Correct tool sharpening technology

The technology for sharpening a professional meat ax is practically no different from a similar procedure for other piercing and cutting tools (Figure 5).

To carry out the procedure correctly, you must consider the following:

- The work area must be properly equipped. The sharpening tool must be firmly installed on the bed, and the bed must be attached to the floor so that it does not move during operation.

- Before starting work, carefully inspect the abrasive wheel: it must be absolutely smooth, without beating or nicks. Only in this case will you be able to sharpen it technologically correctly and without harm to the blade.

- Take care of personal protective equipment as well. First of all, you need to put on safety glasses. Kitchen hatchets are made of high-quality steel, and during the sharpening process, metal splashes and abrasive dust can fly in all directions and accidentally get into your eyes.

- The sharpening technology itself is as follows: the blade is held in the direction “away from you” towards the rotation of the circle and parallel to its axis. It is advisable to hold the ax with both hands so that you can accurately maintain the sharpening angle.

- During the process, try not to overheat the cutting edge. As a result, the steel of the blade may become too brittle and will crumble during further use.

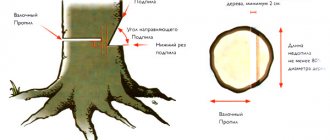

Figure 5. Correct sharpening technology

If during sharpening you notice that a burr has accidentally formed on the blade, do not despair. This does not mean that the instrument is damaged. To correct the situation, simply turn the ax over and start sharpening it in the other direction. It is better to bring the cutting edge to the desired condition on a small abrasive wheel

At this stage, extreme care must be taken so that the edge of the chip does not break off, and the edge itself remains strong. To do this, it is best to use the double sharpening method.

At the final stage, you can check the sharpening angle of the blade using special templates and, if necessary, bring the product to perfection.

How to choose

To choose the right hatchet for cutting meat, pay attention to several important details.

- Tool center of gravity

The most acceptable location for the center of mass on kitchen cleavers is the junction of the blade and the handle.

- Type of steel used

In the consumer goods market, along with factory products, you can find handicraft cutlasses. Therefore, look for a special brand applied to the blade by the factory. The stamp indicates the grade of steel from which the sample is made.

If possible, buy an ax with a forged blade. After such processing, the metal is of ideal quality and acquires a fibrous structure with elongated grains. That is, it combines the necessary viscosity and hardness, which guarantees a long period of use of the cleaver.

- Tool Blade Edge Type

The edge of the working surface must be sharpened on both sides. In the process of using such an ax, certain difficulties arise. The basic rule is that the sharpening angle should be 35-40˚. Then the cleaver will penetrate extremely deeply into the carcass, hitting both bone and muscle tissue.

- Blade Features

A branded blade, as a rule, has a one-piece design, it is massive and thick. The cutting characteristics of an ax depend on the relationship between the weight and thickness of the metal. The blade can have either a rounded or straight configuration.

Choose models with a comfortable handle so that it fits freely in the palm of your hand, since you can use the hatchet with one hand. The handy shape of the handle can have indentations for fingers. This is another plus in favor of the selected sample, as it will prevent the cleaver from slipping out of your hands.

- Minor configuration details

To make it convenient to store the hatchet, there should be a special eyelet in the body of the product, through which it is convenient to hang the tool on a hook.

- Ease of use

Most manufacturers of kitchen hatchets focus on the attractive appearance of the tool. But when choosing a cleaver for chopping bones, you should look not at beauty, but at practicality in use. Therefore, before going to the checkout, take the tool in your hand, evaluate the weight and practicality of the product, the comfort of the handle and other equally important criteria for selecting the model you like. If you ignore this test, there is a high probability of getting a beautiful, but inconvenient tool that will not be fun to use.

When choosing equipment, you should focus not only on the size of the model, but also the dimensions of the user, especially the length of his arms. This parameter significantly affects the practicality of using the cleaver.

Cost, place of purchase

Nowadays, supermarkets and markets offer a wide range of samples in different price categories. When choosing a convenient model, take into account such an indicator as the frequency of use of the hatchet. If you don’t cut meat often, why buy an expensive one.

In addition, do not rush to purchase a cleaver at the first store. Perhaps, if you go to several retail outlets and ask the price, you will be able to buy the model you like at the most attractive price.

