Husqvarna 142 in operation

We prepared the fuel mixture on the basis of AI 92 gasoline and Husqvarna HP branded two-stroke oil in a ratio of 50 to 1. It is interesting to note here that if oil added in the specified ratio is not available, the manufacturer allows the short-term use of high-quality oil diluted with gasoline in the ratio 33 to 1.

We operated Husqvarna 142 for about an hour. It is ideal as a household chainsaw: almost complete absence of vibrations in the hands, a completely bearable noise level and, most importantly, excellent cutting abilities. Fresh pine and dry birch trunks with a diameter of 26 cm were repeatedly sawed in an average of 7 s each. The dry oak yielded a little slower; It took approximately 14 seconds to cut a log with a diameter of 24 cm. Cutting speeds are slightly lower than those of professional chainsaws that we tested, but these are saws of a different order of cost. Husqvarna 142 is not afraid of working at full power; high speeds are even recommended in the instructions. The brake works perfectly - the chain stops instantly.

Read also: Grippers for metal sheets

Then an analysis was made of reviews from Husqvarna 142 owners on three specialized forums

We took into account only those publications whose authors have been registered for a long time and do not use a chainsaw professionally, i.e. not every day for several years

The results of the analysis were not surprising and are briefly as follows: the piston group is reliable, the tire is strong, the saw is comfortable and unpretentious to fuel. Failures do occur infrequently, but are caused by the deadline for replacing consumables or errors in preparing the fuel mixture.

Disadvantages and malfunctions

According to the unanimous opinion of the owners and operators, the Husqvarna 142 saw has no obvious design flaws. This is evidenced by a large number of positive reviews and requests to service and repair centers.

Many failures and malfunctions are the result of illiterate use, untimely and incomplete maintenance, and the use of substandard fuels and lubricants.

In particular, replacing branded chain oils with cheap substitutes leads to failures and malfunctions of the oil pump, reducing the service life of replacement equipment. The performance of the tool is negatively affected by unqualified repairs and the use of counterfeit spare parts and consumables.

Chainsaws Partner and Shtil, their adjustments.

In Shtil and Partner chainsaws, adjusting screws H and L set the proportion of air and gasoline in the mixture. When the screws are loosened, the mixture becomes richer and the speed increases. Screwing leads to a leaner mixture and, accordingly, a decrease in engine speed.

Setting the carburetor of the Partner chainsaw to idle speed is carried out using screw T (Shtil marks this adjustment with the letters LA). Basic tool adjustment is done at the factory during final testing. In most cases, the carburetor is adjusted to supply a slightly richer air-fuel mixture than the optimal calculated one. The settings set by the manufacturer must be saved during the first few hours of operation, during the break-in period. After this, finer adjustments can be made, although this is not necessary; the saw will work normally at the basic settings.

For fine adjustment of the carburetor, a tachometer is required, in addition, technical documentation will be needed in order to carry out work in strict accordance with the manufacturer's requirements. The best solution would be to entrust the fine tuning of fuel equipment to specialists.

If you still decide to adjust it yourself, you should start with screw L, then move on to jet H, after which you set the idle speed by rotating screw T (or LA - if it’s a Stihl saw).

By smoothly turning screw L in both directions, a position is sought at which the idle speed will be maximum. Once this point is found, you need to unscrew screw L 1/4 turn. If the chain continues to move while the engine is idling, screw T (LA) is slowly unscrewed until the chain stops.

After setting the maximum speed with screw H, the value of their frequency is checked using the tachometer. If the maximum rotation speed does not correspond to the values specified in the documentation, the adjustments are repeated. If at maximum speed the mixture is too rich, too much smoke comes from the muffler; if the mixture is lean, the saw makes a squealing sound and the engine heats up excessively. The adjustment ends with setting the idle speed - the position is considered correct if the engine runs exactly at minimum speed and the chain is stationary. The idle speed setting can be seen in the video below.

Specifications

Engine

- Type: two-stroke air-cooled

- Working volume: 40 cm 3

- Power 1.9 kW (2.58 hp)

Ignition system

- Type: CD (capacitor ignition)

- Applicable spark plug type: Champion RCJ7Y

- Interelectrode distance: 0.5 mm

Fuel system

- Fuel tank capacity: 0.37 l

- Volumetric gasoline-oil ratio: 50 to 1

- Recommended gasoline: high octane unleaded

Chain lubrication system

Tank capacity: 0.19 l

Cutting set

- Tire Length: 15inch/38cm

- Chain Pitch: 0.325"

