This is the very first question that arises before the owner of a Shtil 180 chainsaw, which for some reason has stopped functioning normally. There is no clear answer to this question. It would be correct to say: it is possible, but is it necessary? Repairing a chainsaw in a service center is of course more expensive than trying to fix problems yourself, but by using the services of specialists, you receive guarantees and confidence that the chainsaw will be properly configured and adjusted. In general, the choice is yours.

Another small nuance regarding the choice to repair it yourself or not is that in order to diagnose a chainsaw and its further disassembly and repair, you need to have some specific tools and certain knowledge of the design of the saw. Otherwise, you will not be able to even unscrew and remove the flywheel without damaging it.

When carrying out independent saw repairs, the aluminum fan blades located on the flywheel very often break off. This happens because during disassembly they do not use a special crankshaft stopper, but try to fix it by installing a screwdriver between the saw body and the flywheel blades, which leads to dire consequences. The flywheel nut has a serious tightening torque, and the blades are fragile and cannot withstand such force.

Main types of breakdowns and methods for eliminating them

Before starting work on diagnosing faults and eliminating them, you must prepare the necessary tools.

General view of the Stihl MS 180 chainsaw with main components

Due to the fact that a chainsaw is a relatively simple unit, the list of accessories includes the following items:

- a set of flat and Phillips screwdrivers;

- open-end locksmith's wrenches;

- spark plug key;

- socket set with wrench

- Stihl multi-tool.

Multifunctional tool

In order to qualitatively eliminate any breakdowns that occur and restore operational performance, it is necessary to determine as accurately as possible the malfunction that preceded the failure of the unit. Based on the fact that the chainsaw is equipped with an internal combustion engine (ICE), the main causes of breakdowns should first of all be looked for in the power unit.

Before starting work, it is necessary to turn off the engine, allow it to cool and prevent the chainsaw from starting. To protect your fingers, it is recommended to wear cotton gloves.

The most common faults when repairing a Shtil 180 chainsaw include:

- the engine does not start;

- the engine runs intermittently, and when running for a short time, the chainsaw spontaneously stalls;

- oil leaks near the chain lubrication mechanism;

- the engine does not develop full power.

Frequent breakdowns of the transmission part of the saw include rupture of chain links. You can independently restore its integrity by riveting the links or replacing them with a new one.

Despite the relative simplicity of the design and the absence of complex mechanisms, experts recommend troubleshooting in a certain order. First of all, the presence of the mixture in the fuel tank is checked, and if everything is in order with the liquid level, you need to proceed to inspect the chainsaw starting unit. If this mechanism is also in normal condition, you need to check the functionality of the spark plug.

After performing the manipulations to diagnose the spark plug (determining the presence or absence of carbon deposits, the correct gap between the electrodes, the condition of the o-ring), we turn our attention to the carburetor. Due to small sawdust, dust and soil particles, the fuel system often becomes clogged.

If cleaning the carburetor of a stihl 180 chainsaw did not help restore the unit to its previous performance, the reason most likely lies in the cylinder-piston group (CPG). The power unit is one of the most complex mechanisms of the tool, the diagnosis of which requires almost complete disassembly.

Fuel system problems

The first stage of diagnosing the fuel supply system is checking the level of the fuel mixture in the tank.

The main components of the fuel system of the 180 Shtil chainsaw

Even if the owner is sure of the availability of gasoline, this makes it possible to eliminate the vacuum created as a result of a clogged bypass valve. It is designed to optimize pressure in the tank with fuel consumption. To make it easier to clean the chainsaw breather, use a regular medium-sized sewing needle.

When inspecting the fuel system, you should pay attention to the integrity of the pipes, the tightness of which may be compromised by mechanical damage or long-term operation of the unit. Sometimes the cause of mixture leakage and, as a result, incorrect engine operation, is the wear of rubber gaskets and primer (choke button). In this case, to repair the Shtil 180 chainsaw with your own hands, you need to purchase a repair kit for seals and replace them.

Problems with the starting and ignition mechanism

The cause of problems with a chainsaw of this model may be a malfunction of the ignition system and the engine starting unit.