Manual sharpening option

There are also quite a lot of tools for manually sharpening an ax blade. Their advantage is that you do not have to spend a lot of money to purchase the necessary device, and its small dimensions will allow you to store it in any kitchen drawer. The downside is the length of the sharpening procedure itself, especially if you are working with a meat cleaver with a large blade (Figure 7).

To cut meat in one motion, use the following hand sharpening tools:

- Musat:

as a rule, this tool is used for final straightening of the blade, and not for its direct sharpening. Externally, the musat is a long file rod with notches and an abrasive coating. Despite its limited functionality, it is still worth including the grinder in your arsenal of kitchen utensils, as it will help correct a burr on the blade or make it sharper in just a few movements. - Whetstone or Stone:

This is a more serious sharpening tool that is used to directly improve the sharpness of the blade of a kitchen ax or knife. If you want a truly sharp axe, it is better to buy several stones coated with different degrees of grain. - Special sharpening kits:

an ideal option for those who want to sharpen not only kitchen hatchets, but also knives, without going into the details of working with a whetstone or machine. As a rule, such sets include several stones coated with varying degrees of grain, a special fixing stand and additional accessories.

Figure 7. Tools for manual sharpening: sharpening sets, grinding stone and whetstone

If you are not a professional butcher and use an ax infrequently and exclusively at home, hand sharpening tools are ideal for you. But for those who, as part of their profession, often work with frozen meat or hard bones, it is better to give preference to sharpening the ax blade on special electrical appliances.

Meat cleavers and axe. Comparative test.

Hello, dear ladies and gentlemen, viewers of our channel, knife lovers!

Today I’ll remind you a little about our chopping assortment. There were comments that we specially prepare knives for ourselves. It's wrapped up, this hoe was taken from the warehouse. This is my worker, I’ve already chopped her meat with bones, I don’t know, 300 kilograms, probably. I’ve never done anything to it; you see, it’s even in such an unsightly state, rusty. Moreover, the cost of a new one is 5,000 rubles. The funny thing is that she still cuts paper. Maybe someone will think that I sharpened it, no, I didn’t sharpen it. It’s clear that the new one cuts paper really well.

I will test it on bear meat. I declare myself that I have killed four bears in my life, but I don’t have any bear meat. Here in different packages these are two different bears. Why do we put them in different bags, large pieces? Because we send the diaphragm and the legs of the bear’s diaphragm to the veterinary hospital for analysis, so that we can understand, if we suddenly come across a bear with trichinosis, what package it was in. I say again that the strongest bones are bear bones. Even in terms of weight, if you compare it with the same piece of beef, it is almost twice as heavy.

Let's try. I'll chop one leg with a new hoe. These are paws that will be used for soup. Amazing. It's me in the joint, let's assume that it doesn't count. Let me chop off a piece of shank. The bones of a bear are very similar if you chop with scrap metal. Chopped. I'll try it right away. Dear Sirs, this is a very high figure. You may not agree with this, but I didn’t take this hoe out of the frame. I cut with the entire plane, please note, this is for skeptics. This is an ordinary product. This hoe is made of Damascus. This is the quality. This is a hoe from a warehouse, it’s not my personal one, I didn’t make it specifically for testing.

Again. If the hoe is holding a bear bone, and the bear, as you can see from its paw, is quite big. The bear's bones are strong and difficult to chop, but they are just right for testing - any bone, even beef, would have been chopped long ago. I crumbled it a little, it’s okay, it’ll go into soup or cutlets. Let's try it now, it's interesting. Visually nothing. I hope no one has the idea that this is a trick. This is not a trick, gentlemen, this is the quality of our Damascus hoe. Everything, even if someone buys it, has been tested.

I chop the next leg with a taiga ax. Even the ax bounces off. In the joint, there is spongy bone, so it will be used as jellied meat. Visually nothing. the paper becomes damp very quickly, after all, today there is cover, today there was a little snow and rain. It cuts, but it didn't cut very well to begin with.

I won’t cut up the whole bear for you, it will take a very long time. Chopping meat for an hour is not interesting. Now I’ll try to cut the shank with my hoe, cheap, for 5000, and we can finish filming. This chopper was not sharpened; it had already been used to completely chop up the previous bear.

