrenches GOST 18981-73. Why are pipe (gas) wrenches adjustable?A natural question. Everyone is familiar with universal adjustable wrenches manufactured in accordance with GOST 7275-75. The jaw of the adjustable wrench can be adjusted using an adjusting nut to the desired size of hexagon or square. With our pipe wrenches, adjustment to the desired pipe size is done exactly like with adjustable wrenches. The adjustment mechanism is the same, only the designs differ. By the way, GOST 7275-75 did not introduce the concept of an adjustable gas or pipe wrench. The concept of adjustable gas wrenches is used in everyday life and it is so ingrained that we do not think at all when we say the word adjustable wrenches in relation to pipe wrenches. | The section of the catalog for pipe lever wrenches (gas) contains photos and pictures of gas wrenches and large photographic material from almost all major manufacturers. Photo of a Ridgid gas |

| Photo gas key Rothenberger (Rothenberger) |

The review of pipe lever wrenches (gas wrenches) includes models with basic technical characteristics and photographs of the world's leading manufacturers. The information is presented in a summary table of gas keys of the following brands: Ridgid, Rothenberger (Rothenberger), etc.

Model/brand Name of wrench Pipe diameter, inch Weight, kg

| Ridgid 1140 | Gas pipe wrench No. 0 | 3/4 | 0,4 |

| Ridgid 1141 | Gas pipe wrench No. 1 | 1 | 0,7 |

| Ridgid 1142 | Gas pipe wrench No. 2 | 1 1/2 | 1,3 |

| Ridgid 1143 | Gas pipe wrench No. 3 | 2 1/2 | 2,9 |

| Ridgid 1144 | Gas pipe wrench No. 4 | 3 1/2 | 5,3 |

| Ridgid 45° 1″ | Gas pipe wrench No. 1, jaw angle 45° | 1 | 0,9 |

| Ridgid 45° 1 1/2″ | Gas pipe wrench No. 2, jaw angle 45° | 1 1/2 | 1,4 |

| Ridgid 45° 1/2″ | Gas pipe wrench No. 0, jaw angle 45° | 1/2 | 0,4 |

| Ridgid 45° 2″ | Gas pipe wrench No. 3, jaw angle 45° | 2 | 2,7 |

| Ridgid 45° 3″ | Gas pipe wrench No. 4, jaw angle 45° | 3 | 3,5 |

| Ridgid 90° 1″ | Lever pipe wrench No. 1, jaw angle 90° | 1 | 0,4 |

| Ridgid 90° 1 1/2″ | Lever pipe wrench No. 2, jaw angle 90° | 1 1/2 | 0,9 |

| Ridgid 90° 2″ | Lever pipe wrench No. 3, jaw angle 90° | 2 | 1,4 |

| Ridgid 90° 3″ | Lever pipe wrench No. 4, jaw angle 90° | 3 | 2,7 |

| Ridgid 90° 4″ | Lever pipe wrench No. 5, jaw angle 90° | 4 | 3,5 |

| Ridgid S 1″ | Lever pipe wrench No. 1 type “S” | 1 | 0,9 |

| Ridgid S 1 1/2″ | Lever angle pipe wrench No. 2 type “S” | 1 1/2 | 1,4 |

| Ridgid S 1/2″ | Lever pipe wrench No. 0 type “S” | 1/2 | 0,4 |

| Ridgid S 2″ | Lever angle pipe wrench No. 3 type “S” | 2 | 2,6 |

| Ridgid S 3″ | Lever angle pipe wrench No. 4 type “S” | 3 | 4,2 |

| Rothenberger 45 (series) | Gas pipe wrench No. 1; No. 2; No. 3; No. 4 jaw angle 45° | 1/2-3 | 0,4 – 3,4 |

| Rothenberger 45 SUPER S (series) | Pipe lever wrench type “S” No. 0; No. 1; No. 2; No. 3; No. 4 jaw angle 45° | 1/2-3 | 0,4 – 3,4 |

| Rothenberger 90 (series). | Gas pipe wrench No. 1; No. 2; No. 3; No. 4; No. 5 jaw angle 90° | 1 -4 | 0,74 – 5,6 |

The largest manufacturers of gas pipe wrenches from the USA and Europe are presented in this section of the catalog - Ridgid, Rothenberger (Rothenberger). Most foreign companies have their representative offices or companies representing their interests in Russia. For each manufacturer, the address, company name, phone number, website, main specialization and manufactured tools are indicated. List of gas wrench manufacturers included in this section: Ridge Tool Company, USA Rothenberger Werkzeuge AG, Germany Sale of pipe lever wrenchesThe sale of pipe lever wrenches, including spare parts, is carried out by manufacturing plants and official dealers in Russia. Sales are carried out from equipped warehouses. You can select and buy the required key in our catalog. | All videos of models of pipe lever wrenches are available on the video channel Communal Machines - kommashPRO.ru. |

Lever pipe wrenches (gas) – purpose

A pipe wrench is a lever or gas wrench, used for gripping and rotating pipes with both hands during installation work on pipeline gas and water supply systems in populated areas, apartment buildings, and industrial enterprises.

