Necessary skills and tools for repair

Most of the malfunctions of gasoline chain saws can be fixed with your own hands. True, this requires an understanding of the structure of the chainsaw and how the components function among themselves. As for the tools, the most often needed are:

- screwdrivers (slotted and power);

- combination wrench included in the kit or regular wrenches with heads of various sizes.

How to repair a chainsaw with your own hands

Today, chainsaws have become the property of a wide range of consumers, although until recently they were considered exclusively a professional tool for a lumberjack. The secret lies in the fact that reliable and easy-to-maintain chainsaws have appeared on the market. To use and operate them, a basic knowledge of the operation of an internal combustion engine and a simple tool, which is usually included with the device, is sufficient. If the chainsaw does not start or refuses to function for other reasons, the master must be able to repair it with his own hands.

Engine

In most cases, the following problems occur in engine operation:

- the engine stopped starting;

- the engine starts, but after a while it stalls;

- the engine is not able to develop the required power;

- The engine is extremely unstable.

How to check crankshaft seals

The presence of oil seal leaks can only be checked by getting to the crankshaft itself and carefully examining it for leaks. You can see how to do this correctly in the video:

How to check compression on a chainsaw

At a compression level below 8 atmospheres, the engine will not have enough power, which means the chainsaw will not be able to fully function.

To measure compression you need:

- Remove the protective cover and unscrew the spark plug.

- Insert the tip of the compression gauge into the hole where the spark plug should be located.

- Using the starting cord, rotate the piston and remember the maximum readings of the measuring device.

How to properly install a piston on a chainsaw

The work of replacing the piston for most models of modern chainsaws is carried out according to the following algorithm:

- The top and side covers are removed.

- The candle is unscrewed.

- The stoppers are removed from the shock absorbers and the handle is disconnected from the body.

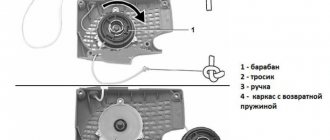

- The drive sprocket and starter are removed.

- A piston stopper is installed in the spark plug hole and the nut securing the flywheel and clutch is unscrewed.

- The flywheel, clutch, and worm drive of the oil pump, located immediately behind the clutch mechanism, are removed.

- The screws securing the carburetor and air filter are unscrewed, after which these components are removed along with the engine control lever.

- The ignition coil is removed, as well as the muffler.

- The saw is turned upside down and, by unscrewing the screws securing it to the body, the engine is disconnected.

- The pan is unscrewed and the piston is removed.

- Since the piston is removed only together with the crankshaft, to disconnect it it is necessary to remove the retaining rings.

- The old piston is replaced with a new one, but as carefully as possible. This is caused by the high fragility of compression rings.

- The crankcase is put in place, and sealant is used instead of a gasket.

All subsequent actions are carried out according to the reverse algorithm of disassembly.

Types of chainsaws

Chainsaws are classified into 3 main subtypes:

Maximum trunk diameter - 20 cm

The service life of semi-professional saws is twice as long as that of household models.

Only professional saws are used in forest felling

A one-handed saw is very convenient in gardening

Rod chainsaws are used for cutting and felling perennial and tall trees located in hard-to-reach places. For gardeners and summer residents, this type of saw is practically not applicable. But professionals who are involved in logging speak very positively.

Household and one-handed saws are often called loppers. The price of a one-handed instrument is closer to professional than to amateur ones.

The power of chainsaws varies from 1.5 to 7 kW. Moreover, the semi-professional level starts from 2 kW and ends at 2.5 kW. The service life is up to 1200 hours. For comparison, household chainsaws have a service life of approximately 500–600 hours. For professional ones - 2–2.5 thousand hours.

In addition to the main classification based on power and performance indicators, saws are distinguished by type and manufacturer.

The headset is the working part of the chainsaw, consisting of a bar, chain and sprocket. The difference between the headsets is in size and design.