This, gentlemen, is our cutting tool.

I have a fairly large collection of knives, many knives for personal use, each for its own purpose. And lately I've become attached to one knife that I keep on my belt all the time. Moreover, even when you take the cotton off to dry, it hangs on your belt, i.e. it doesn't crash in any way. I can reach it with one hand - I rest and pull it out. This knife has been with me all the time lately. On my bag, as you saw, hangs “Finka NKVD” from Elmax, but in case of opening a can of food, let her have two knives with her rather than one. This is not the first time I’ve shown this, “Northern No. 3”. I really liked the Yakut handle because of its convenience, but the descents are still closer to me than the Yakut ones, but like this one, and the size turned out to be optimal. I constantly do something with it, even when I need to do something at the site, it’s always on my belt.

I won’t tell you everything further, show you everything, it will tire you. What I would like to say is the last thing. The fact is that it is the way it is in our family that we eat exclusively wild meat. There were several comments, the gist of which was: “Don’t you have anything to eat, are you shooting bear meat?” I will answer the same. There is something to eat, everywhere. There are domestic cows on the market, fed on chemical feed, with all the GMOs that can be found. There are domestic broilers, which, for reference, do not grow without feed. I tested it, tried it - the broiler does not grow on grain, and even if you add normal additives and vitamins, it still will not grow. Because he needs what is contained in the feed.

Wild meat is, first of all, the health of the family. I will answer this way. There is something to eat in the store, but the food is tasty, healthy, without any chemical additives - this is only, unfortunately, wild meat, or it is a bull that you yourself kept and are completely sure of. This is, let’s say, the situation now.

And there was one more comment. This is not for my film. I watched a Ukrainian film, very good on YouTube, “Hunting with a Pointing Dog.” The man was hunting for snipe. Snipe is a small bird. And one citizen wrote the following comment: “How can you kill a bird for 40 grams of meat?” This is a separate story, I’ll tell you about it separately. There, just these 40 grams of meat are secondary. Snipe hunting, hunting with a gun dog is a separate culture, a separate hobby, and what a person spent on these 40 grams of meat is completely incomparable. And the person who writes this comment has absolutely no idea that he is humiliating himself, because he looks at the world through his stomach.

Of course, I also love hunting with a pointer and mainly for birds, I really like it. But bear and elk hunting means providing yourself and your loved ones with healthy food, which lived in the forest, which was not given vaccinations, injections, or fed with chemical feed. Therefore, there is an opportunity - we hunt, there is an opportunity to store meat in freezers for a year - we stock it. Last year, however, I had to buy more beef in the last two months before the hunt, unfortunately I didn’t calculate it a little.

All the best! Goodbye!

What determines the method of sharpening an ax?

Proper sharpening of an ax

“I sharpened my ax with firebrands and the yard is full of firebrands” - this is the statement that speaks best about the importance of properly sharpening this device. The method of sharpening an ax is determined by the following factors:

The method of sharpening an ax is determined by the following factors:

- The density and hardness of the wood that is planned to be processed.

- The quality and condition of the processed material. An abundance of knots, twisted and dense wood requires a sharper cutting edge.

- Wood moisture level. Dry wood is tougher and puts more stress on the cutting edge of the tool, while wet wood is soft and does not dull the blade too much.

- Specifics of the work performed. Cutting wood in the transverse direction uses up the cutting edge more than trimming it tangentially.

- Metal grade. The harder the steel, the more difficult it is to sharpen, but the longer the serviceability of the cutting edge.

Of all the above factors, the main one is the grade of the metal, since the ability of the steel to hold an edge, withstand work loads and not break, forming nicks and gouges on the blade, depends on it.

Ax for chopping meat: basic requirements

A quality ax designed for chopping meat and bones is a very serious kitchen tool. As a rule, it is purchased for a long period of time, therefore the quality of the product should be as high as possible (Figure 3).

Some believe that the best hatchets are provided by Japanese manufacturers, but recently domestic brands have also been producing strong, reliable and durable models with comfortable handles and sharp blades.

