When is carburetor adjustment necessary?

Initially, from the moment the tool is sold, all carburetors are adjusted and configured at the manufacturer. However, during operation, the settings are gradually lost, and the operating mode changes in accordance with operating conditions. Signs of a carburetor malfunction may include:

- gasoline consumption is too high, thick smoke comes from the exhaust pipe;

- the engine power is clearly not enough to perform normal tasks;

- engine speed “floats”;

- after starting, the engine stalls either immediately or after a few seconds;

- the engine cannot be started at all;

- the chainsaw “shoots”, sharp bangs occur in the tool’s engine.

Note! The cause of poor engine performance may be a worn-out piston group, then adjusting the chainsaw carburetor does not fully resolve the problem. Also, no adjustment will give the expected effect if the node is not simultaneously cleaned of small particles of debris. The most problematic elements are jets and filters, both gasoline and air.

It must be taken into account that during the break-in period of the new engine, the carburetor is adjusted to a reduced fuel supply in order to limit engine power. After the break-in is completed, the fuel supply increases to the nominal value. These adjustments are made using the adjustment screws on the carburetor body (usually two or three).

Launch

According to the requirements of the Operating Instructions, the saw must be fully prepared and checked before starting. The preparation includes operations for assembling the chainsaw after purchasing it. This includes mounting the bar and saw chain, refueling with fuel and oil.

After completing this work, the functioning of all components and parts of the chainsaw is checked. Particular attention is paid to the absence of fuel and oil leakage, the reliability of all fastenings, and the integrity of parts. Then the engine starts. The instructions describe in detail how this is done.

Design and operating principle

A carburetor is a device in which fuel (gasoline) and air are mixed in specified proportions, followed by supplying the prepared mixture into the engine cylinder. Almost all models of chainsaws have the same type of carburetors, so their design and operating principle are the same.

The main elements of the carburetor design are:

- body, which is cast from aluminum to reduce weight. Chainsaws constantly have to be moved from place to place; they are held by hand during operation, so reducing the weight of the tool is the primary task of manufacturers;

- diffuser with an air damper, which are located at the inlet;

- jets, which are valves for metered fuel supply;

- a sprayer that provides gasoline injection into the chamber (in the diagrams it is designated as the main jet);

- fuel (float) chamber.

Figure 1 – Chainsaw carburetor diagram

The operating principle of a carburetor can be described as a cycle consisting of the following actions:

- When starting the engine, the air damper opens.

- The stroke of the piston creates a vacuum in the air channel, as a result of which air enters the diffuser, the amount of which is regulated by the position of the air damper.

- Gasoline flows from the gas tank into the float (fuel) chamber. The speed of its flow is regulated by jets.

- In the diffuser, gasoline and air are mixed, resulting in the formation of a fuel-air mixture, which then enters the engine cylinder. The more mixture enters the combustion chamber of the cylinder, the higher the power and speed at the engine shaft will be.

Important! It should not be assumed that the operation of the carburetor has a cyclical basis, as it may seem from the description. All processes occur constantly and continuously.

How to dilute oil and gasoline

The Makita 4610 chainsaw engine runs on a mixture of gasoline and oil. In order to prepare it correctly, take 50 parts of high-octane gasoline (for example, AI-92) and 1 part of special MAKITA oil for two-stroke engines. These components are mixed together in a clean container. To do this, you can use a canister or any similar container.

Original Makita fuel and lubricants

First, the oil is poured into half of the required fuel, everything is mixed well, then the remaining fuel is added and everything is mixed well again. As an example, the following proportion is given: 1 liter of gasoline requires 20 cm³ of oil.

In a desperate situation, when it is not possible to purchase MAKITA oil, it can be replaced with any other for two-stroke engines. In this case, the mixture is prepared in a ratio of 40:1. In digital terms, it looks like this: 1 liter of gasoline requires 25 cm³ of oil.

To accurately measure the oil, you can use disposable medical syringes.

