Chainsaw carburetor design

Almost all carburetors used in the production of chainsaws have the same design. The only difference is the mechanisms with which Chinese garden tools are equipped.

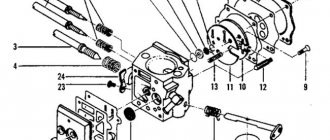

As standard, the fuel unit consists of the following parts:

- float chamber - this element is designed to continuously maintain the required amount of fuel. When the unit is operating, fuel is transferred through a built-in nozzle to the atomizer;

- tube - through it, fuel enters in portions into the chamber. The fuel supply is regulated by the position of the built-in factory damper;

- atomizer - this part is necessary for injecting fuel into the intake air flow.

The operating principle of a chainsaw carburetor is quite simple. During operation of the unit, air is sucked into the tube and passes through it at a speed that is regulated by the built-in damper. When the damper opens, the float located in the chamber is activated. After passing through the diffuser, the air is mixed with fuel and instantly atomized. Next, the high-quality fuel mixture enriched with air passes through the intake channel and enters the engine cylinder. The diagram will clearly tell you about the operation of the carburetor.

The fuel circulates in the unit under pressure. In the float chamber it is close to atmospheric, but in the standard tube that sucks in the air, it is more rarefied. Due to the difference in the pressure generated, the fuel mixture enters the tube. The greater the amount of fuel, the higher the speed the engine of a household chainsaw can create.

How to flush a chainsaw carburetor?

You can clean the carburetor on a chainsaw using any aerosol cleaner. The brands Mannol, Hi-Gear and Nowax have proven themselves best. These compounds are good at cleaning the walls and parts of the carburetor from accumulated dust, carbon deposits and hardened resin.

Both Chinese and German carburetors are washed in the same sequence.

Cleaning the carburetor on a chainsaw is performed in the following order:

- First, you need to drain the used fuel remaining in the fuel tank. Next, you need to unscrew the mount and remove the protective cover of the chainsaw body, and also remove the standard air filter;

- Next, you need to remove the hose responsible for supplying fuel. To do this you will need to open the latches. After this, you need to unscrew the fasteners and remove the top cover of the factory assembly housing;

- Next you will need to remove the cover with the blue gasket, which plays the role of a fuel pump membrane. Near the body there are brackets in the form of springs. They will need to be removed and the screws removed;

- Then you need to unscrew the screw and carefully remove the needle valve. Directly below it is a built-in spring, which also needs to be removed. After this, you need to pull out the damper and the standard axle, carefully pulling them along towards you;

- After this, you will need to remove the drive arm, as well as the throttle body and its factory axle;

- All extracted parts of the chainsaw carburetor will need to be laid out on paper and their integrity checked. If necessary, worn parts must be replaced;

- Next, all dismantled parts must be washed with a spray can. The same must be done with the float chamber and carburetor body.

- After complete drying, all parts must be installed in the reverse order.

After washing, the carburetor will need to be installed in its regular place in the chainsaw. Next, you will need to start the garden tool and observe its operation at idle and maximum speed.

Adjusting the chainsaw carburetor

This procedure is necessary specifically in cases where a garden tool does not start or, after starting, immediately stalls. Adjusting the carburetor of a chainsaw is also necessary when its power has dropped or the amount of fuel consumed has noticeably increased.

For self-adjustment, each manufacturer includes adjusting screws in the package of their garden equipment. The bolt, marked H, is used to adjust the position of the main jet and the operation of the internal combustion engine at high speeds. Bolt L is necessary for basic adjustment of the position of the built-in idle speed jet generated by the motor. Accordingly, the T screw is required by the chainsaw owner to quickly adjust the idle speed of the factory engine. In some cases, this bolt is also marked with the letters S or LA.

How to properly adjust the carburetor on a chainsaw?

Before setting up the carburetor on a chainsaw, you need to carefully prepare for the procedure. First of all, you need to find descriptions of the angles of rotation of the adjusting screws in the instruction manual. If you arbitrarily turn the bolts without following the manufacturer's instructions, this can lead to serious damage to the engine of the tool.

The motor itself must be in full working order. You should also thoroughly clean the air filter before tuning. Otherwise, it will not be able to pass air in the volume required to enrich the fuel mixture, which will lead to incorrect carburetor settings.

Adjustment of the unit must be performed on a flat surface. The saw itself should be installed so that its saw attachment is located away from the operator's feet and face. Immediately before tuning, you will need to remove the upper part of the protective plastic body of the tool, as well as remove the foam rubber and part of the standard air filter. To configure the unit, you will need a thin shaped screwdriver.

Why does the chainsaw not pick up speed and gets lost?

If the chainsaw can't get up to speed or stop when you pull the trigger one minute after starting, the carburetor or crankcase may be leaking. As in the previous case, the problem can be solved by checking the leaks and adjusting the carburetor.

If the chainsaw does not pick up speed and stops after running normally for about 5 minutes, a faulty breather hole may be the cause. The vacuum created in the fuel tank while the tool is running will prevent the engine from receiving the required amount of fuel to operate properly, and therefore it will not be able to accelerate or stop. However, if you stop the tool, open and close the fuel cap, and start the chainsaw again, the tool will return to normal operation for about five minutes, after which it will stop accelerating or be delayed.