When choosing a hatchet for the kitchen, you need to pay attention to the requirements for such a tool. Firstly, its blade must be made of high quality steel. The ease of use and a number of other factors will depend on this, in particular, notches will form on a high-quality blade less often, which means that such an ax will have to be sharpened much less often.

Figure 3. Main characteristics of the tool

Secondly, the handle of the hatchet should have an ergonomic shape and not be slippery. The ease of use of the tool will directly depend on this. In addition, pay attention to the overall weight of the product: the heavier the hatchet, the faster you will get tired while working. Also pay attention to the location of the center of gravity: it should be clearly between the butt and the handle. In this case, you can cut even the thickest bones in just one blow.

How to sharpen an ax using an electric sharpener

An electric sharpener is a machine with an electric drive. Its main working body is the abrasive wheel. The surface used is the generatrix of a cylinder, which eliminates lateral movement of the tool being sharpened.

In addition to the sharpening machine itself, you will also need:

- double-sided hand sharpener;

- polishing paste;

- marker;

- protective equipment: glasses, gloves, thick overalls and shoes;

- goniometer device

Before you start sharpening, you should put on glasses and gloves. Next perform the following operations:

- Paint over the existing chamfer with a marker.

- Secure the ax in the machine's mounting fixture.

- Bring the tip to the grinding wheel.

- Set the sharpening angle using a protractor and an adjusting nut.

- Turn the grinding wheel by hand.

- Check the bevel - if the angle is set correctly, the ink will be completely erased at the point of contact with the stone.

- Adjust the angle as necessary.

- Only now should you TURN ON the sharpener.

- Sharpen the chamfer until all nicks and nicks are leveled.

- Level the working surface of the abrasive with a hand sharpener.

- Bring the sharpening to perfect condition.

- Remove the tool from its mounts, lubricate a leather or felt wheel with polishing paste and polish the bevels of the tip.

- Apply anti-corrosion fluid.

Sharpening an ax with an electric sharpener

During operation, be sure to periodically moisten the surface of the abrasive with water or oil. The blade also needs to be wetted regularly. This will help avoid overheating of the metal and unwanted changes in its structure, leading to a decrease in strength and other performance qualities.

If you need to change the sharpening bevel, you should skip the operations with a marker and manually turning the disk and immediately set the angle using the protractor.

An electric sharpening machine allows even the least experienced sharpener to achieve ideal angles and bevel widths. However, high-quality equipment is not so cheap. It will give an economic effect when there is a large number of sharpened tools and the frequent need for sharpening them.

Tips for use and care

In order for a tool to serve for many years, it needs to be properly cared for and stored properly. Recommendations to follow:

It is better to store axes for chopping meat in a separate box, away from all other tools. If it is convenient for the housewife to keep the product at hand, on an open kitchen surface, ideally she will need a special stand for this.

You can store the ax in a case made of thick leather, or in a suspended state if there is a recess or hook on the handle - this will save space in the kitchen and extend the life of the product. It is important to remember that the worst enemy of metal and wood is a damp environment. A prerequisite for storing the instrument is a dry and warm room. The hatchet will serve for a long time if you use it exclusively for its intended purpose, and immediately after use, rinse it well with a special product and wipe it dry with a towel.

For cleaning, it is permissible to use a dishwasher. Work should be done on a cutting board. You can use a wooden or plastic variation; glass models quickly dull the hatchet. The blade of a meat cleaver stays sharp for a long time, but sooner or later it will still need to be sharpened. For this purpose, it is better to contact professionals who specialize in servicing such products. Be sure to periodically wipe the metal parts of the product with kerosene, and lubricate the blade itself with vegetable oil to protect the material from premature destruction. When using an ax, you must ensure that the blow is completed in one approach, otherwise there is a risk of crushing the bones into small pieces. This will negatively affect the quality of the cut meat and its subsequent preparation. If the handle is made of wood, you can purchase special protection for it in the form of a spray. Treatment is required if the product is to be stored for long-term storage.

The most important thing is not to forget about safety precautions when working with a tool; you should not use an ax whose structural integrity is in doubt.

