How to start a gasoline trimmer?

- Prerequisites

- How to start the engine of a trimmer or lawn mower?

- Starting the lawnmower for the first time or after a long period of inactivity

- Adding fuel through the spark plug holes

- Checking the ignition system

- Engine cleaning

- Checking the integrity of the spark arrestor

- Unstable carburetor operation

- Draining fuel from the gas tank

How to start a trimmer correctly is a question that owners are puzzled by if the device breaks down. And after successfully repairing the trimmer, the owner tries to avoid a repetition of the same situation.

Read also from the section

How to Remove the Coil from a Husqvarna Trimmer

How to change the fishing line in the trimmer and which one is better to choose Since we discussed the choice of trimmer in the previous article, now we will tell you how to correctly fill the trimmer with fishing line, and which one is better to choose based on the operating criteria. After you have purchased a trimmer and started using it intensively, at some point the question of replacing the fishing line will arise, so [...]

How to Replace the Gearbox on a Champion Electric Trimmer

From time to time, in the midst of busy mowing work, your trimmer begins to make an unpleasant, grinding sound. This complains about the lack of lubrication of the gearbox - a more actively loaded unit of the device. And soon these “warnings” may be followed by jamming of the drive... During operation, the mechanical part of the trimmer is loaded with contact forces on the teeth, resistance reactions from adhering grass (with […]

How to Thread Line into a Patriot Trimmer Video

How to thread the line into the trimmer Installing the newest thread into the Makita UM 4030 trimmer Installing the thread head Related posts Disassembling the Patriot PT 3055 Trimmer... Tools The Patriot PT 3055 gasoline trimmer is a comfortable and productive tool for processing grass areas that require careful and precise cutting and trimming in height . The unit is used for fast mowing and trimming [...]

How to start a trimmer correctly is a question that owners are puzzled by if the device breaks down. And after successfully repairing the trimmer, the owner tries to avoid a repetition of the same situation.

Prerequisites

The reason why the trimmer fails may be:

- tank overflow;

- excessive pumping of fuel into engines equipped with a manual supercharger;

- wear in the engine of valves, cylinders, injectors, cam followers and other moving parts;

- the tanks have run out of gasoline and/or oil;

- the spark plugs are not in order;

- clogged fuel or air filters;

- The valves in the engine are misadjusted or burnt.

The check begins with the presence of oil and fuel both in the tanks and a small portion of it in the engine system. An “empty” engine will not start, despite a full tank, as well as an overfilled one.

How to start the engine of a trimmer or lawn mower?

The new trimmer is easy to put into operation.

- Check the device motor type. Trimmers are equipped with a 2- or 4-stroke motor.

- Buy oil for this type of engine. Gasoline for the trimmer – AI-92/93/98, sold at all gas stations.

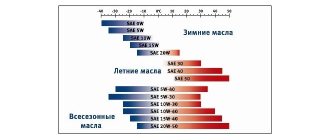

- Mix oil and gasoline. Mineral oil is mixed in a ratio of 1:34 with gasoline, synthetics - in a ratio of 1:50. Follow the trimmer manufacturer's recommendations for oil viscosity (see the label on the flask). All-season oil 5W-30 is most often used. Do not use untested motor oils.

- Pour a small amount (for example, 0.5 liters) of the resulting fuel into the tank.

- Close the air damper by sliding the desired lever (see instructions).

- Turn the ignition key (or handle) to the “on” position - without this, the trimmer will not start. Beginners often make this mistake.

- Pump some fuel into the carburetor - if you have a manual “pumper” with a separate button or lever (see instructions). 4-7 clicks are required.

- Place the trimmer on a flat surface.

- Gently pull the starter cord until you feel it slow down. Then pull it out sharply, but not all the way. Repeat this movement up to 4 more times.

- If the engine does not start, open the air damper again, otherwise the spark plugs will flood with gasoline as the cord moves further. Make 2-3 attempts to start the engine with the handbrake open.

- If the engine still does not start, close the choke and make a few more attempts to start it.

- After starting the engine, press the throttle lever to idle.

Let the engine warm up - 5-10 minutes is enough. Do not start mowing the grass immediately after a cold start - the trimmer motor needs to break in.

Review of Homelite trimmers and brushcutter. Features of application and operation

Basic malfunctions and their correction

The task of every owner of Brenna Homelite lawn mowers is to know how to correct the most common malfunctions. Below are the main breakdowns and ways to fix them.

Best Homelite Models

In total, the Homelite brand offers a large number of trimmers, which differ in their power and handle.

The most attractive lawn mower models for private use are Homeline F2020 and F3045. They are light, quite powerful and consume a small amount of fuel.

But for long-term use, it is recommended to use HBC30SBS or HLT26CDY. They have an improved protective casing and better cooling to maintain operating temperature for a longer period of time.

READ Gasoline For Trimmer Which Is Better

How to start a lawn mower. gasoline trimmer Starting a cold lawn mower

Petrol mower Homelite F2020

This is the first lawn mower in the Homelite brand lineup. The F2020 motor power is 42.5 cm3 and weighs 4.44 kg.

- Despite the modest power and weight, the spindle speed is high at 9,000 rpm.

- gripping width of the Homelite F2020 trimmer is 432 mm.

Starting the lawnmower for the first time or after a long period of inactivity

A brushcutter differs from a trimmer in that the grass cutter is not a fishing line, but a mechanical gearbox or a gear-based winch equipped with a knife. The blade drive is much more powerful than the line mechanism - a powerful brush cutter is also used when cutting bushes. Both Chinese and European lawn mowers are nothing special when the declared power is real.

Starting a trimmer (mower) after winter

To lubricate the gears of the gearbox, litol or grease is used. After checking the gearbox, prepare the motor itself for work according to the instructions above. If the start is unsuccessful, the problem is already in the engine.

Adding fuel through the spark plug holes

If the trimmer engine does not have manual pumping and the device does not start, add some fuel to the engine itself through the spark plug passages. Do the following.

- Check if the fuel level in the tank is sufficient to drain a small amount of it. Only 20 ml is required.

- Remove the cap from the spark plug and unscrew it using a spark plug wrench.

- If the spark plug on a used trimmer is dirty, wash and heat it. There should be no deposits on the spark plug electrodes. Do not damage the ceramic insulator of the center conductor. In a new trimmer, check the spark plugs for manufacturing defects.