Ergonomic characteristics

- Noise level: 98–108 dB depending on measurement technique

- Weight of the “dry” chainsaw without bar and chain: 4.8 kg

Analysis of the data provided allows us to note 3 interesting features. Firstly, Husqvarna 142 has sufficient power for a household chainsaw, which is approximately 20% less than the average power of professional saws from the same manufacturer. Secondly, its cutting set is standard for Husqvarna and, if replacement is necessary, will not lead to a long search or wait

Thirdly, the manufacturer focuses on the undemanding quality of gasoline, without indicating the minimum permissible octane number. Therefore, the conclusion at the first step of the review is the following: the characteristics of the Husqvarna 142 chainsaw are suitable not only for work in the country, but also for semi-professional use

Causes of malfunctions and repairs

No spark

Spark problems are the most common in practice. The following factors can cause them:

- Errors that occurred when adjusting the carburetor;

- Exceeding the proportion of oil in the mixture with gasoline;

- Air filter clogged.

All of the above problems one way or another lead to the appearance of carbon deposits on the electrodes of the spark plug, resulting in a corrosion process.

You can determine the absence of a spark using the following sequence of actions:

- The first step is to remove the tip of the high-voltage wire.

- The next step is to unscrew the spark plug.

- The tip is put back on.

- The candle's skirt leans against the cylinder.

- Starting is done using a starter.

If everything is in order, a spark will run between the electrodes. Otherwise, you need to clean everything, and if necessary, use a probe to change the distance between the electrodes. The required distance can be read in the instructions. Depending on the manufacturer, the distance can be from half a centimeter to one fifth.

The solution to the problem described above is not exhaustive, since there are other reasons for the chainsaw to fail. Some of them can be solved temporarily, for one start of the tool, if the work needs to be done urgently. This is done by doing the following:

- Using a key, the spark plug is unscrewed.

- The candle is wiped with a clean rag.

- Next, the candle needs to be dried. This takes about half an hour.

- Using a file, carbon deposits are removed and the gap between the electrodes is adjusted.

- Fuel is leaking from the spark plug channel.

- The canal is dried.

- All parts are returned and an attempt is made to start the saw.

As mentioned above, these measures are temporary. After finishing work with the saw, it will stall again, and the best solution in this situation would be to have it repaired by professionals.

Fuel supply problems

The first thing you need to do when checking the serviceability of the fuel supply is to make sure that it is present in the tank. If the tank is full, you can check the pumping. To do this, the tube is disconnected from the carburetor. Now you can start checking. If there are no problems, fuel will be supplied in spurts in the volumes specified by the manufacturer. The reason for the absence or very weak fuel supply can be either a clogged channel through which the fuel is transferred, or problems with the fuel filter.

In some cases, starting problems may be due to the tank being too full.

Another reason may be the quality of the fuel mixture. If you fill it too much and then do not use the saw for a long time, chemical processes may begin to occur, which will then lead to problems with the tool.

Filter failure

The reason why a chainsaw does not start well may be a malfunction of one of the filters. The fuel filter can be checked after pumping, which was described above. After it has become clear that the fuel is not flowing or is flowing too poorly, you need to empty the tank of the mixture. Then you should remove the filter itself. If it is clogged, it can be cleaned, but it would be better to replace it with a new one. If your saw is frequently used in dusty areas, cleaning the filter should become a routine activity.

A clogged air filter will cause the saw to stall frequently or stop starting altogether.

To clean, the filter must be pulled out, but very carefully. If handled carelessly, dust can get into vital segments of the saw.

This risks leaving the repairs to professionals.

The above describes the most common problems that can arise with a chainsaw. If the damage is minor, you can fix it yourself, but first of all you should study the instructions. Different saws have their own characteristics. Accordingly, the details of the repair may vary.

Alternative fuel option

To refuel household and professional chainsaws, it is recommended to use motor gasoline of the AI-92 type that does not contain alcohol components and additional additives.

The question of whether it is possible to pour 95 gasoline into a chainsaw remains controversial to this day. Theoretically, the anti-knock properties of AI-95 gasoline are higher than those of standard AI-92 fuel, but in practice it is better to give preference to the second option.

The problem is that in order to improve the anti-knock characteristics, manufacturers and distributors introduce additives into the composition of 95-grade gasoline, the quality and effectiveness of which raises reasonable doubts among experts.

Such fuel does not fully meet the required characteristics and does not have proper stability during long-term storage. After 3-4 months of exposure, its working properties deteriorate by 25-30%.

Basic equipment

The basic package of the Chinese Husqvarna 5200 includes:

- saw body with motor;

- chain and bar;

- operating instructions for the tool;

- warranty document;

- packaging - cardboard box.

