Technical features

A jigsaw for wood becomes indispensable when you need to form a complex figure on the surface of plywood, and if you change the blade you can work with metal. Translated from German, the word that has become so familiar to us means a curvilinear trajectory. The design of the tool is simple:

- arcuate frame;

- lever;

- clamps for attaching thin, narrow cutting parts.

The saw blade makes cuts; this is its main functional part. Therefore, how high-quality and sharp the metal strip will be depends on the quality of the work performed. In addition to hand-held devices, there are also jigsaws. They do not replace in any way, but they effectively complement each other.

If you have to cut through a thick, dense piece of wood, use an electric device, but when thin, careful processing is necessary, you cannot do without a hand tool. In addition, it costs less than its electric counterpart, and it is safe to start working with it.

Children's jigsaw

Teachers recommend buying a children's jigsaw for crafts during labor lessons. A convenient tool allows you to make cuts and cut out shaped holes.

Depending on the installed saw, material of different strengths is cut into the frame:

- plastic;

- metal;

- drywall;

- ceramics;

- tree;

- plywood;

- sheets of chipboard or fibreboard.

The master directs the device along the line he needs. It can change direction and process the edges of workpieces thanks to the clearance between the frame and the saw. Figures are cut out both internal and external. The blade is easily removable, which allows you to make cuts of complex configurations. After completing the saw steps, you can:

- replace;

- install;

- thread into a circle;

- continue processing according to the planned scheme.

To solve different problems, jigsaws of different designs are used.

How to choose a jigsaw

Before choosing, it is advisable to familiarize yourself with the rating of the best jigsaws in 2021, and better for 2021. When purchasing, be sure to study the characteristics of the model you like.

Motor power

The indicator affects:

- functionality;

- service life of equipment;

- duration of continuous operation;

- depth of cut.

For household jigsaws, the power ranges from 350 to 500 W, for professional ones it reaches 1500 W.

Blade stroke

The greater the amplitude of movement of the saw blade, the greater the number of teeth that will cut the material. The parameter affects performance and efficiency .

Kerf thickness

This characteristic is the main one. It determines how thick a workpiece the tool can process. With a minimum cutting depth, the edges of a wooden beam 10 cm thick will be unclean. For processing wooden materials at home, this figure should be from 80 to 110 mm , metal sheets - 6 mm .

Speed adjustment

Adjusting the speed is necessary when processing different types of materials. When sawing metal and plastic sheets, set the minimum number of revolutions , which will prevent the blade from overheating. For cutting wood, choose the highest number of revolutions .

Pendulum mechanism

This function is needed to adjust the direction of movement of the saw. Thanks to the pendulum mechanism , sawing speeds up, but the quality of the cut decreases.

Weight

Professional high-power models weigh more than amateur ones. It is difficult to work with them for a long time, your hand gets tired.

Features that increase comfort of use

In the top are jigsaws that are equipped with additional options. They process easier , but also increase the cost. The ability to blow air over the cut area and the tilt of the sole are considered useful functions.

You need to choose a model, taking into account all the main characteristics

Characteristic features of the tool

Hand jigsaw for wood for schoolchildren

For a novice craftsman, especially if he is a child, it is better to buy a manual jigsaw for wood for a schoolchild in order to gain experience and not break the file.

This is the most fragile part of the tool, which has a different shape and arrangement of teeth. This is how a straight blade with double teeth is used to make cuts in wood and plastic along a straight line. The spiral type of cutting part is used for curved, winding trajectories. Specialists in decorative crafts work with this kind of fabric. The shape of the frame varies:

- rounded;

- pointed;

- rectangular.

This part is made from materials:

- aluminum;

- gland;

- titanium;

- become.

Aluminum frames are not durable. For long-term use, buy tools made of metal alloys. The steel base will withstand the loads exerted by the master’s hand. There are basic factors that should be followed when choosing a tool:

- the shape of the frame determines how long the cut can be made;

- the structure will not break due to the applied efforts, but will spring back thanks to the good raw materials used for production;

- strength is determined by the height of the product; this size should not be greater than the length so that the rigidity of the device does not decrease;

- the methods of fastening the file, the length of the nuts, and the diameter of the thread must be correctly selected in order to securely fix the blade.

When purchasing, pay attention to the design of the clamps. It's good if there is a thumbscrew installed there. Simple nuts will have to be unscrewed by selecting the size of the keys. They take into account the status of the manufacturer, which has become known to the consumer for the quality of its products.

The best professional jigsaws

Models for specialized use in workshops and construction sites have the ability to cut wood, metal, fiberboard, plywood, etc. Our 2021 rating includes cordless jigsaws that were in greatest demand.

