Differences

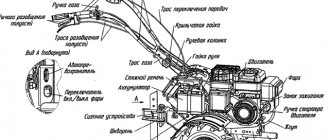

The Neva MB 1 walk-behind tractor, in demand among summer residents and farmers, is not difficult to operate or maintain. Thanks to its compactness and low weight, agricultural equipment is distinguished by maneuverability and, due to large pneumatic wheels, maximum maneuverability. In agricultural applications, Neva MB 1 walk-behind tractors are used for:

- Plowing.

- Loosening.

- Harrowing.

- Hilling up.

- Planting tubers.

- Harvesting.

If you wish, you can put a small trailer on the model, allowing you to transport even half a ton of cargo. The technology was able to achieve such versatility due to the high power and endurance of the motor. The model is equipped with various engines - it all depends on the year of manufacture and the purpose of the walk-behind equipment.

Note! The standard configuration of the agricultural unit includes a gasoline powered motor, model DM-1. This is a powerful 4-stroke internal combustion engine with a 25 mm output shaft that rotates counterclockwise.

The engine consists of 1 chrome cylinder, the diameter of which is 76 mm. Piston stroke range 70 mm. The engine for the Neva MB 1 walk-behind tractor is equipped with a float-type direct-flow carburetor, which is necessary to saturate the fuel with air and stabilize the engine crankshaft speed in different operating modes. To purify the sucked in oxygen, the technical device includes an air filter element made of foam rubber.

We also advise you to pay attention to the excellent amber fertilizer for plants.

The motor to the Neva walk-behind tractor is turned on using a built-in manual starter. Electric ignition is provided. To normalize the operating temperature, the walk-behind equipment has an air cooling system that sucks in oxygen due to the functioning of centrifugal forces. Those. The characteristics of the DM-1 motor are as follows:

- Volume – 316 cubic cm.

- Power – 5 l/s.

- Rotation speed – 3 thousand rpm.

- Torque – 13.8 Nm.

- Tank for 4 liters of fuel.

- 1.3 liter oil sump.

- Fuel consumption under average loads is 2 l/h.

The motor is compact. The engine length is 400, width – 450 and height – 470 mm. Weight – 28 kg.

The MB 2 walk-behind tractor is a modernized model of the MB 1 walk-behind tractor. It is even more reliable and durable. At the same time, the manufacturer managed to reduce the consumption of fuel when operating the walk-behind tractor at maximum load. Like the MB 1 model, the best version MB 2 is equipped with different 1-cylinder 4-stroke engines with carburetors and manual start, retractable cord. Each power device has an air cooling system that operates under the influence of centrifugal forces.

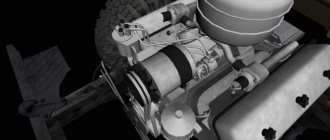

The engine for the Neva MB-2 walk-behind tractor is mounted to the load-bearing frame using reinforced fasteners. In the factory model of the engine, a three-groove pulley is responsible for transmitting the rotation created by the engine to the gearbox or suspended equipment. For normal operation of engine speed during starting, the agricultural walk-behind tractor has an air damper. The model of the Neva MB 2 walk-behind tractor is an MB 2K machine, it has an engine from an internal combustion engine DM 1K.

On a note!

The base crankshaft of this farm unit is located horizontally, and the factory valves are located on top of the engine. The working volume of the internal combustion engine is 317 cubic meters. cm, and its maximum power is 6.5 liters. With.

Each engine for the Neva MB 2 walk-behind tractor meets certain parameters. These are presences:

- A ball bearing built into the base supports of the crankshaft - it is necessary to stabilize the vibration load of the engine and ensure its smoothest operation under the highest loads.

- Basic automatic decompressor.

- An aluminum block suitable for repairing a standard cast iron liner - this allows you to increase the service life of the liner.

- Reliable air filter element made of foam rubber, with 2 levels of purification.

- Reduced noise levels and modest fuel consumption were achieved thanks to the location of the valves at the top of the engine.

- A modernized ignition system that makes it possible to start the engine without problems in difficult weather.

Another important feature of the motors is their factory protection from heat, dust and pollution. Thanks to this, Neva MB 2 walk-behind tractors are better suited for implementing almost any complexity of tasks. Before use, you should read the operating instructions.

What does replacing the engine on a Neva mb1 or mb2 motor cultivator give?

