A chainsaw is an indispensable tool for people living in private households. It is a mechanism consisting of carefully fitted parts and assemblies.

Like any mechanism, it requires periodic maintenance and adjustment. Especially due to low-quality fuel. Let's look at the principles and procedure for adjusting the carburetor of a Husqvarna chainsaw.

The design and principle of operation of the carburetor

The carburetor serves to prepare a combustible mixture of gasoline and air in a proportion determined by the operator.

An overly rich, as well as an overly lean, mixture will lead to unstable engine operation, may cause overheating and accelerate wear of the piston system.

The proper functioning of the device depends on proper configuration and adjustment.

And for this you need to know the principles of operation of the Husqvarna chainsaw carburetor.

Its design consists of the following elements:

- housing with clamping bolts and a set of gaskets;

- fuel pump - a device that pumps a gasoline-oil mixture into the carburetor;

- diaphragm - designed to limit the flow of combustible mixture into the engine;

- float chamber - fuel is collected in it, the level is adjusted by a float, and as necessary, the mixture is supplied to the main chamber for mixing with air;

- main chamber - air passes through it, and fuel is injected there; the amount of mixture supplied to the engine is regulated by a throttle valve located here;

- diffuser - a narrowing section of the air supply tube at the point of fuel injection;

- needle valve - a device that regulates the fuel supply;

- jet - screws that regulate the flow of mixture at high and low speeds, as well as the idle screw.

Also in the carburetor design, in addition to the throttle, there is a damper located at the inlet of the air filter. It artificially reduces the air supply, making the mixture richer for easier starting of a cold engine.

The injector valve is responsible for injecting fuel into the main chamber, and it also prevents air from entering. When setting up the carburetor on a Husqvarna chainsaw, special attention should be paid to this valve, since its condition has a direct impact on the operation of the engine. If stored for a long time, the nozzle may stick. This will restrict the flow of fuel and prevent the engine from starting.

Also, due to prolonged use or due to a manufacturing defect, the valve may allow air into the main chamber. In this case, only replacing it will fix the problem.

The carburetor operates as follows: the air flow entering the diffuser is mixed with the injected fuel, and the resulting mixture is supplied to the engine. The amount of mixture is controlled by the throttle valve. The more mixture, the higher the engine speed.

Conditions for self-repair of chainsaws Partner

It is possible for the owner of the tool who has the skills to repair household appliances to fix the malfunction independently after the end of the warranty service. First you need to learn the technique. Experienced craftsmen believe that repairing a Partner 350 chainsaw with your own hands begins with correct diagnosis. To determine the nature of the repair, you must:

- check the ignition system;

- perform diagnostics of carburetor operation;

- fuel system efficiency;

- clean the muffler;

- determine the performance of the piston system;

- check chain lubrication;

- determine the wear of components and the required spare parts for the Partner chainsaw.

Complex issues must be resolved with the involvement of specialists for consultation.

If the engine refuses to start, first of all check whether the spark plugs are working properly. They must be dry and have a contact gap of 0.5 -0.65 mm. Based on the condition of the unscrewed spark plug, you can determine signs of problems in the fuel system and equipment operation.

Check the serviceability of the spark plug by connecting it to the starter through the cap and placing it on the cylinder body. The spark plug is good if it produces a spark on the housing when the starter is pulled. If there is no spark, the wire is faulty or the spark plug is flooded or has expired.

A saw that has been used a lot may experience carburetor malfunctions. But first you should adjust the carburetor of the Partner 350 chainsaw, as shown in the video:

Repairing the carburetor can temporarily extend the engine's operating time. The passages in the carburetor can become clogged with low-quality fuel or through a leaky air filter. When disassembling the unit, it is necessary to wash and blow through all parts.

It is better to entrust the repair and adjustment of the carburetor, as the most critical component, to a specialist.

If fuel does not enter the cylinder:

- You can clean the fuel filter after you have made sure that the fuel flow from the hose is low. Depending on the degree of blockage, it needs to be cleaned or replaced with a new one.

- If the injection is clogged, remove the hose and clean the hole with a needle.

- Not enough air enters the carburetor through a clogged air filter. The supply of mixture to the engine is disrupted.

- Incorrect carburetor adjustment will lead to the same result.