Wortex JS 8008-2 LE 850 W

Tool with options: adjustable stroke rate, quick-release fastening of the file. There is a backlight and a laser marker . Cast aluminum sole. The cutting area is cleaned with a vacuum cleaner. The cutting depth for wood is 80 mm, for steel alloys – 9 mm.

saw blade movement frequency – 3000 strokes/min;

pendulum stroke – 4 steps;

saw stroke – 18 mm;

sole angle – 45°;

weight – 2.4 kg.

Prices in online stores

Status JS800 800 W

The model has a quick-release fastening of the file, adjustable stroke rate, laser marker , and backlight. Aluminum cast sole. Cleaning the cutting area: blowing away sawdust, connecting a vacuum cleaner. The cutting depth for steel alloys is 10 mm, for wood – 100 mm.

saw blade movement frequency – 800-3000 strokes/min;

pendulum stroke – 4 steps;

saw stroke – 22 mm;

sole angle – 45°;

weight – 2.5 kg.

Prices in online stores

Fiolent PM 5-750E M 750 W

Model with adjustable stroke rate and molded sole . The cutting area is cleaned by blowing away sawdust and connecting a vacuum cleaner. Cutting depth for wood – 135 mm, aluminum – 20 mm, steel alloys – 10 mm.

saw blade movement frequency – 2800 strokes/min;

pendulum stroke – 4 steps;

saw stroke – 26 mm;

sole angle – 45°;

weight – 2.4 kg.

Prices in online stores

Hanskonner HJS0811LPE 800 W

There is a quick-release fastening of the saw, adjustable stroke rate, protective shield, and backlight . Aluminum, cast sole. Power cable 4 m long. Cleaning the cutting area: blowing away sawdust, connecting a vacuum cleaner. The cutting depth of the wood is 120 mm.

saw blade movement frequency – 500-3000 strokes/min;

pendulum stroke – 4 steps;

sole angle – 45°;

weight – 3 kg.

Prices in online stores

Jigsaw assembly

A hand-held jigsaw for wood can be turned into a universal one, and can be used to process materials of various properties. To do this, you need to learn how to change the working surface.

Hand jigsaw for wood

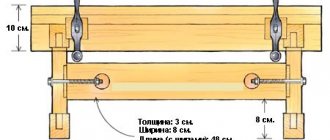

If the saw is positioned incorrectly, it will be difficult to work with the workpiece. When installing the actuator, the ends are clamped by 2 mm. from the edges, and the teeth are directed towards the handle. To do this you need to do:

- fix one end of the canvas near the handle;

- compress the arc along the edges, secure the opposite side with other hardware, the emphasis can be placed on a workbench or tabletop;

- After installing the file in the groove, tighten the nut.

Depending on the method of fastening, a wrench or pliers are used if there is not enough strength for manual fixation. When working with a frame in the form of a tubular arc to tension the saw, the base is installed in the grooves. They can be in a table or other device; you need 2 rounded recesses into which a jigsaw is inserted, then tightened.

Principle of operation

Hand jigsaw for metal

A manual metal jigsaw means that it can process alloys no thicker than 1 cm.

The strength of the material will not allow working at high speed; the physical strength of the master will not be enough for this. A steel file for such finishing is chosen with a high carbon content in the alloy and fine teeth. But regardless of what work needs to be done, the principle of operation of the jigsaw is the same.

If a worker is sawing a log with a simple saw, the cutting occurs while pushing the tool away from the body of the actor. The jigsaw cuts the object in reverse when the master pulls it towards him. The beginning of creative actions consists, as in any field of production, from preparing the workplace and securing the desired canvas in the frame. Processing is performed in the following order:

- select a workpiece, determine the configuration of the cutting, if necessary, transfer the design diagram onto the surface of the product using carbon paper or fill in the outline with a pencil;

- fix the stand on the workbench or tabletop with clamps, attach the part to it and begin to cut out.

The worker sits comfortably and holds the jigsaw with the handle down. The tool must be in a vertical position and move freely from top to bottom. If the clamps hold the blade tightly, there will be no movement along the cutting line. When it is necessary to change direction to perform a curved pattern configuration, the workpiece is moved, the actuator remains in the same position. To cut an acute angle, saw until the saw begins to turn freely, otherwise the applied force can damage the quality of the design and the blade itself.

When forming patterns, a mark is made in the center of the workpiece, a hook for starting work.

Drill a hole with a small diameter drill, then insert the blade without a frame, after which you attach the base with a handle and begin sawing. The master will distribute the sizes so that chips do not form. Upon completion of work with a jigsaw, the sawed areas are sanded with sandpaper, and the figure is varnished or painted.

