Vadim

8318 0 1

Vadim December 9, 2017

Roofing asbestos-cement slate is perhaps the most popular material in the CIS. However, for many young roofers, cutting sheets accurately and quickly remains a challenge to this day. A slate sheet is strong, but fragile, and both the tool and the technology are important for proper cutting. Therefore, next we will talk about 3 cutting methods and try to sort out rumors about the harmfulness of the material.

In roofing work, cutting sheets is indispensable.

Features and properties of slate

Slate is a rather fragile material, so it must be cut carefully.

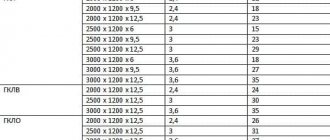

Depending on the number of waves on the surface, there are 5-, 6-, 7- and 8-wave products. They differ in profile thickness, ridge parameters, length, width, weight, color, physical and chemical characteristics.

Flat and corrugated sheets are produced using the same technology; the composition includes Portland cement, asbestos fibers, and water. Properties depend on the volume of cement and the amount of chrysolite asbestos.

Material characteristics:

- slate is produced in thicknesses from 5.2 to 8 mm, width 980 – 1130 mm, length 2000 – 2800 mm;

- Pigments are added to the raw material mass, so products of different colors are obtained; surface coloring additionally increases moisture resistance and improves strength properties;

- the slate layer can withstand a weight of up to 200 kg per square surface, so people can walk on the roof during installation and repair;

- density at the level of 1.6 - 1.7 g/cm³, as the indicator increases, the strength and weight of the products increases;

- frost resistance at the level of 25 cycles of grades 54/200 (wave height 54 mm, pitch 200 mm) and 40/150 (wave height 40 mm, pitch 150 mm) with a thickness of 6 mm;

- material with a thickness of 7.5 mm of the specified parameters can withstand up to 50 cycles of freezing and thawing without destruction or deformation.

Slate is durable, its use is designed for 25 - 40 years of operation. The material does not conduct heat and soundproofs the room.

The disadvantages are the large mass of the panels, so the truss structure needs to be strengthened. But under slate you can use a sparse lathing system, which saves wood. Moss may grow on the surface of the coating, which must be cleaned periodically.

Basic Rules

Despite the emergence of new materials for creating roofs, slate continues to be actively used in construction. When installing it, it becomes necessary to trim individual elements. This operation is specific: the gray roofing material contains asbestos fibers. They are carcinogenic. Inhaling asbestos dust can cause lung cancer. Therefore, you need to cut sheets very carefully, observing safety rules. They are extremely simple:

- Before work, you need to put on thick clothing that completely covers the body, gloves, safety glasses and a respirator. Cutting is always accompanied by a lot of noise; if you refuse to use earphones, you can become deaf for some time.

- It is important to thoroughly wet the surface of the roofing material before starting, then less dust will form. Experienced roofers, when talking about how to cut slate, advise watering it right while cutting. This is the most effective way to protect yourself as much as possible from inhaling the strongest carcinogen.

Slate must be moistened with water when cutting Source maja-dacha.ru

- The operation must be performed outdoors, preferably in a well-ventilated place. If you position yourself on it so that the wind immediately blows away the dust, which contains asbestos particles, you will be able to protect not only yourself, but also passers-by.

Sometimes it becomes necessary to cut slate indoors.

In this case, you must first remove all workers from the room and leave only the operator in overalls. Before cutting, he must tightly close the windows and doors, cover them with old rags, and after cutting, collect the resulting dust with an industrial vacuum cleaner. The same technologies are used for cutting flat and wavy slate. But there are some nuances in the process of its implementation.

Cutting flat slate Source stroychik.ru

See also: Catalog of companies that specialize in roofing materials.

The need to cut roofing slate

The dimensions of roof slopes vary, so when installing piece roofing elements, they need to be cut to the required size. Slate can be cut using different methods; the choice of tools depends on the physical properties of a particular sheet model.