- Return the spark plug and check the spark ignition (discharge between the electrodes) when the starter operates.

- Remove the spark plug again. Using a 20 or 50 cc syringe, pour 20 ml of gasoline into the spark plug hole.

- Insert and fix the spark plug, setting its technological gap to no less than and no more than a millimeter.

- Pump up the fuel using the pump button (or lever) - if your trimmer model has one. Press the button every 4 seconds.

Now try to start the engine. Close the air damper immediately after starting.

Preparing the fuel mixture and refueling

For the convenience of preparing the fuel mixture, it is better to have a special canister. where one part contains gasoline, and the other contains 2-stroke oil. We recommend getting one like this, it is very easy to use https://ru-sad.ru/prinadlezhnosti-dlya-sadovoy-tehniki/dlya-benzopil/kanistryi/

Next, take a measuring container with a scale marked on it; with its help you can prepare the mixture as accurately and quickly as possible. Look in the instructions which brand of gasoline and 2-stroke oil https://ru-sad.ru/prinadlezhnosti-dlya-sadovoy-tehniki/masla-i-smazki/ are recommended by the manufacturer of your model of lawn mower. Pour gasoline and oil into the container for preparing the fuel mixture, according to the proportions specified in the instructions. Then carefully pour the finished mixture through a funnel into the trimmer’s fuel tank. The ratio of gasoline and oil should be exactly as indicated in the instructions. This is a very important point!

Starting a warm engine

It's very simple. Move the switch to the operating position and pull the cord until it starts. If you do everything according to the instructions, then there should be no problem starting a working lawn mower.

Recommendations for use

The stability of the operation of any lawn mower and the absence of problems with starting the power unit of such devices directly depend on the conditions in which the tool is used and the quality of maintenance. And we are talking about the following basic rules:

- during operation it is necessary to pay special attention to the cooling system and other elements; It is strongly recommended to promptly and efficiently clean the channels located on the body of the scythe and the starter ribs;

- in the process of processing various elements, you can use solvents, gasoline, kerosene and other effective means;

- the specified work should be carried out after the power unit has completely cooled down;

- it is necessary to fully comply with all the rules specified in the relevant instructions drawn up by the developers of the described tool, which will avoid overloads in a warm engine, which in turn is the most common cause of serious breakdowns;

- all remaining fuel in the internal combustion engine should be completely drained before long breaks in the operation of the scythe; It is worth considering that the gasoline-oil mixture quite quickly breaks down into so-called heavy fractions, which inevitably clog the carburetor;

- after removing the fuel, you need to start the engine and let it run at idle until it stalls; in this way, the remaining mixture will be completely eliminated from the internal combustion engine.

Particular attention must be paid to preparing the instrument for long-term seasonal storage. This should be done in order to minimize the risk of problems with starting the engine. Proper preparation includes the following manipulations:

- completely disassemble the trimmer;

- thoroughly rinse and clean all accessible elements;

- inspect the parts of the lawn mower in order to identify defects (mechanical damage detected in this case should be eliminated);

- pour engine oil into the gearbox;

- carry out high-quality cleaning of the air filter element from clogging;

- Having the appropriate knowledge and practical skills, you can perform partial disassembly of the power plant, followed by purging and lubrication of the moving elements;

- wrap the assembled gasoline scythe with a pre-oiled rag.

In addition to everything already listed, it is necessary to lubricate the piston group. This algorithm provides the following simple manipulations:

- remove the candle;

- use the starter to move the piston to top dead center (TDC);

- pour a small amount of engine oil into the cylinder;

- Turn the crankshaft several times.

Regardless of the cost and brand of equipment, you should strictly follow all the requirements of the relevant instructions and adhere to the recommendations of the developers and experienced specialists. Today, detailed information regarding the correct use of such equipment can be easily found on many specialized websites and forums.

Next, see how to determine and eliminate the reason why a gasoline trimmer does not start.

More reasons

There are not only situations when gasoline trimmers do not start, but also cases when, after starting, they work for a couple of seconds and immediately stall. Inspect the spark plug again: if it is “flooded”, and this situation is repeated even after wiping and drying it, proceed to “inspecting” the air filter.

Most likely, it is completely oily and needs to be replaced. If everything is fine with the filter, it may be that the ignition coil has failed.

If gasoline trimmers do not start, and you have done everything described above, the muffler may be clogged. It needs to be dismantled, burned on a burner, after which all carbon deposits can be easily shaken out.

More complex reasons for lawn mower failure

If the step-by-step troubleshooting algorithm does not produce results, and your scythe still does not start or stalls, it is worth inspecting the carburetor and the engine itself. A clogged carburetor can be one of the reasons for unstable operation of the tool. There are three main problems here:

- Clogged channels or jets. All this is cleaned with special washes or blown with a powerful jet of compressed air from a compressor. Do not use needles or wire, as the bores may be damaged;

- Worn carburetor gasket. The solution is to replace the failed gasket;

- Violation of tightness. To check this indicator, you can use a regular household tonometer, replacing the pressure gauge with a suitable one. Keep an eye on the readings: if they do not change, everything is fine, but if the pressure starts to drop, it means that some part of the carburetor is faulty. You'll have to find it and replace it with a new one.

READ Petrol trimmer does not work without suction

If everything is in order with the carburetor, then the gasoline trimmer may not start due to wear on the piston group. If chips, scratches or burrs are found on the piston or cylinder, they should be replaced. Piston rings must be checked. A slight luffing of the piston when the connecting rod swings indicates that it is time to change the rings. This procedure is best left to the service center specialists.

Perform a cold start correctly!

Often, gasoline trimmers do not start after they are tried to be “put into operation” after long-term storage. Launch failures in this case are often caused by incorrect user actions.

If you are faced with this particular phenomenon, then during a cold start you need to close the damper, and then pump a small amount of the fuel mixture into the carburetor. Then pull out the starting handle until you feel resistance, then start the trimmer with sharp and vigorous movements.

After a few jerks, it will start and stall, which is normal. Having moved the damper to the working position, start the tool again and start working.

How to start a gasoline trimmer

The process of commissioning a lawn mower, whether you bought it now or took it out after winter storage, the rules listed below will allow you to avoid basic mistakes that can damage the tool.