The headset is the working part of the chainsaw

The length of the tire can vary from 30 cm to 105 cm for both household and professional machines. The longer the tire, the larger the diameter of the tree you can cut down. But you need to remember that installing a large bar on a low-power saw will not lead to the desired result. The chainsaw will work, but when it comes into contact with wood, the chain will “stick” and stop. Figuratively, this can be compared to a heavy truck on which an engine from a subcompact car was installed. The engine roars, but the cart is still there.

Owners of chainsaws need to remember that although the design of the tool is relatively simple, there is not much scope for amateur performances with it. The ratio of the headset length, engine power and saw weight is calculated theoretically and tested in practice. Experiments to change them end, at best, in the breakdown of the instrument. At worst - severe injuries and mutilations.

Fuel system

Malfunctions of the fuel system are also quite often the main reason that prevents a chainsaw from working as efficiently as possible. First of all, you need to check the quality of the fuel mixture.

Some owners prefer to use alcohol-containing solutions rather than the recommended brand of gasoline, or add more oil than required.

Gasoline leaks from a chainsaw

If gasoline drops periodically appear on the body of the chainsaw, then it is necessary to check the tightness of the fuel tank. Over time, it may dry out. Or the gasket has become “stiff” and it can no longer perform its direct function.

If full-fledged gasoline streams appear, then there is a high probability that you will have to change the burst hose connecting the carburetor and the fuel tank.

Gasoline does not enter the chainsaw cylinder

There are several reasons why the fuel mixture stopped flowing into the cylinder:

- The air filter is clogged.

- The carburetor settings have been lost.

- The carburetor membrane is no longer intact.

- The channels through which gasoline is transported are clogged.

Chainsaw won't idle

In this case, you should start looking for a problem with the filter elements. For the most part, it is precisely because of the reduced capacity of the air and gasoline filters that the idle speed begins to “float”.

If everything is in order with the filters, then you need to check the components of the gas supply system, and also make sure that there are no spontaneous changes in the carburetor settings.

What is required to repair problems yourself

For successful and long-term operation of any equipment, it is necessary to understand the structure of the main components and mechanisms. And also know the operating rules.

It is not recommended to start repairs without familiarizing yourself with the technical side of the matter, as this can only aggravate the problems and lead, in the future, to even bigger problems.

If the reader is familiar with the structure of a chainsaw, he can safely skip this section and go straight to the next one, which describes the main types of breakdowns and how to fix them.

Video: disassembling the Shtil 180 chainsaw

For those who are holding a non-working saw in their hands for the first time, we present a brief, summary summary of the structure of a chainsaw.

The power unit driving the cutting chain is a single-cylinder, two-stroke, air-cooled internal combustion gasoline engine. The engine is controlled by adjusting the amount of gasoline supplied to the combustion chamber, as well as its quality composition. The control is a carburetor throttle valve connected to a button on the handle.

Location of chainsaw controls

Its operation is ensured by a fuel supply system consisting of:

The gas tank consists of a housing, a lid and an extended hose with a breather

The throttle valve regulates the quality of the injected fuel mixture

The ignition system consists of magnets built into the engine flywheel, an ignition module with electronic circuitry, and a spark plug. A high voltage wire is installed between the electronic unit, in which electrical impulses are induced, and the spark plug.

2-plug terminal, 4-electronic unit, 5-flywheel

Air enters the carburetor through the air filter.

The air is purified by passing through dense synthetic fabric

Exhaust gases are removed through a muffler.

A metal gasket is installed under the muffler

There is no engine lubrication system. To prevent the cylinder walls, piston and crank mechanism from wearing out during operation, a special synthetic lubricant is added to gasoline (in a ratio of 1/50).

Motor oil for two-stroke engines

A fast-rotating chain needs lubrication. For this purpose, an oil supply system is provided for the chain movement channel. A pump located at the base of the drive sprocket forces lubricant from the oil tank. There are two types: piston or membrane. Some models are equipped with manual oil supply adjustment.

The crankshaft clutch with the chain drive is automatic. The sprocket begins to rotate as the engine speed increases. Thanks to this, the operation of the chainsaw has become much safer - when the chain gets jammed in the wood, the clutch immediately opens automatically.