Properties of slate regarding cutting:

- asbestos or mineral fibers in the composition are easy to cut even with a knife, they are pliable;

- The hardened binder cement gives the material strength comparable to that of dense oak and teak wood.

Slate slabs are cut along the grain if they do not fit across the width of the eaves overhang. You can also saw slate along longitudinal lines if the distance from the ridge to the overhang is not a multiple of the length of the sheet.

↑ Cutting with power tools

You can cut slate with the following power tools: a manual angle grinder (grinder), a jigsaw, and a drill.

Procedure for working with an angle grinder:

- Mark the cutting line. For wave slate, the line is first drawn along the ridges, then the cut location in the depressions is manually marked. If there is a small strip of evenly cut slate, then straight lines perpendicular to the direction of the wave can be drawn using it.

- Install a diamond cutting disc for stone or concrete.

- If there is an appropriate adjustment, set the speed to low.

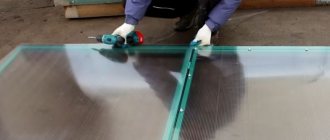

- First moisten the entire cutting line with a sponge or rag.

- They start the machine. If there is an option such as “soft start”, use it.

- Cut the sheet exactly along the line, trying to make the cut in one pass. It is advisable to work together, so that your partner constantly waters the cutting area.

It’s even easier to cut flat sheets, since a cutting wheel of any diameter can cut right through slate in one pass.

If you have a small grinder at hand, and the diameter of the disk does not allow you to cut through the wavy sheet at one time, then it is cut in two steps:

- Mark a line and cut the slate on one side.

- Carefully, the two of you turn the sheet over and place it on the same base.

- Focusing on the cuts in the concave part, mark the line of the counter cut.

- Wet the cutting line on this side.

- The sheet is finally divided into two parts.

After this, the edge of the cut is polished with the same diamond wheel to remove small irregularities that are likely to form at the convergence of two cuts.

If the cut is complex and it is impossible to make it with a disk in one go, additionally mark the adjacent line, marking the top of the corner with a core and drilling a hole in this place. To drill a hole, use a drill with a Pobedit tip. The second line is cut like the first, starting from the edge of the sheet towards the corner.

Note. Wet sawdust is removed from the surface of the disk immediately. If they harden, the cutting wheel will become unusable.

An electric jigsaw will not be able to provide the same efficiency as an angle grinder. It is better to use it for small tasks and for cutting out pieces of complex shapes - with a jigsaw, arcs and curves are obtained well, rather than straight lines.

For cutting, metal blades with fine teeth are used, and the operating mode is in low gear. When cutting, it is important not to apply large vertical forces, otherwise the runners will push through the slate, and the blade will crumble the edges in the working area.

An electric drill equipped with a drill with a pobedit tip is used as follows:

- The sheet is placed on a hard and flat surface.

- Mark the dividing line.

- Drilling points are drawn on the line so that the holes are located as close to each other as possible (taking into account the diameter of the drill).

- Drill through holes, making sure that the cartridge does not hit the sheet.

- A small cross-section block is inserted under the sheet, along the edge of the line of holes. Its length should be longer, and the ends should protrude beyond the edges of the slate. Then, with a sharp and short movement, the sheet is broken.

Another way to separate two parts without lifting the sheet onto the beam:

- Insert slate nails into the holes and lightly hammer them in.

- Gently break apart by lifting one piece and holding the other.

Important! Do not use an impact drill or hammer drill for this work - such sudden impacts will lead to cracking of the slate around the holes.

Basic cutting rules and dust-free work methods

You need to cut slate outdoors, using personal protective equipment, since the material emits asbestos dust.

Regardless of the choice of method for cutting panels, you must follow the recommendations for the use of tools. This is especially true for electrical types, since this produces a lot of dust. Slate based on asbestos fibers is harmful to health, because the smallest particles have a bad effect on the respiratory system.