Not included in the package:

- tire protective cover;

- protection for the right hand.

Cost of husqvarna 5200 chainsaw

The average cost of a Husqvarna 5200 chainsaw is 6 thousand rubles (about 1.5 thousand hryvnia). This price is due to the fact that this tool is a copy of conventional Husqvarna saws, has a small cylinder volume and is not accompanied by a Swedish manufacturer’s warranty, which is typical for original chainsaws.

Chainsaw malfunctions and how to fix them

Owners of the Husqvarna 142 model often encounter typical breakdowns caused by improper use of garden tools or simple wear of its parts.

These malfunctions include:

- the chainsaw does not start - the cause of this breakdown lies in the spark plug being flooded. To be able to start the saw motor, you need to remove, wash and dry the spark plug. After this, you need to blow out the cylinder by sharply pulling the starter cable several times with the spark plug turned out. After this, you need to screw in the spark plug and start the engine of the garden tool;

- increased vibration during operation of the saw - repair of this breakdown is carried out by cleaning or replacing the muffler. You will also need to inspect the springs of the anti-vibration system. If necessary, sagging parts must be replaced;

- shooting sounds - if loud popping noises are heard during operation of the Husqvarna model, then the causes of the breakdown should be sought in the carburetor or muffler. The operator will first need to adjust the carburetor. After this, you need to remove and wash the muffler;

- leakage of oil to lubricate the chain - to eliminate this breakdown, you need to check the condition of the oil pump and pipes. The faulty part will need to be replaced.

https://auramm.ru/remont-benzopily-huskvarna-142-svoimi-rukami/ https://benzopilok.ru/brend/husqvarna/142-benzopila.html https://pro-traktor.ru/benzopily/huskvarna -142.html

Malfunctions of Husqvarna Chainsaw 142

Content

DIY chainsaw repair Husqvarna 137, 142, 240, 365 - video

A chainsaw is an indispensable assistant for every real owner.

Since the instrument's inception, its popularity has grown rapidly.

Thus, the Husqvarna 142 chainsaw has the highest functionality. It is widely used not only in forestry, but also on private plots.

Choosing a chainsaw is quite simple. So, it is best to focus on well-known brands such as Husqvarna. This company produces a wide range of such tools. Husqvarna 240 and other models are of the highest quality and functionality. But, unfortunately, even such tools are not immune from breakdowns.

Possible faults

After a chainsaw appeared in the house, many owners breathed a sigh of relief.

After all, this tool allows you to solve complex problems quite quickly and simply.

But, here it is worth considering that the chainsaw often fails. This is due to the fact that it is subjected to enormous loads during operation. Therefore, it is necessary to always be prepared to eliminate breakdowns.

Now there are a huge number of workshops that offer their services for repairing chainsaws and other tools. But this does not mean that if a malfunction occurs, you need to immediately run to a repair shop.

Some faults can be removed with your own hands. To do this, you just need to know the main reasons for the occurrence of breakdowns and the method of eliminating them.

READ How to Properly Fuel a Chainsaw

Thus, during frequent use of the tool, breakdowns may occur:

- carburetor;

- muffler;

- oil pump;

- ignition and fuel supply systems.

Each of these breakdowns can be fixed with your own hands . The main thing is to know the sequence of work when eliminating a particular malfunction.

Read the article about self-repair of the Shtil 180 chainsaw here.

Ignition system

If the tool suddenly stops working, then the first thing you need to check is the ignition system. And you need to start with a candle.

The work must be done very carefully. A special hook is used for this. First you need to disconnect the wire and remove the spark plug.

If it is dry, it means that fuel is not entering the cylinder.

Disassembly and assembly of the HUSQVARNA 142 chainsaw

my chainsaw start?

.Cause.How to eliminate.

The chainsaw does not start or does not start well. Reason and how to fix it.

common problem of huswarna 137/142

.

If there is splashes on it, then the breakdown may lie in the carburetor or in the starting rule. To fix the breakdown, you need to wipe the spark plug and turn off the fuel supply. After this, the starter starts.

Thus, the combustion chamber is ventilated and excess fuel is removed. After this, the spark plug is installed in place and the chainsaw starts.

If there is carbon deposits on the spark plugs, this indicates that the Husqvarna 137 chainsaw runs on low-quality fuel. Carbon deposits also form as a result of an incorrect ratio of fuel and oil. In order for the tool to work as long as possible, you need to carefully study the operating instructions.