General view of the 180 chainsaw ignition

If no deviations are detected when measuring the gap between the flywheel and the module, you need to pay attention to the spark plug.

Most manufacturers, including Shtil chainsaws, recommend setting a gap of 0.2 mm. To do this, you will need a coin-shaped, coin-wire or flat probe, which can be purchased at any automotive store.

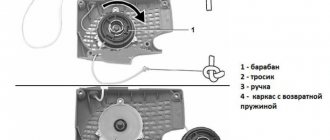

Shtil 180 chainsaw starter assembly

Having removed the spark plug from the shaft, we measure the gap of the chainsaw spark plug between the central and side electrodes. If its value is excessive (more than 0.7-1.5 mm), a spark may occur periodically, and if it is minimal (less than 0.7 mm), it may not be sufficient for optimal ignition of the fuel mixture.

If gasoline enters the combustion chamber, and no discrepancy in the ignition system has been identified, the likely cause of the breakdown may be the carburetor. This unit is designed to mix fuel with air and supply them to the cylinder. After dismantling the carburetor, we clean its channels and jets using universal products.

It must be remembered that the carburetor consists of many small parts, and therefore its dismantling, disassembling and cleaning require special care.

After diagnosing the ignition system of the Shtil 180 chainsaw and restoring it, we move on to finding problems in the power unit, namely in the cylinder-piston group of the saw.

Chainsaw engine breakdowns

During operation, parts of the cylinder-piston group of the saw fail due to friction forces, high temperatures and loads. If the tool does not develop full power when starting up and stalls at idle, the possible problem may be broken engine parts. To disassemble the power unit, you need to unscrew 4 bolts and remove the cylinder. The owner needs to carefully inspect its internal working surface for the presence of chips, nicks and cracks.

Even the slightest damage to the cylinder “mirror” can negatively affect the compression of the chainsaw engine and its performance.

Cylinder piston group of Stihl MS180 chainsaw

When diagnosing an internal combustion engine, we also perform a visual inspection of the piston and compression rings. Made from duralumin alloy and cast iron, respectively, they are more subject to abrasive loads in contrast to a steel cylinder. If the piston rings are damaged or excessively worn, they must be replaced.

If upon visual inspection there is an ovality of the working surface of the cylinder, it will need to be bored. To do this, we measure its diameter according to the larger size, select the piston and carry out subsequent machining.

Malfunctions in the lubrication system of the 180 chainsaw: causes and repairs

During the process of sawing wood, the cutting part of the tool is subjected to high loads. In order to reduce friction forces and subsequent chain wear, the Stihl chainsaw is equipped with a lubrication system that gradually supplies oil to the bar. The rapid loss of cutting properties by the teeth and the absence of traces of lubricant may indicate leakage or clogging of the pipes.

Stihl 180 chain lubrication principle

First of all, when diagnosing the chain lubrication system for the ms 180 chainsaw, we pay attention to the oil supply hoses and their fixation points. Damaged pipes cannot be repaired and therefore must be replaced. You can clean the oil channels using compressed air. For these purposes, we use a compressor or a regular automobile hand pump.

Due to its ease of operation and repair, the chainsaw of this model has gained wide recognition among professionals and amateurs in the field of woodworking.

What kind of damage may occur?

Chainsaw malfunctions can be divided into groups:

- Engine malfunctions (ignition, exhaust and cylinder-piston systems, fuel supply).

- Failure of components such as the clutch, chain brake, lubrication system or tire.

Chainsaw engine failure is more common than others. Most of the time is spent on its detection and repair. As a rule, it comes down to such manifestations when the engine runs unstably or stalls altogether, the engine does not start, and does not develop power.

Before you start repairing your chainsaw, first check all the possible causes of problems in its functioning, or better yet, watch the video. Fortunately, today you can find any material of interest on the Internet.

Then you will have to prepare the necessary tools to repair the damage:

- device diagram (must be included in the delivery kit);

- keys, including spark plugs.

Ignition system malfunction

When the engine refuses to work, but there is a spark at the spark plug and fuel is flowing, you should check the ignition.

Checking it is not at all difficult: unscrew the spark plug, adjust the gap between the contacts, connect it to the wire and press it against the cylinder body. After this, watch for a spark to appear.