In most cases, such fibers are fastened with cement grains, which securely hold the threads and prevent harmful emissions from spreading. There is little harmful effect from the coating on the roof, since the material is in a restrained state. To enhance safety, it is recommended to paint the slate profile. But if the integrity of the fabric is damaged (cutting), fiber particles are released into the air and have a harmful effect on health when inhaled.

Conditions that need to be created to cut slate:

- the work is carried out outdoors, because dusting in a closed hangar or shed is not permissible;

- it is advisable to position the workplace so that the wind carries the dust stream away from the master and nearby rooms;

- wet material emits much less dust, so the cut area must be moistened with water, using rags, brushes, and watering cans.

The raw profile generates less dust during processing, and cutting slate moistened with water is much easier. Wet sheets gain additional elasticity and soften.

The panels are positioned so that the two parts that will be obtained after cutting have reliable support. Otherwise, when one half with a sharp edge separates, it may injure the operator.

How to cut slate without any dust

If wave slate is quite difficult to cut due to its shape, then flat slate is so simple that it is easier to break. Why is this so? The fact is that when cutting slate, a lot of dust is released, which is harmful not only to the tool, as we just said, but also to your health. Therefore, those who take care of both find many ways to do without cutting at all. Moreover, precisely because of the large amount of dust, it is not recommended to cut slate indoors - all that remains is to break it.

Slate really breaks easily - all thanks to its fibrous structure. It is only important to do it smoothly without damaging the corners. And there are three ways to do this:

Method number 1. Breaking thin slate

So, the easiest way is to mark the desired cut line, draw it with something sharp, place a block and carefully break the slate:

- Mark the location of the future fracture with a pencil.

- Place the lath on the cutting line.

- Place the slate on the table and press evenly over the area of the part to be broken off.

Or they simply cut a 1 mm hole - flat slate will easily break in this place.

Method number 2. Breaking slate with a nail

- Mark the cut with a simple pencil.

- Use a sharp nail to mark this line.

- Drive this nail into the line every 2 cm. The more holes you make, the easier it will be for you to break the sheet later.

- By pressing on the piece of slate, easily break it along the punctured line.

Method number 3. Sawing thick slate

- Lay the slate on a level table so that most of the material is on the tabletop. Let an assistant hold the hanging part of the slate.

- Take your saw and start cutting the sheet just like you would a thin piece of wood or plywood.

A hacksaw for foam concrete is also suitable for cutting slate.

Method number 4. Cutting slate with a cutter

If you have to cut flat slate right indoors, forget about power tools, there is too much dust and noise. Take a good steel cutter and follow these instructions:

- Step 1: Lay the slate sheet flat.

- Step 2. Attach a ruler and draw a line under it with a cutter.

- Step 3. Remove the ruler and begin to press harder on the cutter, deepening and widening the line.

- Step 4. Now place a strip or pipe under the sheet parallel to the cut line and press down. Moreover, there is no need to press hard - otherwise the slate will simply crack.

- Step 5: If any piece does not come off, tap the cut line with the side of a hammer.

If there is no other equipment at hand, most often flat slate is sawed with a fine-toothed hacksaw. True, it will have to be sharpened from time to time.

Electrical tools

To make slate less dusty, you need to moisten the cutting area with water.

Use a cutting saw with a disk for cutting stone. Preparation includes marking a line on a slate sheet and wetting the cutting area. When working, you should not allow a deviation from the intended line, drawing exactly along it.

It will not be possible to cut off a part at once, so after wetting, an additional line is drawn, simultaneously deepening it with a core. This way the disc wheel will not stray from the mark track. If using a circular saw, you need to make several approaches.

Use an electric drill with a drill bit that has a pobedite tip.

Work order:

- the sheet is laid flat on a leveled surface, a dividing line is marked on it across the waves or along them;

- holes are drilled on the marked line, as close to one another as possible, drilled until the end of the sheet, while trying not to move away from the line;

- take a hammer and tap along the line of holes every 6 - 10 centimeters;

- lift one half of the panel and carefully separate it from the second side of the sheet.