Adjustment Tools

To adjust the carburetor, you will need Phillips or slotted screwdrivers of different lengths or thicknesses. The size depends on the design of this unit and the features of the engine assembly. It is necessary to take into account that some manufacturers make carburetors designed for the use of special tools.

In particular, special types of screwdrivers may be required to adjust Husqvarna carburetors and other imported tools. It is advisable to clarify this question when purchasing a chainsaw so that you can purchase the necessary additional equipment in advance.

In addition, to wash and clean the device you will need purified gasoline or acetone. They are used to clean the external surfaces of the carburetor. All internal channels are washed with kerosene, diesel fuel or white spirit. Before washing, the carburetor is disassembled, all rubber or plastic parts that may be damaged by contact with aggressive chemical compounds are removed.

To disassemble the carburetor, open-end or ring wrenches are used. The internal channels are washed in specially designated baths; sometimes plastic syringes are used for this.

How to properly adjust the carburetor with your own hands?

After washing and completely cleaning the carburetor, it is assembled and adjustments begin. First of all, you should understand the purpose of the adjusting screws. The instructions will help with this, but some general points should be considered immediately. The most common designation for screws is:

- H - adjusts the state of the main jet, i.e. adjusts the maximum rotation speed of the motor shaft;

- L — adjusts the idle jets (responsible for the minimum shaft rotation speed);

- T - regulates engine idle speed. It can also be designated by the letters LA or S; on some carburetor models it is completely absent.

READ Chainsaw Husqvarna 372 Xp 18 Fuel Consumption

Turning screws H and L clockwise leans the fuel-air mixture, and counterclockwise turns it rich (the amount of gasoline increases). When screw T rotates, the shaft rotation speed at idle speed changes - clockwise it increases, and in the opposite direction it decreases.

Figure 2 – Carburetor adjustment mechanisms

Before you begin direct action, you should find and carefully study information about the position of the adjusting screws (the magnitude of the rotation angles when adjusting). This information is available in the instructions for the chainsaw. Then you need to prepare the workplace - lay the saw on a flat horizontal plane, pointing the chain in the direction opposite to you. Disconnect all covers, remove foam and air filter. At this point, the preparatory operations are considered completed, and the main part of the work can begin.

- Smoothly tighten screws H and L clockwise until they stop. Be careful not to break the screws - this will cause complete loss of the carburetor.

- Unscrew both screws one and a half turns.

- Run the engine for 10 minutes and warm it up. This is a necessary point, since it will not be possible to adjust the carburetor correctly on a cold engine.

- By turning screws H and L, alternately adjust the rotation of the shaft at maximum and minimum speed.

- By adjusting the position of screw T (or it may have a different designation), the idle speed of the chainsaw is adjusted. It is necessary to achieve smooth and stable engine operation. It is important to monitor whether the chain moves at idle or not. If it moves, turn the screw counterclockwise a little more.

Important! It is better not for an inexperienced person to adjust screw H. If it is not configured correctly, a lean air-fuel mixture will be supplied to the cylinder combustion chamber at maximum speed. This will lead to accelerated wear of the piston group.

You can check the engine's operation visually and by ear. A mixture that is too rich causes thick smoke to come out of the exhaust. When feeding a lean mixture, a whistle is heard while the saw is running. Excessively economical mode is harmful - if screw L is set to “lean” fuel, problems will arise with starting the engine. When setting screw H to a lean mixture, the saw will noticeably lose power. The correct setting can be determined by the following criteria:

- at idle, the engine does not stall, and the chain does not move;

- there is no excessive smoke from the exhaust pipe when the engine is running;

- the engine demonstrates good throttle response (quickly picks up speed when you press the accelerator).

A detailed description of the settings is available in the instructions that come with the tool in the package. It should be carefully studied, since there may be some features or specific requirements established by the manufacturer and relating only to this model of saw. If all requirements are met exactly, the operation of the chainsaw will be restored to its original state.

Basic faults

A gasoline saw has a complex design. The engine, carburetor , clutch and starter all experience serious stress during operation and break down over time. But there are malfunctions that happen much more often than others, and we’ll talk about them further.