If any deviations occur, you need to adjust the ignition system. In general, this process is similar to adjusting the ignition in other two-stroke engines.

Checking the ignition system

In case of various equipment breakdowns, it is always necessary to pay attention to the spark plug . To do this, carefully connect the wires, and then unscrew the element using the appropriate key. Then you need to evaluate the condition of the candle.

- If it is dry, then this indicates that fuel is not entering the cylinder. Accordingly, the problem is not related to the spark plug.

- If such an element is splashed with fuel, you should make sure that the carburetor starts correctly. The same applies to adjustments. The spark plug itself is carefully wiped, and then the gas supply is turned off and the starter is started. This will help get rid of excess fuel and at the same time ventilate the combustion chamber. After this, the spark plug is screwed into place and the mechanism is started again.

- If black carbon deposits are visible on this element, then most likely low-quality oil was used when using the Shtil chainsaw. It could also be due to an incorrect fuel/oil ratio or incorrect carburetor adjustment. In this situation, the candle is carefully washed, then carbon deposits are removed with a sharp knife or needle and the electrodes are wiped. When checking the spark plug, it is important to make sure that the distance between the electrodes is no more than 0.5–0.65 mm.

As mentioned earlier, upon inspection, you can notice black carbon deposits . In this case, experienced craftsmen recommend checking whether a spark occurs. For this purpose, the ignition cable is fixed to the spark plug, after which the nut and cylinder are connected using pliers. Then all that remains is to start the chainsaw starter. If a spark does not occur, you will have to replace the spark plug. In a situation where the use of a new element is also unsuccessful, it is necessary to check the high-voltage wires and connection to the spark plug.

Instructions, manuals for equipment and tools STHL, VIKNG, METABO

Operating instructions for STIHL equipment and tools

Operating instructions for sawless saws STIHL MS 170, 180

Watch/Download 2.35 Mb (pdf)

- Section name Page

- Safety and operating instructions 3

- Cutting set 16

- Installing the guide bar and saw chain (front chain tension) 17

- Installing the guide bar and saw chain (quick chain tension) 18

- Saw chain tension (front chain tension) 20

- Saw chain tension (quick chain tension) 20

- Saw chain tension control 20

- Fuel 21

- Refueling 22

- Chain oil 23

- Fill chain lubrication oil 24

- Checking the saw chain lubrication system 24

- Saw chain brake 25

- Start/stop motor 26

- Operating instructions 30

- Maintenance of the guide bar 31

- Cover 32

- Cleaning the air filter 32

- Carburetor settings 33

- Spark protection grille in muffler 34 Exhaust gas catalyst 34

- Spark plug 34

- Start cable 35

- Storing the device 36

- Checking and replacing chain sprocket 36

- Maintenance and sharpening of the saw chain 37

- Instructions for maintenance and care 41

- Minimize wear and avoid damage 43

- Important components 44

- Technical data 45

- Special accessories 47

- Ordering spare parts 47

- Repair instructions 48

- Declaration of Conformity EC 48

- Quality certificate 49

If you are not yet the happy owner of a STIHL MS 170 or MS 180 , but want to buy such a chainsaw, you can do this in branded stores in Kharkov, which are located at the following addresses: st. Sukhumskaya, 24; Gagarin Ave., 38.

You can send an application to purchase a chainsaw right now from our website.

Operating instructions for professional chainsaws STIHL MS 650, 660. Currently - updated chainsaw STIHL MS 661

Watch/Download 2.3 Mb (pdf)