Some roofers additionally cut a line along the holes using a sharp ax blade. This procedure is not necessary, since the slab will split in the direction of the drilled holes. Do not use a drill with an impact effect (perforator) for work - such sudden forces will lead to the appearance of an oblique crack not along the intended line.

Cutting asbestos cement sheets with a grinder or jigsaw

A stone wheel or diamond disc is placed on an angle grinder to cut slate.

In the first case, a continuous supply of a water jet is organized at the point where the circle touches the slate surface in order to cool the working edge of the disc and prevent dust. For convenience, the work is performed with an assistant who uses a hose or a plastic bottle with holes in the lid. When working alone, the hose is fixed in a comfortable position.

Operating procedure:

- The sheet is laid on the floor; if you need to cut off a narrow edge, then a wooden block or board is placed under it.

- Make the first cut along the intended line on the protrusion of the wave from the beginning to the end of the panel.

- The plate is turned over, the cut location is in the concave area of the sheet.

- Cut along the line, if everything is correct, the profile will be divided into two parts;

- Dust on the side surface of the disc is removed immediately with a wet cloth; if it hardens, the circle will have to be thrown away.

If you use a diamond blade on a grinder, you can cut the sheet in two directions and it is not necessary to turn the panel over. In winter, it is recommended to lay asbestos cement slabs directly on the snow - this way the released dust will mostly be absorbed into it. A diamond wheel is used to grind the edges of the material in a cutting pestle to increase resistance to negative factors. The disk is used to trim the corners of the profile if the sheet does not move halfway during installation.

You can cut flat slate and corrugated sheets with an electric jigsaw. To do this, insert a file with fine teeth into the tool and set the operating mode to a lower gear. When cutting, do not press on the slate with the jigsaw runners, so as not to crumble the material. Use a jigsaw for small jobs.

How to cut slate using power tools

In addition to the grinder, a cutting machine equipped with a disk for cutting stones can be used to cut slate. The preparatory procedure here is the same as in the case of an angle grinder: the sheet is first marked and then moistened. When working with a cutting machine, it is important not to allow any shifts, moving the disk exactly along the markings. It is usually not possible to cut slate in one go, so after wetting the cut with water, the procedure is repeated again, due to which the cut deepens. As a rule, to comfortably break the slate, 3-4 such approaches will be required.

To cut wet slate, you can use a regular jigsaw, equipped with blades with fine teeth. The spindle is set to low gear mode. When using this tool, it is important to be extremely careful, avoiding any pressure on the slate, otherwise it will crumble. The use of a jigsaw is justified only in the case of small volumes of such work.

Mechanical tools

You can use a hacksaw for metal.

Hand tools are used for small cutting volumes. If the work takes place in closed garages and other rooms, you can cut corrugated slate using improvised means.

Take a metal hacksaw, which has fine teeth, and it is possible to replace the blade. Spare parts will quickly become dull on hard cement, so they are stocked in advance. A hand saw is used if you have the skill of cutting without pressure and distortion, so that cracks do not appear on the slate. Hacksaw blades are made from high-alloy metals to withstand the physical stress of processing hard material.

The parameters that matter are:

- Saw tooth size. For metal paintings, the size does not exceed a millimeter; such elements are more durable.

- Sharpening angle. It is important that the lower flat parts of the teeth are sharpened, since steel is sawn on these surfaces.

A sharp knife or hand cutter is also used. Before using them, the markings are deepened exactly along the intended line; for this, a solid core is taken. After this, a cutter is used. It is important not to tilt your hand and make the cut exactly along the mark.

Break off a piece of the sheet after the knife has penetrated 2/3 of the sheet thickness into the material. For the procedure, a flat wooden block is placed under the panel at the incision site. Press the edges of the sheet with your hands, and it should separate along the line. Choose a sharp knife or cutter without burrs on the edge of the working blade.

