What can be made from a chainsaw

Homemade chainsaws belong to a very wide class of devices. This is a hand-held tool with a motor drive, such as:

- Bulgarian;

- motor drill;

- cultivator;

- snow blower;

- stationary machines and devices: sawmill;

- electric generator;

- motor pump;

- snowmobile;

And these are probably not all the possible homemade chainsaws.

What kind of homemade products can be made from the Druzhba chainsaw and other devices?

Even without the use of additional parts, the chainsaw is capable of performing a wide range of tasks. If you purchase additional attachments for the classic design, you will be able to expand the possibilities of using the device on the farm and get the following devices:

You can purchase special attachments for a chainsaw or make the necessary tool using it.

- snow blower;

- brush cutter;

- pump for pumping water;

- petrol cutter;

- decanter.

Some craftsmen, armed with basic knowledge of mechanics, create additional accessories for chainsaws with their own hands, which can significantly expand the scope of use of the tool. To remake it, you need to understand the operating principle of a universal motor drive, which is easy to use for the manufacture of other devices. Thus, taking a motor from a chainsaw, you can create the following devices:

- ice drill or drill hole;

- boat engine;

- a car or bicycle with a motor;

- lawnmower;

- generator.

The reason for the popularity of homemade chainsaws “Druzhba-4”, “Shtil” or “Ural” is a large number of advantages:

- powerful engine;

- light weight and compact dimensions;

- Possibility of use in extreme conditions.

As a rule, homemade products are made from chainsaws “Ural”, “Druzhba”, “Shtil”

Rework principle

The principle of alteration is very simple and combines the entire range of home-made devices and assemblies. A chainsaw is used as a drive. The unique qualities of the chainsaw motor, capable of operating at very large tilt angles, perhaps not upside down, allows this universal drive to be used in many designs. In the case of using a chainsaw as a drive for a homemade hand-held power tool, most of the parts of the original chainsaw are retained, and only the working part is changed.

Walk-behind tractor from a chainsaw

If, on the basis of a chainsaw, you make a stationary machine or vehicle with your own hands, the alteration becomes deeper. A gearbox, variator or belt drive is added to the design, the fuel tank is replaced with a more capacious one to ensure long-term operation without refueling.

Useful items from a chainsaw

Here everything depends on the imagination of the master . From a chainsaw you can make:

- snowmobile;

- motorized towing vehicle;

- motorbike (moped);

- motor cultivator;

- lawnmower;

- motor drill;

- outboard motor;

- snow blower

A snowmobile is very simply made on the basis of a small bicycle.

A ski is placed at the front, and a pair of ultra-low pressure wheels are placed at the rear on a solid axle. This homemade saw “Druzhba” or “Ural” will run quite briskly on ice or compacted snow. For deeper, loose snow, this model of snowmobile is unsuitable; the power of the saw engine is not enough. A snowmobile that uses a caterpillar as a propulsion device is more versatile. The simplest caterpillar is assembled from a conveyor belt. The role of hooks is performed by flat wooden slats attached to the tape. Because of this, such snowmobiles are traditionally called “stick insects.”

The same principle is used in the construction of motorized towing vehicles (motorized dogs). This option is even preferable to a regular snowmobile, since this homemade Ural chainsaw allows you to move even on loose snow. In addition to the engine, a motorized towing vehicle or snowmobile must be equipped with a gearbox to reduce the speed while simultaneously increasing the torque.

The easiest way to make a bicycle with a chainsaw motor is to make it yourself. Any frame bike will do this. The throttle control cable is routed to the steering wheel. Chainsaw and bicycle chains have the same links, so no special gears are required. Torque can be directly transmitted to the rear wheel of the bicycle. You just need to put a sprocket with an increased number of teeth on the rear wheel to increase the gear ratio and increase power. At the same time, the speed will drop. This is good because a regular bicycle is not designed to ride at speeds greater than 20 kilometers per hour.

A motor cultivator can also be made using a chainsaw as a drive. However, the power of a walk-behind tractor made from a chainsaw is low, and it is not widely used in agriculture. It is unrealistic to plow virgin soil with such a device, but digging furrows for planting potatoes is quite possible.

The lawnmower is also quite easy to assemble. The basis is a conventional four-wheeled hand cart. A chainsaw engine is mounted on top of it. The torque is transmitted to a rigid shaft, the second end of which is brought out under the bottom of the cart. There, either a metal knife or a block with fishing line from a trimmer is attached to it.