READ Where to Sharpen a Chainsaw Chain

The reason your chainsaw won't pick up speed could be due to excessive soot in the muffler, which makes it harder for the exhaust gases to exhaust itself, thereby reducing engine power and speed.

If desired, it is necessary to check the crankcase for leaks, but if a special tool is not available, the following testing procedure can be used.

Algorithm for checking crankcase tightness

- Remove the side cover and bar from the chainsaw.

- Unscrew the spark plug and pass the cord with the knots in the cylinder through the spark plug hole, thereby stopping the movement of the piston and crankshaft.

- You can use an old starter cord as a knotted thread, tying 3-5cm knots in it.

- Unscrew the chainsaw guide sprocket.

- Remove the oil pump cover and the pump itself.

- Remove the starter from the chainsaw.

- Unscrew and remove the flywheel.

- Remove the carburetor.

- Using a syringe, pour gasoline into the crankcase through the carburetor hole in the cylinder, keeping an eye on the crankshaft seal oil. If gasoline leaks through them, the seals have become unusable and must be replaced with new ones.

- It is better to entrust the installation of oil seals to professionals.

What to do if gasoline does not flow into the carburetor of the chainsaw?

The first reason for this failure is that the fuel filter is clogged with dust and dirt. This happens due to the presence of a large amount of harmful impurities in gasoline and the used motor oil. Over time, they accumulate on the surface of the filter, causing it to lose its ability to pass fuel. To solve the problem, you will need to thoroughly clean the filter by rinsing it in a bath of cleaning agent. If the filter develops holes or other signs of wear, it needs to be replaced immediately.

The second cause of failure is contamination or breakage of the tube through which fuel is supplied to the carburetor. If the hose is not torn, then cleaning it will be enough to thoroughly blow it with compressed air from an aerosol. If the tube is broken, it will need to be replaced. When installing the hose, the joints between it and the fittings must be carefully treated with sealant.

There is one more malfunction that occurs much less frequently than the previous two. It consists of a breakdown of the valve that regulates the rate of fuel supply to the carburetor. If dust or small chips get inside its mechanism, the damper is blocked and remains in the closed position. Repair of the unit can only be done by replacing the damper, since it most often cannot be restored.

Faulty timing belt

Malfunctions in the operation of the gas distribution mechanism are generally similar to problems with ignition. In particular, the exhaust valve opens at a time when the gasoline has not yet burned out. Accordingly, it enters the exhaust gas removal system, leading to the already familiar popping sounds in the muffler.

There are several causes of malfunctions in the timing system:

- Timing belt wear . A sign of this malfunction is the appearance of additional metallic pops or noises when the engine is running at low speeds. In this case, you need to inspect the belt and, if necessary, tighten or replace it. You can read how to do this in the corresponding material.

- Worn toothed pulley . In this case, it is necessary to replace it.

- Partial valve failure . Over time, they become covered with soot (especially when refueling the car with low-quality gasoline), which leads to deterioration in the operation of the mechanism. And due to hanging valve springs, the engine overheats. Therefore, it is worth checking the valves. If you find slight roughness or bends on their surface, then grinding them in is a mandatory procedure. If the scratches are significant, you need to polish them or replace the valves.

Read also: Tin-copper alloy

Usually, if the timing belt is faulty, popping noises in the muffler are heard when the engine is warm . If the engine is “cold”, then they are not there. This is another indirect evidence of the timing's guilt. However, to find out exactly, it is necessary to perform additional diagnostics.

Why does a chainsaw shoot into the carburetor?

Often, chainsaw carburetor malfunctions are associated with loud extraneous sounds that come from the unit. Ignoring them will lead to even more serious damage, which will be much more difficult to eliminate.

First of all, you need to understand the causes of extraneous sounds. The first of them is an incorrectly set ignition, due to which the used fuel does not have time to burn in the internal combustion engine cylinder in time. This leads to the formation of a short-term shooting noise that is repeated with each cycle of fuel injection into the cylinder.

To fix the problem, you need to adjust the gap between the flywheel and the standard ignition coil of the chainsaw. To do this, you need to remove the left protective cover of the plastic case and clean the parts underneath. To the right of the ignition coil there are 2 screws, turning them counterclockwise will allow you to move the flywheel away from the standard coil. Next, you will need to attach a template to the side of the coil and begin to slowly turn the factory screws in the opposite direction. As soon as the built-in flywheel comes close to the previously installed template, you will need to stop turning the screws.

After adjusting the ignition gap, you need to check the operation of the chainsaw. If it still fires, then you need to inspect the spark plug. If carbon deposits have accumulated on it, the part must be cleaned and completely dried.

Another reason why the chainsaw you are using is firing is due to the incorrect proportion of the prepared fuel mixture. If there is too little gasoline or motor oil, the engine of the garden tool will not be able to operate stably. In this case, you will need to completely drain the fuel and prepare the mixture in accordance with the manufacturer's instructions.

In some cases, a disturbance in the supply of fuel to the engine cylinder may be caused by improper operation of the standard carburetor jets. In this case, you will need to adjust the carburetor and alternately check the operation of the tool at idle, low and high speeds.