If there are no suitable cutting blades or knives, you can use the old method of dividing slate along a line using roofing nails and a hammer. These nails differ from ordinary hardware with a soft, movable head to reduce the sharpness of the impact.

Operating procedure:

- A fault line is marked on the sheet.

- Holes are punched through it as often as possible and as close to each other as possible, from start to finish along the entire length of the cut.

- If the line runs along the wave, the panel is turned over so that the line is in the lower part (the depression).

- A wooden longitudinal lumber or any pipe is placed under the seam, pressure is applied to both edges of the sheet (preferably with an assistant), the two parts are separated along the cut line.

Despite the outdated technology, this method has an advantage over using an electric tool. When the sheet is broken and pierced with nails, little asbestos dust is released, which is important for the environmental cleanliness of the workplace.

The evenness of the cut depends on the number of holes and the accuracy of the craftsman. To help separate the two pieces of sheet, you can tap the row of holes with a hammer.

Cutting slate with a grinder with a stone disc

Using an angle grinder and cutting machine (grinder) equipped with a stone disc, you can cut a sheet of corrugated slate without much effort. The work technology requires the use of water, which should be supplied in a thin stream to the cutting site - this will simultaneously cool the working part of the tool and prevent the appearance of harmful asbestos dust

.

Be sure to read: Standard slate sizes and their cost

To supply water, you need an assistant who will hold the hose or water the cut with water from an ordinary plastic bottle. In this case, the dust will not fly away, but will flow along with the water to the ground. If you don’t have an assistant, you can use improvised means to secure a hose with water so that it flows onto the cut.

An angle machine (hereinafter referred to as OGShM) with a stone disc is convenient for cutting sheets of roofing material along the wave. You should first mark the place of the cut, place the sheet on a flat piece of ground so that the cut falls on the lower wave, or on wide boards so that the place of the cut is not far from the edge of one of them.

If you have to cut a sheet across a wave, the operation is carried out in two steps: at the first stage, convex ridges are cut along the intended line, at the second stage, the sheet is turned over, and the convex ridges that previously remained below are cut again. Using this method, the slate is cut through and breaks into two parts.

Upon completion of work, immediately clean and wipe the tool dry, paying special attention to its working part. Asbestos cement particles, stuck and hardened, are very difficult to remove later.

Features of cutting flat sheets

It is better to cut flat asbestos-cement slabs with an angle grinder, setting a stone circle on it.

Work schedule:

- By analogy with a wavy profile, flat panels are placed on a flat surface, the ground or floor.

- Place a board under the cut edge.

- The cut area is spilled with water.

- Cut in several passes, each time cutting through ¼ of the sheet thickness.

You can take a diamond disc. In any case, you need to work carefully, without unnecessary pressure and distortions of the blade away from the line.

Cutting flat slate at home

To separate flat slate sheets, any method of cutting corrugated slate can be used. However, it is most convenient to cut smooth slate with a grinder with a stone disc. To carry out the procedure, a flat surface is selected on which the material is laid - it can be a simple wooden flooring, or a dense soil area. The main thing is that the lower base is not expensive, since it will certainly be damaged during cutting. When cutting near the edge of the slate, it is advisable to place a wooden strip of the required length under it. Before cutting flat slate at home, you need to organize a water supply to the work site to reduce the amount of asbestos dust

Regardless of which disc you use to cut the slate, it is important to avoid haste and be as careful as possible. Any careless movement can lead to splitting of sheets, which, as we know, cannot be glued together. If such work is being carried out for the first time, you should definitely read the recommendations on how to saw off slate. If possible, it is better to first practice on an unnecessary old piece of material.

Safety precautions and recommendations

When cutting, be sure to wear respiratory protection to protect yourself from inhaling harmful asbestos particles. The effectiveness of gauze and paper masks is low, so it is better to use respirators in which the filter elements can be changed.