Rating of the best jigsaws

| Place | Model | ||

| 1. | Makita 4329 450 W | Prices | Review |

| 2. | BOSCH PST 900 PEL 620 W | Prices | Review |

| 3. | DeWALT DW349B 500 W | Prices | Review |

| 4. | BISON L-570-65 570 W | Prices | Review |

| 5. | Wortex JS 8008-2 LE 850 W | Prices | Review |

| 6. | Status JS800 800 W | Prices | Review |

| 7. | Fiolent PM 5-750E M 750 W | Prices | Review |

| 8. | Hanskonner HJS0811LPE 800 W | Prices | Review |

| 9. | Daewoo Power Products DAJ 550 W | Prices | Review |

| 10. | PATRIOT LS 650 2021 570 W | Prices | Review |

| 11. | Interskol MP-55/500E 500 W | Prices | Review |

| 12. | Kolner KJS 480 480 W | Prices | Review |

What difficulties arise during work?

The jigsaw requires a lot of patience when working

Such a tool is considered a means of completing tasks for creative people who can spend hours cutting out a technically complex structure. When they begin processing in childhood, they get acquainted with the device, gain experience with exposure in order to obtain as a result a beautiful frame or household item.

Manufacturers have tried to install a comfortable, ergonomic handle, but this still leaves your hands tired from constant tension. There are unwritten rules for preventing fatigue at a later time and obtaining a high-quality cut without breaking the blade:

- The handle is held firmly during vertical movement; the jigsaw must always be in a straight position without angular deviations, then the file will not tear.

- Achieve a neat stitch. This doesn't require much effort. Entry into the structure of the raw material occurs when the canvas moves downwards, which should easily fall under its own weight and slight pressure from the worker’s hand.

- The cutting part is also lifted up freely, friction occurs to a minimum.

- Both hands are equally occupied in the work process. One rotates the part along the curves of the pattern, the other holds the jigsaw without rotating towards the contour.

- The location of the blade should not be in the central part of the figure, but closer to the edges of the cutting line.

- Replaceable cutting inserts do not cut corners. When this cannot be avoided, the work is stopped in order to continue on the other side according to previously made markings, taking into account the necessary vertical or horizontal deviations.

- The file is installed for its intended purpose in accordance with the processing tool and the configuration of the cut. The spiral type is used for curly cuts, straight teeth are needed for the same cuts.

- Poor processing will result if the workpiece is weakly fixed; a reliable clamp is chosen and firmly attached to the work table or stand.

- Keep in mind that the tool is designed to form shaped notches, but this is not a saw, it must be handled with care so as not to constantly change the cutting element to prevent it from breaking under strong pressure. In the work process, efforts are applied with a gradual increase. The guideline is a visual assessment of the chips. It should be small and uniform. When rough grinding appears, change the mode to prevent the formation of unevenness along the edges.

- Avoid sharp turns; to do this, use a drill to create holes, remove the canvas, and insert it into a new structure.

Jigsaw

There are several secrets that figure sawing specialists successfully use.

Despite the complexity of shapes and figures, turns and bends are often repeated, so they concluded:

- An acute angle will be obtained if you bring 2 lines to one point;

- an obtuse or right angle can be made by idle movement of the blade while smoothly turning the workpiece with the second hand;

- to get a curl in the design, increase the speed of the saw together with the rotation of the product;

- beautiful patterns are achieved on thin, sanded plywood even by those who do not yet have experience operating a jigsaw.

Specialists have become very interested in polystyrene sheets. This is a durable multi-colored plastic that lends itself well to processing. Interesting things come out of it.

You need to start practicing with simple diagrams, after all the procedures begin to be carried out automatically, you can begin to more serious drawings. For example, choose the simplest patterns with straight lines, then move on to curves.

There are specific conditions for successful work that must be followed for any amount of work. After every 60 minutes of hard work, you need to take a break and devote at least a quarter of an hour to rest.

What rules will protect against injury?

The mechanism seems harmless and simple only at first glance.

When performing any work, you must follow basic safety rules to avoid injury. There is work to be done

Safety rules when working with a jigsaw

with a sharp, metal part that hurts painfully, and on occasion will reach the bone. Before work, you need to inspect the jigsaw, check that the handle is firmly and firmly secured. If the fastening is broken during creative actions, the handle will fall off, but the hand will continue to move until it comes into contact with the metal pin. Which won't bring anything good.

A workbench or metalworking table must also be equipped with all special devices for safe work. Sometimes even a fall from a simple, unstable chair can cause injury and bone fractures.

The master always tries to take a closer look at his creation. This should not be done during work processes. If you lower your head too low, shavings will get into your eyes.

When a person gets used to a jigsaw and overcomes all the difficult moments, working with it becomes a real passion, and crafts become a source of pride. But a hobby can be combined with a source of income. Manual labor has always been valued much more than mechanical stamping.

- Related Posts

- DIY metal clamp

- Grinding machine - how to choose

- Rating of manual riveters

« Previous entry