The chain is not lubricated. To avoid overheating of the chain and its pulling, lubricant must be supplied to the working unit automatically. But since the oil is supplied through the channels, they can become clogged with fine wood dust. After each cycle of work, the canvas and gaps must be cleaned of dust and dirt. If oil is leaking, you need to check the integrity of the hose and the tightness of the connection to the tank. Replace the faulty hose or temporarily cover the hole with sealant. Repair the oil pump.

Malfunctions of the Partner 350 chainsaw include failure of long-term use parts. If the sprocket, tire, rubber anti-vibration seal is worn out, or the chain becomes dull, you need to take action in a timely manner. In harsh operating conditions, they must be under control, replaced, sharpened, and tightened on time.

Chainsaw Partner 350 in action - video

Today, when carrying out repairs or any kind of construction, you cannot do without a chainsaw. The entire process of wood separation and the implementation of the planned building project will depend on the quality of its work. That is why you should carefully consider the choice of a high-quality chainsaw, which will allow you to carry out the process of dividing wood-based building elements practically and more efficiently.

An excellent example would be the purchased Partner 350 chainsaw. But, like any other type of chainsaw, it can become unusable and require repair.

To complete it, it will be important to correctly understand the cause of the breakdown and correctly replace the elements that have exhausted their service life.

As a rule, you can carry out repairs yourself, you just need to understand where it’s best to start. Considering the operation of the oil pump or existing carburetor. To do this, you will need to study the structure and operating principle of the Partner 350 chainsaw.

Using a Partner 350 chainsaw with a 1.8 hp engine. allows you not to worry about the chain jamming, making it possible to carry out the necessary volumes of work on collecting firewood or conducting construction work. This is ensured by an automatic inertia brake and chain lubrication during operation.

The CCS system with a powerful air filter allows the unit to be cooled in a timely manner and prevents it from overheating. The saw has low production noise due to a properly designed housing that dampens it.

The available 3/8" chain pitch allows the applied load to be evenly distributed. The fuel tank capacity of 0.4 liters provides the necessary amount of fuel for long-term operation, and does not burden the design of the saw with a weight of 4.7 kilograms. The engine capacity is 34 cc.

When adjustment is necessary

The need to adjust the carburetor of a chainsaw rarely arises. More often there are problems with the supply of fuel, air or wear of parts. But sometimes adjustment is still required:

- a running engine stalls after a few seconds, or does not start - the reason for this is that the mixture is too rich;

- excessive exhaust, high speeds, increased consumption - in this case, on the contrary, the mixture is too lean, i.e. there is not enough air;

- the speed remains at the same level after the operator reduces or increases it - the cause may be a stuck needle valve.

Factors leading to such changes may include the following:

- Strong vibration damages the protective cover, and the adjusting jets are unscrewed, changing the setting. In this case, it is possible to adjust the carburetor on the chainsaw.

- Wear of piston system elements. Adjusting the carburetor in such a situation may provide temporary relief. Replacement of worn components is recommended.

- Poor quality fuel, a faulty filter, or long-term storage can cause blockages. In this situation, the carburetor must be removed, washed with a special liquid or clean gasoline, reassembled and adjusted again.

It is best to start adjusting the operation of the saw by checking the jets, fuel and air supply. After this, proceed to dismantling the carburetor, and then to checking the piston system.

What tool will you need?

First of all, you need to prepare a tool for adjusting the chainsaw carburetor. You will need a set of screwdrivers and open-end wrenches, a special cleaning composition that dissolves carbon deposits and debris.

It is better to disassemble on a table or workbench. Lay a piece of clean, preferably light and plain fabric on part of the table, on which the parts to be removed and a container for washing will be laid out. It is optimal if it is an ultrasonic bath.

How to remove the carburetor and whether it needs to be done before tuning

In the event that the chainsaw does not develop speed or, on the contrary, operates at too high speeds, the carburetor can be adjusted without removing it.

But if the chainsaw does not start, the speed hangs at the same level or it works unstably. Adjusting the chainsaw carburetor will not change the situation. It must be removed for cleaning or replacing parts. You must proceed in the following order:

- After unscrewing the retaining fasteners, remove the upper casing of the saw.