Brittle material produces a lot of small fragments that fly apart and upward under pressure, especially when working with power tools. To protect your eyes, wear safety glasses. Gloves and special clothing are used to protect hands and body.

How to organize slate cutting

Slate is characterized by sufficient fragility, which is why very small asbestos fibers and particles are formed when breaking or sawing sheets. Asbestos is known to be a harmful substance that causes cancer. To ensure that cutting the material is not accompanied by its destruction, with the appearance of asbestos dust, you need to know what slate is cut with and use protective equipment.

Requirements when cutting slate sheets:

- Mandatory use of personal protective equipment. For the respiratory system this is a respirator, for the eyes - special glasses, for the skin - gloves and thick clothing. In addition, when working with an electric cutting tool, a lot of noise is generated: noise-cancelling headphones will help.

- To reduce the amount of dust generated by an order of magnitude and make the slate less fragile, the cut area is wetted with water before cutting. To do this, you can use wet rags or directly water the cutting line while working.

- When working outdoors, it is important to find a location where the resulting asbestos dust is blown away from the operator by the wind.

- If the procedure is performed indoors, there should be no one in it except workers. All doors must be tightly closed, taking measures to further seal them.

General advice on work

In order to ensure an even cut, avoid breaking the slate and not harm your health, you should follow a few simple recommendations.

Be sure to protect your respiratory system.

- This rule applies to cutting asbestos-cement roofing materials. Both asbestos and cement have a very negative effect on the human body; all measures must be taken to minimize the harm. Choose a respirator especially carefully; experienced builders strongly do not recommend using simple paper or gauze masks, their effectiveness is very low. Especially in cases where the worker has to constantly move. Reliable respiratory protection can only be provided by a professional respirator with replaceable filters.

To work with large amounts of slate, you should choose a high-quality dust respirator with replaceable filters

Safety glasses are a must when cutting slate sheets.

Overalls and gloves will also come in handy when cutting slate.

Practical advice. To reduce the amount of dust when cutting asbestos-cement slate, the cut area should be constantly moistened.

If work is carried out in an open space, then you should always stand on the leeward side. There is no need to cut slate in the rooms - all surfaces will be covered with dust, removing it is difficult and time-consuming.

What is a grinder disc for concrete?

It is very convenient to cut ceramics, concrete, and brick with a grinder or a manual grinding machine. You just need to use a special disc for concrete, because corundum and carbide abrasives used when cutting steel or soft stone are not suitable.

To cut a concrete product, discs of a special design and a different composition are needed. The cutting element in them is diamond chips, obtained artificially from carbon minerals. The cost of these tools is much higher than abrasive wheels for cutting metals.

The basis of the disc is strong, hardened steel, which can withstand the highest temperature loads. Its cutting part is the outer edge containing a layer of diamond crumble. Such layers contain very small technical diamonds distributed throughout the volume.

When cutting, the outer layers are actuated, but the abrasive composition is actuated even more slowly than the mass being cut. After the first layer is triggered, the next one is cut into the work, so an expensive cutting tool allows you to do work that is significantly larger in volume compared to ordinary ones.

Cutting with a saw: selecting the coating and teeth

A saw with a special Teflon coating cuts slate perfectly, which, on the one hand, protects the saw blade, and on the other, significantly reduces friction with the material. And less friction means less dust and easier work. This type of saw is not much more expensive than an ordinary one.

Secondly, you should pay attention to the saw teeth: the larger they are, the faster the slate will be sawed. And it’s definitely faster than a regular hacksaw.

READ How to cut plywood smoothly with a jigsaw

Three cutting methods

Asbestos-based roofing sheets have been used for more than half a century. At the moment there is wave and flat slate. Specifically in the roofing industry, the wave option is more popular.

But flat sheets have a much wider scope of application; in addition to roofs, they cover walls, make fences from them, and even use them as borders for garden beds. But wherever this material is installed, cutting is required.

