Cutting machine / grinder stand

Cutting disc machines are very often used in the field of metal processing, mechanical engineering, furniture production, and in the woodworking sector. This equipment is also suitable for household use - it is used as a very convenient tool to perform various tasks in the garage and workshop.

It is convenient to perform a wide variety of tasks on a cutting machine:

• divide the metal profile into segments of the required length; • cut sheet metal; • make blanks of the same type in large quantities in a short time; • cut ceramic tiles; • cut parts at any angle, obtain cuts of the required length and depth.

Homemade wood cross-cutting machine

With the help of a miter saw, a summer resident will significantly simplify his life. A saw of this type is offered in all construction supermarkets, but a branded miter saw is a very expensive pleasure.

In order not to buy such a tool, it can be assembled with a broach using scrap materials and old tools that almost every owner has in his arsenal. Now we will see how you can assemble a homemade miter saw with your own hands. An example of making a cross-cutting machine can be seen here.

Pendulum saw + (Video)

It’s not difficult to make accessories for an angle grinder with your own hands. You don't even need drawings here. It is enough to know the principle that is embedded in a particular machine. A pendulum saw based on a grinder is no exception. This is the same cutting machine, but its weight is distributed almost in half.

It is somewhat similar to a children's swing. A frame is located on a movable bushing, and an angle grinder is mounted on it. The counterweight can be any weight in combination with a return spring.

An angle grinder, simply a “grinder”, has three main areas of use.

- Cutting hard materials;

- Grinding with abrasives;

- Cleaning surfaces with brushes.

The technology involves holding the angle grinder with your hands while working.

However, for convenience and expanding the capabilities of the tool, many devices have been invented. Let's take a brief overview:

How to make your own circular saw from an angle grinder

From time to time, a home workshop requires a tool such as a circular saw. However, for these infrequent tasks, purchasing a saw is not profitable. In this case, it is recommended to make a circular saw driven by a grinder. This option is much cheaper than buying a factory saw to work with for a couple of hours. You can see an example of such a homemade product here.

Homemade lawn mower

Instead of a new lawn mower, it is quite possible to assemble the model with your own hands - for this you need an angle grinder and straight arms.

This lawn mower is less powerful and has small dimensions. In most cases, instead of knives, special fishing lines are installed on it to cut the grass - this is shown in the photo. A grinder mower is convenient because the tool can be easily removed and used for its intended purpose. How to make a lawnmower from an angle grinder is described here.

Mini grinding machine (grinder for workshop)

For high-quality processing of wooden and metal workpieces, it is convenient to use belt sanding machines (more popularly known as grinders).

A grinder driven by an angle grinder is a rather interesting and useful homemade product.

The design of the homemade product is light and compact, and accordingly, it does not take up much space on the desktop and does not cause trouble during transportation.

1

Electric bicycle powered by an angle grinder

Today we will look at how to assemble a full-fledged electric bicycle with our own hands, using an angle grinder as a drive.

The author of this design is Alexander Kryukov. He, together with a group of like-minded people, assembled this model of a bicycle with their own hands from a grinding machine and scrap materials. You can read about this bike here.

Grinder milling cutter + (Video)

Sometimes there is a need to mill a hole or surface, but there is no familiar milling machine operator, and there is nowhere to look. But there is an angle grinder - an angle grinder. This is the solution to the problem. We choose a machine from two options - a movable machine and a movable table.

In the first case, we secure the workpiece or material that needs to be milled, and the grinder is attached in a vertical plane to the frame. On the frame it is possible to move the plate to which the grinder is attached left - right and forward - back. In other words, we can move the angle grinder relative to the workpiece.

In another version, the grinder is fixed rigidly, and the workpiece moves, by analogy, left - right and forward - back. These are the main directions for milling. For milling along the up-down axes, it will not be difficult to supplement the device.

Having chosen the machine option, you can begin implementation. The only place that will require the involvement of a turner is the cutter holder. It is turned from a hexagon of at least 16 mm, because the thread of the grinder is 14 mm. Collet type holder. It is easy to manufacture and does not have large runouts. A regular jaw chuck does a worse job.