READ How to Level a Chainsaw Bar

If there is carbon on the candle, it must be carefully removed. You can use an awl for this. The electrodes are carefully rubbed with sandpaper. After this, it is installed in place. You also need to fill in the fuel that is recommended for this model of chainsaw.

the article about repairing the Partner 350 chainsaw with your own hands here.

Problems with the fuel supply system

If the tool does not work, it may be due to the fact that there is no fuel entering the cylinder.

First of all, you need to check the fuel filter for contamination levels. To check this, you need to remove the fuel hose and check how fast the fuel flows.

If it is supplied under low pressure, then the problem lies in the filter.

In this case, you need to clean the filter. It is taken directly through the tank. The filter is cleaned and installed back. It is washed under running clean water.

After this, the filter is dried and carefully installed back. To prevent this problem from occurring in the future, it is necessary to periodically clean the filter.

If cleaning the filter does not give a positive result, then you should pay attention to the breather. A clogged hole in this hole causes insufficient air to enter the carburetor.

Malfunction of muffler and carburetor

If the chainsaw is used frequently, muffler malfunctions may occur. This is very easy to determine.

READ Chainsaw Ural2 Ussr Chainsaw Ural 2, 1979

If the tool works normally, but when the speed increases, it starts to stall, then the reason is the spark arrester.

Most often, the breakdown of this element is a result of clogging with combustion waste. You can easily solve this problem with your own hands.

First of all, you need to remove the muffler and disassemble it. It is worth considering here that in some models spark arresters are not disassembled. After this, the muffler is cleaned of carbon deposits. For this purpose, special detergents are used.

When the carbon deposits are removed, the spark arrestor is dried with a hairdryer. At the final stage, the muffler is installed in place.

As for the carburetor, its adjustment and repair can be done at home. But in order to perform such work efficiently, you need to know the structure of the carburetor and the principle of its repair.

Poor repairs can lead to serious damage to the device. Therefore, experts recommend that it be configured and repaired in special workshops.

As you can see, many chainsaw malfunctions can be fixed with your own hands. But to do this, you need to have certain information. If you are not confident in your abilities, then it is better to seek help from specialists.

Watch the video in which a specialist shows in detail the disassembly and assembly process for DIY repair of the Husqvarna 142 chainsaw:

Adjustment Husqvarna 142

Adjusting the Husqvarna 142 chainsaw is simple if you follow the instructions. The extra tenon can be used as a twist when making a cut. Loosen and remove the chain brake nuts and chain brake from the saw. Attach the bumper spike (optional) with two screws. Check that the saw is assembled correctly. Loosen and remove the chain brake nuts and chain brake. Remove the plastic shipping pad (if equipped). The adjusting pin and screw are used to adjust the chain tension. Turning the screw will move the adjustment pin up and down. Make this setting before use.

- Turn the adjusting screw counterclockwise by hand until the adjusting pin locks into place. This should allow you to install it in the correct position.

- Move the guide rod behind the clutch drum to the sprocket limiting the clutch drum.

- Prepare the chain by checking the correct direction. Without instructions, it is easy to place the chain on the saw in the wrong direction. Use the circuit illustration in the instructions to determine the correct direction.

- Place the chain by installing the drive links in the drum sprocket.

- Place the bottom of the drive links between the teeth of the guide rod nose.

- Connect the chain drive teeth into the groove.

- Pull the bar towards you so that the chain is clamped in the guide groove.

- Check that all drive links are secure.

- Now place the chain brake, making sure the adjuster is positioned in the hole at the bottom. Once the chain is tight, you need to tighten the chain brake nuts. When adjusting the tension, make sure the brake chain nuts are tightened tightly.

For lovers of chainsaws with average performance but high quality, we offer a review of the excellent model Husqvarna 137, the characteristics are very similar to model 142.

It is also important to remember that the Husqvarna 142 engine is certified to run on unleaded gasoline. Before starting work, gasoline must be mixed with good quality air-cooled engine oil

The manufacturer recommends using Husqvarna brand oil. Do not use motor oil. It may cause engine damage.

Engine won't start?

If the engine does not start or only starts for a few seconds, turn the ignition switch to the ON position or fill the tank with the correct fuel mixture. A new spark plug may need to be installed. Check for a dirty fuel filter; may need replacement. A dirty air filter reduces engine performance and increases fuel consumption and emissions. Always clean after every five hours of operation. Clean the cap and surrounding area to prevent contaminants from entering the carburetor chamber. Check the fuel lines for serviceability.

Is the engine not running or lacking power? Clean or replace the air filter. Clean or replace the plug. Disengage the chain brake. Contact your authorized service dealer. Follow the instructions. Always read and follow safety rules.