Arranging beds with straight or wave slate is a fairly common practice.

Method No. 1: disk power tool

Various types of disk power tools are now used in the vast majority of cases, because cutting is easier with them and is disproportionately easier in terms of labor costs. The big plus is that the tool can be different, but the cutting technology is almost the same everywhere, so we will start with the technology.

Most often, sheets are cut using a grinder; the tool is accessible and relatively inexpensive. In addition, a grinder can be used to cut both flat and corrugated sheets. The step-by-step instructions look something like this:

There are 2 options here - you can cut with a diamond disc or a simple cutting disc. Both options work, but the diamond blade lasts longer and I recommend it.

You can work on the ground or on a table, but it is inconvenient because you will have to turn the sheet over a couple of times. It’s easier to knock down a small frame from boards and cut on it.

Here the process is standard, you just need to measure and draw a line with a tape measure.

Disc tools are also good because the cutting lines can go both along and across the wave.

You can unravel the sheet with one wire, but there is a risk that it will burst.

Therefore, first we cut all the upper waves on one side, and then we turn the sheet over and combine the cut lines on the reverse side.

The main problem is dust; in order to knock it down, the disk and sheet are constantly watered with water during operation.

Step-by-step diagram for cutting straight sheets using a grinder.

The grinder is the most common, but not the only power tool that can be used to cut asbestos-cement sheets. Second in the ranking is a miter circular saw.

True, only its manual modification is more suitable for such purposes, and it is also better to take a diamond blade; models designed for cutting wood quickly shrink.

Cutting slate with a circular saw is as convenient as cutting with a grinder.

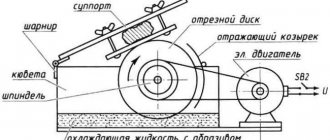

Another representative of the disk-based community of power tools suitable for cutting asbestos-cement slabs and specifically slate is a cutting machine. Moreover, this tool was specially developed for such purposes. In fact, it is one of the modifications of the grinder adapted for cutting slate.

It is easiest to cut slate with a cutting machine, since that is what it is designed for.

Method number 2: cutter

At a time when there were no grinders and other similar power tools, experienced craftsmen used steel cutters to cut sheets. The main requirement for such cutters is the strongest possible steel.

- A metal ruler is pressed along the cutting line;

- Then, relying on this ruler and with great pressure, several dozen cuts are made. The number of cuts depends on the strength level of the sheet and the quality of the cutter;

- When the groove from the cutter reaches half the thickness of the material, the sheet is placed on the edge of the table and breaks off with light pressure.

The technique of working with a steel cutter is extremely simple.

The problem is that flat sheets can be cut anywhere with a cutter, but corrugated slate according to this pattern is cut only along the wave.

There is a professional tool that can be used to perform such work, but it is often taken only by people engaged in such work; there are few places where it can be used in everyday life.

There are professional tools for working with slate and slate.

Using the technology described above, slate can be cut with a sharp shoe knife made of high-strength steel, but only the blade quickly “sits” during such cutting and few people agree to spoil a good knife.

Our wise people have adapted to making such cutters from broken hacksaw blades for cutting metal. A groove is machined on the back side of the blade, resulting in a kind of tooth that perfectly cuts sheet materials.

And to make it more comfortable to hold, the handle is wrapped with electrical tape. The tool, of course, is far from ideal, but its cheapness can be called an indisputable advantage here. After all, you would have thrown away the broken canvas anyway, otherwise it will go into use.

A hacksaw blade cutter is an inexpensive and quite effective tool.

By the way, with such a folk cutter made from a hacksaw blade, you can cut not only asbestos-cement sheets, but also textolite, gitinaks, and any types of plastic.