Let's assume that you just bought a gasoline trimmer. Take the instructions out of the box and see if you have all the parts of the lawn mower that are indicated. After this you can start assembling.

READ How to Choose a Petrol Mower Based on Quality Video

Starting a lawn mower with a cold engine

To start the lawnmower for the first time, find the choke lever and place it in the “closed” position. Turn on the ignition on the handle. If your model has a manual fuel pump, popularly called a choke, then press it 3-5 times until you see the fuel mixture inside the primer. The tool is now ready to run. Place the trimmer on a flat surface to ensure a stable position. Smoothly pull the starter cord until you feel resistance, and then with a sharp movement, pull the cord towards you 3-5 times.

If the engine starts after 5 jerks, open the choke. If this does not happen, open the choke anyway (if the choke is open and you continue to try to start the engine, fuel will flood the spark plug and you will have to dry it, which is a waste of time).

If the engine does not start with the throttle open, close it and continue pulling the cord. The first launch can be quite difficult and require up to 15 jerks. After the engine starts running, press the gas lever once to engage the idle speed. Now let the engine run and warm up. After this, it can be stopped by pressing the “Stop” button.

Basic mistakes when starting

Let's list the main mistakes that beginners make when starting a gasoline trimmer:

- starting the engine with the ignition off;

- starting with the valve closed with more than 5 jerks;

- incorrect fuel mixture.

Step-by-step instructions on how to mow grass with a lawn mower and save fuel

Starting the lawn mower requires mostly on the ground. Some craftsmen can wind the instrument while holding it in their hands, but this is quite difficult and unsafe. After starting the tool, you can start using it. First, you should put on protective clothing and an unloading belt. Depending on the model of the tool, the unloading belts can be on carabiners or ties. If you use a carabiner or latch, then after starting the motor, the tool should be secured and start working. If zip ties are used, then it is necessary to wear the belt together with the operating equipment.

The belt must be balanced first. This means that, regardless of the total weight of the tool, the mower’s hands should bear a minimum of load. The mower only moves the tool with his hands, and if balancing is not done, rapid sluggishness will be observed during work. The entire weight must rest on the worker's shoulders.

When the tool is ready for use, the instructions for cutting grass with a lawn mower look like this:

- It is necessary to make movements to the right and to the left slowly, while keeping the

trimmer at a similar distance from the ground - The mower's movements should be slow (half a step). Experts call the movement of a mower duck steps

- The biggest challenge new riders face is maintaining a steady rpm. The rotation speed should be changed during mowing, depending on the density of the vegetation. If the grass is young, then mowing it does not require working at full capacity

- The mower must feel the work of the tool. If the scythe does not cope with the grass, you need to increase the speed. However ,

it is not recommended to operate the equipment at full speed all the time. - Experts have developed the best mode for cutting grass with gas trimmers - in one direction it is necessary to increase the speed above average (almost at full throttle), and when moving the lawn mower back, the gas is released, taking a step forward at the same time

. This method is vital for cases when you need to carefully lay the grass in windrows

READ How to Thread Line into a Stihl Trimmer Reel

Often, among mowers using gas trimmers, disputes arise about how to mow correctly with a trimmer, whether it is necessary to release the gas or whether it is better to work in a constant mode. Let's look into these issues carefully.

- There is a worldview that it is better to mow with a lawn mower in one speed mode. This worldview is not correct. Working with the same power not only affects the increase in fuel consumption, but also the wear of parts. Relieving gas during reverse movement of the equipment is useful, because during this period the engine cools down and the CPG is also lubricated. The release of gas leads to the throttle valve closing, as a result of which the fuel passes through the XX channel, and thus the parts are lubricated

- Relieving the gas allows you to not only mow the grass, but also carefully place it in windrows. Moving the tool in one direction allows you to mow, and when moving in reverse, a swath is created

- The disk moves exclusively in one direction, so it is simply stupid to keep the tool at constant speed when it is moving in the opposite direction

- Relieving the gas leads to the fact that the cutting disc begins to rotate the crankshaft by inertia, and coasting is always useful

If you mow with a lawn mower in one speed mode (this is what new ones usually do), this will affect the increase in fuel consumption and overheating of the engine. For comparison, you can imagine the operation of a chainsaw. The sawyer gives the highest speed only when necessary, but when the tree is cut down, the chainsaw works at XX, which means it cools down.

This is interesting! Petrol mowers have air cooling, which is realized due to natural air flow, therefore operation at constant speed increases the possibility of overheating. The higher the constant speed, the faster the engine will overheat.

Starting a walk-behind tractor after winter

Owners of walk-behind tractors often encounter this problem when the equipment does not want to start after wintering. This is due to storage conditions. If the car was in a cold room with high humidity, then you may end up with a number of serious breakdowns.

Before the first start in the spring, you must completely change the oil and fuel. Ensuring that liquids are at ambient temperature is extremely important.

You may encounter that the walk-behind tractor refuses to start immediately. And this is quite normal. Let the equipment warm up a little. It should warm up even after starting the engine.

If the start of the walk-behind tractor still fails, you need to perform the following steps:

- Bleed the fuel system. There could be residues from gasoline or diesel in it;

- check the spark plug. The contact can even be cleaned a little with sandpaper;

- Check all wiring to ensure there are no breaks or damage.

Starting a gasoline and diesel unit

The equipment is equipped with gasoline or diesel engines. There are differences between starting a diesel walk-behind tractor and a gasoline machine. For this reason, it is necessary to analyze the factors due to which the unit does not start for each specific type of engine.

Before purchasing a walk-behind tractor, special equipment is prepared. It is necessary to make sure that absolutely all elements are present and to make sure that the mechanisms are securely fastened.

Mechanisms often refuse to work after winter. A long break becomes a prerequisite for the occurrence of problems in the walk-behind tractor systems. Storing in a cool and humid area will cause the following problems:

- oxidation of contacts;

- violation of wiring insulation;

- watering of fuel and oil;

- clogged carburetor jets.

Before starting a new walk-behind tractor, absolutely all connections, clutch cable, reverse and gas are checked. Do not turn on the device if there are clamps or twisting of the harness threads.

During the first start-up, be sure to check the oil level in the crankcase. Lack of lubrication will damage the piston group. The crankshaft spins up to 1400 revolutions per minute at idle. It only takes a couple of seconds to create a scuff mark on the cylinder plane.