Chain Husqvarna 142

When choosing a chain for this chainsaw model, rely on the following data:

- standard length, cm - 38;

- maximum chain speed, power, m/s - 16.3;

- pitch, inches - 0.325;

- thickness of the drive link, mm - 1.3, number of teeth on the drive sprocket.

Sharpening a chain is a difficult task that requires special tools.

What problems can arise with the chain? How to solve a problem? The chain can move at idle speed. This means that the idle speed needs to be adjusted or the clutch needs repair. To perform repairs correctly, contact your authorized service dealer. The chain brake should be checked a couple of times a day. The engine must be running during the test. This is an exception where the saw can be placed with the engine running. The chain brake is replaced when wear is detected to a thickness of half a centimeter. Chain brake repairs must be carried out by an authorized dealer.

Video review

https://opilah.com/benzopila-husqvarna-142-brendovyj-instrument-byudzhetnoj-gruppy/

Technical characteristics of the Husqvarna 365 saw

- Type - chainsaw;

- Construction - manual;

- Power - 3900 W/hp;

- Chain pitch - 0.375 inches;

- Tire length - 38 cm;

- The maximum length of the tire is 70 cm;

- Engine capacity - 65.10 cc;

- Weight - 6.00 kg;

- Noise level - 114 dB;

- Fuel tank capacity - 0.77 l;

- Oil tank capacity - 0.42 l.

The Husqvarna 365 XP chainsaw is one of the most controversial models on the modern garden tool market. On the one hand, this is a Chinese analogue of the Husqvarna 5200 chainsaw, which has practically nothing in common with the Swedish brand. On the other hand, this fact does not prevent the 365 model from being in demand among buyers, because the chainsaw has such important qualities as reliability, durability and high performance.

The design of a Chinese chainsaw includes the same elements and mechanisms that can be found in any European-made saw. In addition to them, the Husqvarna 365 XP chainsaw received several additional options that allow it to stand out from other garden tools. Among the design features of the Husqvarna 365 XP chainsaw, the following should be highlighted:

- The presence of a durable magnesium-aluminum crankcase allows the chainsaw to successfully cope with its tasks even during prolonged operation under extremely high loads;

- The Husqvarna 365 chainsaw is equipped with a high-quality oil pump, the function of which is to distribute lubricant to the tool chain. If necessary, the volume of supplied oil can be adjusted;

- Availability of free access to the saw chain tension screw - thanks to this, the operator does not need to remove the protective cover each time;

- The decompression valve in the device is responsible for reducing the pressure in the cylinder of the Husqvarna 365 chainsaw;

- The handle is located at an angle for ease of operation of the chainsaw. The controls are located on the side cover, which greatly simplifies the adjustment of the Husqvarna 365 XP model.

Among other things, the Chinese manufacturer equipped the Husqvarna chainsaw with an effective easy-start system, the presence of which significantly extends the service life of the motor and other components of the model.

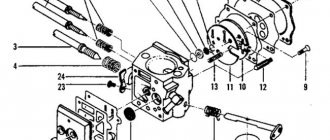

The device of the Husqvarna 142 chainsaw

One of the main advantages of the 142nd model of the Swedish brand Husqvarna is the competent selection of its components and the high quality of the original assembly. The basis of the garden tool consists of a 2-stroke gasoline engine, the chrome-plated cylinder of which has a volume of 30 cm3. Starting a standard internal combustion engine is done by pulling the recoil starter cable. A proprietary Japanese Walbro brand carburetor with forged jets and an improved fuel injection system is responsible for preparing and enriching the fuel mixture with air in the internal combustion engine configuration. The manufacturer equipped the engine with a fuel and oil tank with a volume of 370 and 190 ml, respectively.

The Husqvarna 142 chainsaw is equipped with a durable clutch, which is responsible for the continuous connection of the engine with the saw set. All spare parts of the mechanism are made of durable steel, resistant to high temperatures and corrosion.

For instant ignition of fuel in the internal combustion engine cylinder of Husqvarna garden tools, a proprietary capacitor ignition system is used, which includes a Champion RCJ7Y spark plug. The distance between the flywheel and magneto electrodes in the operating state of the ignition system is 0.5 mm.

For sawing wood, the Husqvarna 142 chainsaw is equipped with a high-quality saw set made of wear-resistant alloy. It consists of a 38 cm long tire, as well as a chain with a pitch of 0.325". An oil pump operating in fully automatic mode is responsible for the continuous lubrication of the saw set. To allow chain adjustment without the use of hand tools, Husqvarna has provided easy access to the tensioner sprocket. The built-in inertia brake is responsible for the safe operation of the model, which is activated whenever the chain hits a wire, nail or any other solid object.