To make a motorized drill, you will need a small worm gear and an auger from a fishing ice drill. With this device you can easily drill a large number of holes on the river in winter. If you plan to use the drill to drill holes in the ground, the auger and nozzle will have to be strengthened.

To build a homemade boat motor from a chainsaw, you do not need a gearbox. You just need to weld a frame with two clamps for mounting on the transom of the boat and install the propeller on the shaft. Those who have made homemade products from a trimmer with their own hands can easily make a boat motor from a chainsaw.

You can construct a simple snow blower from a chainsaw. To do this, you need to install the saw on the runners of the sled and add a homemade auger assembly. A guide for folding snow can be made from a regular sewer pipe.

The power unit from the saw can even be installed on a scooter.

Transport

Based on a chainsaw engine, you can make many homemade vehicles. It is important to remember that transport is a means of increased danger and the author and owner of the homemade product bears full responsibility for its safety.

Snowmobile

Structurally, a snowmobile is one of the most complex homemade products. The following components will need to be made:

- Support frame.

- Frame.

- Caterpillar.

- Front ski.

- Steering wheel with controls - gas and clutch handles.

- Suspension.

- Transmission.

The supporting frame is welded from a square steel profile 20*20 or 20*30, it is necessary to provide a swing arm for the shock-absorbing rear suspension and install a motorcycle-type steering fork for the front. There are options with two skis - here the design of the front suspension will be more complicated - the steering wheel will not turn the axis of the ski, but pull the levers to control the steering linkage. This option is more difficult to manufacture, but guarantees better controllability and stability. For a snowmobile, a centrifugal clutch with a V-belt and chain is suitable. To increase the traction force, a gear is installed on the working shaft of the caterpillar, which is larger in diameter than the drive gear on the chainsaw shaft. For the caterpillar, you can take ready-made drawings from a light snowmobile with an engine of the same power as a chainsaw.

In order for a homemade product to confidently carry one or two people, the engine power must be at least five horsepower.

Snowmobile

A snowmobile is much simpler in design than a snowmobile; according to the principle of its operation, it resembles a small propeller-driven airplane moving on the ground. The load capacity, maneuverability and stability will be noticeably lower than that of a snowmobile with equal engine power. The advantage will be simplicity of design, greater reliability and greater speed in open spaces. The pusher type screw is installed in the protective casing of their mesh behind the driver's back and pushes the device forward. The device is controlled by turning the ski, the gas lever and the snow brake.

Homemade snowmobiles

In order to properly accelerate a homemade snowmobile or drive not only on the smooth ice of a frozen river, but through fields and small snowdrifts, you will need a chainsaw engine with a power of at least 10 horsepower.

Moped

A homemade summer vehicle with a chainsaw engine is unlikely to compete with industrial designs. Home craftsmen often assemble it as a test of their strength or as a training session before more serious designs. In addition to the chainsaw, you will need an old bicycle, or at least the main components from it, including bearings. Craftsmen weld the frame themselves from pipes or square profiles. It looks scary, but it is reliable. The drive is carried out to the rear axle by a bicycle chain.

The most advanced home craftsmen use a mountain bike with high-quality brakes and shock-absorbed suspension as a basis. A gearbox with a gear ratio of 1:15-1:20 and a variator are added to the chainsaw. With such a homemade product you can already travel quite comfortably at speeds of up to 30 km/h.

Homemade kart based on a chainsaw

What else can be made from a Ural or Druzhba saw? For example, a go-kart is a maximally simplified car model designed specifically for circuit racing. It is devoid of a body, shock absorbers, and sometimes even brakes - everything is done to make the design as light as possible to increase speed. The homemade kart frame is made from profiles or steel pipes. DIY wheels are often taken from industrial carts for transporting small loads. The drive is carried out to the rear axle by a bicycle chain, the steering linkage is taken from a minicar. To assemble the card you will need intermediate level metalworking and welding skills. It is better to take ready-made drawings as a basis and adhere to their basic parameters - although karting is considered a “children’s” sport, the speeds developed are quite adult, and you can seriously injure yourself.

Using a similar scheme, based on a chainsaw motor, craftsmen assemble the kart’s older brother, the buggy. This carriage has a reinforced suspension with large strokes and is designed for racing over rough terrain. The homemade center of gravity is located low to improve stability; the driver and passenger seats on top are protected by a powerful roll bar. The process of making a children's ATV will also be very similar.