You need to chop with an ax on a cutting board

Be sure to sharpen on time

If the handle is made of wood, it must be treated with a special spray

Homemade hatchet knife using simple tools

Greetings to those who like to work with metal, in this instruction we will look at how to make a hatchet knife with your own hands. With this device you can chop branches, sharpen sticks, cut and more. This knife is also useful for culinary purposes. The knife is made of high-quality steel and is hardened, so it keeps its edge for a long time and does not become dull when cutting fairly hard materials. But here everything will depend on the correctness of the hardening.

Making such a knife is not at all difficult, as it might seem at first glance. The author makes it using available tools, and everything turns out quite well. The blade is cut using a grinder, with the help of which the bevels are formed and the main grinding takes place. As for hardening, if you don’t have a furnace, that’s also not a problem; you can handle the task with a gas burner. When making the knife, the author damaged the handle, so part of it was made from cold welding. But with a skillful approach, you can make the overlays entirely from wood, as was originally planned. So, let's take a closer look at how to make such a knife!

Materials and tools used by the author:

— high-quality high-carbon steel (tool steel or from a car spring will do);

- a wooden board for making overlays;

- copper tubes, brass rods (or other parts for making pins);

- epoxy glue for the handle (the author did not use it);

- cold welding (used to finish the handle).

— welding machine (optional);

— grinder with cutting and grinding discs;

— gas burner, refractory brick and oil for hardening;

- varnish, oil, paint or other for the handle;

The process of making a knife-axe:

Step one. Preparation of material

Sharpening angle

You also need to choose the optimal sharpening angle. For a construction ax it is 25-30°; carpentry tools are sharpened at 35°. The cleavers are sharpened at 40°. In this matter, the main importance is not so much the angle itself as the shape of the cutting edge. There are three types:

Figure 3 – Ax sharpening angle

- Straight. The chamfer is flat, uniform along the entire length of the blade.

- Convex. The chamfers stick out slightly.

- Concave. The chamfers are sunken, similar to a straight razor blade.

Straight chamfer is a universal option, suitable for any type of work. A convex chamfer is made when working with material of heterogeneous density, which greatly consumes the tool blade. A concave chamfer allows you to hold an edge for a long time, but is only suitable for more delicate, precise and neat work.

Standard errors

There are several common mistakes when sharpening:

- Overheating of the material when working on an electric grinder. This leads to a change in the internal structure of the steel and, as a consequence, to a loss of strength and elasticity. At the same time, the wear resistance, sharpness and other performance qualities of the tool are significantly reduced. To avoid overheating, you need to periodically moisten the abrasive with water or other coolant.

- An attempt to sharpen an ax on a grinder. When holding the grinder in your hand, beating cannot be avoided, and the blade will constantly move to the side. In such conditions it is impossible to talk about observing any angles. Here it would be nice to just hold in your hands a dangerous tool that is flying to the sides. Attaching an angle grinder to the machine will improve the process, but not much. The problem of lateral slip will not go away.

- The desire to sharpen a blade on old equipment with a worn-out sharpening wheel. Axial runout and unevenness of the abrasive surface will not allow you to sharpen the ax efficiently, in compliance with the required angles and width of the chamfers.

It is better to spend more time sharpening the tool by hand than to use low-quality or unsuitable equipment.

Making an ax with your own hands

If you are interested in the question of how to make an ax, then remember that you will not be able to make a blade from scratch yourself. You can only give a regular blade the desired shape by processing it with a grinder or an emery wheel.

But it’s quite possible to make an ax handle. To do this you need:

- select a workpiece with a diameter of more than 120 mm and a length 200 mm longer than the planned handle;

- dry for several months at a temperature of 22-24 degrees and a humidity of 15%;

- using an ax or large knife, remove excess wood in accordance with the outlined contour;

- carry out processing with a chisel and hammer.

Now it is important to learn how to mount an ax correctly. This is done using gauze and epoxy resin.

The presence of a wedge provides better strength. After this, grinding is done, and the ax handle is varnished. Sharpening is done on a machine or manually.

An ax is a useful assistant both in the country and on a hike and when working in the forest. You just need to choose the right model, focusing on the required characteristics and workmanship of a particular instance.

The process of sharpening an ax

Sharpening an ax properly requires attention and concentration. You will need:

You will need:

- a set of abrasive stones with different grains;

- a piece of rough cloth;

- measuring stick or protractor;

- water;

- The belt is usually made of genuine leather.