The advantage of such a machine, like all machines based on an angle grinder, is that they can easily be transformed back into an angle grinder. As a type of milling cutter, you can make a drill from a grinder.

Homemade electric cultivator

Those who are engaged in farming, as a rule, have in their arsenal such equipment as a cultivator. Using this equipment, you can process the soil without turning out large layers of soil or disturbing its fertile layer. The only significant drawback of such a device is its price. Because of this, farmers in our country often use a manual or electric cultivator, which is made with their own hands from an angle grinder.

Manufacturing of grinding discs for bur machines

Also, in addition to angle grinders, we quite often use a drill with small cutting discs, but the quality of such small discs is very poor, they break even from the slightest blow, so you can make such small discs from a broken large one. Just apply a small disk, trace it, cut it out with metal scissors, make a hole in the center and you can use it.

From one broken disk you can get up to 10 small pieces, depending on the size and quality and strength they will be much better. These discs can be used to saw off fairly thick metal and will wear out less.

The well-known angle grinder, with its cutting, grinding and cleaning capabilities, has turned out to be capable of several more functions. Expanding the functionality requires doing some work with your own hands in order to obtain the necessary devices for the job.

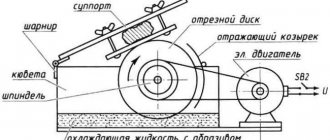

This device is a small machine with which you can easily, safely and very accurately cut metal pipes, profiles or rods. It consists of a base or small table attached to the ground or to a metalworking table.

The machine is assembled in a simple sequence:

- install a hinge on the base;

- We weld the supporting pipe to the hinge;

- We attach the U-shaped plate for attaching the grinder to the pipe;

- We put a rubber handle on the supporting pipe;

- install the disk and check its position.

As a result of some simple work, we got a machine or stand for an angle grinder. Now the grinder can rise and fall down on a hinge onto the part installed for cutting. In order for the angle grinder to rise up without loads, we install a spring on the pipe.

Do-it-yourself wall chaser from an angle grinder

The grinder can be used for tasks such as cutting cuts in the wall. These are cuts for laying wiring, pipes, and other elements. If you use a stock angle grinder for such work, it is very difficult to control the immersion depth of the disc. To solve this problem, a special frame can be made.

Read also: Is it possible to charge a screwdriver with a car charger?

This frame is made in the form of a sole with a stop, with the help of which the tool can be moved along the wall with uniform penetration. In this way, you will learn to drill the required depth. To make such a wall chaser, you need to remember such details as a protective cover and a special dust collector. For the latter, a bag can serve, but connecting a hose from a vacuum cleaner will be more convenient.

Various accessories for angle grinders allow you to expand the functionality of the tool and make it convenient.

Cool ideas for an angle grinder:

- Grain crusher.

- Lathe.

- Knife sharpener.

- Powerful drill.

- Tape grinder.

- Assembly saw.

- Home mini sawmill.

- Milling machine.

Making a wall chaser

What can you make from an old grinder? Home craftsmen ask themselves this question quite often. But if your angle grinder works properly, you can use it to make a wall chaser. By using equipment without modification, you are putting yourself at risk. In order to avoid risk, you can make a nozzle with a solid base, which will allow you to make cuts in the walls over the entire diameter of the disk.

READ What is the difference between an angle grinder and an angle grinder?

This addition is a footplate in the form of a stop that allows you to move the tool along the wall. The efforts will be uniform. When you make such a device, take the time to install a closed cover, which will be supplemented with a pipe for connecting a vacuum cleaner.

For outboard motor

The gear ratio of the angle grinder allows the propeller to give the necessary speed for efficient operation. Electric motors from many household devices are suitable for the production of a homemade boat motor. In the following video, an electric motor powered by a car battery transmits rotation to the propeller through a long shaft in a pipe and a gearbox connected to it.

The grinder gearbox is not intended to work in the water element. It is imperative that it be revised. Firstly, make a seal at the output of the spindle from the gearbox, and secondly, plug the place where it is necessary to remove the mechanism for securing the angle grinder from turning when changing tools. Such measures do not guarantee 100% no water getting inside the gearbox. However, more frequent changes of lubricant will make it possible for the grinder gearbox to work as a component of a boat motor for quite a long time.