Checking the spark plugs

The first step is to check the spark plugs. You need to disconnect the wire that goes to the latter and unscrew it with a special key. Based on the condition of the spark plug, you can determine possible problems:

- a dry spark plug indicates that there is no access of the incendiary mixture to the cylinder; the ignition system has nothing to do with it. The cause of the breakdown may be a clogged conductive tube or a problem with the carburetor. It is necessary to clean the fuel line and check the functionality of the fuel pump and carburetor. If one of the mechanisms does not work, it is necessary to replace it with a new one, since repairing the latter is impossible in the absence of professional skills;

- A wet spark plug indicates an excess of fuel mixture in the cylinder or water getting into it. It is necessary to dry the spark plug, remove any remaining liquid and blow out the cylinder chamber - with the fuel supply turned off, start the starter. Then you should put the spark plug on and start it again. When checking, you need to measure the gap between the electrodes; an indicator from 0.5 to 0.65 mm is considered acceptable. In case of damage or signs of abrasion, the gasket must be replaced. If after the above operations the spark is good, there may be a problem with the quality of gasoline. Absence or unevenness is an ignition problem. There is a possibility of damage to the supply wire or spark plug. If the new spark plug does not respond, it is necessary to inspect the starting system in more detail;

- a spark plug with a black coating of soot is evidence of the possible use of low-quality lubricant, an imbalance in the “gasoline-oil” balance in favor of the latter, or a clogged one of the filters. Clogging leads to a loss of power of the chainsaw and its subsequent stoppage. The dust does not burn completely and settles on the cylinder walls as a layer of black soot. You need to change the fuel, clean the fuel filter, wash and dry the air filter. Remove soot from the candle using an awl or needle, and clean the contacts with medium-sized sandpaper.

How to extend the life of a carburetor?

To prevent the breakdown of a standard unit, the owner of a garden tool should adhere to a number of rules. These include:

- using a properly prepared fuel mixture - each time you mix gasoline and engine oil, you must strictly adhere to the proportions specified in the operating instructions;

- use for refueling gasoline of the brand specified by the manufacturer - for operating an engine running on AI-92 gasoline, AI-95 fuel is not suitable, and vice versa;

- regular washing - cleaning the unit from dust and dirt accumulated on the walls will make its daily work easier;

- tuning the unit immediately after detecting problems - there is no need to delay adjusting the carburetor, as this can lead to even more serious damage.

During operation of the chainsaw, you need to ensure that dust, sawdust and small debris do not seep under its body. Otherwise, they will quickly clog the carburetor and block its operation.

Summarize

At the first sign of a chainsaw malfunction, it is necessary to carry out a full diagnosis. To avoid damage to your saw due to improper maintenance, it is best to leave the job of identifying and repairing engine problems to professionals. And most importantly, you don't want to use a chainsaw with minor defects because it will lead to even bigger problems.

Source

There are several simple rules for operating and maintaining chainsaws, the observance of which will increase their service life. Preparing the correct fuel mixture, regularly cleaning filters and periodically replacing parts will save you from having to repair the tool for a long time. If it is impossible to avoid a breakdown, you can find out the cause yourself. This applies to all brands of chainsaws, from the more complex Husqvarna and Stihl models to the simplest Makita and Patriot models.

Chainsaws immediately

What to do if immediately after starting the chainsaw? First you need to check the fuel in the gas tank. If its level is insufficient, the fuel mixture must be prepared in strict accordance with the ratio of gasoline and oil specified in the operating instructions. Gasoline must have the highest possible octane number, and the required brand of oil is usually indicated in the chainsaw's passport.

READ Made from a Hand Circular Saw

Next, check the spark plug, as well as the contact of its tip with the high-voltage wire. The gap between them should be no more than 0.5 mm. If necessary, the candle is cleaned of carbon deposits and dried. It is recommended to periodically replace the spark plug with a new one. The reasons why the tool stops when you press the gas are hidden in the fuel filter or carburetor jet. Cleaning the gas filter will not take much time and effort, but it is better to entrust disassembly and cleaning of the carburetor to service center specialists.

Chainsaw chains idling

It is common to see a chainsaw idling. First of all, you should check the muffler and, if it is dirty, clean it of any resin deposits. Also on carburetors of some models and others there are bolts marked H and L. respectively, rough and fine installation. By adjusting the L bolt while the chainsaw is running to increase its speed (turning the bolt only half a turn), you can solve this problem. Adjusting the carburetor requires an electronic tachometer and is a rather labor-intensive process. That is why in such cases it is better to turn to professionals.

Chainsaws during loading

If the chainsaw is under load, the cause may be the fuel system or a dirty air filter. Change the fuel to the correct gas/oil ratio or clean the air filter. universal solutions to this problem. An incorrectly prepared mixture of low-quality gasoline and, for example, motor oil is the main reason for the failure of a chainsaw, including when it heats up and lags.

Chainsaws at tilt

When the chainsaw is positioned horizontally, the fuel pipe lies at the bottom of the fuel tank; when the tool is tilted, the pipe is above the fuel mixture, that is, in the air. This is why the chainsaw stands on its side.