- Section name Page

- Safety and operating instructions 3

- Cutting set 16

- Installing the guide bar and saw chain 17

- Sharpening saw chain 18

- Checking saw chain tension 19

- Fuel 19

- Refueling 20

- Chain oil 21

- Fill in chain lubrication oil 22

- Checking the saw chain lubrication system 23

- Saw chain brake 23

- Winter operating mode 24

- Electric heated handle 25

- Start/stop motor 26

- Operating instructions 29

- Adjusting the amount of oil 30

- Maintenance of the guide bar 31

- Air filter system 32

- Removing the air filter 32

- Cleaning the air filter 33

- Carburetor settings 33

- Spark protection grille in muffler 35

- Spark plug 35

- Launcher 36

- Storing the device 37

- Checking and replacing chain sprocket 37

- Maintenance and sharpening of the saw chain 38

- Instructions for maintenance and care 43

- Minimize wear and avoid damage 45

- Important components 46

- Technical data 47

- Special accessories 48

- Ordering spare parts 49

- Repair instructions 49

- Waste disposal 49

- Declaration of Conformity EC 50

- Quality Certificate 50

Watch/Download 2.3 Mb (pdf)

buy a STIHL MS 661 chainsaw in our specialized stores of STIHL, VIKING equipment and tools in Kharkov. If problems arise with a STIHL tool, we recommend contacting our “Service Center” , which provides warranty repairs and maintenance of STIHL tools. Experienced specialists will always advise you on all issues related to the operation and maintenance of Shtil equipment.

You can apply for the purchase of a STIHL MS 661 chainsaw right now on the website.

Instructions for sharpening saw chains for STIHL chain saws

- Section name Page

- High technology STIHL 1

- Structure of saw chain 3

- Preparing the saw chain 6

- Basic principles of saw chain sharpening 8

- Sharpening help 12

- Saw chain tension 17

- Errors during sharpening and types of damage 18

- Maintaining the guide bar 23

- Checking the chain sprocket 27

- Selecting the right cutting attachment 28

- Checklist 33

Watch/Download 10.7 Mb (pdf)

Owners of chain saws can always buy original sharpening accessories for STIHL Here you can get FREE advice on proper chain sharpening and saw chain care, as well as buy new STIHL saw chains .

You can view the range of sharpening accessories, sharpening equipment and their prices in the catalog on the website. The website presents all saw chains for STIHL chainsaws. A convenient product filter will help you choose and buy the right saw chain.

Operating instructions for motorcycle shears STIHL HLA 65, 85

- Section name Page

- To this instruction manual 2

- Safety and operating instructions 2

- Application 9

- Device contents 11

- Electrical connection for charger 12

- Charging the battery 12

- LEDs on battery 13

- LEDs on charger 15

- Setting the knife crossbar 15

- Adjusting the telescopic shank 17

- Applying a hanging strap 18

- Backpack system 19

- Turning on the device 20

- Turning off the device 21

- Storing the device 21

- Sharpening cutting knives 22

- Instructions for maintenance and care 23

- Minimize wear and avoid damage 24

- Important components 25

- Technical data 26

- Troubleshooting 28

- Repair instructions 30

- Waste disposal 30

- Declaration of Conformity EC 30

- General safety instructions for power tools 31

You can get acquainted with motorcycle shears and buy them at any specialized retail outlet. a detailed description and characteristics of the HLA 65 motor shears in the catalog. Here you can order motorcycle shears right now .

NOTE. To order a product in our catalog means to reserve it at one of our retail outlets at the price at the time of order. Our managers will contact you to agree on a time and place for receiving your order that will be convenient for you. At the same time, you will receive professional advice on the operation of the chainsaw and safety precautions when working with it.

Typical breakdowns of Stihl chainsaws and electric saws

According to Servy statistics, the main faults are*

when working with chainsaws and electric saws Stihl are:

- The Stihl chainsaw does not start, there is no spark formation reasons: faulty spark plug, faulty ignition coil (magneto), damage to parts of the manual starter, clogged fuel system, wear of the cylinder-piston group;

- The Stihl chainsaw stalls, possible reasons: fuel system clogged (no fuel supply), wear of the cylinder-piston group, carburetor misaligned, air filter clogged;

- There is no rotation of the chainsaw chain, the main reasons are: wear of clutch parts (cams, springs, clutch cup), wear of the drive sprocket, wear of the bearing, chain tension is not adjusted;

- Oil is not supplied to the chainsaw chain, the main reasons: malfunction of the oil pump parts, the lubrication channels of the tire are clogged.