- We remove the gasket and part of the air filter by unscrewing the bolts or snapping off the fasteners.

- There is a fuel hose on the right side of the carburetor. We remove it together with the air damper control rod.

- Remove the carburetor from the mounts holding it.

Disassembling the carburetor is carried out in accordance with the instructions supplied with the kit. When disassembling, take special care to place the parts on a previously prepared cloth. Due to its small dimensions, there is a risk of losing components during disassembly and washing.

All parts obtained in this way are washed in a special liquid, dried and wiped with a lint-free cloth.

Channels, tubes and jets are purged with compressed air, if possible, after having previously washed them in an ultrasonic bath.

DIY chainsaw carburetor repair Partner 350

The carburetor parts of the Partner 350 chainsaw do not experience strong mechanical and thermal loads during operation, unlike, for example, a piston system. Therefore, in theory, there is nothing to break in it. In practice, after many years of operation, gaskets most often depressurize and the elastic membrane fails. Over time it can become tough.

Failures of counterfeit carburetors are unpredictable. Anything can break in them at any time - damper axles, needle valve, pump, diffuser, etc.

In addition to breakdowns, the carburetor of the Partner 350 chainsaw may fail due to contamination. For repairs and cleaning, the carburetor is removed and disassembled.

It is worth noting that the accelerator pump of the Partner 350 carburetor is its weak point.

How to remove and disassemble: step-by-step algorithm

Before removing, the carburetor of the Partner 350 chainsaw and the space around it must be cleaned with a brush so that dirt does not get inside the engine. After which they remove:

- Air filter.

- Fuel hose.

- Throttle linkage.

- Then the screws securing the carburetor to the engine body are unscrewed.

After removal, place the carburetor on a clean surface and unscrew the screws securing the cover to the body. Remove the cover and gasket. Parts and fasteners are laid out sequentially. Disassembly is carried out slowly, remembering well which part was removed from where. It is extremely important not to confuse screws H and L when assembling. They are the same in shape, but different lengths.

After the operations have been completed, the Partner 350 carburetor is available for cleaning.

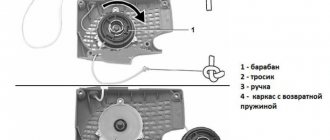

This is what a half disassembled carburetor looks like

Cleaning the carburetor: basic points, how to clean it correctly

Whether the carburetor is clean or not is usually determined immediately, visually.

First of all, the smallest holes become contaminated - in the nozzle, diffuser, channels. There may be dirty sludge in the chambers. The disassembled carburetor body and parts are washed in a bath of gasoline or kerosene. Then the channels and holes are blown out with a car pump or air compressor. It is best to use a special nozzle with a thin channel at the end. Wash again.

During assembly, if necessary, replace the gaskets and membrane with new ones from the repair kit.

When cleaning the carburetor, be sure to clean the hole in the cover under which the membrane is located. Marked in the photo with a red square

Repair kit: what is included in it and where to buy

Repair kits are sold with two sets of configurations.

The first includes gaskets and a membrane, that is, non-metallic spare parts. The second one additionally comes with a crosspiece with a needle valve.

Repair kits cost approximately from 300 to 370 rubles. and are sold in specialized stores and on many online platforms.

How to adjust correctly

For this purpose, the design of the device provides 3 adjusting jets. The idle air adjustment screw (T) is located at the top of the carburetor. Below there is a pair of jets for adjusting the fuel supply at minimum (L) and maximum (H) speeds, left and right, respectively.

The procedure for adjusting the carburetor on a Husqvarna chainsaw is as follows:

- Warm up for 5 minutes.

- By turning screw L, we bring the engine to the highest speed in an unloaded state and return it back a quarter turn.

- Hold the gas button with one hand for 15 seconds. At this time, turn the jet H to the right until it stops and reaches maximum speed. Then we turn it back one and a half turns or until the “squealing” of the engine disappears.

- After releasing the gas, turn the idle speed screw (T) clockwise until the chain begins to move. After this, we rotate it in the opposite direction until the chain stops moving.

During the adjustment process, a situation may arise in which the chainsaw stalls. This could be due to the jets being too tight or the mixture being too rich or too lean.