Chainsaw chains at high speeds

If the tool lags at high speeds, there are three parts that need to be checked: the air filter, the fuel pump and the gasoline filter. The air filter needs to be cleaned; you can even rinse it under water and dry it thoroughly. Then it is enough to disconnect the fuel hose from the carburetor and see whether fuel flows out of it or not. If it leaks completely, the gas filter cannot be tested. If on the contrary, the fault is detected. The breather can be cleaned with a regular needle, and the filter can be carefully disconnected from the suction hose, cleaned or replaced with a new one. The gas pump is checked for wear: if fuel does not flow through it, there is nothing wrong with it. If the problem with your tool stalling at full speed is caused by some damage to the pump, the part simply needs to be replaced with a new one.

- Blog

- About the service center

- Brands are served

- Diagnostics and repair prices

- Delivery

- Spare parts

- Contacts

Repair and maintenance of garden equipment.

Specialized service, Comprehensive warranty and post-warranty service for gardening and municipal equipment from global manufacturers! We sell spare parts with delivery throughout Russia!

Source

Chainsaws are no longer a luxury, but a necessary tool for those who have a country plot or household. But like any other method, this tool usually fails, despite its simple design.

The classification of main faults includes:

- Complete absence of engine

- Engine starts and stops

- Unstable operation of the tool

- Stopping work during loading

- Electricity losses.

If the chainsaw does not start at all, the reason may be as follows:

- Manufacturing defect

- Lack of fuel

- Problems starting the ignition system

- No spark from spark plugs

- Poor fuel mixture

- Carburetor

- Problems with high voltage wire

- Without compression.

Why does the chainsaw start and lag, what should I do in this case? The reasons for this must be considered in detail.

No. 1. Chainsaw won't start

If difficulties arise with starting a chainsaw, many immediately blame the carburetor. In fact, there are several options and the cause of the malfunction can be any:

- Air and/or fuel filters are clogged. The problem can be solved by cleaning the filters.

- Lack of fuel in the tank. Yes, there is such a reason - some owners forget about such an insignificant detail as refueling a chainsaw and think that a couple of liters of gasoline will last for six months. In addition, fuel in the tank should not be stored for more than 14 days, because gasoline evaporates and the octane number is lost.

- Check the pipe from the fuel tank to the carburetor - it could be clogged or broken, so gasoline does not flow into the tank.

- There is no spark at the spark plug. Why there is no spark - there can be many reasons: there is no contact, the spark plug needs to be changed or it is flooded. Why the spark plug on a chainsaw fills is another question. But if this happens, you need to dry it and reinstall it, and then check for a spark. If there is heavy carbon deposits on the spark plug, it is recommended to replace it.

- Check the muffler for carbon deposits. If there is carbon deposits, thoroughly clean the muffler, but it is still recommended to take the chainsaw to a service center to have the cylinder and piston checked, because carbon deposits are a sure sign of improper operation of the elements of the cylinder-piston group.

- The carburetor is clogged. How to properly adjust a chainsaw so that the carburetor works well is discussed in a separate article.

If none of the above methods helped, then the reason is more serious - a breakdown of one of the connecting rod-piston group units. In this case, it is recommended to take the chainsaw to a service center.

Chainsaw Sneezes and Stalls

Content

The chainsaw starts and stalls, the reason

A chainsaw has long been no longer a luxury, but a necessary tool for anyone who has at least some suburban area. With its help you can carry out gardening work, harvesting firewood, processing lumber and much more. There are many models of chainsaws on sale, varying both in power and overall quality. You can verify this here. e-catalog.ru.

But no matter what equipment can be capricious, and chainsaws are no exception. Let's look at more relevant difficulties.

The tool stalls immediately after starting

One possible reason is a lack of fuel. Check the amount of fuel in the gas tank and add as needed. In all this, you should strictly follow the advice in the instructions, especially with regard to the properties of gasoline and oil. In our country, such subtleties are often ignored, filling the saw with whatever is necessary, which causes accelerated wear of the motor and leads to failures.

READ Dismantling Chainsaw Shtil 180 Video

The saw may also stall due to deterioration in the contact of the spark plug with the high-voltage wire. This may be caused by mechanical shear or carbon deposits. From time to time, it is recommended to occasionally replace the candle with a new one, even if the old one did not show any problems in operation.

Chainsaw stalls when pressing on gas

The video discusses a fairly common malfunction of chainsaws

and 100% carburetor option method. How did you do it?

The chainsaw stalls when you press the gas

The chainsaw stalls

when you press the gas.

The Partner 370

chainsaw to stall with the slightest pressure on the handle.

The chainsaw can work normally when in a straight horizontal position, but stalls when tilted to the side. Usually this is also associated with a lack of fuel: the fuel tube rises when tilted, and if there is not enough fuel, it rises above the fuel level.

Chainsaw stops idling

Firstly, it is recommended to check the muffler, because its contamination can lead to a deterioration in the exhaust gases, which is why the engine stops.

