How to test a coil with a multimeter

Most often, we think about repairing a chainsaw when it stops starting. If you have problems starting, you should check the ignition coil. Main symptoms of a malfunction:

- The chainsaw does not start or has difficulty starting until it warms up;

- The chainsaw starts, but runs unevenly, sneezes, shoots, etc.;

- The power of the chainsaw has dropped;

- Fuel consumption has increased.

To diagnose a breakdown in the ignition system, we will use a device such as a multimeter. For these purposes, any model of digital multimeter complete with probes will suit us. DT brand models have proven themselves well, such as the basic DT9205A or a multimeter of the same brand - DT9205A, with more advanced functionality.

Digital measuring device - multimeter

We carry out diagnostics:

- Be sure to study the instructions for our chainsaw: find out the operating indicators of the average resistance for the circuit winding (standard resistance is 0.2 - 4 Ohms);

- We install the device so that the arrow shows 200 Ohms;

- We connect the multimeter to the circuit winding (probes on “+” and “K” - the coil body) and measure the resistance. If the indicators are normal (0.2 - 4 Ohms), we continue testing;

- We switch the multimeter to 20 kOhm mode, transfer the probe from the body to the candle holder, and perform the test. Acceptable values are 6-15 kOhm (depending on the model).

- If the readings differ greatly from the specified values, the coil should be replaced.

Video

We recommend watching the video, the author of which explains in detail how to check the ignition coil of a chainsaw with a multimeter. Tests are carried out on different saws and different reels.

How to check the receipt of an impulse from the engine crankcase

Repair of Shtil chainsaw in case of fuel supply system malfunction

- unscrew the spark plug;

- draw 1–2 ml of fuel into a syringe and pour it into the spark plug hole;

- install the spark plug in place and put the cap of the high-voltage wire on it;

- set the control lever to the hot start position;

- Pull the starter handle several times.

If these actions helped start the Shtil chainsaw engine, but it stalled almost immediately, then the problem really was a lack of fuel supply. To fix it, you need to check the fuel system.

The fuel pump is located in the carburetor. Its operation is carried out by the receipt of impulses from the engine crankcase through the impulse channel. The channel is located in a rubber pipe through which the cylinder and carburetor communicate.

If the pulse channel becomes clogged, the quality of the fuel supply decreases or it does not arrive at all. To gain access to the pipe, you need to remove the air filter housing and carburetor. After this, the channel is checked or cleaned using a metal wire.

Adjusting the idle speed of the Shtil 180 chainsaw carburetor

The design of the Shtil 180 chainsaw contains many rubber parts. All of them require systematic inspection for cracks and other defects. If they are present, the parts are replaced with new ones.

Another reason for the lack of impulse may be depressurization of the Shtil chainsaw engine crankcase. In this case, the air supply to the pump is reduced or completely stopped.

Check the tightness using a vacuum gauge. If it is absent, a medical syringe will come to the rescue. The operation is carried out on an engine with the carburetor removed. Take a little motor oil into the syringe and pour it into the impulse channel, and then pull the starter handle.

If there is no pulse, the oil will remain in the channel. This problem can be resolved by disassembling the engine and replacing the seals. If the oil is squeezed out of the channel, the problem probably lies in a pump malfunction.

What to do if you don’t have a multimeter at hand?

If you are far from home or you simply do not have a multimeter, you can use the express diagnostic method.

Express diagnostics

In field conditions, you can carry out independent express diagnostics of the coil’s serviceability. To do this, you need to unscrew the spark plug and apply the body to the cylinder. Pull the starter and observe: is there a spark? If there is a spark, the coil is working.

This method is not ideal and has errors due to the fact that with an unnatural position of the spark plug, without compression, the spark can be very good . But when installed in the cylinder, when compression appears, it will simply disappear. Therefore, this verification method does not provide any guarantees.

Video

The author of the video tells how to check the ignition module without using a multimeter, using one chainsaw. The method is 100% working.

Structural components

All engines, be it a car or another instrument using an internal combustion engine, have similar operating principles.