If this happens, you need to tighten the minimum and maximum speed jets all the way. Then turn them back one and a half turns and try to start the saw.

Setting the ignition after adjusting the carburetor

If cleaning and adjusting the carburetor does not correct the existing problem, you need to check the spark plug and adjust the engine. You should act in the following order:

- The spark plug is unscrewed and a visual inspection is carried out. If it is dry with a slight brown soot, it can be considered in good condition.

- If traces of gasoline are found on the spark plug, the carburetor should be re-adjusted. This happens because it supplies excess fuel to the internal combustion engine, flooding it.

- If the spark plug looks normal, check the operation of the electrical equipment. First of all, the cable that supplies current to the spark plug. Its end is brought a short distance to the radiator grille of the cylinder and the starter is turned with a cord. There should be a spark. If it is not there, the cable is checked with a tester and replaced if necessary.

- If the cable is in good condition, test the ignition coil. If the inspection does not reveal singed or broken wires, the coil is run through a tester, comparing the data with the accompanying documentation. If deviations are detected, the block must be replaced with a similar one.

After replacing the coil unit, the gap in the magneto should be adjusted. The gap between the ignition coil and the flywheel should be from 0.2 to 0.4 mm. To set the gap, you need a set of feeler gauges or you can use foil of a suitable thickness. The probe is clamped between the coil and the flywheel at the time of installation, and then pulled out.

Self-adjustment of the carburetor Partner 350

When starting to adjust the Partner 350 chainsaw, you need to clean it as much as possible from dirt and dust in the carburetor area.

The easiest way to clean a chainsaw from small chips is to use a compressor by installing a blow gun or nozzle on it.

First stage of adjustment

The Partner 350 has special holes on the left side of the top cover through which you can access the adjustment screws, but if you are adjusting the chainsaw for the first time, it is better to remove the cover. This will be more convenient, because you will see in what position the heads of the adjusting screws are located.

Next, you need to set the quality and quantity screws to the fully tightened position, and then loosen them 1/5 of a turn.

If you adjust with the cover removed, then you need to remember that the left screw is the quantity screw, and the right screw is the quality screw. To make it easier, the manufacturer puts markings (L) and (H) on the carburetor body, under each of the screws. (L) – quantities. In some manuals it is also called a screw, which is responsible for traction at low and medium speeds. (H) – fuel quality, regulates the number of maximum revolutions.

Also, there is a third adjustment screw on the carburetor, which is designated by the letter (T). It is necessary to adjust the throttle position in idle mode.

Tip: If for some reason the carburetor does not have markings on the adjusting screws, you can identify the screw (T) by the spring installed on it, which is necessary to prevent spontaneous unwinding during operation. It also has a head for a Phillips screwdriver.

Second phase

After the screws are installed in the required position, the Partner 350 chainsaw must be started and allowed to run for several minutes, since the adjustment must be carried out on a hot engine. As soon as the cylinder becomes warm, you can begin to adjust the quantity screw; to do this, you need to tighten it clockwise until the engine produces maximum speed, then immediately unscrew the screw in the opposite direction by one quarter of a turn.

In this position of the screw (L), the chainsaw should operate confidently at idle. If there is a lot or too little idle, then they are adjusted using the throttle position screw (T).

Next, using the quality screw, the maximum speed is set.

Important: it is worth remembering that correct adjustment of the maximum engine speed is possible only with a tachometer. You can only determine the number of revolutions by ear approximately

Exceeding the maximum engine speed will inevitably lead to scuffing of the CPG and premature destruction of the crankshaft and connecting rod bearings.

According to the technical characteristics of the Partner 350, it can be set to a maximum of 12,500 rpm.

Adjustment without tachometer

When adjusting the carburetor without a tachometer, you need to focus on the sound of the chainsaw and its exhaust. If the saw smokes heavily, this is a sign of improper adjustment. To eliminate this, you need to slightly tighten the quantity screw (L). If the chainsaw does not pick up maximum speed well, but works well at idle, then you need to slowly tighten the screw (H) while fully pressing the gas until the saw starts working easily.

The video below provides instructions on how to independently adjust the carburetor of the Partner 350 saw without using a tachometer. This video does not show a professional master, but an ordinary user who, using the correct algorithm, adjusted his chainsaw with high quality.