Old oil can cause the engine to not run. At the same time, the walk-behind tractor emits white exhaust gases. This begs for an absolute oil change.

It should be taken into account that the mini-tractor does not start easily if there is not enough oil. Keep an eye on this parameter before starting a carburetor and diesel walk-behind tractor. In some modifications, protection is determined by a low level. The device blocks startup and the unit freezes.

HOW TO START A CHAIN MOWER IN COLD DAYS?

It should be remembered that any type of engine requires a specific brand of gasoline. For a two-stroke engine, fuel is prepared separately. The fuel mixture consists of fuel and oil. The number of ingredients is kept in strict balance.

Diagnostic features

Trimmers can be classified as complex devices in technical terms. Based on this, before using them, it is strongly recommended to carefully study the appropriate annotation. But in practice, many people ignore it, and often later find themselves in situations where the gasoline trimmer does not start or picks up speed poorly during operation. It should be noted that similar problems can be encountered when acquiring new standards of technology.

The key to effective and prompt repair will, of course, be competent diagnostics of the device. In the process of identifying defects, you will have to examine and test, first, the main elements. The list of these includes spark plugs, a tank, filter units and fuel system valves. As practice shows, very often malfunctions of these particular parts become a prerequisite for the fact that the lawn mower does not start. The quality and correctness of the production of the fuel mixture deserves special attention, especially when it comes to two-stroke engines. Regarding this parameter, you should follow the manufacturer's advice correctly in order to avoid serious breakdowns and expensive repairs. In the case, for example, with a piston group of an internal combustion engine, costs can reach up to 70 percent of the price of the latest technology.

Often, owners of trimmers have to deal with situations where the designated mixture is of high quality, the carburetor is working properly and adjusted, but the device still shows no signs of life when trying to start the engine. In such cases, you should check the condition of the spark plug. The following steps will resolve the problem:

- unscrew the spark plug;

- wipe and dry the part (calcination is unnecessary);

- remove fuel and dry the spark plug channel for 30–40 minutes; such actions will allow you to avoid flooding the spark plug during the next start-up attempt;

- completely remove traces of soot using a needle file or sandpaper;

- set the appropriate gap;

- put the candle in place.

READ How to Disassemble Electric Trimmer Viking Te 1000

If the spark plug turns out to be working and the seat is one hundred percent dry, but the scythe engine does not start, then the threads should be moistened with gasoline. It is worth keeping in mind that, regardless of the quality of the spark produced, initially in a completely dry chamber there will simply be nothing to ignite. When faced with the fact that there is no spark, you should pay attention to checking the contact between the high-voltage wiring and the spark plugs. If this connection turns out to be of high quality, then it will be necessary to inspect the functionality of the ignition system control unit. In such cases, it is unlikely to be possible without the services of a qualified specialist.

The next step in diagnosing a gasoline spit is checking the condition of the filters. Often the lawn mower starts poorly or does not start at all when it is cold due to the fact that the air filter is clogged. This malfunction can be identified by excluding it from the system. If after this the scythe starts up, you will have to clean or replace this element. Experienced users always recommend blowing out the air filter from time to time to maximize its service life.

The described tool may also fail to start due to problems with the gasoline supply caused by a dirty fuel filter. To quickly and effectively eliminate a similar breakdown, it will be useful to simply replace the filter element with a new one. It is important to remember that the absorption pipe must be equipped with a filter, which is provided for by all instructions. Failure to comply with these rules and advice may result in expensive piston repairs. In the process of diagnosing and searching for the source of problems with starting the mower, attention should be paid to the breather, which is responsible for stabilizing the pressure equalization in the fuel tank. In addition, you need to check the cleanliness of the exhaust channel and muffler mesh. Typically, similar problems are encountered in most cases when troubleshooting old models.

Starting a walk-behind tractor after winter

Such cars tend to have difficulty starting after wintering. First of all, the performance of a walk-behind tractor after winter is affected by the storage conditions of equipment in cold weather. If the car is left over the winter in a cold and damp garage, this can lead to serious problems.

Before starting the walk-behind tractor for the first time this season, it is recommended to change the oil and fuel. It is also necessary to make sure that the performance characteristics of the technical fluids used correspond to the ambient temperature. It is also recommended to read the instructions again to ensure all proportions are observed.

There is a high probability that the walk-behind tractor will not start immediately. This is normal, you need to let the parts warm up well. In addition, it is necessary to warm up the walk-behind tractor even after the engine starts. Over the winter, the fuel could thicken, so it is better not to start using the car intensively right away.

If the engine does not start, you should perform the following steps:

- check if the wires are broken;

- clean the spark plug contact with sandpaper;

- blow out the fuel line.

How to start a walk-behind tractor correctly?

To start a gasoline walk-behind tractor, you must first move the choke lever to the “Start” position. After this, you need to open the gasoline tap and pull the starter several times. Then you can turn on the ignition and pump the starter one more time. At this point the car should start. In models with an electric starter, just turn it on and start the engine.

Diesel walk-behind tractors start in a slightly different way. The first step is to get rid of the air in the fuel line. To do this, you need to open the fuel tap, and then unscrew the supply connections all the way to the injector. When unscrewing the connection, you need to wait until fuel flows from it. After this procedure, you need to open all the taps and move the gas to the middle position. Squeeze and pump the decompressor several times while holding it with your finger. Next, return it to its original position. After this, press it once again and pull the starter. The walk-behind tractor should start.

Possible reasons

Does the walk-behind tractor start and stall? Why is this happening? There may be several reasons why a motorcycle does not start when starting. These include:

- damage to the carburetor (in units with a gasoline engine);

- defective ignition and glow devices;

- low level of basic lubricant.

When unusual changes occur in the unit and its operation becomes unstable, the carburetor is checked first. In this essential unit, the formation of the fuel-air mixture (FA) and its dosage for supply to the cylinders of the internal combustion engine (ICE) take place. And if the jets become clogged, the fuel system becomes obstructed, causing the carburetor to lose its ability to guarantee engine starting. In order to eliminate the defect, the fuel line is repaired, which involves a partial analysis of the carburetor, flushing the pump, and purging the nozzles through the fuel fitting.