No exception, there are such famous chainsaws that are happily used by consumers such as Goodluck, STIHL or Husqvarna.

The drive in them is the familiar internal combustion engine, respectively the fuel tank, the engine and the working element that directly performs the work, as well as other attachments that help with control.

Sometimes during operation some problems may arise with this fairly reliable tool like a chainsaw .

How to adjust?

The greatest load when operating a chainsaw, of course, falls on the engine. Its most vulnerable part is the ignition coil. Minor problems can be fixed yourself, for example, adjusting the ignition.

Ignition adjustment is necessary if:

- you want to extend the service life of the saw - for preventive purposes;

- the chainsaw does not start, a problem has been identified in the gap size (for each model, manufacturers have written their own gap size, the average value is considered to be from 0.2 to 0.4 mm);

- the motor runs intermittently;

- the power of the tool has decreased.

At home, we can adjust the gap in the ignition coil, which in many cases solves the above problems.

Algorithm for setting the gap

To adjust the gap in the chainsaw ignition coil, you will need: a template for setting the gap or a feeler gauge (most often a homemade blank is used, for example, a piece of a plastic bottle or cardboard), a socket wrench of the required size.

All models have the same coil structure; only the gap dimensions recommended by the manufacturer may differ. Let's consider, as an example, the gap adjustment algorithm for one of the most popular and recognizable chainsaw models - Shtil 180.

Ignition system of the Stihl MS 180 chainsaw. A - coil and magnets on the flywheel, B - contact location, C - flywheel.

Let's prepare everything we need, including cutting out a strip from a plastic container without embossing - it will serve as a template. The optimal clearance for the Shtil 180 chainsaw is 0.2 mm. (depending on the model, this value can range from 0.2 mm to 0.4 mm). Next we perform the following sequence of actions:

- Remove the protective cover;

- Let's remove the module with a candle holder and a high-voltage wire;

- Unscrew the ignition bolts to loosen them;

- Let's bring the magnets located on the flywheel to the coil;

- We clamp a plastic strip between the flywheel and the coil. Thus, we set the required gap;

- Tighten the bolts and remove the strip of plastic;

- Let's carry out a check: spin the flywheel a full rotation several times, make sure that the movements are free and the flywheel does not cling to anything.

The smaller the gap, the stronger the magnetic impulse emanates from the flywheel on which the magnet is located, the stronger the spark will occur.

The procedure for adjusting the ignition coil gap will be the same for all brands. However, I would like to note that a distinctive feature of Chinese-made chainsaws is frequent breakdowns of electronic ignition units and loosening of threaded fasteners due to poor quality assembly.

Consequently, the gap will have to be adjusted approximately 3 times more often than, for example, with the same Shtil. It is also worth noting that low-quality spark plugs are often supplied with Chinese-made saws. It makes sense to stock up on them in advance.

Checking the fuel system

The gap between the ignition coil and the chainsaw flywheel

You won't be able to look inside the ignition unit. And the reason for this is the non-demountable design. In service centers, its functionality is checked using a special tool. It will be possible to troubleshoot problems at home if you replace the unit.

But before you run to the store for a new ignition unit for the Stihl chainsaw, you need to make sure that the problem does not lie in the incorrect gap between the contacts of the flywheel and the ignition module. The reason for the lack of a spark can be either too large a gap or its complete absence. In the latter case, the flywheel will begin to come into contact with the module contacts, as a result of which scratches will form on it.

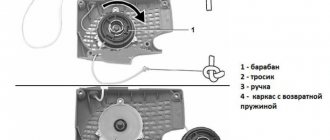

Chainsaw starter device

- remove the starter;

- loosen the screws securing the ignition module;

- place a plate cut from an ordinary plastic bottle between the module and the flywheel;

- tighten the screws.

If all these manipulations result in a spark, the Stihl chainsaw is ready for further work. Otherwise, you will have to re-inspect. If the inspection again reveals a lack of clearance, you will have to look for the cause in the crankshaft bearings.