The Husqvarna 142 chainsaw stands out for its good balance and ergonomics. All switches and buttons necessary for operation are located at the rear of the instrument body. This simplifies the operation of the chainsaw in very limited space.

Adjusting the Husqvarna chainsaw carburetor

Like all other saws, Husqvarna has the same carburetor adjustment algorithm. Therefore, the instructions will be relevant for other tools and models of chainsaws such as Husqvarna 142, 236.

Before starting work, make sure the air filter is clean and all other components are working properly. The fuel supply to the float chamber should operate without interruption, and the ignition system is set correctly and has a fresh spark plug.

Procedure:

- Reset the carburetor to factory settings. This must be done with the engine stopped.

- Now you can start the engine and be sure to warm it up for several minutes. Adjustment of the XX carburetor Husqvarna 137 is carried out only on a warm engine.

- By rotating screw L clockwise, you need to set the crankshaft speed to the highest speed, then turn it back a quarter turn. Use screw T to adjust the crankshaft speed so that the chain does not rotate. It should not be driven without pressing the accelerator.

- Now you need to set the maximum speed and its power. It is enough to connect the tachometer to the ignition system and use the accelerator to set the maximum possible speed. Compare them with your passport data. If they differ, then unscrew or tighten screw H. By changing the range, you can create restrictions to make the saw work efficiently and save the life of the motor.

What you should pay attention to?

Once the adjustment of the Husqvarna carburetor is completed, you need to make sure that the engine is stable and that the saw easily picks up and drops the required speed. The rotation of the chain at idle is considered abnormal, so its connection with the clutch must be adjusted again using screw H.

Do not forget that the unit is not adjusted immediately: you need to wait some time, since the Husqvarna chainsaw does not immediately respond to changes in the position of the screws. This time can range from 5 to 15 seconds. This time is not indicated in the table, so you can only find out experimentally.

If after adjustment a huge amount of smoke appears during operation, then you need to adjust the supply of the fuel and oil mixture. For these purposes, rotate screw L.

What is the factory setting of the Husqvarna chainsaw carburetor?

To ensure that the chainsaw still starts even if the settings are incorrect, the factory positions of the screws H and L are used. Most Husqvarna chainsaws can be started if both screws are unscrewed exactly one and a half turns. Only after this can the screw positions be changed in order to achieve the desired fuel consumption and maximum operating efficiency. XX is also regulated after these manipulations.

If you still have questions about adjusting the carburetor on the Husqvarna 137 chainsaw and other models in this line, I recommend watching this video:

DIY Chainsaw Repair Husqvarna 142

A chainsaw is an indispensable assistant for every real owner.

Since the inception of the instrument, its popularity has grown rapidly.

Thus, the Husqvarna 142 chainsaw has the highest functionality. It is widely used not only in forestry, but also on private plots.

Choosing a chainsaw is easy. So, it is preferable to mention well-known brands such as Husqvarna. This company produces a wide range of such tools. Husqvarna 240 and other models are of the highest quality and functionality. However, sometimes even such tools are not immune from breakdowns.

When a chainsaw appeared in the family, the owners probably breathed a sigh of relief.

After all, such a tool allows you to solve complex problems quite quickly and simply.

But it’s worth considering that a chainsaw often burns out. This is due to the fact that it is subjected to enormous loads during its operation. Therefore, it is always necessary to prepare for troubleshooting.

Now there is a huge selection of workshops that offer their services for repairing chainsaws and other tools. But this does not mean that if a malfunction occurs, you need to immediately run to a repair shop.

Of course, some faults can be fixed at home. For this purpose, you only need to know the main reasons for the occurrence of breakdowns and the method of eliminating them.

So, during frequent use of the tool, breakdowns may occur:

- carburetor;

- muffler;

- oil pump;

- accounting system for ignition and fuel supply.

READ How to properly cut out a countertop for a sink

Of course, each of these breakdowns can be removed with your own hands. The main thing is to know the sequence of work when eliminating one or other malfunction.

Read the article about self-repair of the Shtil 180 chainsaw here.

If the tool suddenly stops working, then the first thing you need to check is the ignition system. And you need to start with a candle.

The work must be done very carefully. A special hook is used for this purpose. First you need to disconnect the wire and remove the spark plug.

If it is dry, this means that no fuel is entering the cylinder.

On the contrary, there is splashing here, then the breakdown may lie in the carburetor or in the starting rule. To remove the damage, you need to wipe the spark plug and turn off the fuel supply. As a result, the starter starts.