READ How to Start a Brushcutter with a Broken Manual Starter

If the Neva walk-behind tractor does not start, the reasons may also be different. Sometimes the problem is hidden in a malfunction of the spark plugs, which play an important role in starting a carburetor internal combustion engine, or the glow plugs, which ensure the start of a diesel engine. If the igniter devices become wet, which happens due to fuel assemblies being thrown into them, the spark begins to disappear in them. In the absence of sparking, the fuel-air mixture is not ignited and, therefore, the engine cannot be started.

This problem can be solved in various ways:

- carry out minor repairs and replace non-working spark plugs with new ones;

- “burn” the flooded candles and use a flame to clean them of traces of fuel.

The equipment does not start due to a defect in the glow plugs. In a diesel engine, fuel is ignited by contact with hot air, which is heated in the cylinder when compressed by the piston. This occurs without complications if the unit is already heated and the operating temperature in it is maintained by the heated walls of the cylinder. However, in cool weather, the engine is heated using incandescent devices, and if they break, it will not be possible to start the walk-behind tractor.

If, upon inspection of a carburetor engine or diesel engine, no defective spark plugs were identified, but difficulties persist, and are also accompanied by popping noises in the muffler, it is necessary to check the functionality of absolutely all devices responsible for the flammability of fuel. A defect in them may also be a reason that the walk-behind tractor does not start. It is more correct to carry out diagnostics in a service center, where specialists will find the cause of the damage and carry out professional restoration.

Motor vehicles will not start even if there is a lack of lubricant in the engine. Certain modifications are equipped with special control sensors, which, if there is a lack of lubrication, prevent the engine from starting. Particular attention should be paid to those machine variants that do not have such meters. Sooner or later, the degree of the lubricant mixture will reach its limit value, and if it is not compensated to the norm, this will soon lead to wear of the elements and, as a result, to a major overhaul of the engine.

How to choose the right brush cutter for you

Petrol trimmer/petrol mower Stihl FS 55. Description of the advantages of the model

- Ergonomic two-handed silver handle. Fits comfortably in the hand and does not slip out during operation.

- The motor control mechanism is built into the handle. This has been done to enhance safe use.

- Replaceable cutting equipment expands the functionality of the tool. The Stihl FS 55 petrol trimmer/gasoline trimmer is supplied with a disc for hard and overgrown grass and a disc for trimming bushes.

- Glasses for eye protection. They provide direct and lateral protection, are blown inside, do not create a greenhouse effect of glass, and provide a good panoramic view.

- STIHL shoulder strap. Comfortable use of the trimmer increases productivity, reduces energy losses, evenly distributes the load, and does not put pressure on the shoulder. Frees your hands for productive mowing and secures the scythe during operation.

- The tank is made of translucent material, which allows the operator to visually monitor the fuel level.

- Fuel consumption is controlled by a special system. Thanks to it, the trimmer

consumes fuel economically and produces little exhaust. - Easy to control trimmer. No special knowledge or experience is required to operate the tool. The user can easily understand the buttons on the handle, indicated by generally accepted symbols.

- Lack of electric drive. The chainsaw works anywhere in a large area without a network connection.

Update

No spark

The spark on the spark plug is checked. The functioning of an element is influenced by various factors. When testing the mechanism, the reasons are revealed:

- insufficient carburetor adjustment;

- large oil in gasoline;

- clogged fuel and air filters.

Due to working in such conditions, carbon deposits accumulate on the spark plug contacts. Subsequent corrosion of the conductors becomes the reason that there is no spark in half of the cases of malfunctions. This happens because the gap between the modular contacts changes. To check the spark do the following:

- the tip of the high-voltage cable is removed;

- the candle is unscrewed;

- the tip is put in place;

- the candle is leaned with its wide end against the cylinder;

- start the starter.

If during startup a bright spark resembling lightning appears between the electrodes, then the ignition unit is working. If there is no flash, clean the entire element and adjust the gap between the conductors. Sometimes there is no clearance between the flywheel and the ignition coil. When the flywheel rubs, scratches are visible on its exterior.

Idle speed adjustment

Before setting up, carry out maintenance of the tool. To ensure that the idle speed adjustment is effective, preventive measures are taken:

- carburetor cleaning;

- engine flushing;

- cleaning the air filter;

- warming up the engine.

To adjust the operation of the mechanism at idle speed, use the appropriate adjusting screw. Its rotation depends on the required setting:

- During standard adjustment, the screw is turned counterclockwise until it turns tightly. After this, make 2 circles in the direction of the arrow.

- If the saw operates at low speeds, then turn the screw clockwise until the chain begins to move. Then make half a circle in the opposite direction.

- At high frequencies, the regulator is turned counterclockwise until the circuit stops. After this, the rotation is continued another half turn in the same direction.

READ Maintenance Trimmer Brushcutter Electric Parma Tk

It will not be possible to adjust the idle speed if there is air leakage into the engine through the gasket, acceleration pump, seals, or for another reason.

Ignition coil malfunction

The module or coil cannot be disassembled; its suitability is difficult to determine without testing devices. Modern ignition systems are durable, lightweight and small in size. They are characterized by almost trouble-free functionality. Problems with a chainsaw malfunctioning due to the ignition coil can be resolved independently.

The outlet wires are tested for damage (including internal damage) that occurs due to vibration leading to friction. If no cracks are detected, then the ignition coil needs to be replaced. Sometimes a module malfunction is indicated by a weak, barely visible flash when the saw heats up. This occurs due to an increase in the temperature of the coil, which leads to an increase in the resistance of the transistor.

The peculiarity is that at the beginning of operation a spark may appear, but after prolonged use it becomes dim and disappears. Modern ignition coils cannot be repaired in a home workshop, so they are replaced with suitable elements.

At idle

Violation of the functionality of the fuel unit system leads to air leaks. In this case, the unit stalls at idle and does not maintain its number. Additional suction reduces the air impulse to the fuel pump and passes through the sump membrane or crankshaft seals. Diagnostics is done with a vacuum gauge.

Stopping the engine when cold occurs for other reasons:

- the spark plug channel contains an excess amount of combustible mixture;

- the gap between the tip of the spark plug and the high-voltage cradle is not adjusted;

- power supply failure.