You can change the motor on Neva walk-behind tractors not only to a version of the brand with which it was made, but also to a different one, for example, more or less powerful. At the same time, you need to know which motor to choose for the Neva walk-behind tractor. In the starting configuration, models with a DM 1K engine were produced. Updated Neva walk-behind tractors can be equipped with foreign engines from the following brands:

- Robin Subaru.

- Bridgestone.

- Honda.

Replacing the engine on the Neva MB-2 walk-behind tractor with a foreign one will increase the service life, but such models are the most expensive. Therefore, if you need to replace the engine on a Neva walk-behind tractor, you need to understand that such motors are durable and wear-resistant, but their price is higher. It is important to know what alternatives there are to engines created in Japan. They take into account whether the motor will be replaced independently or at a service station. There are a large number of replacement options. The replacement option is selected based on the symbiosis of price + quality, suitability for repair, weather conditions and other factors. You can seek advice from an expert.

Review of manufacturing companies

The engine is the heart of the Neva walk-behind tractor. They differ in technical characteristics, as well as in the manufacturer and installation method. To understand how to choose a motor, it is necessary, first of all, to clearly define your goals, and secondly, to find out the basic technical details. characteristics of each Niva option, their differences.

Lifan (China)

This line of motors is considered one of the most economical, but their level of wear resistance is low. Such a motor cannot be considered a poor quality Chinese product. Many summer residents buy Lifan engines and use them for many years. Gardeners note the similarity of the engine with the Honda brand product. If you need to change the “native” engine on a Niva, then Lifan is a rational solution. The advantage of such engines is their fashionable design and simple controls. In addition, the farmer does not have problems with repair work.

On a note!

The manufacturer always supplies spare parts to the market, so there is no need to search and wait months for components.

The collection of Lifan motors is impressive. But we can highlight the best models, according to our compatriots:

- 168F-2. This is a 1-cylinder engine with a horizontal crankshaft. Runs on gasoline.

- The 160F gasoline engine is more powerful (up to 4.3 kW) and at the same time economical in fuel consumption.

- The 170F motor is suitable if you need an engine for a 4-stroke walk-behind tractor on the Neva. There is a horizontal crankshaft here, and an air cooler is also included.

- Engine for walk-behind tractor 2V177F. Cylindrical internal combustion engine. It is considered one of the top characteristics of the Lifan brand.

Motors for Neva walk-behind tractors adapt to the climate in different regions, so rain or wet snow will not interfere with the task.

Briggs and Stratton (Japan)

Another manufacturer of agricultural tools is the Briggs and Stratton brand. Their engines are more powerful than those from China, therefore they are suitable for heavy agricultural manipulations. They are manufactured to the same standards and in the same production facility as Mitsubishi cars. Therefore, they have an impressive service life (4-5 thousand hours) with proper care. Also, all models have a large margin of strength and wear resistance.

One of the collections that has received particular attention among farmers is Vanguard. What makes it different is ease of start-up and a large muffler that guarantees silent operation. Such engines automatically monitor the oil level and will give a signal if it needs to be refilled. Technical characteristics of Vanguard series engines:

- Tank volume up to 4 liters.

- Weight approximately 4 kg.

- Cylindrical sleeve made of cast iron.

- Operates on motor oil.

- Working volume – 110 cubic cm.

- Power – up to 6.5 l/s.

The manufacturer provides a warranty for a certain period, but the ignition coil in the engine receives a lifetime warranty, which confirms the reliability of the technical device.

Yamaha (Japan)

This manufacturer is primarily known as the creator of motorcycles. However, this is not the only equipment; they also make engines for motor cultivators. This high-end engine is designed for very heavy agricultural work. Its power is 10 horses.

Note!

The motors are equipped with a gearbox with powerful traction. The working depth of the cutters is about 360 mm, which makes it possible to quickly plow or hill up the soil.

The control is 6-speed, there is a wheel release and reverse mode. Yes, the engine may seem expensive, but the price will really meet any farmer’s expectations and will more than pay for itself during operation.

Motor problems

Engines running on different types of fuel (gasoline or diesel) have different service life. For engines using diesel fuel, it is much larger, but it is gasoline units that are popular due to their lower cost and ease of operation and repair.

Typically, of all faults, two main types can be distinguished:

- startup problems;

- problems with smooth operation.

Problems in the fuel system

The first thing you need to do is check the spark plugs. If they are dry, this may mean that gasoline is not getting to the engine. The main reasons will be: lack of fuel, the supply valve was closed, the hole in the tank plug is clogged, unnecessary objects get into the fuel system.