In this way, the combustion chamber is ventilated and excess fuel is removed. After which the spark plug is installed in the area and the chainsaw is started.

If there is carbon deposits on the spark plugs, this indicates that the Husqvarna 137 chainsaw runs on low-quality fuel. Carbon deposits also appear when the fuel to oil ratio is incorrect. To ensure that the tool has worked for a long time, you must carefully study the instruction manual.

If there is carbon deposits on the candle, it must be carefully removed. An awl is used for this purpose. The electrodes are carefully rubbed with sandpaper. After which it is installed in place. It is also necessary to fill in the fuel that is recommended for this model of chainsaw.

READ Why The Spark Plug In The Chainsaw Is Pouring

Read the article about repairing the Partner 350 chainsaw at home here.

If the tool does not work, then this is due to the fact that fuel is not entering the cylinder.

Replacing the PISTON on a Husqvarna CPG.

First, you need to check the fuel filter for contamination levels. To check this, you need to remove the fuel hose and check how long the fuel flows.

If it is supplied under low pressure, then the problem lies specifically in the filter.

This is how you need to clean the filter. It is obtained directly through the tank. The filter is cleaned and reinstalled. It is washed under running clean water.

After which the filter is dried and carefully put back. To prevent the occurrence of such a problem later, you need to clean the filter from time to time.

If cleaning the filter does not give a good result, then it is worth noting the breather. A clogged hole in this hole causes insufficient air to enter the carburetor.

With frequent use of a chainsaw, muffler malfunctions occur. Finding this won't be difficult.

If the tool works normally, but when the speed increases, it starts to stall, then the reason is the spark arrester.

In most cases, this element breaks down and therefore becomes clogged with combustion waste. There is an option to solve this problem simply with your own hands.

READ Why the Chainsaw Runs at High Speed

First of all, you need to remove the muffler and disassemble it. Here it is worth considering that in some models spark arresters are not compatible. After this fact, the muffler is cleaned of carbon deposits. For this purpose, special cleaning products are used.

When the carbon deposits are removed, the spark arrestor is dried with a hairdryer. At the final step, the muffler is installed at its destination.

As for the carburetor, there is an option to set it up and repair it yourself. However, in order to carry out such work perfectly, you should know the structure of the carburetor and the principle of its repair.

Quick repair of Husqvarna 137/142. Replacing the oil pump.

Poor repairs result in severe damage to the device. That’s why experts advise setting it up and repairing it in special workshops.

As you can see, some chainsaw malfunctions can be easily removed with your own hands. However, to do this, you need to have certain information. If you do not know your own abilities, then it is better to seek help from specialists.

Watch the video where a specialist carefully indicates the disassembly and assembly process when repairing the Husqvarna 142 chainsaw on your own:

Source

Troubleshooting and DIY repairs

Repairing a Husqvarna chainsaw is complicated by the fact that it requires specific tools that are usually not included in the arsenal of a home craftsman. But all of them can either be bought at an auto parts store or made by yourself.

Chainsaw Husqvarna 142 - technical specifications

In addition to the usual sets of screwdrivers and a hammer, you will need:

- Piston stopper. Can be replaced with a synthetic cord from a starter with knots tied every 2–3 cm.

- Screwdriver for bolt heads on a chainsaw. They can be specific - in the form of semicircles or stars.

- Clutch adjustment key.

- Combination spark plug wrench.

- Compressor for cleaning internal volumes from sawdust, dust and dirt.

If you plan to clean and troubleshoot the cylinder-piston group, you will need a compression measuring device and an adhesive-sealant.

The procedure for disassembling a Husqvarna chainsaw is as follows:

Diagram of a device for checking the ignition of a chainsaw

- the top cover is removed;

- the emergency brake and saw bar with chain are disconnected;

- the starter is removed;

- the candle is unscrewed;

- a piston stopper is installed through the spark plug hole and the flywheel is removed (considerable effort will be required).

After this, the front handle is disconnected, followed by the carburetor, oil pump and lastly the engine.

Troubleshooting the ignition system comes down to replacing failed spark plugs with new ones. Only Champion RCJ7Y spark plugs are used. The ignition coil in Husqvarna chainsaws is electronic, maintenance-free, and if it fails, it is completely replaced, like the starter.

Spark plug Champion RCJ7YThere is no need to adjust the ignition system. The only problem that can be solved by adjustment is setting the gap between the flywheel and the coil. The gap is set using plumbing gauges. The standard value is 0.2 mm.