What can you make from a grinder with your own hands?

There are a lot of ideas, the main thing is to know what and how to do it.

- A tripod for an angle grinder, which will make it possible to set the required cutting angle so that the disc moves in a vertical position. Such a structure using a grinder will allow you to cut metal material and other hard workpieces. Metal sheet, machine shock absorbers, plywood are used for the frame. The installation is reliable and no worse than what was done at the factory. When working at the machine, you must ensure that the casing is in the correct position. This tool is used for sawing wood. Make the switch non-fixed (foot pedal) - this will be safer. You can make a tool quickly, and working with it will become much more convenient.

- Clamp for an angle grinder. We fix the machine motionless in a vice, install the required disk and get an excellent sharpening machine. Before starting work, the fasteners must be unscrewed. We fix a strong stop with a slot across the disk - this will allow us to process high-strength parts.

- Disc sawmill with grinder. To do this, you need a strong frame and an angle grinder firmly fixed underneath it.

- Miter box from a grinder. By turning the tabletop using an angle grinder, we get a miter box. This device will allow you to efficiently cut skirting boards, baguettes, metal profiles, and paving slabs.

- Wall chaser. Used when laying electrical wiring, cutting in the wall. The base of the angle grinder attachment must be strong - this will allow you to easily cut walls using the entire volume of the seat disk. Along the wall, the support sole allows you to move the grinder evenly and smoothly. To connect the vacuum cleaner, you need a closed case with a pipe.

- Fraser. It is known that a grinding machine has a motor with a gearbox, which makes it possible to manufacture a milling cutter. The grinder shaft, which is necessary for processing not too hard trees, is brought out into the hole of the workbench, then the chuck for the milling heads is put on.

- Sawing machine for porcelain stoneware. Caution is needed when tilting the disk, as you can split the disk and damage the part. Controlling the depth of immersion of the grinder into the workpiece and the straight-line movement of the grinder is an important factor in this work. The cutting angle can be changed, thereby expanding processing options. Making a machine yourself causes certain difficulties, but this is one of the cool ideas for using an angle grinder.

- Cooking. Using a two-liter tin can and a piece of galvanized steel, you can make a mill without much effort and spending little time. We make a hole in the bottom of the can along the diameter of the protective casing, instead of which it is put on. We put the galvanized strip on the shaft and clamp everything with a nut for a metal disc.

- Muffle furnace with tiles. A metal plate with a triangle-shaped cutout in the workpiece shelf is required. In this design, it is necessary to make 6 holes, to which self-tapping screws are used to fix the handle, corners, and timber. In this design, all elements are mounted together with the plate. The parts are fastened with self-tapping screws. We bend the first corner to 60 degrees. We install the metal corners and secure the tool itself. To connect the tool and structural parts, use a handle and bolts with nuts.

The coolest ideas for an angle grinder and the use of this necessary tool are quite feasible if you know its design and capabilities well.

A do-it-yourself cutting machine from an angle grinder will increase the safety of work and improve the quality of the cut

Most home craftsmen use an angle grinder as a cutting tool. Some will agree later that the main thing that Bulgarian gaming slots offer is mobility – then this is also not a drawback.

Read also: Cutting tiles with a grinder video

The weight of the tool, vibrations, and the gyroscopic effect (especially on disks with a diameter of more than 150 mm) do not contribute to cutting accuracy.

What remains for our client to do: the advantages of a homemade cutting machine

on this case video

Homemade products, what you can do with your own hands, where to adapt the gearbox

A significant number of mechanisms operate at shaft speeds after the grinder gearbox. there are more options for using an angle grinder gearbox for the operation of other devices . Together with non-standard ways of using an entire grinder for homemade projects, masters of technical creativity create interesting compositions . Some are presented by the authors in specially filmed videos.