Homemade scooter with a chainsaw motor

Despite the fact that this device looks like a children's toy, it can be a serious help to a postman or courier. Even though the scooter's maximum speed is low, 10-15 km/h, it has excellent maneuverability and incomparable efficiency. If the working day consists of many short trips from point to point, you couldn’t ask for a better option.

DIY scooter

Almost the entire structure of the chainsaw is preserved; you only need to remove the bar and the saw chain, replacing it with a bicycle chain that transmits torque to the rear wheel of the homemade scooter.

boat motor

Homemade boat motors first appeared in Southeast Asia after the Second World War. Poor fishermen and peasants built their own wooden boats, but they could not afford to buy a factory-made boat motor. Chainsaws were quite affordable. Without further ado, they put a bamboo stick on the saw shaft, secured it with a wooden cotter pin and, leaning it on a sawhorse with two oarlock pins, lowered it into the water from the stern at a slight angle. A screw cut out of wood was attached to the lower end of the pipe so that it was under water. The entire structure required only bamboo trunks and ropes, and it was assembled in a couple of hours. As the bamboo shaft and crossbar of the trestle wore out, they were replaced with new ones. Such a boat was steered by simply turning the pole behind the engine in the desired direction. The simplest version of a homemade boat motor will repeat the Indo-Chinese design, with the difference that instead of a pole, a steel pipe is taken, a screw from an old boat motor, and the goats are welded from a corner and equipped with a thrust bearing on a rotary support.

Boat motor made from a chainsaw

A more advanced version uses a vertical propeller shaft and a sealed gearbox that changes the direction of rotation by 90 ⁰. A bearing with a device for lifting the propeller shaft and a control handle, to which the gas regulator is connected, are placed under the engine. The propeller is also selected from a boat motor. This option repeats the kinematic diagram of a factory-made outboard motor. It is capable of ensuring that a small boat travels at a modest speed over a considerable distance with enviable efficiency. It is important, however, to remember that not all saws are designed for long-term continuous operation, so you need to monitor the thermal conditions of the motor and periodically let it cool down.

Moped from a chainsaw Ural

Hello tinkerers, today we will look at how to connect a chainsaw to a bicycle, resulting in a moped. The author used a rather old but powerful chainsaw, this is the notorious Ural chainsaw. The author rebuilt the bicycle, made a safe frame, and also replaced the wheel spokes with stronger, reinforced ones. The homemade product is quite simple to assemble, we need to make a bicycle gearbox from bicycle parts and install everything on the bicycle. According to the author, the homemade product pulls excellently; as for the maximum speed, this remains unknown. If you are interested in the project, I suggest you study it in more detail!

List of materials:

— Ural chainsaw;— two driven and one drive sprocket from a bicycle;— a carriage with an axle and connecting rods;— a bicycle chain;— a throttle handle and a cable;— chain tensioners for a bicycle;— a pulley, a spring (for the tensioner);— profile pipes;—iron plates.

Homemade manufacturing process:

Step one. Gearbox

The working shaft of the chainsaw engine develops huge speeds, but we don’t need them, they need to be turned into lower speeds with high torque. We assemble the gearbox from a bicycle carriage, cut off the excess parts of the frame, and also cut off the connecting rods. Next we need a small sprocket from the rear wheel; it needs to be welded to the part of the axle where there is no sprocket. That's all, after this the gearbox will be ready.

To connect the saw to the gearbox, you will need another small bicycle sprocket; it needs to be welded to the chainsaw sprocket. We attach the gearbox to the body of the chainsaw, weld it to the persistent spikes of the saw, and also additionally strengthen everything with iron rods or other parts. We install the chain on the gearbox, start it, and check that the chain does not fly off. If the sprockets are welded too crookedly, the chain is likely to fly off frequently.

Later, the author will install a gear chain tensioner; a machine from a multi-speed bicycle was used.

Important The most popular models of compact American Bobcat loaders

Step two. Driven sprocket

We will need a large diameter driven sprocket to obtain high torque. A drive sprocket from a bicycle will do; cut off the connecting rod from it. The author welds this sprocket to the part of the wheel where the foot brake lever is attached. As a result, our bicycle design remains almost unchanged; you can ride it either by pedal or with the help of an engine. And if the motor power is not enough, you can always help with your feet.