- The Shtil electric saw does not start - reasons: damage to the power cable, faulty power button, worn graphite brushes, faulty thermal protection relay, damage to the motor windings;

- There is no rotation of the Calm electric saw chain, the main reasons: wear of clutch parts (cams, springs, clutch cup), wear of the drive sprocket, wear of the bearing, chain tension is not adjusted;

- Oil is not supplied to the chain of the electric saw, the main reasons: malfunction of the oil pump parts, the lubrication channels of the tire are clogged.

These defects are typical of Stihl chainsaws: some are more common, others less common.

And they often occur due to the simplest reasons: improper operation (no maintenance), the use of a low-quality gasoline mixture (oil and gasoline) or power surges and surges, many hours of uninterrupted operation of the saw, cutting material that does not meet the technical specifications power of the chainsaw. However, with the right and professional approach, all breakdowns can be easily repaired by specialists from the Servy service center in Moscow. Just leave a request for repair of Stihl chainsaws and electric saws on the website or call us by phone - our Service Center specialists will answer any of your questions.

*Notes

• The exact timing of repairs is always indicated only after diagnosis. • Costs are for informational purposes only and may be changed after diagnostics of your equipment. We work with each client individually and a detailed calculation of the repair price is made in accordance with the level of complexity of the breakdown of a particular type of equipment. • Spare parts that we use in repairs are paid separately. • Calculation based on data from the “Servy” client database.

Description of the device and technical parameters

Shtil 180 has a standard configuration. However, like all modern chainsaws. Its components:

- Front and rear handle with anti-vibration system.

- Saw bar with chain.

- Two-stroke single-cylinder engine.

- Fuel and ignition systems.

- Housing made of high quality plastic.

Chainsaw Shtil 180, technical characteristics:

- A gasoline engine that runs on a mixture of fuel and oil in a ratio of 1:50. It has a power of 2 liters. With.

- The weight of the saw is approximately 4 kg.

- The saw is equipped with an easy start system.

- The capacity of the fuel and oil tanks is 250 and 140 ml, respectively.

- The saw bar is 14 inches (35 cm) long.

- Automatic chain lubrication.

How to disassemble, repair and assemble a Shtil chainsaw

To repair the device, it must first be disassembled. It is necessary to remove the side cover, saw chain and bar. Then clean the tool, blow it out with a compressor and clean all the components with a brush. Then remove the handle. To do this, remove the plugs from the shock absorbers using a screwdriver. After this, remove the shock absorbers and handle.

Then remove the starter. Remove the housing cover and unscrew the starter screws. Remove the part. Then remove the flywheel, unscrew the nut that holds it, and unscrew the flywheel nut. You need to turn left. Remove the flywheel. Then dismantle the clutch, oil pump drive and carburetor.

After this, the motor is removed and disassembled. It is held on by 4 screws on the bottom of the saw. You need to unscrew them and remove the motor. Then the engine itself is disassembled. Unscrew the crankcase screws and remove it. Then the crankshaft, seals, bearings and piston rings are dismantled. Upon completion of disassembly, repairs and troubleshooting are carried out.

After repair, the instrument will need to be put back together. To do this, install the piston on the connecting rod. The arrow on it should point along the chain, and to the left of the piston there will be the side of the crankshaft in which the flywheel needs to be mounted. Place the piston in the cylinder. Install the bearings, seals and retaining ring into the cylinder. After this, degrease the place where the crankcase is fixed and install it in its place. When reassembling, follow the reverse dismantling sequence.

How to remove the clutch

Before unscrewing the clutch, you need to remove the drive sprocket. Remove the corkscrew washer and remove the sprocket and needle bearing. Unscrew the clutch. Remove the reflector plate and pump.

How to remove and replace a sprocket

Replacing the sprocket on a chainsaw is necessary in cases where:

- jams chain movement;

- The drive sprocket has worn out.

To replace, you need to remove the chainsaw sprocket. The sprocket teeth must not deviate from the required dimensions, otherwise the operation of the saw will be accompanied by vibration, which will lead to damage to the crankshaft and bearings. The service life of the sprocket is 2 times longer than the working life of the chain. Use 2-3 chains until their cutting surface wears out. After this, change the sprocket. It is located behind the clutch. Remove the clutch assembly cover.