Check the seals by pouring gasoline into the crankcase; the leak is visible visually. This means that the engine does not operate at idle speed, and at high frequencies, leaky oil seals will lead to bearing jamming. If elements leak, they are replaced with new ones and sealed.

Fuel supply

After unscrewing the spark plug, a wet coating is found on its surface. This indicates an excessive supply of gasoline to the combustion chamber. For this reason, the tool does not work or stalls, because the fuel does not ignite.

Another inhibitory factor is a clogged breather - a small hole in the gas tank cap. It is cleaned with a needle, otherwise the Stihl MS 180 chainsaw will not start. To determine the incorrect fuel supply, the following steps are carried out:

- remove the candle;

- pour 2 cubes of gasoline into the hole of the candle with a syringe;

- put the ignition device in place and put on the high-voltage wire cap;

- the lever is moved to the hot start position;

- pull the starter handle a couple of times.

If the tool starts and immediately stalls, then the fuel line is tested further. Check the gasoline filter, splashes from the engine crankcase, and the integrity of the partition in the pump when unscrewing the cap.

When you press the gas

The sawing units operate at idle speed, but the chain saw stalls when the gas is pressed, as the load increases. Before use, warm up the tool by running the engine at idle speed for a minute. If this is neglected, the motor stops after pressing the pedal. Other reasons may be:

Petrol mower STIHL FS 55 C first launch

- clogged or unregulated fuel mixing unit;

- a clogged air filter does not provide the required air flow when the load increases;

- a dirty gasoline filter does not allow the required amount of mixture to pass through;

- the cylinder and piston walls rub.

A low octane number of fuel causes brakes, since this circumstance prevents the engine from achieving the required power when the load increases.

Before starting the walk-behind tractor for the first time

If you have purchased a new car, then first of all you need to carefully read the operating instructions. This step cannot be skipped, even if you have used walk-behind tractors before - the instructions contain the most accurate information on how to start a walk-behind tractor for a specific model.

In addition, before the first start, you should complete the following points:

- Check oil level. Some cars have special sensors that prevent the engine from starting if there is not enough oil in it. Other models can be started with an insufficient level of technical fluid, but this can cause great damage to the car;

- Fill with fuel. In some models, gasoline must be diluted. The proportions are written in the instructions. You also need to be careful with diesel fuel. The instructions must indicate what type of fuel is used at a certain temperature. Using summer fuel during the winter season can lead to clogging of fuel lines;

- Check connections and configure them. The throttle, clutch and steering wheel need to be adjusted so that they move smoothly.

Rules for operating a gasoline lawn mower

Like any equipment, a lawn mower needs some maintenance features and basic principles of use. These rules are simple, but will help preserve your device for a long time.

General operating rules:

- Read the instructions for use and care of the lawn mower, familiarize yourself with the basic rules of operation, storage and safety.

- After each use, clean the body, channels, grass, knives, preferably using special liquids.

- Do not clean a lawnmower with a hot engine.

- During operation, monitor the condition of the engine, do not allow it to overheat, and take breaks.

- Drain the fuel at regular intervals (about a month). At the same time, at the end of the work, the device is given the opportunity to stand up and stand up.

READ Which Gasoline to Pour into a Shtil Lawn Mower

Rules for preparing equipment for winter:

- A visual inspection of the lawn mower is carried out, the main parts are removed, cleaned, dried, damaged

- Drains fuel.

- The air filter has been cleaned.

- Oil is poured into the gearbox.

- All moving engine parts are cleaned and lubricated.

- The motor is wrapped in oiled cloth.

Petrol lawn mower MTD Smart 51 BO

Safety regulations:

- Before starting work, the work area is checked for the presence of foreign objects: stones, branches.

- Bystanders should not be at least 5 m away from the mower.

- The work is carried out in special glasses.

- Visually inspect the lawn mower for damage or loose parts. The faults have been resolved.

- You can mow grass no more than 20 cm in height, no more than a third.

- When working on slopes, you should move along the slope, not up and down.

- The motor stops before changing the bevel height.

- If foreign matter gets into the mower blade, the operation stops and the cleaner is cleaned.

Gas mowers have earned the respect of users for their power and quality of work. To extend the life and efficiency of the unit, it is necessary to learn all the intricacies of care and maintenance of the lawn mower, follow safety rules, and follow the operating instructions for this equipment.

Source

Don't know how to start your lawn mower? We'll tell you. In any village, country house, summer cottage, in order to level the lawn grass or weeds, or clean the area in the garden or vegetable garden, there must be a lawn mower, and best of all, if it is gasoline.

Cracks and noise from lawnmower use can be heard from the first day of summer until late autumn, until grass growth has significantly decreased. Gas mowers have become very popular due to their ease of use. This device is easy to use and care for your lawn; if it breaks, it is not difficult to repair. Below we will take a closer look at how the process of starting a lawn mower is carried out.

The content of the article:

How to start a walk-behind tractor correctly?

After you have bought your walk-behind tractor, you should not start it right away, even if the consultants assure you that the equipment is completely ready for use. You need to start with the preparatory work.

To do this, you first need to check the engine oil level. There should be a sufficient amount of it. If this is not the case, the oil needs to be added. If you start the engine without oil, it will immediately fail. On sale you can find walk-behind tractors, such as Caiman, that have an oil level sensor. If there is little or no lubricant, the engine simply will not start. This is very convenient and significantly extends the life of your equipment.

After this, you need to add fuel. When purchasing, check with your consultant or in the operating instructions for the type of gasoline that is suitable for your model of walk-behind tractor. If the unit has a two-stroke engine, then the fuel must be diluted with oil in a certain ratio. Never use low-quality fuel or fuel that is not suitable for your walk-behind tractor.

The final stage of preparing the machine for launch is checking all connections and fastenings. All moving elements should not be tightly tightened - their operation should be elastic, but smooth.

Starting a diesel and gasoline walk-behind tractor is slightly different. The gasoline unit starts like this:

- open the gasoline tap;

- the choke lever must be in the “start” position;

- the ignition must be turned off;

- pump with a mechanical starter a couple of times;

- now you need to turn on the ignition;

- pull the starter again.

If you have an electric starter, then you can immediately turn on the ignition. The starter will quickly pump fuel into the carburetor.