Step three. Engine Installation

Let's start installing the engine, and we will install it on the rear trunk. Of course, one trunk cannot cope with the assigned loads, so we additionally strengthen the structure with profile pipes.

We install a chain on the bicycle that connects the gasoline engine and the rear wheel. Here the author had a problem, since the sprockets were welded crookedly, the chain kept falling off, and the chain turned out to be long. To solve the problem, the author made two dampers in the form of pieces of profile pipe. A chain tensioner was also made from a pulley from a generator, a profile pipe and a spring. After that the chain stopped falling off.

The author's engine is modernized; a carburetor from a scooter is installed on it. Thanks to this carburetor, the engine starts easier and runs faster. Once the engine installation is complete, you will need to install the gas tank in a convenient location.

Step four. Throttle grip

We install a throttle grip on the steering wheel, the kind you can buy in a store that sells spare parts for motorcycles. We run the cable along the frame and connect it to the carburetor throttle. After this, the homemade product is ready, you can test it.

The author tests the bike on himself, the author helps to move off with pedals, but in general the moped accelerates well. The only thing that remains unclear is how the author plans to brake, because instead of a brake lever we now have a driven moped sprocket. Hand brakes must be installed on mopeds.

This homemade product is ready, I hope you liked the project and found useful thoughts for yourself. Good luck and creative inspiration if you decide to do this again. Don't forget to share your ideas and crafts with us!

Chainsaw for aircraft

Having conquered land and water, the inventors turned their gaze to the sky. The media is full of reports that another inventor has taken off from the ground on a homemade gyroplane or a homemade backpack helicopter with a chainsaw engine. In Australia, there is even a prize for a pilot who manages to fly one mile. However, aerodynamic calculations showed that the engine power is clearly insufficient to lift a 100 kg load off the ground and achieve confident, controlled flight. Four 5 horsepower motors operating synchronously can theoretically cope with this task. The question is synchronization and configuration of the control system.

With the development of quadcopters, there was a chance to adapt their control system to a homemade helicopter.

Technology on the verge of fantasy

For a long time in the Soviet Union there was a story about a prisoner who was able to fly out of the zone in a homemade helicopter made from a chainsaw . In fact, this is just a beautiful legend, although it also has real scientific developments.

In 1971, a group of students from the Moscow Aviation Institute presented a new unusual development to the academic council. It was a flying single-seat platform with eight engines from the Druzhba chainsaw , synchronized in one block. Prototypes of these developments have been repeatedly shown at various exhibitions. Despite this, such models were never produced commercially.

The dream of heaven for those who like to construct something from chainsaws remains a dream for now. However, attempts to make a backpack single-seat helicopter using engines from the Ural or Druzhba do not stop.

Originally posted 2018-07-04 07:16:12.

snow blower

If in the previous design you replace the shaft with plowshares or harrow spokes with an auger mechanism, add a casing, an intake device and a pipe for throwing out snow, the cultivator will turn out to be quite a decent snow blower. Many home craftsmen design their homemade products with replaceable attachments for different seasons. Motor from a Shtil saw with a power of 3-5 hp. It will cope quite well with cultivating the garden in spring and autumn, and with removing loose snow from a summer cottage in winter. The most important unit is the screw mechanism.

Homemade snow blower

If you are not a professional designer, then it is better to download ready-made drawings from the Internet. The auger blades are made of thick rubber, for example, from a conveyor belt. The intake device is made of galvanized steel. A plastic sewer pipe is suitable for the snow disposal pipe.

Motor drill

During the construction season, a motorized drill made from a chainsaw will do an excellent job of digging holes for posts or screwing in screw piles, and in winter it will delight ice fishing enthusiasts. The design of a homemade motor drill will require a speed reduction gearbox, since piles should be drilled and screwed at a speed of 30-60 revolutions per minute. It is better to take the auger from a ready-made motor drill made of good steel. An auger for a hand drill or a homemade one made of simple structural steel will not last long with active use.

Motorcycle made from chainsaws

This Dolmette chainsaw bike was built a while ago, but I've never seen any build information. What a wonderful design!

