Choosing an engine for the Cascade walk-behind tractor

Auto mechanic, specializes in agricultural equipment.

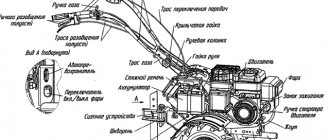

One of the most common technical devices that helps farmers in planting and harvesting crops is the Cascade walk-behind tractor. The units of this Russian brand have proven themselves to be reliable, durable and durable products.

Motoblocks are very convenient to use. They have a steering wheel that can be adjusted horizontally and in height. The center of gravity is located close to the ground, which reduces the effort when cultivating the soil.

These walk-behind tractors are among the most practical

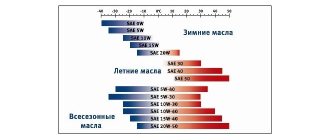

Engine oil

When you have a walk-behind tractor as your assistant, you need to constantly monitor the technical condition. Oil is a very important composition that needs to be changed just in time. It is responsible in the unit for lubrication, sealing, cooling and cleaning of the motor components.

When the device operates in an unchanged mode, the oil remaining in the cylinder may burn out and oxidize, as a result of which the walk-behind tractor begins to smoke. Also, substances with resins are deposited in the parts, which leads to contamination. Therefore, it is recommended to use excellent foreign lubricants that already contain the necessary additives.

Compatibility

Chinese walk-behind tractors usually have engines with a 19.05 or 20 mm shaft. 20 mm shaft is much more common.

In order for this engine to fit without problems you need:

Chinese motor cultivators usually have engines with a 19.05 or 20 mm shaft. For 19.05 cultivators, the shaft is much more common.

Chinese walk-behind tractors usually have engines with a 19.05 or 20 mm shaft. 20 mm shaft is much more common.

In order for this engine to fit without problems you need:

The engines on the Neva walk-behind tractor ( excluding the most powerful 8-9 hp models ) have a 19.05 or 20 mm shaft. Depends on the brand of engine.

In order for this engine to fit without problems you need:

- Neva

- Cascade

- Ray

with a domestic engine and counterclockwise shaft rotation

The native domestically produced engines for these walk-behind tractors have long been discontinued.

To install a modern engine instead of a domestic one, you need a special installation kit (new platform, pulley, damper).

- Ural

- Forward

- Firework

with a domestic engine and clockwise rotation of

Old Soviet Ural walk-behind tractors had a clockwise shaft rotation, while all modern engines have a counterclockwise shaft rotation.

Kutaisi Super 610

The old Kutaisi walk-behind tractors had different mounting holes on the engine.

Therefore, to install a new engine in Kutaisi you will need:

2. Suitable engine (including this one). Everything can be viewed at this link

A modern engine like this can be installed on an old Soviet mole cultivator without problems.

Only the mole pulley must be replaced with a special new one. We have such a pulley.

This engine has a 20 mm shaft. It can fit on a Ugra walk-behind tractor with a modern engine up to 7 hp inclusive, if the old engine also has a 20 mm shaft.

If you have a modern engine with a different shaft or Ugra with an old DM-1 engine , we have the necessary engines and adapters. Just click here to go.

Motoblock Kadvi MB-90

But we have an adapter and motors that will fit with the adapter. Click on the link to go

Motoblock Agro (Agros)

But we have an adapter and motors that will fit with the adapter. Click on the link to go

Motoblock MTZ (domestic engine)

But we have an adapter and motors that will fit with the adapter. Click on the link to go

Engine Installation

To install an imported engine on a Russian walk-behind tractor, you need a pulley, a gas cable, an adapter washer, and a bolt on the crankshaft. If inconsistencies are found in the fastenings, you need to drill holes in suitable places. When the frame of the walk-behind tractor is not compatible with the motor, then a transition platform should be used. It is better to use a steel product to reduce the heating of the unit and prevent the belt from burning.

First you need to remove the old engine. To do this, remove the protection casing and belts, unscrew the bolts that secure the belt and the crankshaft bolt, then remove the pulley. We remove the air cleaning filter and disconnect the accelerator pedal cable. Afterwards we remove the old engine.

Then we put the newest part in the vacant space. If it is installed on the adapter pad, it should not be screwed on immediately, because the drive belt will need to be adjusted.

Next we place the pulley on the shaft and tighten the bolt. We tighten the belt and adjust the degree of tension with the slider. Afterwards, we tighten the bolts on the transition area and the belt stabilizers one hundred percent, install an air cleaning filter and a gas cable, and firmly attach the motor.

Fundamentally! Self-installation requires special equipment and tools.

Gasoline engine of the Neva LIFAN 168F-2 walk-behind tractor

The Lifan 168F-2 engine can be found on such walk-behind tractors as Neva, Cascade, Salyut, Tselina 601, 501, OKA MB-1D1M10, but is also used more widely. Recommended for walk-behind tractors Cascade, Neva, MB, Luch. This is one of the most popular engine models. It belongs to a series of low-power motors for domestic use.