Method number 3: punch

The methods described above work, of course, well, but what to do if the only tool at hand is a hammer and slate nails? It turns out that there is also a way out of this situation:

- Simply lay the sheet on the ground and mark a cutting line on it;

- Next, take a nail and punch a series of holes along the line. You just need to hit at the bottom of the wave, the one that rests on the ground;

- Now turn the sheet over to the other side and hit a row of holes along the line, again at the bottom of the wave;

- As a result, along the cutting line you have an even row of holes with a pitch of about 5 - 7 mm. You just need to rest the sheet on some smooth edge and break it off along the cutting line.

It is impossible to achieve a straight edge of the sheet with a punch.

Required tools and materials

Roofing slate will not surprise anyone - it is the most common roofing material throughout the vast area of the states of the former Russian Union. But what and how to cut thin or corrugated slate – rather fragile products – often remains a mystery for the younger generation. Let's try to clarify this issue.

DISC THAT CUT EVERYTHING

We will send the material by email

Let's look at how to cut slate , what needs to be used for this, how to organize the process so as to do it correctly and not harm your own health. After reading the article, everyone will be able to repeat the operation without the help of others without the services of construction masters.

Which discs are suitable for sawing slate?

Slate is very durable when installed on a sloping roof. But when cutting slate along a line, it turns out that it is a fragile material. You need to cut it off with a grinder with a disc very carefully and carefully so as not to break the edge in the wrong place.

There are two types of slate:

- Wavy (with ridges);

- Flat.

To cut slate (both corrugated and flat), it is best to buy a 125 mm grinder (maximum circle diameter). This size just allows you to cut slate along the waves, and is sufficient for flat sheets.

There are two types of discs on sale that are used for cutting asbestos cement sheets:

- Disc for stone.

This type of cutting wheel is good because it does not require very strong pressure and effort. But before you cut the slate with a stone disc, think about where the constant water supply will come from , otherwise you won’t be able to cope. When cutting with a stone disc, a dense cloud of fine asbestos dust rises into the air. To eliminate it, you need to supply water during cutting to the place where the grinder comes into contact with the slate. This way you can cool the disk and remove dust.

The easiest way to supply water is in a thin stream by hand, from a hose or a plastic bottle. If there is no one who can constantly water the circle, then you need to fix the water hose. Stone wheels are good for cutting flat slate in a straight line. You can also cut wave slate for a roof in the same way, but not across the wave, but along it.

- Diamond-coated steel wheels.

Diamond wheels perfectly cut slate along any cutting line. A solid type circle, without slots, is best suited. It is good because it does not have segments that become clogged with dust. The solid diamond blade is very durable, suitable for the hardest materials. But it is designed exclusively for wet cutting with water supply, otherwise it will overheat in 1-2 minutes. A diamond blade is also used to cut corners and polish the edges of the sheet so that it is more resistant to moisture and temperature changes.

Advantages of slate and its properties

Slate has some advantages over other roofing materials:

- it is very resistant to temperature changes;

- has high moisture resistance;

- resistance to ultraviolet rays;

- excellent sound insulator;

- can be used in other areas of construction.

After breaking the sheet along the edge marking line, it must be sanded. The easiest way to cut slate is outdoors. The sheet is placed on a pallet or on nearby tables. The clearance is necessary for the free passage of the tool. The most commonly used grinder is a grinder.

Scheme for cutting slate with a cutter.

Wave slate drains excess water well. This property allows it to be used as a roofing material for the roof of a house, garage, or outbuildings. It can be used as formwork to prevent groundwater from penetrating under a structure under construction. When working with slate, you need to remember its fragility.

Before cutting slate, you need to ensure that small particles do not get on your hands and face. If you remember its composition, you will immediately have to isolate asbestos. This is a very harmful substance to health. Therefore, a respirator will not be superfluous when working with this material. It is recommended to work in protective gloves and masks. To protect from dust, the cutting areas should be moistened with water.

When using these tools, before cutting slate, you need to place a cloth soaked in water on the marking line for several hours. Then use any of the listed tools.