To the trimmer

Owners of summer cottages and garden plots will be interested in the following video. Many of them use trimmers to maintain the area in proper order. The possibility of failure of the electric motor installed on such a device cannot be ruled out. The author suggests using a grinder instead. Why is a bracket made from waste materials, which is mounted in place of the burnt out engine. In addition to the bracket, you should make an adapter from the angle grinder spindle to the flexible trimmer shafts. A grinder is attached to the installed structure and the trimmer is ready to mow overgrown grass.

The number of revolutions of such a modernized design is about 10,000 rpm . At such speeds, grass mowing is carried out quite efficiently. It is possible that the use of grinders of the minimum power range to reduce the weight and overall characteristics of the trimmer will lead to overheating of the grinders during operation. You should monitor the temperature of the grinder gearbox and take breaks if necessary.

Cultivator drive: Mole and more

Land owners will benefit from the experience of the author of the following video. of the cultivator failed . In its place, the author came up with a mount for the grinder and connected the spindle of the grinder gearbox to the cultivator gearbox . The speed of the grinder is certainly higher than that of a gasoline engine. However, the performance improvement advertised by the author is unlikely to occur. The problem of overheating of the commutator motor will remain and frequent stops, as a protection against it, will remain. Although for owners of relatively small plots the use of such a cultivator will be effective.

Machine

One of the structural elements of the drilling machine is a gearbox from an angle grinder (!you will learn how to disassemble the gearbox here). Working in tandem with an electric motor from a washing machine makes it possible to obtain drill speeds in accordance with the required technological conditions for processing materials. The rotor of the angle grinder is cut to the length necessary to securely fasten the rubber bushing, which acts as an elastic coupling. The other end of the bushing is attached to the motor shaft. Fastening is done using clamps.

The machine has several degrees of freedom . In addition to lifting up/down using a handle and spring-loaded suspension, the lever system allows you to change the location of the cutting tool in the horizontal plane. It is advisable to use it as a tabletop device for making holes in metal and wood parts.

Plasma cutting attachment

A plasma cutter is used to cut round pieces. The frame structure, as shown in the following video, serves as a device for securing and adjusting the diameter of the resulting workpieces. The “trick” in using an angle grinder gearbox is that its conical pair changes the direction of rotation by 90° . Thus, the manual drive creates rotation in the horizontal direction, and the gearbox transfers it to the vertical direction and ensures the correct functioning of the plasma cutter.

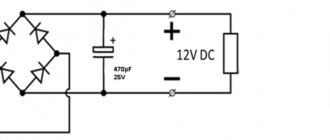

For electric bike/motor

If you are tired of pedaling a bicycle, an idea with a grinder drive is in the next video. Here the author installed a grinder on the frame, and installed a drive sprocket on the spindle for chain transmission to the driven sprocket on the rear wheel. The power source is a rechargeable battery , which is paired with an inverter voltage converter from 12 V to 220 V. The bicycle handle is mounted with a pull rod for turning on the electric drive through an inverter converter, which regulates the rotation speed at partial load modes on the bicycle. An original solution to stabilize the maintenance of the grinder's operating mode using an elastic element in the form of an elastic band requires a more detailed refinement of this unit. In stationary mode, this design is functional, but in “combat” conditions a lot of modifications will be required, especially in terms of adjustment in transient conditions.

For outboard motor

The gear ratio of the angle grinder allows the propeller to give the necessary speed for efficient operation . Electric motors from many household devices are suitable for the production of a homemade boat motor. In the following video, an electric motor powered by a car battery transmits rotation to the propeller through a long shaft in a pipe and a gearbox connected to it.

The grinder gearbox is not intended to work in the water element. It is imperative that it be revised . Firstly, make a seal at the output of the spindle from the gearbox, and secondly, plug the place where it is necessary to remove the mechanism for securing the angle grinder from turning when changing tools. Such measures do not guarantee 100% no water getting inside the gearbox. However, more frequent changes of lubricant will make it possible for the grinder gearbox to work as a component of a boat motor for quite a long time.