Makita DCS34 35 won't start

This is one of the most common situations that happens, but not always due to a malfunction.

If for some reason chainsaw , the first thing you need to start with is to check the presence of fuel in the tank, and also make sure that the fuel filter is functioning properly. Next, you need to make sure that the chainsaw startup algorithm is followed.

If these points are fulfilled, but the chainsaw still shows no signs of life, then you must proceed according to the following algorithm:

- Unscrew the spark plug and check for the presence of a spark; to do this, with the ignition on, install the spark plug in the cap of the high-voltage wire and attach it to the cylinder, then pull the starter several times.

- Plug the spark plug hole with your finger and pull the starter several times (air from the engine should break through under your finger, making a characteristic sound), this way you can check the compression. If it is not there, the saw will not start and will need major repairs.

- Using a medical syringe (this is more convenient), pour about 5 ml of fuel directly into the spark plug hole and try to start the Makita. If the chainsaw starts, then the problem is in the carburetor or the crankshaft seals are faulty. They can seriously poison the air and for this reason the fuel pump will fail.

- If all the previous methods did not help determine the malfunction, then there is a possibility that the spark plug is flooded. To find out, we do the following. We screw the spark plug into place and try to start the chainsaw, then unscrew it and inspect it. A wet spark plug and a large amount of fuel in the cylinder (the saw must be turned over to check the fuel in the cylinder) confirms an overflow.

READ Saw Chop Dig Make friends Found

How to properly adjust the carburetor on a chainsaw with your own hands?

A chainsaw is a useful and sometimes simply necessary tool for the owner of a private home. It has a high degree of autonomy and can be used in field conditions where there is no possibility of connecting to the power supply network. For some craftsmen, a chainsaw is one of the main devices that perform large volumes of work almost every day. Such loads disrupt the factory settings that were set for all important engine components.

The operating mode most often changes at the carburetor, which has to be adjusted again. Without an idea of the design and operating principle of this element, it is impossible to adjust it correctly. The issue concerns many users who use chainsaws closely, so it will be useful to consider it more carefully.

How to set up a saw made in China?

The design of the carburetor on Chinese chainsaws is no fundamentally different. The order and principle of setting also have no differences and are performed in the same order. The only difficulty that may arise during the work is determining the purpose of the adjusting screws. Typically the T screw is at the top and the H and L screws are located at the bottom of the carburetor body. There may be one more, additional screw.

Figure 3 – Location of adjustment mechanisms

Usually their purpose is determined experimentally, slightly changing the position and monitoring the result. Once the purpose of the elements is clearly defined, further configuration is not difficult and is carried out in the usual manner.

Adjusting the carburetor of a chainsaw is an important and necessary procedure that must be performed periodically to restore the normal operation of the tool. This process does not create any fundamental complexity, but requires the user to be careful, attentive, and follow safety rules. The chainsaw chain is usually not removed, since you will need to observe its position. Therefore, it is important to constantly remember the possibility of its launch and exercise the necessary caution.

READ Chainsaw Makita 4610 Carburetor Adjustment

The adjustment should be made smoothly, with small changes in the position of the screws, so as not to cause too sudden changes in the mode of rotation of the shaft. The result depends on the care and diligence of the user, and a properly configured carburetor will extend the life of the tool.

Chainsaw MAKITA DCS4610. Replacing the carburetor.

Instructions

The operating instructions for the chainsaw contain all the necessary requirements, fulfilling which ensures safe operation, proper maintenance and repair of the Makita chainsaw. Following its recommendations will extend the life of the saw.

Fragment from the “Operating Instructions” Makita DCS 4610

The instructions describe in detail and illustrate only those maintenance and repair work that you can do yourself.

Makita chainsaw carburetor repair

Symptoms that adjustment is no longer enough and repair of the Makita chainsaw carburetor is necessary:

- arbitrary changes (jump-like) engine power;

- excess fuel consumption;

- increased vibration and popping;

- “sneezing” and unstable engine operation;

And of course, a clear symptom is that the engine does not start or stalls.

To repair the carburetor, you will need to remove it; it is located immediately under the top cover of the chainsaw and the air filter.