READ Disassembly Reassembly Chainsaw Partner

If cleaning the muffler did not help resolve the problem, and your saw has a carburetor engine, then you can try adjusting it. Most engine models have coarse and fine adjustment bolts (H and L, respectively). By increasing the engine speed with their help, you can eliminate the problem. Keep in mind that carburetor adjustment is a fairly specialized process that requires the implementation of a tachometer.

The engine cannot withstand the load

If the chainsaw stops right in the middle of a particularly thick log, then the problem may be caused by problems in the fuel supply system or problems with the air filter. The engine simply does not get enough flammable consistency to work with a heavy load, and it stops.

The usual solutions to these problems are changing the fuel in strict accordance with the advice in the annotation (we have already talked about this) and cleaning (replacing) the air filter.

The chainsaw stalls when the speed increases

The reasons for this phenomenon are similar to the previous ones: either the problem is in the fuel system or in the air filter. Try disconnecting the fuel hose from the carburetor - if gasoline flows poorly (but you know for sure that there is fuel in the tank), then the reason is the gasoline filter. You can also check the fuel pump - fuel should not leak through it. If this happens, then it is advisable to replace the pump.

READ Chainsaw Adapter for Grinder

No. 2. The engine stalls

The engine starts, but the chainsaw stalls at idle or under load. In this case, most often you should perform the same actions as described above.

How to adjust a chainsaw depends on exactly when the problems start:

Stalls immediately after starting:

- The fuel mixture is not prepared correctly, there is too much oil in it, so the octane number of gasoline is less than it should be, so the chainsaw only runs on choke or stalls immediately.

- Carbon deposits on the spark plug or improper gap between the spark plug and the wire.

It stalls and does not work at idle:

- The muffler is clogged. It is necessary to remove carbon deposits.

- The carburetor settings are off. The idle speed on the chainsaw needs to be adjusted. This is done using adjusting bolts marked L and H. For how to adjust idle speed, see the article about adjusting the carburetor.

Stalls at maximum speed and only runs on choke

- The air or fuel filter is clogged. The seals need to be cleaned and checked.

- The breather is clogged and because of this, fuel does not flow and pumping gasoline on the chainsaw does not work. Take the needle and carefully clean the breather.

- Fuel pump malfunction. Remove the pump and check to see if gasoline is leaking from it. If it oozes, replace the sealing gasket or the pump itself.

The chainsaw does not cut under load and stalls

- The air filter is clogged. It is necessary to take out the filter, clean it well or even rinse it, dry it and install it back.

- Wrong proportion of oil/gasoline mixture. Drain the fuel and remix the oil and gasoline in the correct proportions.

Troubleshooting

If the chainsaw stalls for no apparent reason and it is not possible to establish even approximately possible problems, then it is worth going through all the possible reasons sequentially. Of course, there are typical, standard faults which we will talk about below, but for now we are going step by step!

1.Check the fuel mixture.

Firstly, it must be prepared according to the manufacturer’s recommendations and using high-quality ingredients. Secondly, exhaust the tank completely or drain the fuel mixture before long periods of inactivity or storage between seasons. Read more about fuel here:

Gasoline for a chainsaw: which one to use?

2.Clean the air filter or change it.

A dirty air filter does not allow the supply of air in the volume for which the chainsaw is designed for normal operation. That is, if the carburetor that mixes the air and fuel mixture was adjusted with the same amount of incoming air, then when the air filter is dirty, the amount of air decreases, but the settings remain the same and as a result we get an enriched working mixture.

It would be a good idea to read: How to choose a chain for a chainsaw?

Adjusting the chainsaw carburetor

Choosing the right chainsaw

3.Check the spark plug.

There may also be several sub-items here. The first step is to unscrew the spark plug of the chainsaw and check whether it has flooded during startup attempts. This especially often occurs when the chainsaw is started by inexperienced users who do not follow the sequence of starting the saw when cold. In this case, you need to dry the spark plug or screw in a new one and try again according to the instructions. The spark plug tip may fail. You can check this by unscrewing the spark plug and inserting it into the tip, placing it on the block and pulling the starter cord a couple of times. If there is a spark, then the spark plug and other electrical components are in order.

Another step in checking the spark plug is to check the spark plug gap and for carbon deposits. See the manufacturer's recommendations for clearance. As a rule, this is from 0.5 to 0.65 millimeters. Carbon deposits from the spark plug are cleaned with fine-grained sandpaper or a wire brush. Read more about candles here:

Diagnostics of a chainsaw engine based on the condition of the spark plug

4.Check the fuel filter.

As with the air filter, the situation with the fuel filter leads to a change in the composition of the working mixture. Only if the air is contaminated does the mixture become richer, and if the fuel is contaminated, on the contrary, does it become leaner. The chainsaw engine will not operate if there is insufficient fuel in the working mixture. In addition, if the fuel filter is clogged, the uniform supply of fuel to the carburetor and further to the combustion chamber is disrupted. This is especially noticeable when the chainsaw stalls when you press the gas.

5.Check the breather.

WITH

The breather is a check valve that is located in the gas tank of a chainsaw and prevents the formation of a vacuum in the tank. If it is clogged, then no air comes in instead of the used fuel mixture and the fuel pump cannot cope with the fuel supply.