A gas wrench is the main tool for working with pipes for all professional plumbers; it is also used in the household as an auxiliary tool for all occasions for fixing not only pipes, but also objects of any shape.

A pipe wrench can successfully replace a pipe vice when cutting pipe threads at home or during installation work at a construction site.

The “dead” grip allows the gas wrench to disassemble even very “boiled” connections - pipe / coupling or coupling / bend.

The most popular gas keys are from foreign manufacturers of such brands as Ridgid, Rothenberger (Rothenberger), etc.

Why is a gas key called a gas key?

Really interesting question. Almost every plumber is sincerely convinced that he works with a gas wrench, and not with a pipe lever wrench - that is what it is called according to GOST 18981-73. The explanatory dictionary leads us to the Swedish trace of this instrument.

There we will find a Swedish/Swedish adjustable key or a colloquial Swedish key. The wrench design came to Russia at the end of the 18th century and, according to our assumptions, the Swedish adjustable wrench began to be used in the development of the first oil and gas fields in the south of the country.

The keys were used to form drill rods and, most likely, it was from then on that they began to call it a gas key.

Later, when scientists took up this issue, the gas wrench officially began to be called “Lever Pipe Wrench” and, accordingly, GOST 18981-73, which is in force to this day, is dedicated to it. Now if you are asked what is the difference between a gas wrench and a lever pipe wrench, you can safely answer - they are the same pipe wrench. In our catalog we will use the term about.

Gas key - numbers and sizes

GOST 18981-73, already familiar to us, introduced the concept of key number, which determines its size - the length and diameters of the pipes being grabbed. There are five key numbers, of which the most used are No. 1; No. 2; and No. 3 sizes. It should be noted that pipe wrenches and other sizes are produced according to technical specifications - No. 0; No. 6; No. 7; No. 8.

The pipe lever wrench (gas wrench) size No. 1 has a length of 0.3 m and works with pipes in the range of 10-36 mm. The older pipe lever wrench (gas wrench) size 2 is 0.1 m longer than its counterpart and can handle pipes from 20 to 50 mm.

The most commonly used pipe lever wrench (gas wrench) is size 3, 500 mm long. will freely grip pipes with diameters from the range of 20-63 mm.

The remaining lever (gas) pipe wrenches of sizes No. 4 and No. 5 have a length of 630 / 700 mm and diameters of clamped pipes 25-90 / 35-120, respectively.

Lever pipe wrenches (gas wrenches) – model specifications

The catalog of pipe lever wrenches (gas wrenches) contains a list of models from foreign manufacturers. Detailed technical specifications are published for each model, the country and manufacturer are indicated, and a photograph of the product.

Source: https://www.kommashpro.ru/kliuchi-trubnye-rychazhnye

Opening

When it comes to wrenches, there are a wide variety. Some of them are not only mobile, but also reversible, meaning they can be completely rotated for a larger closure.

- Other models have engraved markings that help determine the size of fastener needed for a particular opening.

- Other features that may include splines attached using tension springs.

- These characteristics apply to the different types of tasks for which a wrench is best suited.

Restraint

The length of the handle determines the gripping ability. Therefore, longer handles are suitable for people with larger hands.

On the other hand, the width of the handle, and especially the thickness, helps determine whether you can achieve the desired leverage when using it.

This feature is especially important when it comes to making adjustments using a very strong nut or bolt. The coating on the handle is also critical as it affects the strength, glide and grip of the handle.

Various models of wrenches

Graduated model. These wrenches have millimeter graduations under the clamps to ensure precise pre-setting.

- This is a very common model as this scale helps us know the size of the nuts or bolts to make our work easier.

- It also usually has a hardened pliers with wheels and rollers that allow for precise graduations.

Side knurled model

This model differs from others in one detail, since the operating principle remains the same. Side-thumb wheel keys feature a stand on one side of the movable jaw.

In order to open the jaw, the central gear was replaced with a wheel on one side. This thus facilitates more accurate calibration of the instrument.

Crocodile model

Finally, crocodile models are the most versatile type because they combine two tools in one, which means even more space savings.

The difference this wrench presents is that there is another V-shaped tool at the end of the handle. It can be used to adjust other types of screws and nuts.

Pros and cons of an adjustable wrench

This tool is used more often in the household than other types of wrenches. Among the advantages of the product are:

- the ability to change the distance between the two lips;

- one key can be used for several tasks;

- the presence of sponges of different shapes.

In addition, the adjustable wrench has a number of disadvantages:

- the large head makes it difficult to work in narrow spaces;

- the presence of play on the moving part does not make it possible to tightly compress the element;

- Over time, the mechanism wears out;

- there is a need to constantly adjust the position of the sponge.