The combined power of 24 engines from DOLMAR chainsaws is transmitted to a five-speed Harley Davidson transmission using a set of twelve timing belts. For use in the Dolmette, the motors were tuned and tuned to provide 5.2 kW (7.1 metric hp) power at 10,000 rpm. The maximum torque is 5.5 newtons per meter at 7,750 rpm. When all 24 engines are put together, the result is a 24-cylinder unit with a total displacement of 1.9 liters, a power output of 125 kW (170 metric hp) and a torque at the centrifugal clutches of 130 newton per meter. The twelve motors are mounted in two rows of six on each side of the drive belt housing. Each motor is held in place by threaded rods, which are typically used to secure the bar to the power head of the chainsaw. The individual motors are held together in sets of three via double-sided drive belts, creating eight modules. The individual motors are not rigidly connected - instead they transmit torque through a centrifugal clutch, which is a standard part of every chainsaw.

The device of a grinder from a chainsaw

In reports about the work of rescuers, everyone saw how the building structures of destroyed houses or a crumpled car after an accident were cut with a hand-held device that produced beautiful sparks. A lightweight version of a professional device can be made by any home craftsman. In weight and dimensions it will significantly exceed the well-known electric angle grinder, or grinder. However, the homemade product is independent of power supply, and the engine power allows the use of cutting wheels with a diameter of 30 cm. Such a mobile device will allow you to cut and clean metal structures before welding or painting, treat the surface of wood and stone, and even cut concrete blocks along with reinforcement. The device will require welding a small frame on which the engine and the working shaft bearing will be mounted. The torque is transmitted to the working shaft pulley by a short belt, and at the other end of the shaft it is necessary to attach a mandrel for grinding wheels or a clamping device of sufficient diameter from an old grinder.

It is important to remember that when working with a homemade grinder, you must use personal protective equipment: goggles or a transparent shield, thick overalls, durable shoes and protective gloves.

How to make a moped from a chainsaw?

The youth dream of most of our fellow citizens was and remains a moped. It develops a higher speed and has a structure that is more advanced than the motorbike described above. Buying a ready-made moped is not a cheap pleasure. We will tell you how to make it from scrap materials.

For this you will need:

- a motor from a working, powerful saw (in our version, this is the “Friendship” model);

- 2 wheels from an old bicycle;

- pipe with a diameter of 2 cm (metal);

- cable;

- bicycle sprockets; as well as forks;

- old spare parts from a motorcycle - a ready-made fuel tank, a headlight, and, if desired, a seat, although this can also be made with your own hands;

- steering part;

- gas lever.

The process of creating a moped looks like this:

- we cook the frame to which we connect the wheels from the bicycle, forks, as well as a gas tank and a lantern;

- we adapt the motor - the composition of the installation will depend on the configuration of the frame;

- screw on the gas tank and battery;

- we check that the newly installed elements do not dangle;

- We make a chain drive - it will allow the wheels to receive the torque of the motor and move. You can use a belt instead of a chain pulley. But we must not forget that its wear will be noticeably higher;

- we set up the ignition system - we connect the battery and brake lever to it;

- adjust the exhaust pipe.

Important How to diagnose KamAZ-6520 Euro-4 “diseases” and what error codes exist

The assembly process is complete: you can start testing the moped.

Winch

A homemade winch will be an excellent help in construction and lifting loads to a height, dragging a cut tree, rescuing a car stuck in a puddle, or pulling a boat out of the water. The thrust of such a homemade winch depends on the engine power and the gear ratio, and can reach one and a half tons. For specific applications, the unit is equipped with additional components: blocks, pulleys, hooks, sling belts and anchors for attachment to the ground or to a tree. To make a winch from a chainsaw with your own hands, you will need to weld a strong frame on which to place the engine, gearbox and drum with a stopper. The frame is provided with holes and lugs for various methods of attaching the device to the ground, a wooden or concrete foundation, or to a tree trunk. The drum can be taken from an old winch, or you can make it yourself according to the drawings.

Gasoline winch

You should follow the safety rules when carrying out lifting and rigging work:

- Cables, hooks and slinging accessories must be strong and periodically tested to tensile strength.

- The stopper must securely fix the drum and prevent spontaneous unwinding of the cable under load.

- When lifting heavy loads, the winch must be secured to a permanent or temporary foundation, the weight of which must be five times the maximum weight of the load being lifted.

- It is strictly forbidden to stand under the load and in the area of its possible scattering when falling, as well as to the side of a tensioned cable when moving objects horizontally.