Remove the bar, chain and clutch. But first you need to fix the crankshaft. Then the puller is placed in the coupling hole and turned clockwise. Remove the coupling. Behind it is an asterisk. Now it is being dismantled. If it is faulty, it is replaced.

Oil pump repair and replacement

Let's look at how to change the oil pump. If the element leaks, the gasket between its two parts should be updated. If this part of the oil pump is not damaged, then it must be wiped and put back in place. Now check the hose. There should be no cracks on it. If the hose is damaged, it is replaced. Then they clean the outlet channels with a compressor.

Replacing the piston

Let's look at how to diagnose and replace the piston group. It is necessary to check the condition of the cylinder and the degree of wear of the piston. After dismantling the engine, unscrew the pan and remove the crankshaft and piston from the cylinder. Unscrew the piston pin stoppers. If the piston is faulty, it must be replaced. The retaining rings are fixed with the cut down. Before installing the piston group into the cylinder, lubricate the piston with oil. Before installing the crankcase, degrease its surface and apply sealant.

How to set the ignition

You need to turn on the ignition on the chainsaw. Ignition adjustment is carried out as follows:

- unscrew the spark plug and evaluate its appearance;

- specify the distance between the magnets and the coil (up to 0.2 mm);

- check the spark.

How to remove the pump

The oil pump is installed on the right side of the bottom of the body; in the same place, an oil line coming from the chainsaw tank approaches it. To remove the pump, you will first need to release the saw from the handle; for this purpose, the rear handle of the unit is unscrewed and the throttle control rod is disconnected. Next, you need to pull out the handle shock absorber plugs and, using a strong slotted screwdriver, squeeze them out of their seats on the handle.

Currently reading: Operating instructions for chainsaw Shtil ms 180

If the handle is removed, the chainsaw body turns upside down. The hose leading from the oil tank to the pump will be immediately visible. It needs to be pulled out of the landing site.

The pump itself is removed using an M5 threaded screw and a wide washer. The length of the screw can be approximately 45-50 mm. A washer is put on the screw and it is screwed into the pump (the inside of the pump has threads). Further, as the screw is screwed in, the stop from the washer will force the oil pump to rise along the thread. In this way the pump is removed from its landing site. Before work, we recommend reading the article on how to disassemble Shtil 180.

To better understand the process of removing the pump, see the video below. In the video, the service center master carefully indicates how to remove the oil pump from a chainsaw, and also outlines the main malfunctions of the complex of supply accounting programs.

The Shtil 180 oil pump is a very high-quality and reliable part, therefore it needs to be replaced only in the latter case, when our client has already tested other elements of the accounting software complex.

When the pump is removed, it needs to be cleaned and purged. Usually, the main failure of the oil pump is its blockage. Having eliminated it, a pump is installed in the area.

Replacing the pump is required only if it is prohibited to remove the blockage.