The Shtil chainsaw may not start even if there is a spark. In this case, it is necessary to look for problems in the operation of the fuel system. To do this, you need to inspect the spark plug for wet deposits. Its presence indicates excessive fuel supply. When the fuel mixture begins to literally flood the spark plug, it cannot ignite it.

Faulty chainsaw spark plugs

- unscrew the spark plug;

- turn the Shtil chainsaw over, draining the fuel;

- in the same state, pull the starter handle several times to remove any remaining fuel;

- screw the spark plug into place;

- set the engine control lever to the hot start position;

- pull the starter handle several times.

All these manipulations must be carried out with the ignition off, positioned as far as possible from open fire.

If the problem was improper starting of a cold engine, “blowing it through” will help return the Stihl chainsaw to performance. If even after “blowing” the Shtil 180 chainsaw does not start, you need to look for a solution to the problem in the carburetor.

First you need to check the condition of the fuel filter. To remove it, you need to unscrew the fuel tank cap. Next, aluminum wire with a bent end will come to the rescue. With its help, remove the fuel hose, at the end of which there is a filter.

Chainsaw device Shtil 180

The condition of the filter can be checked by blowing into it. If air does not pass through, then the filter needs to be cleaned or replaced. If air flows freely, you need to look for a blockage in the fuel hose by disconnecting it from the carburetor. The blockage can be cleared mechanically or by replacing the hose.

If the fuel hose and filter are clean, but fuel does not flow to the spark plug, the cause may be a malfunction in the air pulse supply to the fuel pump.

There is a membrane in the pump body, which during movement ensures the supply of fuel to the carburetor and engine. If the Stihl MS 180 chainsaw does not start, the diaphragm may have ruptured. You can check its integrity by removing the pump cover. If any defects are found during the inspection, the membrane is replaced.

Chainsaw repair Shtil 180

Question: During operation, the stihl ms 180 c chainsaw stopped idling and stalled. I started it with difficulty, but stalled again at idle.

After this it doesn't want to start. The next day, after unsuccessful attempts to start it, I removed and washed the air filter. It didn’t help, I had to remove the spark plug - it turned out to be dry, although there were plenty of attempts to start it.

I cleaned the breather with a needle (it was not clogged). I changed the fuel filter (although the old one was not visually dirty). I cleaned the carburetor and installed a new spark plug just in case. The saw won't start! I unscrewed the spark plug again - it was dry. What to do?

Answer: Remove the muffler. Look at the piston, if there are longitudinal stripes on it, then it needs to be replaced.

Question: What is the difference between the drive and chain sprocket of the Stihl 180 chainsaw?

Answer: There is no difference between a “drive sprocket” and a “spin wheel”; these are different names for the same part.

Question: I bought a Shtil ms 180 chain saw, I really liked it, but I want to ask you, can my saw cut thick wood?

Answer: The standard length of the MS 180 tire is 35 cm, it is possible to cut a log of 70 cm in diameter, if logs of this diameter predominate, then you need a chainsaw of greater power.

The MS 180 will, of course, cope with the task, slowly and surely sawing all large-diameter logs, but you need to remember that by giving heavy loads to a device not designed for this, you (at best) reduce the service life of the chainsaw, that is, bring its major repairs closer .

Currently reading: Stihl petrol trimmers in Perm: 500 items: free delivery [go]

Question: Please tell me, is it possible to use a 45 cm guide bar on a Stihl 180 chain saw?

Answer: The MS 180 chain saw can be equipped with a bar of maximum length 40 cm.

Question: Where is the breather located in the Shtil ms 180 chainsaw?

Answer: The ventilation system valve (“breather”) is located “on top” of the gas tank and oil tank, it cannot be seen visually, because everything is covered by the starter housing.

Question: On the MS 180, the gas button gets stuck in a horizontal position. What to do?

Answer: Most likely, the lever-traction mechanism is faulty; when the unit is turned over, one of the levers or rods “falls”.

Question: Why does the cylinder heat up and when it heats up, does the Stihl 180 chain saw stall?

Answer: The problem is in the ignition module, perhaps there is no compression (necessary).