How to Make Your Own Chainsaw

Content

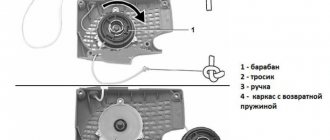

Chainsaw sawmill. How to make a sawmill from a chainsaw with your own hands

Wood is perhaps the most common building material today. How to make a starter on a chainsaw yourself? How to bend the spring on a chainsaw starter? How to wind a spring and how to wind a chainsaw starter rope. Everything, as usual, is simple and easy, and most importantly. Long gone are the days when the process of building a house was carried out using the simplest tools. At the moment, to perform this kind of work, new technologies and the most modern equipment are used, including a sawmill, with the help of which wood is processed to suitable sizes. Unfortunately, this tool is not easily accessible to ordinary Russians, because it costs hundreds of thousands of rubles. But there is a way out of this situation - constructing a homemade sawmill. You will find out how this happens in our current article.

Why is it more profitable to make a sawmill from a chainsaw?

In general, a chainsaw is a unique device, because on its basis you can make virtually any tool, from a homemade lawn mower to snowmobiles. In our case, the introduction of this device allows us to design a suitable element practically without the use of any additional parts and assemblies. Sharpening a chain for How to make your own device for perfect sharpening. Judge for yourself - we already have the engine, along with the gas tank, the frame is also there, and even the chain remains in working order. How to disassemble a chainsaw quickly and accurately? It’s not just about assembling the circular yourself. We will not change or re-equip any of the above. The only thing we will need to make is an iron canopy that will be attached to the saw body. You can see the approximate design of such a device in the following photo.

READ The Difference Between a Circular Saw and a Circular Saw

You see, homemade chainsaw sawmills are actually no different from a real saw. In other words, the effort and foreign exchange costs required to complete this operation are small. This is the whole advantage of using this tool as a sawmill.

How to make a sawmill from a chainsaw?

To create such a device, you need to have two channels measuring 150...180 x 8000 mm (height and length, respectively). Apart from this, you will need several 50 x 100 mm corners and two rails for your work. The latter must be turned upside down. When developing a base for a sawmill, you should drill several holes of 14-18 mm each in it. The interval between them should be approximately 1-1.2 meters.

You will also need zip ties for your work. They can be made from an ordinary water pipe 250 mm long. Bolts should be used as connecting parts rather than welding. Racks are made from rectangles, onto which the sawmill base is then attached. By the way, it is unacceptable to use deformed elements when making the base. All parts must have a strictly even shape. How to do it yourself For winter work, it is better to buy a chainsaw. In order to make a saw cut on a hacksaw, the essence of the saw cut is how to do it yourself. As for the distance between the posts, they should be placed to the end of the base at intervals of 80-100 cm. Additionally, you can weld braces between them to make the structure seem stronger.

How to make a chainsaw using a 775 engine and PVC pipes

HomeMade powerful chainsaw

. The most common malfunctions of the Calm petrol saw How to make a Calm chainsaw. Parts you need DC 775 motor GT2 pulley, Bearings, Chainsaws.

How to make an Electric Chainsaw

Thank you everyone for 70 subscribers!!!!!

What to do next?

At the next stage, the chainsaw sawmill is equipped with a movable trolley. It will be based on a steel plate measuring 600 x 50 millimeters. A metal corner 40 x 40 millimeters should be welded to it from below. Then the cart needs to be placed on bearings or rollers. Also weld 2 corners to its upper part. The chainsaw itself is attached to the latter.

READ Which reciprocating saw to choose

At the final stage, a structure is made to fix the log. What do I need to do? Here you will need a metal tube with a diameter of 35-40 millimeters. Also, during the work, it is necessary to use a movable hose, which will be positioned and then secured at the desired height. In this case, the height value should not exceed the length of the pipe itself. how to make a screw saw how to repair a chainsaw at home 365 with your own hands - video. So, our homemade sawmill with our own hands has been successfully made. You can safely start using it and process wood of almost any diameter.

How to make a sawmill from a chainsaw? Method number 2

Here is another method for making a sawmill at home. In principle, this option for creating a cutting device is not much different from the previous one - the drawing and tools for work will be the same as in the first case. However, this sawmill manufacturing technology will be more refined. How to make a sawmill from a chainsaw with your own hands in this case? On the drawing you will need to indicate 4 main elements. This is a saw, its drive, a mechanism by which the thickness of the resulting board is adjusted, as well as an element that allows you to move the saw part of the structure. You should also indicate the layout of the device for fixing the log.