Video: chainsaw device

Modern tools are equipped with additional systems that increase user productivity and safety. These include:

Filter

A “rich” or “lean” fuel mixture will sooner or later cause a breakdown. Perhaps even expensive. To prevent this from happening, it would be a good idea to regularly check the filter for abrasions, as well as for breaks in the filter fabric itself.

How to check the fuel filter and replace it

To check the current condition of the fuel filter, you must perform the following steps:

- Remove the fuel hose from the carburetor fitting and direct it into a working container.

- Press the so-called “paging” button several times.

If gasoline flows unevenly and jerkily, then it’s time to install a new filter element. This is done quite simply:

- The fuel tank cap is unscrewed.

- Using tweezers or any other device, the filter itself is removed.

- After disconnecting the old filter, you need to install a new one and lower it into the fuel tank.

How to clean the air filter

If a sufficient amount of air is not supplied, the fuel mixture becomes too rich, which leads to disruption of normal engine operation. Regular purging of the air filter, and in particularly advanced cases, washing in a soapy solution will help avoid such problems.

Please note that washing in acetone, gasoline or other aggressive solutions is not allowed. This may lead to damage to the integrity of the filter element.

Malfunction of unspecified category

In some cases, owners of chainsaws have to solve more complex problems to fully restore the functionality of their cutting tool.

The chainsaw does not develop full power

In addition to the problem discussed above with a lack of gasoline or air entering the cylinder, the cause of low power may be a clogged muffler.

If you do not periodically clean the muffler clogged with combustion products, then the problem of poor engine power may not be the only one.

Carburetor depressurization and nozzle blockage

Over time, the screws holding the carburetor cover in place can become loose or the gaskets can become unusable. A clogged filter or improper replacement can lead to clogged injectors. All this also negatively affects the operation of the chainsaw and shortens its service life.

To prevent this, it is enough to periodically inspect the saw and, if necessary, evenly tighten the screws.

Chainsaw won't idle

It often happens that after long-term transportation and constant use, a chainsaw refuses to idle smoothly. As a rule, this problem is eliminated by adjusting the carburetor.

You can learn how to properly debug the carburetor from this video:

If the carburetor is tuned like a clock, then you need to check:

- Fuel system. It makes more sense to start with the fuel pump.

- Muffler. There is a high probability that due to the abundance of accumulated soot, the engine cannot function normally.

Chainsaw loses power under load

If during operation the power of the saw disappears somewhere, then the problem should be looked for in the following places:

- In the muffler. It, as you already understood, tends to get clogged.

- In a clogged fuel filter.

- A poorly functioning fuel pump.

Chainsaw Forward Doesn't Idle

The main malfunctions of chainsaws and their repair in artisanal conditions

A chainsaw is a worthy replacement for hand saws and axes. Now this popular rumor tool is found in almost every household - it is indispensable when arranging a summer cottage, construction and repair work. Severe use and improper care of equipment lead to its premature failure. But the owner of a chainsaw does not necessarily have to immediately go to a workshop - probably because of defects that may happen to it during operation

, really remove it without the help of others.

Content

Chainsaw design and general classification of faults

The main condition for successful repair is correct diagnosis. Because in order to find out why the chainsaw failed and, most importantly, how to make it work again, you first need to know the features of its design.

It should be noted that it is not particularly complex, as it includes:

- engine (two-stroke petrol);

- multifunctional part (saw bar and chain);

- a set of accounting programs that ensure the joint operation of these two components (ignition, filtration, lubrication, etc.), in other words, the entire tool.

In order to simplify the diagnosis of faults, they are usually divided into two main categories:

- motor malfunction;

- malfunctions of other chainsaw components.

For the most part, failures occur in motor systems, but other parts of the tool, due to intensive use or improper care, may always fail. How to find where exactly the breakdown occurred? Ordinary logic will help us solve this issue.

If the problem is in the engine, it will:

- won't start;

- stall;

- work unstably;

- overheat;

- smoke;

- develop insufficient power.

As for all other defects, they manifest themselves with a normally running engine.