There is often a situation when fuel is pumped into the carburetor using a primer (pump for pre-priming fuel) and the chainsaw starts up. After the fuel supply in the carburetor is used up, and due to the blockage of the breather, fuel is not supplied, the chainsaw stalls.

6.Checking the carburetor

In 50% of cases, if not more, the reason that a chainsaw stalls is an incorrectly configured or failed carburetor.

Read about carburetor settings here: https://benzopilatut.ru/benzopila-husqvarna-xuskvarna-137-regulirovka-karbyuratora

What malfunctions can a carburetor conceal?

- The jets, injectors, filter, and channels are clogged. Given the “quality” of domestic fuel, the fuel filter often fails to cope with its responsibilities of cleaning gasoline from dirt, debris, and impurities. In this case, the jets become clogged and fuel is either supplied in insufficient quantities or not supplied at all. Often the chainsaw noticeably loses power. The carburetor needs to be disassembled and cleaned. Remember that the carburetor consists of small and very small parts! Therefore, before disassembling it, prepare the place in advance!

- The accelerator pump needle sticks. Often, as a result of wear or foreign objects, the accelerator pump needle may become stuck. In this case, the chainsaw may simply not start, work unstably, or stall for no apparent reason at any time.

- The check valve needle does not fit tightly to the seat. In this case, the spark plug will flood, the saw will work unstably or stall under load. It is very difficult to grind the needle to the valve seat! It is often easier to replace the carburetor...

- Worn or damaged rubber seal in the accelerator pump. If cracks appear on the cuff or it is damaged, for example during disassembly, then additional air flow (“suction”) will begin. This, in turn, will first lead to an increase in speed, and then the chainsaw will simply stall. All you need to do is replace the cuff.

- Sometimes it happens that air begins to “suck” from under the carburetor gasket. It is often very difficult to determine where exactly the “suction” is going, and in this case, you may have to change all possible seals and gaskets.

7.Checking hoses, seals, gaskets

One of the most common problems that cause a chainsaw to stall or not start is air leaks. A saw can suck in air in many different places. Check in order:

- Fuel hoses. Often, from time to time or when using low-quality materials, micro, and even non-micro, cracks can form in fuel hoses. In most cases, they can be identified by visual inspection. It is also worth inspecting the attachment points of the hoses. If the hose does not fit tightly, there may be a leak there.

- Oil seals. Even the highest quality seals can lose their tightness under the influence of time and during operation. In this case, the quality of the mixture is compromised and the saw either works unstably or starts and stalls. How to check chainsaw oil seals? There are only two of them and both are installed on the crankshaft. In order to check their tightness at home, I know of two options: 1. Check them by supplying air under pressure. This can be done using a compressor, preferably a stationary one, but you can also use a car one. It is necessary to plug all holes, namely the outlet on the muffler side and the inlet on the carburetor side. We unscrew the spark plug and apply air under pressure. If pressure is not created or you just hear a hissing sound, then this is a clear sign that the seals need to be replaced. 2. You can check it with a special device. More details in the video:

- Gaskets can also cause air leaks. Most often they are damaged during unqualified chainsaw repairs. If you have recently assembled and disassembled your saw, then there is a very high probability that the air leak occurred precisely as a result of damage to the gasket or its incorrect installation.

Video on how to check the tightness of a chainsaw crankcase

8.Checking the muffler

As a result of long-term operation, especially if the fuel mixture is prepared with excess oil, deposits form in the muffler that prevent the free removal of exhaust gases. In this case, it is necessary to clean the muffler.

Cleaning the chainsaw muffler

Video on how to remove a chainsaw muffler

9. Failure of the cylinder-piston group (CPG)

This is probably the most unpleasant of the breakdowns that are possible in a chainsaw. Often the cost of replacing a CPG can exceed the cost of half the entire chainsaw! This is especially true for professional models. In our case, when we consider the reasons why a chainsaw may stall, problems can be caused by scuffs on the walls of the cylinder and piston. You can check this by removing the muffler and visually inspecting the surface of the cylinder and piston. In most cases, scuffing occurs precisely on the muffler side, but sometimes the opposite situation can occur. Keep this in mind!

Video about diagnosing CPG

Recommendations Be sure to use up all the gasoline before storing the chainsaw for the winter or just for a long period of time. Properly dilute gasoline with oil (more about this here).

These are perhaps the main reasons why a chainsaw can stall. If these recommendations did not help you, describe your symptoms in the comments. We will help!

No. 3. The engine "shoots"

If during operation there are extraneous sounds similar to gunshots, then there is a problem with the muffler or carburetor. How to make a chainsaw run quietly? It depends on which node is faulty.

Shoots the carburetor:

- Ignition is too late - the air-fuel mixture does not have time to burn out in the cylinder, so the sound is similar to a small explosion.

- Lean air-fuel mixture. Too little gasoline enters the mixture - the chainsaw, or rather the jets, needs to be adjusted to increase the fuel supply. Why the chainsaw revs on its own is for the same reason.