With a diesel walk-behind tractor, things are a little more complicated. The new unit is completely airless, unless, of course, no one started it. To bleed it, you need to turn the starter. The process will take longer than when starting a gasoline car, but eventually the walk-behind tractor will start.

If you have a manual starter, you can pull it, but you can also start the walk-behind tractor in another way. To do this, you need to open the fuel tap, and from there, unscrew each connection all the way to the injector. You unscrew the connection, wait for the fuel to flow, and tighten it, moving on to the next one.

When starting mechanically, you need to open all the valves and put the gas in the middle position. After squeezing the decompressor, pump it a couple of times, holding it with your finger. After this, lower the decompressor and pull it to its original position. Press it again and do not hold it, but immediately pull the starter. The walk-behind tractor should work.

Take this into account when working

Usually the lawn mower is equipped with a fixing belt.

You need to first adjust it to your height so as not to have to do this when the device is already running. Gasoline trimmers, due to their power, have high performance. However, not all gas trimmers are capable of working, interrupting only for refueling, especially in extremely hot weather. You should not test the tool for strength and work it “to wear”, because this can lead to a significant reduction in its service life. The same applies to cutting off vegetation that is too tough, such as thick branches of bushes. Carefully read the instructions for use and permissible loads for your trimmer. If he is able to cut a 1.5 cm branch with a steel knife, you should not try to do this when its diameter is 2 cm. A good tool and a high-quality knife will, of course, cope with this, but after a couple of such experiments there is a possibility that it will need to be repaired . And it’s not a fact that you will be able to do this under warranty.

Use the trimmer only for its intended purpose. It's one thing when it comes with factory-made brush cutters or snow removal attachments, and quite another when you try to use homemade attachments.

A gasoline trimmer is often used for cutting grass over large areas when making hay. You should not use fishing line for this, otherwise you will get vegetable “porridge” instead of high-quality straw. Use knives or saw blades. And, by the way, for such a process it is advisable to have a model with a T-shaped handle: it is most suitable for long-term use.

After finishing work, clean the tool from any vegetation that has accumulated in it. Do not leave the mixture in the tank, use it completely or drain it, and prepare a new one for the next use. Check the equipment for integrity and secure fastening. Monitor the condition of the air filter. Clean or replace as necessary. The same applies to the fuel, but it can only be replaced.

What's in the fuel tank?

A visual inspection of the spark plug and its testing indicated that this item can be crossed off from the list of possible faults. But, at the same time, the problem with the fact that the moped does not start after winter has not disappeared. Therefore, you should check the presence of fuel in the carburetor. And if a careless owner forgot to drain it before winter, this is one of the first reasons why the moped will not start.

It should be noted that with repeated temperature changes in winter, condensation appears in the fuel tank in the form of water droplets. And during the downtime of the iron horse, the amount of such condensate accumulates in a large volume. This is precisely what can become the second problem why the moped does not start after winter.

READ Petrol mower does not develop speed and stalls

It is worth noting that in some models, this factor was initially taken into account, and in order to avoid the accumulation of water, an additional appendix is installed on some mopeds during assembly. It is an extruded stamping in the tank, directly next to the gas line. This design makes life much easier for motorcyclists, but in any case, it is sometimes necessary to remove the tank and get rid of this liquid. Because over time, condensation will begin to enter the fuel tank. As a result, the moped will refuse to start.

During the warm season, gasoline is constantly renewed and moved in the tank. As a result, any sediment that appears gets mixed up and gradually goes away with the gasoline without being noticeable. But, when the iron horse goes to the garage for the winter, then by spring a water plug will necessarily be formed. It can be located in the fuel line, in the pump or in the pneumatic valve, or “conveniently” located in the carburetor. Thus, stop the flow of gasoline. Particularly susceptible to this defect are those units that still have their original mesh filters, since they do not allow water to pass through. Of course, this kind of protection is very useful for the moped, but on the other hand, such meshes block the normal operation of the iron horse. And so that the question of how to start a moped after winter does not torment the owner’s head, these filters should be cleaned sometimes, especially before the start of spring operation.

Repair of electric lawn mowers

The drive circuit, despite the similarity, is determined by the type of electric motor. Malfunctions associated with engine operation look like this:

- the car won't start;

- after starting, the unit stops working almost immediately;

- during operation, the motor does not increase the number of revolutions;

- There are strong vibrations after starting.

During the repair of electric lawn mowers, it is discovered that the capacitor required for the phase shift fails, this is indicated by the following indirect indicators:

- the engine begins to twitch after fuel arrives;

- when working with a light load, the engine gets very hot;

- the unit operates at reduced speed;

- a monotonous hum is heard.

If checking the brushes and capacitor shows their serviceability, then the cause is a burnt out winding. You can repair lawn mowers yourself, but it is better to take it to a specialist workshop. If the owner is confident in his abilities, then he can identify and fix problems in the electric motor himself. To do this, do the following:

- Measure the voltage in the power circuit and check its compliance with the operating indicator in the unit passport. In case of significant deviations, use a voltage stabilizer or do not work with such a network.

- They examine the plug and cord, check the fuse, and identify mechanical damage. Replace faulty electrical fittings and cables.

- Remove the power button on the unit and test it with a special device (multimeter, tester or indicator screwdriver). Oxidation spots on the capacitor are checked and swelling characteristic of a malfunction is identified.

- Burnt areas of the winding are diagnosed on an electric motor, and its integrity is checked with a device. After detecting a malfunction of the electric lawn mower at any stage and getting rid of the breakdown, they will test the performance of the unit.

The start button can be tested without the device by using a temporary jumper to close the contact. A working unit after connecting plus and minus indicates the serviceability of the part. To replace the button, remove it from its seat after unscrewing the screws using a screwdriver. To check, you need to reassemble the mower.

When replacing worn brushes, they are removed and new elements are installed. Removing old bearings requires effort as they can be difficult to remove from the shaft

Hit or knock them down carefully so as not to destroy the rotor or landing site. Replacement of a burnt out motor is done after dismantling the fan and rings with bearings

Moped won't start after winter - check the battery

How to start a moped after winter is a question that in most cases arises from owners who neglected their iron friend in the fall. In other words, they did not preserve it before the onset of cold weather. And since this happened, then it is necessary to start checking and finding out the cause from the very heart of the moped, from the battery.