For a screwdriver

The screwdriver used by the author of the following video already has to work under extreme loads . The use of a reduction gear from an angle grinder increases the amount of torque and allows you to cut threads in more comfortable conditions. Here we use a burnt angle grinder , where the rotor is cut to a length that at the same time allows us to securely fasten the end of the cut shaft in the screwdriver chuck and fit the plastic body of the angle grinder tightly onto it. For a more thorough connection, the screwdriver is attached to the body of the angle grinder with fasteners, while the gearbox bearing of the angle grinder fits into its seat. Drilling and cutting threads with tooling prepared for such work does not require any additional effort.

Sliding gate drive

The following video shows one of the options for driving sliding gates based on a gearbox from a burnt angle grinder and an old screwdriver. The drive is equipped with an automatic device for controlling the opening/closing of the gate. The chain drive with a drive sprocket on the gearbox spindle operates at high speeds to perform the gate control function, therefore creating increased noise during operation.

On a chainsaw, how to use an angle grinder as an attachment and other options

The various capabilities of angle grinder attachments to perform technological operations (cutting, stripping, grinding, polishing and others) are reduced to zero in the absence of power supply. The grinder performs its functions only in the presence of electricity. However, in outdoor conditions there is a device in the form of a chainsaw on which angle grinder attachments can be installed. Why do the following with a chainsaw:

- remove the standard chains and tires from it;

- install a pulley instead of the sprocket;

- put the belt on the pulley and press it with the lid;

- tension the belt using a special device.

The following video shows the installation of an angle grinder attachment with a cutting disc and the tools used for this.

On a scooter

For people obsessed with technical creativity and who want to make their young children or grandchildren happy, the idea of creating an electric scooter is in the next video. a cordless grinder that is not currently in use , and materials for making the scooter itself. Of course, the main thing in the success of this homemade product is that the master has universal skills of a mechanic, turner, welder and many others. By the way, the grinder can be easily removed and used for its intended purpose.

Sections: How to make, Gearboxes

Previous article: Do-it-yourself repair of grinder gearboxes Next article: Do-it-yourself soft start of an angle grinder

Advantages of a cutting machine from an angle grinder

If necessary, simply cut pieces of an old water pipe for gartering cucumbers - accuracy is not a matter of principle. In cases where precise cutting of the material for welding any structure is required, a tolerance of 3-5 mm will be critical.

The next problem is maintaining the perpendicularity of the cut. It is virtually impossible to achieve a straight strip at an angle of 90 degrees to the axis of the workpiece, holding the grinder on your palms. The same goes for fixed angle cuts. When misaligned, abrasive discs are often destroyed, and fragments can cause injury.

When you cut a lot of workpieces, after 2-3 hours of work you will generally not have the strength to hold the tool in your palms, there is no need to talk about accuracy here.

Sawing wooden blanks is a separate topic. Carefully about the grinder blades for wood, not about how you can cut wood with them here. Using special discs, which can be used to safely work on wood, you will not achieve a high-quality cut. And proper circular saws mounted on angle grinders are fatally unsafe for the master holding the tool in his palms.

There are factory versions of machines that fix the grinder without turning the work of cutting blanks into a harmless, unclear task. But such devices are quite expensive, and are not even always universal. Simply put, finding a specimen that is perfectly suitable for your angle grinder is a difficult task.

Homemade products from an old grinder

What other homemade products can you make from an old grinder? For example, you can simply design a grinding machine on rollers, which is very easy to use. To produce a grinding machine from a grinder, you will need two narrow strips of metal, a pin with a diameter of 8-10 mm, washers and nuts.

The photo of a homemade grinding machine shows that two rollers or bearings are attached to the bottom of the iron strips, which allow you to effortlessly move the grinder along the workpiece. With all this, the grinder is attached to strips of metal using a pin, which actually allows you to adjust the height of the grinder above the workpiece.

It’s quite easy to make a homemade garden mower out of an angle grinder. For these purposes, you will need to use an old wheelbarrow, at the bottom of which there is a grinder

with knives or fishing line for cutting grass. The only drawback of this homemade grinder will be that to connect the power tool you will need to use a rather long carrying case. In this case, it is even better and more convenient to use an old cordless screwdriver.