Shoots at the silencer:

- Enriched air-fuel mixture. Why does a chainsaw “shoot”? There is too much gasoline and not enough air in the mixture, so the mixture does not completely burn out in the chamber and partially burns out in the muffler. Carbon deposits on the exhaust are a clear sign of this. The air filter needs to be cleaned or the carburetor adjusted.

Chainsaw maintenance and repair

By taking into account the manufacturer's recommendations, you can significantly extend the service life of the device. Other specific faults include:

- Starter failure.

- Incorrect operation of the brake system, which stops the chain.

- Worn bar or saw chain.

Fault repair methods are selected depending on the design itself. In some cases, it is necessary to replace the entire assembly, in others only individual elements.

If you find an error, please select a piece of text and press Ctrl+Enter.

Shots from the exhaust tract are a malfunction inherent in the carburetor fuel supply system; on modern cars with an injector, it occurs much less frequently. In most cases, the car owner is able to cope with the breakdown on his own, without contacting a car service center. But first you need to make a diagnosis and determine why the engine is shooting into the muffler.

Read also: What is the difference between salt and alkaline batteries?

No. 4. Chainsaw overheating

Why does the chainsaw get hot? The engine or tire may overheat - in any case, the fault is due to a small amount of lubricant.

- Engine overheating. The proportion of the fuel mixture is incorrect or pure gasoline is poured. Drain the fuel and make a mixture using the correct proportions of oil and gasoline, as specified by the manufacturer.

- Tire overheating. The oil pump needs to be cleaned or adjusted because... No oil is supplied to the tire.

No. 6. The chainsaw cuts to the side

When cutting, you may notice that the result is an uneven cut. Why does a chainsaw cut crookedly? There are several reasons:

- Incorrect chain sharpening. The teeth are sharpened at the wrong angle or only in one direction. Proper sharpening is required.

- Incorrectly selected chain. At very high speeds, a difference of even 0.2-0.3 mm between the width of the groove or the width of the seat will be visible, which is why the chainsaw cuts to the side. An appropriate circuit must be installed.

- Uneven tire wear. Over time, the tire wears out on one side and then the chain pulls to the side. Rotate the tire regularly to ensure even wear on both sides. If the wear is excessive, replace the tire.

No. 7. Chain lubrication problems

For normal operation, the chain must be constantly lubricated to reduce friction between the bar and the links, and also to prevent premature wear of the links.

- If the chain on the chainsaw is not lubricated, then there is a problem with the oil pump - oil is not supplied due to a clogged channel. Lack of lubrication is the reason why the chain stretches or why the chain breaks. Clean the channels; tiny particles of chips constantly get there and clog them. The oil hose may also break. If you need to adjust the chainsaw oil pump or repair it, it is better to contact a service center.

- Oil splashes from the chain. Incorrectly selected lubricant - it is too liquid, so it does not so much lubricate the links as it splashes onto the wood. Replace the lubricant with a thicker one.

Chainsaw starts and stops: reason, video

The reason why a chainsaw may be put aside immediately after the factory is due to a malfunction of certain equipment.

- The most common reason why chainsaws twist and stall can be due to low fuel levels in the tank. This can be confirmed by stopping the tool while tilting when fuel residues accumulate in a certain area of the fuel tank. If the fuel is of poor quality, problems with the operation of the chainsaw may occur, in which case it must be completely replaced.

- The fan is clogged, which significantly reduces fuel consumption for the engine.

- Insufficient contact between the wire cap and the spark plug, resulting in excessive heating of the spark plug insulator. Deterioration of contact may occur due to mechanical movement or carbon deposition.

- Damage to spark plugs.

- The muffler is clogged, which impairs the output of exhaust gases, which leads to the engine stopping. For this reason, the chainsaw can be started and lowered at idle speed. Muffler deposits can also occur due to poor fuel consumption or improper tool use.

- Poor carbohydrate regulation.

- Piston group failure

- Problems with the fuel filter or pump. In this case, gasoline may leak through the pump or flow poorly through the fuel filter to the carburetor. As a result, the chainsaw starts and dims as speed increases.

- The air filter is dirty. Problems with this piece of equipment lead to the fact that when the load on the engine increases, it simply cannot cope with them due to clogging and stopping. A similar result is also obtained with increasing speed.

- Short circuit due to insufficient or insufficient lubrication and also due to a problem with the chain brake.

READ Ignition From a Chainsaw in Tula

No. 8. The chain falls off

Why does the chain fall off the tire? There may be several reasons and they are all different:

- Worn drive or driven sprocket. Due to the fact that the sprocket is worn out, the grip on the chain decreases, which is why the chain flies off the chainsaw. The sprocket needs to be replaced.

- The chain has stretched. Why the chain on a chainsaw stretches is due to insufficient lubrication. The metal heats up and stretches, even by a fraction of a millimeter, but if you take into account the number of links, then even 3-4 mm is enough for the chain to fly off the bar. The chain needs to be replaced.

- The chain tensioner that regulates its tension has become loose. how to regulate a chainsaw, or rather the chain tension? You need to adjust the tensioner - this can be done in just a few minutes.

No. 9. The chain does not rotate

Why doesn't the chainsaw chain rotate when the engine is running even at full speed?