Location of the carburetor in a Makita chainsaw.

Design and principle of operation of the Makita DCS4610 carburetor

Makita chainsaw carburetor , like any other, is to mix fuel liquid (in this case a mixture of gasoline and oil) with air in certain proportions necessary for effective ignition. When these proportions are not met, the engine does not operate correctly and efficiently. And subsequently, such incorrect operation can lead to its failure.

Diagram and principle of operation of a Makita chainsaw carburetor

In general, the carburetor is a one-piece cast metal body.

Air for further mixing with the combustible mixture enters through the air filter and enters the diffuser (8). This is a chamber defined in shape with existing narrowings, thanks to which the air flow speed increases. The result is a thinner air mass.

The diffuser has air and throttle valves (7.9). The air damper regulates the volume of incoming air mass. The throttle valve, in turn, connected to the engine speed control lever, regulates the supply of fuel to the combustion chamber of the cylinders, thereby regulating the power developed by the engine.

At certain points in the diffuser there are fuel channels (11,12). Fuel is sucked through them by the flow of air masses. The carburetor fuel system includes:

- fuel pump;

- jet system;

- fuel-air mixture control system.

The fuel supply mechanism works due to changes in pressure in the crankcase, which is caused by the reciprocating movements of the piston in the cylinder. The pulse chamber of the fuel pump through the pulse channel (1) is connected to the internal volume of the engine crankcase.

The increased or discharged pressure that occurs in the crankcase activates the membrane (4) of the fuel pump. Thanks to this connection, the fuel pump operates synchronously with the engine and depends on its speed. Fuel comes from the gas tank under the action of the pump membrane, through the carburetor inlet channel (2). It then passes through the inlet valve (3) and outlet valve (5) of the pump.

Preliminary cleaning is carried out through the filtration mesh (6) through the channel (10) past the needle valve (14) and enters the chamber (16), where the control membrane (18) is located. The needle mechanism of the valve (14) is connected through the lever (17) to the control membrane (18). The space below the membrane is connected to the outside air atmosphere through channel (19).

In general, the process of operation of the Makita DCS4610 is carried out under the influence of variable pressure in the engine crankcase.

At the moment of suction, a rarefied pressure arises in the diffuser (8) and air rushes here. The strength of the flow depends on the power (revolutions) of the engine at the moment and on the position of the throttle valve (9). Also, under the influence of air vacuum, fuel flows through the jets (11,12) from the chamber (16). The fuel mixture and air are mixed, resulting in the formation of a fuel-air mixture, which in turn enters the cylinder and burns.

At the stage of suction and combustion of fuel, since the space located below the control membrane is connected to the outside atmosphere through the hole (19), the membrane (18) moves upward. At this moment, it activates the lever (17), which pulls the valve needle (14). The valve opens and a new batch of fuel mixture enters the chamber (16). When the chamber is filled to a certain level, the control membrane moves to its initial state and the valve closes. In this way, the fuel supply is regulated and maintained.

The volume of fuel entering the diffuser is regulated by the main screw (13) and the idle screw (15). When the screws are unscrewed, the fuel-air mixture is rich, and vice versa, if the screws are screwed in, the mixture becomes lean. There is also the additional possibility of adjusting the idle speed with another screw. When screwed in, it rests against the lever, which is mounted on the throttle valve axis. These three screws allow you to adjust the carburetor for more efficient operation of the Makita DCS4610 in various conditions.

Carburetor chainsaw device

Repair work is not complete without knowledge of the basics of the mechanism. By understanding the components and operating principle, it is easier to determine the cause of the failure.

Any malfunction in the carburetor threatens to stop the engine

The carburetor is one of the main functional parts of the engine, which is used to prepare and supply a fuel mixture consisting of certain proportions of fuel and air. As soon as the proportions are violated. The engine begins to act up or even stops working completely.

You can ensure proper operation of the carburetor by studying its “priming”:

- Tube with cross valve to regulate air flow.

- Diffuser. This is a constriction to increase air flow, located at the fuel inlet.