If you can’t start the moped right away, then unscrewing the battery starter until the crankshaft is completely plugged is a stupid thing. When the engine does not start right away, you should not force it, since it is advisable to save the battery power, it will be useful later.

How quickly the moped will start depends on the condition of the battery. Naturally, lighting the battery through the wires can give a positive result, but it will be less effective than a well-charged own scooter battery.

Therefore, before taking your first ride on an iron horse, it is worth checking the condition of the battery. Better yet, take the battery home and charge it. And after driving under current, make the first attempts to start the moped.

What if it's about the candles?

The moped won’t start after winter, which means you should check the spark plugs. It is necessary to unscrew the spark plug and assess its condition, dry or not. If it is dry, then put it in place, but before that you should check the spark. And to perform such a manipulation, they insert a candle into the cap, do this so that the thread fits tightly to the mass. Then, you need to rotate the crankshaft with a sharp movement.

Another way to check is to take a small piece of wire, screw one end to the motor, or rather to its body, and the other to the spark plug, on the side where the thread is located. If there is no spark, then the problem is in the spark plug; in such a situation, the only option is to purchase a new one.

Well, if the spark plug gives a spark, then they put it in place and try to start it, but it doesn’t work, which means the “diagnostic operation” continues.

A cheat sheet with some useful tips

The spark plug gives a spark, but a very weak one. The problem is that the ceramic insulator can become damp. And therefore, part of the energy simply flows down it, and the rest is not enough to ignite the fuel. It is this property that, in most cases, makes candles that worked flawlessly in the fall inoperative. If the candle is damp, you can try to dry it on an electric stove, but the correct thing to do is to replace it with a new one.

Before sending the moped for the winter, it is advisable to drain the remaining gasoline from the tank. Because this substance can be exhaled. In other words, the light fractions evaporate, and the remaining gasoline performs a chemical reaction with oxygen. As a result, gasoline changes its color, becomes dark and loses its ignition properties. This change is especially noticeable if the gasoline was not stored in a sealed or half-empty container.

If gasoline remains in the fuel tank over the winter, then in the spring it is drained and replaced with fresh one. Old gasoline can be added in small quantities to new gasoline, but in the warm season.

If all of the above manipulations helped and the iron horse started, then before the first spring trip you should check the oil level, cooling fluid, and of course the tires. After the manipulations have been completed, you can safely hit the road.

Possible problems

Unfortunately, gasoline generators can fail after a long period of inactivity. And not all users understand what may be the cause of the system malfunction. Accordingly, they leaf through the instruction manual in an attempt to find a solution to the problem. But the design of a gasoline generator is not so complicated, and you can find a fault without much knowledge. First, you should consider the sequence of operation of the generator system. To start the engine, you need a free supply of fuel and the presence of a spark.

To check the flow of fuel into the cylinder, you need to unscrew the spark plug and inspect its electrodes. If they are dry, no fuel is supplied. Wet electrodes indicate the flow of gasoline. In some cases, it happens that the spark plugs are filled with fuel when starting the generator. There seems to be a spark, but the engine cannot be started This situation occurs after the generator has been idle for a long time. To solve the problem, you need to wipe the spark plug electrodes dry and screw them back. Next you need to check for spark. To do this, you will need to stick it into the mouthpiece and connect the external electrode to any metal element of the motor.

READ How to Correctly Assemble a Cutter for a Motoblock

You just need to connect it at a far distance from the screwing point. In an unpleasant case, the spark that appears may flare up from gasoline fumes from the cylinder. After the spark plug electrode is attached, you need to pull the starter. If there is a spark, then everything is in order. If a spark does not occur, you will have to find a solution to the problem on a more global scale, because the absence of a spark indicates wear of the spark plugs or an electrical malfunction of the generator. Next, we suggest you familiarize yourself with several methods for eliminating problems in the absence of a generator plant.

- If there is incoming fuel and a spark, you need to wipe the spark plug and then tighten it. And again start

according to the rules of the annotation. - If the candle turns out to be dry after unscrewing, you can give a technical injection. To do this you will need a syringe with one or two cubes. Gasoline is pumped into it, which is then poured into the cylinder. Then the candle is quickly twisted, a mouthpiece is put on it, and the winding is done. With this approach, the engine will start from the 1st or 2nd test. But during the upcoming work it may stall. If the generator still stalls, you will have to contact a service center.

- If suddenly there is no spark from the spark plug, and it was not possible to get one by replacing the mouthpiece, it means that the electronic system of the generator needs to be repaired. And only a specialist can repair the device.

Often users, faced with a non-working generator system, begin to disassemble it and examine its internal state. But experts first advise checking the oil level and the presence of fuel. In some cases, the generator stops working when the air filter is clogged. Cleaning it yourself is not so difficult, and to determine its location, just look at the instruction manual.

The solution to the problem is similar if the fuel filter becomes dirty. It also needs to be cleaned or replaced. If suddenly the generator engine still does not start after these manipulations, the problem is probably that the carburetor is dirty.

Subsequently, you will see how to properly start a gasoline generator.

How to start a moped after winter using ether

How to start a moped after winter is quite simple to do with the help of ether, provided that the iron horse has not been struck by another, larger-scale breakdown. For this procedure, it is necessary to remove the air filter cover and spray a large volume of ether directly onto the filter part. Then quickly close the lid so that the ether does not evaporate.

Well, start trying to start it, if you couldn’t start the engine the third time, then you need the help of a good mechanic and the only way is to the service station. Well, if the iron horse “made an attempt” to sneeze, you can repeat this procedure.

At the same time, it is worth remembering that if in the fall the moped started up and worked flawlessly, it means that all of the above methods will help start up the iron friend in the spring. Well, if your moped had problems running in the fall, then you shouldn’t waste time, you need to take it to a self-service station.

Of course, every owner of an iron friend must prepare his moped for the winter, but this does not always work out, due to simple negligence. And since in the spring there is no chance that an iron friend will start immediately, it means that it is worth remembering all of the above methods that will help cope with this task.

Sources:

https://ru-sad.ru/sovety-polzovatelyam/kak-zavesti-benzinovyy-trimmer/ https://stroy-dvorik.ru/kultivatory/kak-zavesti-kultivator-posle-zimy.html https://avtomoto -best.ru/kak-zavesti-moped-posle-zimy.html