Starting the engine: checking the spark plugs

If the chainsaw does not start, the first thing you need to do is check the presence of a fuel mixture

. By the way, it must be prepared in the proportions specified by the engine manufacturer, otherwise the tool simply will not start.

After making sure that the fuel mixture is correct and available, you should check the ignition system. To do this, you need to inspect the spark plug.

READ How to Start a Chainsaw After a Long Idle Time

Her condition can say a lot:

indicates that the fuel mixture does not enter the carburetor, which means the problem is not in the ignition;

- fuel-spattered candle

is the result of an excess of the fuel mixture, which lies either in a violation of the engine starting algorithm or in incorrect carburetor adjustment;

This is a signal about the presence of low-quality oil in the engine lubrication system, incorrect carburetor settings, or an incorrectly prepared fuel mixture.

If the spark plug is splashed with fuel, it must be thoroughly wiped after removal. The fuel supply system should also be cleaned. To do this, it is closed, after which the starter is turned on. A candle covered with soot must be carefully cleaned using an awl and sandpaper.

When checking spark plugs, you should pay attention to the distance between the electrodes (the normal gap is 0.5-0.65 mm), as well as the condition of the gasket and the presence of a spark. A damaged or worn gasket will need to be replaced, and the spark can be checked by putting on the ignition cable, connecting the cylinder and spark plug nut, and turning the starter.

If the discharge does not occur, the spark plug needs to be replaced. If a spark does not appear even with a new spark plug, then the problem is in the connection to the high-voltage wire or in it itself.

DIY chainsaw repair: fuel supply system

If the fuel mixture does not enter the cylinder, but the spark plug works normally, this may mean that:

- The fuel filter is clogged.

To clean this unit, remove the fuel hose and check the flow. If it is weak, the filter must be removed through the filler hole of the fuel tank and cleaned or replaced if completely worn out.

What to do if the chainsaw does not idle?

In this video you will learn one of the breakdowns in which the chainsaw does not work

at low speeds and start.

Adjusting the idle speed of the chainsaw

Article: Buy a chainsaw

: .

As a preventative measure, it is recommended to replace the fuel filter at least once every 3 months.

This is nothing more than a hole in the fuel tank cap, which is cleaned with an awl.

- The fuel mixture is not supplied or is supplied in insufficient quantities.

There may be several reasons for this:

- the air filter is clogged (in this case, it must be removed, washed with water, dried and replaced);

- the carburetor settings have gone wrong (which means this unit needs to be adjusted again);

- the integrity of the carburetor membrane is damaged (must be replaced);

- the carburetor channels are clogged (it must be disassembled and all parts and components cleaned).

READ Fuel Mixture For Shtil Chainsaw

Troubleshooting muffler problems

If the chainsaw engine operates normally at low speeds, but starts to stall and smoke at high speeds, the problem may be hidden in the muffler.

To check the quality of its work you should do the following:

- dismantling (with mandatory closing of the outlet);

- disassembly (if the muffler is dismountable);

- cleaning from carbon deposits using special detergents or the dry method;

- drying (using a hair dryer);

- reassembly and installation.

Dry cleaning without respiratory protection is not recommended. Carcinogens present in carbon deposits will be released into the surrounding atmosphere in the form of dust, the inhalation of which is extremely dangerous to health.

To prevent clogging of the muffler during operation of the chainsaw, you should carefully monitor the composition of the fuel mixture and the quality of its components.

Repair of cylinder-piston group (CPG)

If the chainsaw engine does not start or cannot develop normal power, it is likely that there is not enough pressure in the engine cylinder to burn the fuel mixture. The reason for this may be wear of the elements of the cylinder-piston group - piston, rings, bearings, etc. In order to assess the condition of this unit, it should be visually inspected after first removing the muffler.

For a more complete diagnosis, a compression gauge is placed in the spark plug hole of a two-stroke chainsaw engine. It is used to measure compression in the engine. Based on the test results, one can judge the condition of the CPG, but accurate facts can only be obtained by completely disassembling the unit.