- The nozzle from which fuel is supplied (fuel arrow in the diagram).

- A float chamber that regulates the fuel level at the entrance to the channel.

Here's what it looks like in a diagram:

Diagram showing the interaction of fuel and air flow

Operating principle: the air flow in the diffuser atomizes the fuel, creating a mixture that enters the cylinder. The greater the amount of fuel supplied, the higher the engine speed. Carburetors of different models work according to the same scheme.

READ How to Change the Sprocket on a Chainsaw

Do-it-yourself adjustment of the Makita DCS4610 chainsaw carburetor

Changing carburetor settings may be necessary in the following situations:

- Unstable engine operation. The reason is a lean fuel mixture.

- Excessive fuel consumption, black exhaust. The reason is that the fuel-air mixture is oversaturated, and its complete combustion does not occur.

Adjustment also help if the chainsaw has difficulty starting or does not idle stable.

READ Chainsaw Makita Dcs4610 Carburetor Adjustment

Before you begin to independently adjust the carburetor, you should familiarize yourself with its structure, operating mechanism and the necessary set of tools.

Basic malfunctions and their elimination

Random changes in power may be caused by damage to the adjustment screws. Eliminated by replacing them.

A popular malfunction that is accompanied by unstable engine operation may be associated with a clogged filter mesh in the carburetor. It can be eliminated by cleaning it.

Damage to the control diaphragm or diaphragm in the fuel pump is also common. The fuel supply needle valve may become clogged, become jammed during a long break in operation, or simply wear out.

Problems can arise as a result of the fuel pump gasket losing its seal. All these carburetor malfunctions can be eliminated by purchasing a repair kit and replacing damaged parts.

Chainsaw reviews

Users note the ease of working with the saw, ease of maintenance, high engine power, reliability and endurance in operation. Almost all reviews are positive.

There are a small number of negative reviews, but all of them are caused by non-compliance with the requirements of the “Operating Instructions”.

The Makita DCS 4610 chainsaw is an amateur tool. Powerful enough, it allows you to perform all sawing work in the country, in the garden, at a construction site. Video. Excerpts from Japan chainsaw Makita dcs 4610 found carburetor adjustment. With timely and correct maintenance, the owner will never say “won’t start” to her, and she, in turn, will work conscientiously for many years.

What carburetors are used on Makita chainsaws

Makita has a wide range of chainsaws; they are equipped with Zama diaphragm carburetors.

Repair it yourself or entrust it to a professional

The question is quite sensitive. Makita chainsaw carburetor yourself only if you are completely confident in your abilities. Some knowledge of the mechanics and operating principle of the carburetor is required.

The carburetor is a rather complex part of the engine; it has small parts and replacing them requires great care and skill. As for malfunctions, you can fix almost everything yourself, since they boil down to finding the damaged element and replacing it. The parts cannot be repaired; there is no need to edit anything with a hammer.

In general, you need to soberly assess your capabilities; if in doubt, it is better to contact a service center.

Design and operating principle

A carburetor is a device in which fuel (gasoline) and air are mixed in specified proportions, followed by supplying the prepared mixture into the engine cylinder. Almost all models of chainsaws have the same type of carburetors, so their design and operating principle are the same.

The main elements of the carburetor design are:

- body, which is cast from aluminum to reduce weight. Chainsaws constantly have to be moved from place to place; they are held by hand during operation, so reducing the weight of the tool is the primary task of manufacturers;

- diffuser with an air damper, which are located at the inlet;

- jets, which are valves for metered fuel supply;

- a sprayer that provides gasoline injection into the chamber (in the diagrams it is designated as the main jet);

- fuel (float) chamber.

Figure 1 – Chainsaw carburetor diagram

The operating principle of a carburetor can be described as a cycle consisting of the following actions:

- When starting the engine, the air damper opens.

- The stroke of the piston creates a vacuum in the air channel, as a result of which air enters the diffuser, the amount of which is regulated by the position of the air damper.

- Gasoline flows from the gas tank into the float (fuel) chamber. The speed of its flow is regulated by jets.