The engine is 4-stroke, single-cylinder, air-cooled, with a power of 6.5 hp, 4.8 kW. Thanks to the cast iron cylinder liner, the engine boasts an increased service life. Has a shaft with a diameter of 20 mm. This engine appealed to consumers due to its ease of operation and repair, low noise level and fuel consumption, as well as its low price.

Brief instructions for repairing Cascade walk-behind tractors

If a person notices that his technical assistant is a little “sick,” he should carefully study the information below.

What to do, if:

- The walk-behind tractor does not start. You need to check the spark plug; if it is wet, it means there is an excess of gasoline and you cannot do without drying the cylinder;

- The engine has lost its former power. The reason may be simple clogging of the carburetor filter, because it often leads to over-enrichment of the fuel and the cessation of engine functionality;

- The engine runs intermittently. Most likely, the problem is a clogged muffler, which needs to be rid of excess and washed with gasoline;

- The ignition system is malfunctioning. Clean the spark plugs and adjust the electrode gap.

These problems are the most common, so repairs can be easily done with your own hands or, if you lack tools and the slightest knowledge of technology, contact specialists.

The following videos, shot by the owners of Cascade walk-behind tractors, who have considerable experience in working with the device and share it with the world, can be excellent supporting sources of information.

Do-it-yourself repairs and customization | Topic author: Abundius

We share our experience in repair, diagnostics, upgrades and troubleshooting methods.

Andrey (Nolwenn) Igor Vizulis

Hi all! ATTENTION, USEFUL INFO. I came across a question on our website about the fact that the spark plugs are blowing and the idle speed is floating. Actually, this made me sad. And GOD gave me a smart man to meet! In short, we unscrew the spark plugs and throw them into pure acetone. We remove the seat and unscrew the gas tank to unscrew the air filter pipe, there is a clamp there. Show in full.. Put the filter box to the side. The carb opens in front of us. On the carb there is a crap round like a tablet, right under it there is a RUBBER PLUG and under the plug there is a tricky screw. We take out the candles and clean them with a brass brush, and put them in place. We start the engine and use the speed screw (it is on the left along the way) to achieve stable engine operation. And now we tighten the above tricky screw completely WITHOUT EFFORT. The engine will work. And now we unscrew this screw smoothly and the engine will increase speed. After about 1.5-2 turns of the screw, the engine speed will begin to decrease. We leave the tricky screw at the fastest speed and close it with a rubber stopper. Using the speed screw (it's on the left as you go), we reduce the engine speed to the minimum stable speed. We put the air vent, tank and seat in place. It’s 300 km there and back to my village and it took my entire tank. Now one third still remains. The revolutions do not float, the candles are pure sand-colored. I hope my memoir helps someone! Smooth roads everyone!

Andrey (Nolwenn) Changing the oil on the LIFAN LF250-B motorcycle ATTENTION. The oil volume in the system is 1400 ml (without filter replacement). And 1600 ml. with replacing the filter with a paper (disposable) one.

Andrey (Nolwenn) Adjusting the chain tension of the LIFAN LF250-B motorcycle

Andrey (Nolwenn) Mikhail Kostyuchok

I decided to redo the steering wheel a little. The standard steering wheel seemed a little small to me, I don’t feel very comfortable in steering and the appearance strives to equalize my horse with mopeds) This situation does not suit me, of course I wanted to change the steering wheel to another, but this entailed huge hemorrhoids with the search and selection of other cables, hoses and etc. So I decided to redo the stock one a little. To do this, the turner turned out two blanks, inserted them into the steering wheel on both sides and scalded them. The handlebars widened by 9cm on each side, the seam was perfectly hidden under the handles. Of course, I wanted it to be even wider, but the length of the original cables did not allow it. All the cables and wires are still original, we just had to route them differently. The only thing I changed was the brake hose, I bought it 15 cm longer.

Bottom line: we have a wide steering wheel, which I personally really like! Of the advantages: comfortable fit and control, chic appearance of the motorcycle, the mirrors are positioned wider, which allows you to see in them what is happening behind you, and not your shoulders, as before) Of the disadvantages: someone might say that the motorcycle is now widened by 18 cm in traffic jams you can’t pass between cars, etc. You’ll get through everything just fine, especially since my rear panniers will be the same width. As they say, GOOD LUCK to everyone!

Andrey (Nolwenn) Alexander Rudenko

Hi all! I recorded a video testing the updated headlights. Used: 1) External right low beam headlight from VAZ 2106 (in particular, reflective element and lens). 2) Lamp OSRAM 64193 CBI H4 60/55W white. 3) And a little profanity during installation