For maintenance you should:

- refuel the walk-behind tractor;

- unscrew the fuel supply valve;

- clean the gas tank cap;

- remove all gasoline from the tank, having first removed the fuel valve, and wash it with clean fuel. Then blow out the jets in the carburetor using the fuel supply pump.

When the candles are left wet

The following malfunctions are identified:

- The appearance of carbon deposits on the spark plugs. They should be cleaned with a rough surface and washed.

- The gap between the electrodes has been increased or decreased. You need to adjust it to the required size.

- Wiring insulation is damaged. It is usually replaced with a new one.

- There is a ground short to the STOP button.

- The ignition system starter is faulty.

The rubber carburetor seals may also become loose, causing air to be sucked in. It is necessary to tighten the bolts, spark plugs and inspect the gaskets between the cylinder and the spark plug head.

Another option for poor engine starting may be that the carburetor air damper does not close completely.

Candles in a walk-behind tractor should not be wet

If the compression is broken, it will also be difficult to start the engine. The reasons are: carbon deposits on the valves, the intake valve is deformed, or the piston rings are already worn out.

Problems during operation usually appear when the engine's node connections, subject to overload, fail, which leads to failures.

Important! If you realize that the engine is starting to make noise or run jerkily, you should immediately turn it off and cool it, and only then try to repair it.

When the engine begins to pick up and slow down on its own, this is possible when the traction and the fastening of the levers are weakened. To eliminate this, simply adjust the control drive.

If the engine loses power, it means it has overheated. In this case, the engine may jam, which happens when the oil level in the crankcase is low, a nadir forms on the connecting rod head, or the oil squirter has become unusable.

Terms of use

The basis is to buy the right engine and see how it is installed on the walk-behind tractor. And also follow the instructions correctly and take care of the engine while it is running. The first thing you need to do before purchasing the product is to get advice from a specialist about the features of using the unit. It is important to carefully read the installation and operating instructions so as not to make mistakes during operation. It is necessary to systematically carry out preventive maintenance - change the oil, clean components.

When it is clear that the engine is not functioning stably, contact a service center for help. The guarantee document will be useful. There are many reasons for breakdowns, so if you don’t have repair skills, it’s best not to fix it yourself, so as not to worsen the situation. A professional will definitely find the reason, determine whether the oil seal on the crankshaft needs to be replaced, whether to use a different fuel, or whether the internal wire needs to be replaced.

How to convert a Ural walk-behind tractor to a Chinese engine

I have this question. and if during the installation of a Chinese motor, so that the rotation of the cutters is in the appropriate direction, turn the gearbox so that the pulley faces the left side. Accordingly, put the engine backwards to front. Do I understand correctly? If you sell, what can stop it? And why don't others do this?

Zhenya Zhekin what is the meaning of such a rework. It is necessary to cut off the entire gearbox and weld it back to the frame. Among other things, after a revolution, the gearbox also begins to work backwards, that is, the rear one becomes frontal. The only thing you need to guess when remaking is weight distribution.

Here I found a video ru-tv.org/tv/video-5gSmo5y_Lik.html

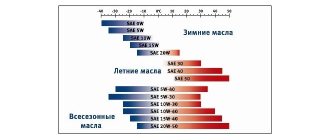

what kind of oil do you put in the engine? I FILLED 15W40 MINERAL WATER, I'M AFRAID I WILL NOT REGRET THIS Situation, I TRIED IN OIL ON THIS THING. THE ENGINE OPERATED ON MINERALA FOR 5-6 HOURS, CAN THIS HAVE A BAD AFFECT ON THE ENGINE? THANK YOU

I won’t tell you about the oil, my father uses a walk-behind tractor

WHAT SPEED DO YOU WORK AT?

I also bought a Lifan engine without a gearbox. The shaft is short, the engine will have to be moved to the side. How did you solve the myth? I don’t understand it from the video?

READ Walk-behind tractor Changing the Oil in the Gearbox Video

The platform for the engine is homemade, first they fixed it to the frame and then adjusted the engine.

What model of Lifan motor? Does it of course have a gearbox?

I don’t remember the model, there is no gearbox and the power is 6 or 6.5 hp.

They threw out the original motor, bought a large Lifan pulley (pigeon), made a motor mounting platform from an 8mm plate. Because the rotation goes in the other direction, they rearranged the control knobs. That’s all. I forgot to sell, the tension rollers had to be tricked out by others.

As I know, the blue pulley (Neva) has both wedge grooves, and the original pulley has one rectangular groove, it is for an inverted belt for reverse. Is reverse gear designed like you? You turn the reverse belt over or it works at random. Is the reverse drive stable?