- In the diffuser, gasoline and air are mixed, resulting in the formation of a fuel-air mixture, which then enters the engine cylinder. The more mixture enters the combustion chamber of the cylinder, the higher the power and speed at the engine shaft will be.

Important! It should not be assumed that the operation of the carburetor has a cyclical basis, as it may seem from the description. All processes occur constantly and continuously.

Makita dcs 4610 chainsaw does not start

Screws for adjustment

Adjusting the carburetor of a Makita chainsaw is carried out with a set of adjusting screws, which are located in the body of this design:

- screw marked L – corrects low speed;

- a screw marked H, which is used to adjust high speeds;

- Screw T for adjusting carburetor idle speed.

- The engine is left to warm up (run the chainsaw for 10 minutes).

- Checking the air filter and cleaning this part.

- Stop the chain by turning the screw marked T (turn until it stops).

- place the chainsaw on a flat surface;

- After removing the chain, set it aside.

To diagnose carburetor problems, use a tachometer.

Important! Experts advise listening to the sound the screws make when turning. A "squealing" sound may indicate that the mixture is oversaturated.

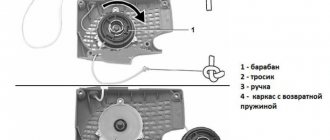

Repair kit for carburetor

The repair kit for the Makita chainsaw carburetor includes:

- membranes (control and fuel pump);

- gaskets;

- needle valve (needle, spring, lever).

It is clearly presented in the figure; the parts of the repair kit are indicated by a contour line.

Specifications

The saw is characterized by its small size and weight with a rather massive engine. This makes its use comfortable and reliable in any area where sawing of wood is required. More properties are given in the table.

The engine is two-stroke. It runs on a fuel mixture of gasoline and oil. Has easy starting at positive and negative temperatures. The electric ignition system facilitates this.

The anti-vibration system together with ergonomic handles make handling the Makita DCS 4610 chainsaw less painful.

The inertial chain brake installed on the saw operates in manual and automatic modes, which firmly ensures personal safety when handling a running chainsaw.

The chain catcher stops the movement of the chain when it breaks. This prevents damage to the saw and injury to the operator.

Tire and chain. Refers to consumables. Chainsaw "Ural", adjusting the carburetor Ural 2 electron. When replacing, these parts must be installed in accordance with the recommendations in the instructions for using the Makita DCS 4610 chainsaw. Particular attention is paid to maintaining the dimensions.

Currently reading: Tuning the Carburetor of the Husqvarna 137 Chainsaw

Automatic chain lubrication system. Oil is supplied to the bar only while the saw chain is rotating, which reduces overall oil consumption.

A more detailed review of the Makita 4610 chainsaw is presented in the video

- Chain with 3/8" pitch.

- Fuel tank 0.37 l.

- Automatic oil pump.

- Oil tank 0.25 l.

- Chain links with a width of 1.3 mm.

- The total weight of the tool is 4.75 kg.

- The kit includes a tire, a tire cover, and a combination wrench.

Adjusting the Makita chainsaw carburetor

Adjusting the carburetor of a Makita chainsaw affects the performance of the device and the quality of work. To correctly set up the working unit of the equipment, it is important to: understand the principle of its operation, have the necessary tools, take care of fasteners, as well as closely located elements responsible for the operation of the chainsaw.

Sources:

https://vsekarby.ru/benzoinstrument/benzopily/karbyurator-Makita-regulirovka.html https://zemlyaselhoz.ru/pily/regulirovka-karbyuratora-benzopila-Makita.html

Purpose

The Makita 4610 chainsaw belongs to the semi-professional class - it successfully copes with a wide range of work in the country, on a personal farm and on a farm. Tidying up the garden, pruning branches, cutting down trees, preparing firewood, filing elements during construction - the possibilities of the saw are truly endless.

Makita 4610 at work

In addition, using special attachments, the functions of the saw change. It easily turns into a winch, ice drill, wood router and a number of other useful tools.

The use of unlicensed attachments is not recommended.