How is the saw and its drive made?

There is nothing complicated here. Their experience will allow you to quickly diagnose a chainsaw and How to make a snow blower. Since the sawmill is made from a chainsaw, all these elements, including the motor, will already be ready. Therefore, all that is required of you is a working saw with cutting teeth and a working engine, which, in principle, is present in the design of this tool.

Now about how to do it

mechanism for adjusting the thickness of the board. The actual sawing of a log on a sawmill occurs by lowering or raising the base of the device, which is held on by 4 screws or welded to the plate with nuts whose edges are bent. There is a lock nut at the top of the base. It is tightened after the chainsaw sawmill has been set up. How to make a chainsaw starter yourself. How to wind a chainsaw starter spring, how to make an ergostart for a chainsaw. And how to make a starter with. Adjust to the appropriate thickness of the log being processed.

READ How to Correctly Install a Starter on a Chainsaw

How to make a sawmill from a chainsaw with your own hands

? The saw part of the tool must move along the guide angles along the frame. In this case, a distance of 50-55 centimeters must be maintained between these elements. 2 rollers are welded to each rack, the upper one rests on the guide angle, and the lower one keeps the sawmill from lifting. If it is not possible to use rollers, you can use 20 mm bearings.

A device that fixes a log on a sawmill

The wood on this tool is secured using two combs, one of which moves with a screw, and the second remains stationary. After installing the log, the first movable element is secured in a stationary state using several screws. After installing the fixing device, you can safely start operating the sawmill and process the first wooden pieces.

And finally.

Let us note a few rules for operating a homemade sawmill:

- From time to time, lubricate and sharpen the tool chain, since the quality and speed of the work you perform depends on these factors.

- Before fixing a log or board, make sure that there are no foreign metal objects (nails, screws, etc.) in it, other than those nailed when fixing the device to the wood. Teeth that get on the surface of such parts instantly become dull, and it is possible that such a chain will only need to be replaced.

- Under no circumstances remove the product from the sawmill before the engine has stopped. Otherwise, operator injury and device failure are simply inevitable.

Source

Power station

For a mobile power plant with a power of up to 5 kW, there is a time-tested solution: a homemade generator based on a motor from a Druzhba or Ural saw. They are actively used on expeditions and in remote logging operations. The device includes a steel frame welded from a corner, on which an engine, a generator and a waterproof electrical distribution box with sockets for connecting electrical equipment or an extension cord are mounted. Through the gearbox, torque is transmitted to the generator shaft.

For low-speed generators, there is an option for a homemade power station with a belt drive. This design is smaller in size.

Motorized winch made from a chainsaw

Many owners living in the private sector have an old chainsaw in stock, usually a “Druzhba” or “Ural”. However, they sometimes use a saw when preparing firewood. Folk experts found another use for it, coming up with the idea of making it into a motorized winch with a set of rope-traction tools. From now on, it has become easier to plow the ground for planting vegetables, hill up, dig, and plow the land.

The traction device with a saw weighs approximately 40 kilograms, so it will be quite easy to master the new tool on the site. The implements used in processing are equipped with wheels, and therefore the device can be rolled across a field or piece of land with ease and ease.

The plow is able to stay in the furrow on its own, without requiring the use of physical force by the plowman. So, thanks to the tool, the plowed strip has a depth of 20 centimeters.

Pay attention to the manual: how to sharpen a chainsaw chain correctly.

When planting potatoes in ridges at the end of plowing, the plow is replaced by a hiller, equipped with the same wheel drive. Thus, the motorized winch can cut even ridges. As soon as the time for hilling comes, the winch will quickly float across the site, leaving behind only loosened rows.

As soon as the opportunity arises to dig up potatoes, we enrich the device with a redeemer, attach it to a winch, and then work through each row of land.

You can also use a chainsaw to make a sawing tool like a huge grinder. It is worth noting that the idea of creating such a tool is quite popular.

Bulgarian

A portable power station from a chainsaw engine is quite possible when you have the time and desire.

Power station

A rubber boat can easily be equipped with a motor if you have an unnecessary chainsaw. This will be a real joy for a true fisherman.

As you might guess, adapting an old chainsaw for other purposes is quite possible. The main thing is ingenuity and desire.