- Leading sprocket. Either it is jammed, or the crown is worn out so much that it does not engage and the chain does not spin on the chainsaw. In any case, it is necessary to disassemble the sprocket to find out the exact reason why the chain does not spin. If the crown is worn out, it is necessary to replace the sprocket (or the crown itself, if the sprocket has a prefabricated structure).

- The chain brake is stuck. As a result, the sprocket is blocked by the brake mechanism, while the motor runs. It is necessary to turn off the engine and release the brake. If this happens under load, the brake mechanism will have to be changed, as well as the sprocket, because Due to the high temperature, many elements can melt and overheat.

No. 10. Chain brake does not work

All chainsaws are equipped with a main and inertial (emergency) brake. The latter turns on only when a backfire occurs. The main brake is designed to stop the chain while the engine is running. Why does the chain on the chainsaw jam and it doesn’t stop? Option two:

- The brake band is badly worn and does not provide sufficient stopping effect. The brake band needs to be replaced.

- Contamination of the tape. When working, debris may become clogged in the under-cover space: shavings, sawdust, dirt, etc. Debris is blocking the brake mechanism, so if the brake does not work, you need to clean the brake mechanism.

Home page » Chainsaw Shoots Carburetor

Related Posts

The chainsaw does not start: causes and solutions

Today, it is probably difficult to find an owner who does not have such a universal, practical, and multifunctional tool as a chainsaw.

This device is deeply rooted in everyday life, and this is not surprising because the chainsaw has become an indispensable assistant for us in the field of cutting wood of various types, preparing firewood for the winter, cutting down trees, and it is also used in the construction industry, etc.

Naturally, one can talk endlessly about its positive aspects and it copes with its task simply superbly . But, like any technology, no matter how unique and highly practical it is, it breaks down over time and that’s normal. Why does the Ural chainsaw shoot into the carburetor? Cause of malfunction, consequences. Why does a chainsaw shoot into the muffler? The most important thing at this moment is to correctly determine the cause of the malfunction and quickly eliminate it.

Naturally, you can turn to various kinds of services that, for a fee, will put your equipment in order. But you will have to pay a significant cost. What for? After all, you can try to determine the extent and cause of the breakdown yourself and fix it.

Since there are such minor breakdowns that can be repaired within five minutes. We will talk about them and ways to eliminate them in this article.

Diesel and injector shots

In old-style diesel power units, the timing of diesel injection could be manually adjusted mechanically. If the settings were incorrect, the fuel was compressed too late and the diesel engine “sneezed” with white smoke. Nowadays, injection and diesel engines are controlled electronically, so firing from a muffler has become a rarity.

The main reasons why popping noises occur in modern engines:

- failure of one of the main sensors - mass air flow sensor, DBP, lambda probe or throttle position;

- severe contamination of the working surface of the crankshaft position sensor with metal shavings;

- problems in the high-voltage ignition unit;

- accumulated controller errors.

Advice. Electronics diagnostics is a complex issue that must be resolved by service station technicians. But you can reset the errors by disconnecting the battery for 15 minutes. Often, engine operation is improved in this way, but a check at a car service is still necessary.

When the power unit shoots into the muffler when releasing gas, the culprit may be automotive gas equipment. The installation that supplies liquefied propane to the cylinders is controlled by its own electronic unit and, in addition to the cylinder, includes valves with a reducer. If, as a result of a malfunction, the system begins to “overflow” gas, shots are inevitable. Such equipment should be handled by specialists; independent repairs are not allowed.

Read also: How to connect wiring to a double switch

1200 rub. for the photo report

We pay for photo reports on car repairs. Earnings from 10,000 rubles/month.

Write:

shoot into the muffler on cars with both carburetor and injection engines. At the same time, oddly enough, the muffler itself has nothing to do with it. It is only a source of sound, and the factors causing loud sounds lie in completely different parts of the car. Most often, the causes of popping sounds in the muffler are malfunctions of the ignition system, fuel supply or gas distribution system. Next, we’ll figure out how to get rid of the problem when it shoots into the exhaust pipe , and what you need to pay attention to first of all during “explosions.”

Plant structure

The first and practically main element of a chainsaw is the engine, namely a two-stroke carburetor (see carburetor adjustment). Its direct power can be varied, it all depends on the model of the device and its intended purpose. Chainsaw set The second no less important part of the tool is the set (saw) which consists of a chain (cutting), bar, sprocket, wheel (chain) . It is worth adding to this that completely different manufacturers provide their own specific range of this headset.

It is important that it always needs to be directly selected from the specific characteristics of the engine. Since the larger the pitch of this type of headset, the deeper the chainsaw’s cut will be, one might even say that the more powerful and productive it will be. Often chainsaw owners think about why the chainsaw shoots into the carburetor, or why gasoline does not flow into the chainsaw carburetor? But do not forget that for the device to fully operate, the engine should also not be inferior to it in terms of power.

Its lubrication is carried out using special oil directly from the second tank, which is located on the hand unit. It is worth noting that the mass of this type of tank has such features that the oil and fuel intended for the engine run out at the same time.

We have figured out the general outline of the device, and most likely its basis, and now it’s time to start understanding why the chainsaw stopped working, what the reasons could be for this and how to eliminate them.