If the piston is chipped or scratched, it will obviously have to be replaced. The same applies to deformed or broken piston rings - for normal engine operation they must be fully functional and free of carbon deposits.

Checking the carburetor and signs that it needs adjustment

A correctly functioning carburetor guarantees maximum efficiency of the chainsaw, that is, it is possible to develop full power with the most economical consumption of the fuel mixture. Adjustment of this unit is usually carried out by the manufacturer, but its design provides for the possibility of adjustment during operation.

The fact that such adjustment will have to be made by the owner of the chainsaw is evidenced by:

- Strong vibrations or damage to the protective cap.

- CPG wear.

- Carburetor clogged.

- Inability to start the engine or its spontaneous stopping after starting.

- Increased fuel consumption and exhaust emissions with a simultaneous decrease in engine power.

READ M8 oil for chainsaw chain lubrication

The chainsaw carburetor is adjusted in strict accordance with the manufacturer’s instructions using three special screws, which are responsible for the maximum (“M”) and minimum (“L”) speeds, as well as engine idle speed (“T”). In order to exclude unwanted interference by an inexperienced user in the operation of the carburetor, some manufacturers install only one idle screw.

Calibration algorithm and safety precautions when troubleshooting a chainsaw carburetor

Carburetor adjustment is performed in two stages:

- Basic (carried out with the engine off).

- Finish (carried out with the engine running, preheated).

For basic adjustment, screw screws H and L until they stop and turn them back 1.5 turns. Final adjustment requires that the engine be warmed up for 5-10 minutes at low speed .

The final calibration is performed by turning out the idle screw until the minimum engine speed is reached (its operation must be stable and the chain must be motionless). If the engine stops idling, the screw must be returned back, and if the saw chain still moves, you should continue turning it counterclockwise.

Calibration check is performed by test:

- Acceleration (when you gently press the accelerator, the engine should quickly gain speed to its maximum).

- Maximum speed (if there are misfires, screw H should be loosened slightly).

- Idling (the chain should not move, and the engine should pick up speed as quickly as possible).

If the owner of the chainsaw is not familiar with the carburetor structure and does not have the necessary tools to calibrate it, you should contact a specialist. A carburetor is a very complex unit, so any incorrect action can lead to irreversible consequences, such as complete engine failure.

Other chainsaw malfunctions

If the diagnostics showed that everything is in order with the engine and its systems, then the cause of the malfunction should be sought in other components of the chainsaw. The most common problems are:

- starter failure;

- improper operation of the lubrication system;

- incorrect operation of the chain brake;

- saw chain wear, etc.

Source

Malfunction of other systems

In some cases, chainsaw users report other problems that do not significantly affect the operation of the tool.

Why does a chainsaw smoke?

Most often, excessive smoke appears when oil is added excessively to the fuel mixture, which does not have time to burn completely. You should also check to see if the carburetor settings have gone wrong.

Recoil when starting a chainsaw

In most cases, recoil at the moment of startup signals the decompressor clamping. If the tool is not equipped with a decompressor, then most likely the ignition system is faulty.

Possible malfunctions of the chainsaw, in which cases the device does not start

Let's look at common chainsaw breakdowns.

Ignition system

Typical signs of a malfunctioning ignition system are:

Checking and diagnosing the ignition system usually begins by inspecting the spark plug. If the unscrewed spark plug is “wet” and clearly filled with gasoline, most likely the carburetor is adjusted incorrectly and supplies a mixture that is too rich into the combustion chamber. If the spark plug is dry, this indicates that there is no fuel inside the cylinder; the reason for this should not be sought in the ignition system.

Heating a candle over a fire destroys the ceramic insulator

You can check the operation of the spark plug in a simple way, as all car enthusiasts do. After wiping the case and contacts from excess moisture, connect it to the high voltage wire. With one hand they pull the starter cable, and with the other they hold the spark plug on the metal body. If a spark jumps at certain intervals, it means the spark plug is working. A blue spark is considered “correct”; a red spark (with a red tint) indicates a possible problem in the electronic unit - low voltage.