First you need to measure the current sharpening angle. This is done by applying a measuring block. The block is made with a bevel equal to the angle at which you decide to sharpen the tool.

to sharpen an ax, place it on a flat base (table, stool) and begin to draw a block along the blade, describing half rings. The block should be held at a sharpening angle. Coarse abrasive is used to restore the required slope and width of the chamfer. The operation is repeated on the other side of the blade.

Next, you should take a block with a medium grain and sharpen it on both sides. And finally, it’s the turn of the third, smoothest sharpener - it is used to remove burrs and the smallest irregularities. The surface of the chamfer should be smooth to the touch.

The testamentary operation is editing on a tense leather belt.

During work, the ax and abrasive bars must be moistened with water. Dust and small metal particles are removed with a piece of cloth.

During initial sharpening and in cases where the ax has become very dull, experts recommend removing it from the ax handle. And the tilt will be easier to maintain, and the handle will not get in the way.

Professionals use special sharpening devices - electric sharpening machines. There are adjustable stops for the sharpened tool, allowing you to sharpen it at a given angle.

Sharpening an ax for chopping meat

Even if the chopping ax was sharpened by the manufacturer flawlessly, there comes a time when it is necessary to restore this parameter of the tool.

You can carry out sharpening work at home using different tools:

- a sharpening stone is the most affordable and simple, it should have a rounded shape and a bend, which will allow you to accurately maintain the sharpening angle;

- band-type file – simplifies the sharpening task many times over, involves manual work with a minimum of physical effort;

- a grinding machine, a grinding wheel are power tools that can only be operated if you have at least minimal experience.

Some people use a grinder to restore the sharpness of an ax blade, but this method has many disadvantages - sparks fly in all directions, the sharpening angle is not maintained, and the metal overheats. All this significantly reduces the quality of the blade and leads to the need to replace the kitchen tool soon.

How to sharpen a butcher's ax correctly

The technology for carrying out sharpening work is identical for all types of cutting/chopping tools. Safety will be maintained only if a person strictly follows certain rules:

- You need to properly organize your workspace. Place the sharpening tool on a horizontal surface, make sure it is firmly fastened so that it does not get torn out of place during the sharpening process.

- The abrasive wheel should be checked for quality before use. There should be no cracks, nicks or gouges on its surface.

- Be sure to use safety glasses. The fact is that meat hatchets are made of high-quality steel and during the sharpening process sparks and abrasive surface particles fly - injury cannot be avoided without protection.

- The blade is held “away from you” towards the rotation of the circle, the blade is held parallel to the axis of the sharpening tool. You need to hold the hatchet with both hands, which will help maintain the correct sharpening angle.

It is important to remember that you should not allow the blade to overheat, because this will cause the metal to deteriorate and become brittle. If a burr has formed on the surface of the blade, then you need to turn it over and start processing the other side

Chamfer width

Chamfer is the width of the plane between two planes of the blade; the parameter can be one/two/three-sided. For kitchen axes, manufacturers maintain the dihedral width of the chamfers and do not change it during self-sharpening. The optimal chamfer width is 18-20 mm.

It is possible to change the width of the chamfer on one side of the blade, which makes it possible, if necessary, to change the sharpening angle.

Sharpening angle

This parameter varies within 25-30 degrees; to comply, you can cut out a template and navigate according to it. The sharpening angle directly affects the cutting/chopping characteristics of the product: the smaller this parameter, the sharper the blade will be.

Electric sharpening tool

You can use a special tool - an electric sharpener. It is distinguished by its impressive dimensions and considerable cost, but such a device allows you to work on restoring the sharpness of the cutting edge not only of a meat ax, but also of all other types of knives.

More often, a sharpening machine with an abrasive wheel is used to sharpen a butcher ax. It makes it possible to perform work at a professional level, but requires experience in operating machines.

Sharpening an ax on a grindstone: 1 - stop; 2 - ax; 3 — grinding wheel; 4 - protective casing.

The disadvantage of using a machine with an abrasive wheel is the rapid heating of the blade metal, and this deteriorates the quality of the kitchen tool and reduces its performance.