What else can be made from an old grinder? Here is a compact compass for cutting circles or, for example, a belt grinder, as in the photo. To do this, you need to take two square pipes of different diameters, insert a spring into the larger one to tension the tape. The shaft of a homemade grinder from an angle grinder is made of wood with a nut inserted inside to secure the shaft to the angle grinder.

READ How to Make a Chainsaw Hiller

You can also make a machine for sharpening twist drills from a grinder, as well as a full-fledged circular saw. It should be seen that the design of circular saws made from an angle grinder can be very different. The pictures below show perhaps the most common version of a circular saw.

It won't be too difficult to do

from an angle grinder, you will just have to work hard in advance to install 3-4 disks (depending on the appropriate width of the groove) on the angle grinder shaft.

There is only one way out - make a cutting machine with your own hands

What elements must be foreseen in the design:

- A strong, not languid frame. The best option is to securely fasten the structure to a stable workbench;

The stand for the rocker will fit strictly perpendicular to the table.

- A swinging bracket (yoke), which is made taking into account the design features of your angle grinder;

- Comfortable grip handle, which ensures safe vertical movement of the angle grinder;

If you can secure the grinder in such a way that you can use the standard handle, this is the most reliable option.

A spring that will return the tool to its initial position after finishing the cut;

The correct option is a tension spring with a return stroke of less than 2-25% of the stroke of the angle grinder gear axis.

Mandatory with the use of any kind of disc, for example an abrasive, as it is also called an iron circular. The open working sector is not expected to be oriented towards the operator.

Self-refinement to a cutting machine

The simplest homemade machine is a machine made from a small angle grinder. The work will be accompanied by a minimum of costs, and manipulations will take a few hours. The exit structure will be a long metal pipe that serves as a handle and frame.

A metal transverse strip with two holes for fastening the tool is welded to one of the ends. On the same side, the pipe is fixed to a piece of angle on a movable shaft. The first one can be fixed to the desktop or to the floor in the workroom. If you are faced with the question of what can be made from an angle grinder, you can use a cutting machine using the described algorithm. According to it, on the opposite side of the fastening it is necessary to fix a spring, which will ensure the return of the structure to its original position. After completing this stage, you can use your homemade product. You just need to install the device correctly.

This version of the machine is the simplest solution for metal processing, while complex work will require precision, so the design for solving such problems must be made more stable, which means the work will have to be approached more thoroughly.

Starting device for a homemade machine

Let's look at this component in more detail. There is a good old version of the NVG 30-U start button.

The principle of operation is as follows - to start the device you need to press the “start” button with force. To turn it off, simply lightly touch the “stop” button, which is located above the start key. For emergency shutdown

very convenient and safe.

There are also modern interpretations. The principle of operation is the same - the shutdown button is more accessible than the start button.

The safest way to turn on an angle grinder on a cutting machine is with a non-fixed pedal. Control is performed with the foot, both hands are free at the time of launch. In case of an emergency, simply remove your foot from the pedal - the instrument is de-energized.

Of course, this makes the design more expensive, but safety issues have no monetary value.

Read also: Checking sand compaction with a density meter

Quite a lot of designs have been invented, using different materials - wood, textolite, metal profile. In our opinion, the most successful in terms of safety and accuracy of work is a homemade machine made of profiled steel pipe.

How to properly make a machine from a grinder?

Let's take a step-by-step look at the process of making one of the successful specimens. The design is quite complex from a technical point of view, but at the same time its versatility and functionality exceed the characteristics of factory copies.

A special feature of the design is the ability to adjust the reach of the angle grinder along the guide. To do this, use a pair of old shock absorbers from a car.

Since shock absorbers cannot be used as a supporting structure (the walls are too thin), strong brackets are made from a suitable pipe.

All blanks were purchased at a scrap metal collection point, that is, practically free of charge.

Related Posts

DIY Apple Crusher From a Grinder

Types of crushers for a farm plot Chopping equipment on a summer cottage has a very diverse application. When using it, of course, grind coarse grass feed, crush fruits into juice, and create combined mixtures for feeding young animals. Such mechanisms are often quite expensive. However, there is always the option of making a crusher in . 1 Types of crushers for a farm plot Before […]

How to Make a Drill At Home.

How to make a drill at home.