Question: We use a Stihl 180 chainsaw with a standard bar; we recently found out that people are installing a Carving bar on this model. According to the catalog, you can install a 30 cm tire of this type, but is it possible to install a 25 cm tire or is it not possible on this model?

Answer: Carving has a very small nose radius. It is better to use a chain with a 1/4 pitch with this tire. And this is where the problems begin. Chains like this are very rarely available in retail, and in addition to the 180th, you can also find a 1/4 sprocket.

Maybe it makes sense to look for a 30 cm Rollomatic Mini tire on 3/8 1.1. Its article number is 3005 000 3905, if I’m not mistaken. She has a small nose with a 7-tooth star. Somewhat larger than Carving, but not so picky about lubrication.

Question: Where should the arrow on the piston point to the muffler or vice versa on the Stihl 180 C chain saw?

Answer: The arrow should point towards the muffler (the rule for all STIHL chainsaws).

Question: Tell me, what is the clutch thread (left or right) on the MS 180 chain saw?

Answer: All STIHL chainsaws have a left-hand thread on the clutch.

Question: The starter on the Shtil ms 180 chainsaw pulls out jerkily, what is the reason?

Answer: There may be several reasons - from a faulty starter (starter spring, etc.) to a faulty cylinder-piston group.

Question: Why is there play in the chain sprocket on the Stihl 180 chainsaw?

Answer: The clutch cup needle bearing is worn out, but even on a new saw the chain sprocket has minimal play!

Question: Shtil 180 chain saw. Second fill of gasoline, full tank. Gasoline is seeping from below. Why?

Answer: The gas hose rubber could have popped out and could overflow through the gas tank breather. The first needs to be corrected, the second is acceptable!

Question: On the Stihl 180 chainsaw, the chain does not move during operation while the brake lever is in the middle position, and only begins to rotate when you move it towards you. What can be wrong?

Answer: The chain brake on a chainsaw has two positions: the extreme position, “pull away”, - this is the brake in the working position “on”, the chain does not move; move the extreme “towards you” until it clicks - this is the brake in the cocked position, the chain rotates.

You most likely have the brake on, you need to move the handle to the extreme “towards you” position, i.e. Pull the handle until it clicks and if this does not help, then the brake is faulty and you need to contact a service center!

Question: How to properly adjust the carburetor of the Shtil MC 180 chainsaw?

Answer: On the Stihl 180 chain saw, only the idle speed is adjusted, since the carburetor is rolled and adjusted at the factory. The idle speed is adjusted so that the chain does not rotate at minimum speed, or according to the tachometer.

Question: Tell me what to do. The Shtil 180 chainsaw does not start. There is a spark, but the spark plug floods and does not want to start. Where to start repairing or disassembling?

Answer: All repairs must begin by removing the muffler and seeing what the piston looks like.

Question: The Stihl MS 180 chainsaw does not stall when moving the lever up, I turn it off with the air damper, what should I do?

Answer: By moving the lever up, you interrupt the contact, in your case the contact is not interrupted, the contact spring has “moved away” (bent), the contact spring wire may be broken, the control shaft (the lever that you lift up) is worn out.

Question: Tell me how to replace the clutch springs on a Shtil 180 chainsaw?

Answer: clutch springs can be replaced even without removing the clutch. All you need is a small but strong hook made of strong wire and a standard spark plug wrench. We remove the cup, put the key on the hexagon of the coupling and use the hook to unhook the stretched spring.

We immediately put a new one in its place - it’s simple. We hook one hook of the spring with our fingers, and use the hook to pull the second hook into the hole. It will catch, then we push it with a screwdriver so that it fits into the hole properly.

We turn the crankshaft 1/3 of a turn, put the key on the hexagon again, hold it from turning and also replace the spring with a new one. Next - the third. We put the cup in place and work. You can also check the condition of the springs with your fingers.

The stretched spring allows the weights to move on the cross and can be removed very easily. When we replace the springs with new ones, the clutch should become like a monolith and it is not possible to pull the weights off with your fingers, only if you push against it with a screwdriver.

Currently reading: Trimmer head ht35 champion buy in Moscow in the online store