Hand tool

Its advantages are its low cost, small size - it can be stored in the kitchen, and no experience of use is required. But there is also a drawback to a manual sharpening tool - the work to restore the sharpness of the cutting edge will be lengthy, especially in the case of a large/wide blade.

Effective hand tools for sharpening a butcher ax are:

- musat - it is used to edit rather than sharpen a blade; it can also restore the sharpness of an ax in just a few movements or quickly remove a burr on the blade;

- block/stone – you will need several types with different abrasive surfaces;

- special sets - can be used by absolute beginners, do not require independent setting of the sharpening angle.

Proper sharpening at home

Figure 5 – Proper sharpening at home

The sharpening technique largely depends on the type of abrasive used to chamfer and form the cutting edge.

Working techniques on different tools differ radically from each other, depending on the method of removing the metal layer.

The choice of the optimal option is usually determined by the following factors:

- Availability of one or another tool.

- Possession of skills and experience in sharpening using this method.

Each method of sharpening has its admirers who give strong arguments in favor of one method or another, however, it is impossible to name the ideal option. All technologies demonstrate their own pros and cons, so you should consider them more carefully:

On the grinding machine

Figure 4 – Sharpening an ax on a grinding machine

Sharpening an ax on a sharpener is much easier than by hand.

The ax is held with the cutting edge facing the rotation, the central plane running tangent to the rotating abrasive wheel.

With even a little skill, it is not difficult to form an even chamfer and grind off a neat and uniform working edge.

However, there are also negative aspects of working on an electric grinder.

A major issue is continuity of exposure. Friction causes the metal to become very hot, which creates the threat of overheating and changes in the crystal lattice of the material. It is necessary to keep a container of cold water on hand, into which you must constantly dip the ax to cool. This distracts from the sharpening process, but helps prevent overheating.

While working, you must constantly check the template, check the angle and other chamfer parameters. Most often, they first do preliminary sharpening on both sides, after which they bring one of them until a continuous burr appears along the entire length of the blade, turn the ax over and sharpen the second chamfer until the burr breaks off. The edge is then finished by hand using an abrasive stone.

Special devices have been developed to hold the ax in a stationary state and help to obtain a uniform, even chamfer with a constant angle. However, they can only be used for axes with a straight cutting edge, so they often work while holding the tool in their hands.

On sandpaper or with a block by hand

This method takes a lot of time and requires skill. However, experienced craftsmen claim that this is the only way to get a non-overheated and even working edge and sharpen it correctly. A block or waterproof sandpaper is used as an abrasive. The surface is moistened with water, the ax is applied at the desired angle and in a circular motion, with medium pressure, sharpened until the expected result is obtained. The process is lengthy and labor-intensive, as well as tedious. But the main danger of overheating the blade is absent, and there is also no threat of awkward movements to ruin the edge or change the sharpening angle.

Often the work is speeded up with the help of a file. Pre-grind the blade with coarse sandpaper to remove burrs and other large irregularities. Then the ax is fixed in a comfortable position, a bastard file is taken and an edge is formed on both sides. During this, you need to periodically check the form using the template. When the edge is finally formed, the ax is brought to the desired state on an abrasive wheel (bar) by hand.

Bulgarian

It is not recommended to use a grinder to sharpen an ax. The rotation speed of the disk is too high, which creates the danger of instant overheating of the ax, the appearance of depressions and irregularities on the working edge. If the angle grinder is secured and used as an electric sharpener, there is a serious risk of injury with an unpredictable outcome. Occasionally, an angle grinder (angle grinder) is used for sharpening, but this option cannot be called optimal due to the danger of overheating and the impossibility of fully monitoring the condition of the edge and maintaining the desired angle of inclination.

Ax for chopping meat

Somehow my relatives drew my attention to the fact that the ax for chopping meat and bones was completely falling apart. Studying the instrument led to the disappointing conclusion that it was beyond repair—it had burst. A new ax was needed.

The toad crushed me to go to the store and buy something. But, on the street, under my workbench, there was an old ax without an axe. At one time he ended up under a workbench after dismantling a shed. The ax was still made in the Soviet Union, obviously forged. Condition: very rusty