Prices for services

| Name of works | Price in rubles |

| Diagnostics (diagnostics are not paid for during repairs) | 600 rub. |

| Comprehensive maintenance (consumables and labor) | 1800 rub. |

| Engine overhaul | 1500 rub. |

| Cylinder replacement | 1500 rub. |

| Replacing the engine crankshaft | 1500 rub. |

| Replacing the piston | 1500 rub. |

| Replacing the piston ring | 1500 rub. |

| Flywheel replacement | 500 rub. |

| Replacing the flywheel key | 500 rub. |

| Replacing engine seals | 1500 rub. |

| Crankcase replacement | 500 – 900 rub. |

| Replacing the crankcase gasket | 500 – 900 rub. |

| Replacing the spark plug | 100 rub. |

| Carburetor replacement and adjustment | 500 rub. |

| Replacing the fuel tank | 500 – 1000 rub. |

| Replacing the fuel primer | 100 rub. |

| Replacing shock absorbers | 100 – 500 rub. |

| Replacing the drive sprocket | 500 rub. |

| Replacing the brake cover | 100 rub. |

| Replacing the brake spring | 100 rub. |

| Replacing the oil pump | 500 rub. |

| Replacing the oil line/filter | 500 rub. |

| Replacing the inlet pipe | 300 rub. |

| Replacing the chain tensioner | 200 rub. |

| Replacing the clutch | 500 rub. |

| Replacing the clutch spring | 500 rub. |

| Magneto replacement | 500 rub. |

| Replacing the fuel hose | 200 rub. |

| Replacing the fuel line/filter | 300 rub. |

| Replacing the trigger/throttle blocker | 500 rub. |

| Replacing the air filter | 100 rub. |

| Replacing the oil pump plunger (professional) | 500 rub. |

| Muffler replacement | 200 rub. |

| Replacing the recoil starter | 200 rub. |

| Replacing the starter spring | 500 rub. |

| Replacing the starter cord | 600 rub. |

| Replacing the pawl/spring | 300 rub. |

| Replacing the ignition switch | 200 rub. |

| Recoil starter repair | 500 – 1000 rub. |

| Carburetor repair | 600 – 2000 rub. |

| Carburetor adjustment | 500 rub. |

| Adjusting the throttle cable | 100 rub. |

| Cleaning the fuel system | 600 – 800 rub. |

| Cleaning the air filter | 200 rub. |

| Flushing the gas tank | 500 rub. |

Fuel Tank Check Valve

the main reasons why stihl 180 oil is not supplied.

So that as the fuel mixture is used up, the fuel tank is filled with air and negative pressure is not created in it, which will prevent fuel from flowing from it into the carburetor, and at the same time, so that fuel does not flow out of the air hole, in the cap covering the filler hole, breather made. And by the way, if the breather becomes clogged with dirt, the chainsaw will stall.

Currently reading: Why Chainsaw Shtil 180 Doesn't Start

Prices for Stihl chainsaw repairs

| Type of repair | Repair cost | |

| Collection and analysis | 600 rub. | Order repairs |

| Replacing the spark plug | 200 rub. | Order repairs |

| Replacing the air filter | 200 rub. | Order repairs |

| Cleaning the air filter | 200 rub. | Order repairs |

| Cleaning and adjusting the carburetor | 800 rub. | Order repairs |

| Replacing the carburetor | 300 rub. | Order repairs |

| Carburetor adjustment | 600 rub. | Order repairs |

| Starter repair | 600 rub. | Order repairs |

| Replacing the fuel filter | 200 rub. | Order repairs |

| Cleaning the fuel filter | 200 rub. | Order repairs |

| Replacing the on/off switch | 150 rub. | Order repairs |

| Replacing the needle bearing | 300 rub. | Order repairs |

| Change of oil | 160 rub. | Order repairs |

| Replacing the chain tensioner | 300 rub. | Order repairs |

| Replacing the CPG gasket | 800 rub. | Order repairs |

| Starter replacement | 600 rub. | Order repairs |

| Clutch replacement | 600 rub. | Order repairs |

| Replacing the fuel tank | 300 rub. | Order repairs |

| Chain replacement | 300 rub. | Order repairs |

| Replacing the CPG | 150 rub. | Order repairs |

| Replacing the clutch cup | 300 rub. | Order repairs |

| Muffler flushing | 500 rub. | Order repairs |

| Speed adjustment | 600 rub. | Order repairs |

| Chain tensioner mounting repair | 500 rub. | Order repairs |

| Cleaning and repairing the chain mechanism | 600 rub. | Order repairs |

| Cleaning carbon deposits | 300 rub. | Order repairs |

| Cleaning the saw | 300 rub. | Order repairs |

Didn't find what you were looking for?

Leave your phone number and find out the cost of repairs within 15 minutes!

By filling out the form and clicking on the “Submit” button, you consent to the processing of your personal data.

- About Us

- Delivery

- How it works?

- Helpful information

- Contacts

- Site Map

Copyright REMMARKET © 2012 — 2020

All rights reserved. The use of site materials is prohibited.

Submit a repair request

Enter your feedback information and our manager will clarify the cost, as well as the nearest possible date for repairing your instrument.

Please call back

Enter your feedback information and our manager will clarify the cost, as well as the nearest possible date for repairing your instrument.

Thank you!

Your application has been successfully sent. In the next 15 minutes, a manager will contact you and clarify the details of the order.