Setting up the fuel system

The fuel system of Husqvarna chainsaws is complex. At home, it is better not to repair it, as well as service the cylinder-piston group. The maximum malfunction that can be fixed at home is cleaning the breather, eliminating kinks in the hose and replacing the filter. The same applies to the oil system - troubleshooting comes down to cleaning the hole in the breather with a needle or compressed air. It is recommended to do this preventively every 2–6 months, depending on the intensity of saw work.

Chainsaw Husqvarna 142

Carburetor adjustment

The Husqvarna 142 carburetor has 3 adjusting screws, marked H, L and T. The first is designed to set the injection at maximum speed, the second at low speed, the third determines the fuel injection parameters at idle.

Adjusting the carburetor of the Husqvarna 142 chainsaw

First, the idle injection of the fuel mixture is adjusted by turning screw L ¼ turn counterclockwise. If the saw chain moves, the movement is stopped by clamping the screw T. The adjustment is made with visual and auditory control - the motor should not squeal and white smoke should not come out of it. The correct position of the screw is determined empirically.

After this, the chainsaw accelerator is clamped and the injection at high speeds is adjusted using screw H in exactly the same way.

The leakage of excess air into the carburetor is eliminated by replacing the torn hose - the black tube going to the carburetor, or by fitting it more tightly.

How to Assemble a Husqvarna Chainsaw Starter

High-quality DIY chainsaw starter repair

- Common faults

- Starter repair work

- Practical advice

A chainsaw is the main tool with which you can stock up on firewood for a bathhouse or fireplace; you can also use it for construction work on a summer cottage or in a personal home. If all operating conditions are met and preventive measures provided by the manufacturer are followed, the chainsaw can last a long time. Husqvarna 128r cleaning how to repair a chainsaw starter. How to assemble a starter. But over time, small malfunctions may appear that can be dealt with without the help of others. For example, repairing a chainsaw starter with your own hands is entirely possible if you follow the sequence of operations.

Chainsaw starter device: 1 - starter screw, 2 - bushing, 3 - easy start spring, 4 - screw, 5, 6 - starter coil, 7 - deflector, 8 - starter cover, 9 - handle and cord, 10 - screw.

Content

Typical faults

The most common tool failures include the following:

- problems in the ignition system;

- stopping the chainsaw while cutting;

- loss of power during operation;

- wear of certain structural parts of the chainsaw (brake band, drive sprockets, anti-vibration parts);

- obstacles in the fuel supply system;

- starter related problems.

In addition, you need to carry out a visual inspection of the chainsaw before performing work and preventive measures. These include chain lubrication, control of the amount of fuel mixture, and the presence of the required amount of oil.

The spark plug is turned out to check its condition.

Any of the defects is eliminated using our own technology. So, for example, repairing the fuel system of a chainsaw should begin with inspecting the corresponding filter. After that, the correctness of the carburetor adjustment, which is carried out using screws, is inspected. The gaps must be set in strict accordance with the manufacturer's instructions, which must be included with the chainsaw. Repair of the ignition system includes inspection of spark plugs. If heavy carbon deposits, changes in the gap or other visible damage are detected, this element must be replaced.

READ Chainsaw Ignition Adjustment Partner 350

Starter repair work

Tasks in the starter operation may not ensure starting of the tool. In other words, after the cord is pulled, the chainsaw does not start working.

The causes of the malfunction are:

- breakage or crack of the pulley;

- broken spring;

- a gust of the starting cable.

Before repairing the starter, you need to prepare the tools with which to do the work:

Chainsaw starter repair (broken spring)

Routine chainsaw starter

with your own hands.

Replacing the starter spring for Husqvarna 236\240 chainsaw

The process of installing the spring and assembling the starter for Husqvarna chainsaws

(Husqvarna).

Repairing a chainsaw starter, how to repair a chainsaw starter, how to do it. Spring, coil and starter

.

- a set of screwdrivers or a special tool, which is included with the tool by the manufacturer;

- a rope that will be used as a replacement for a broken cord if necessary.

A large amount of black carbon deposits on the spark plug indicates problems with the engine.

Before proceeding directly to repairing the starter and identifying the causes of malfunctions, it is necessary to remove it from the tool body. To do this, you need to unscrew several screws holding the side cover to which the starter is attached. This is done with a screwdriver or a specialized tool.

After the lid is unscrewed, it is turned over and inspected. Next, unscrew the screw that secures the starter. After this, the clamp and spring are dismantled for a smooth start. Now the pulley on which the cord is wound is accessible for removal. How to repair a chainsaw starter. youtube. Once the knot on the rope is undone, it can be pulled out from the pulley and replaced with a new one. Provided that the loss of starter functionality is associated with a break, this may be enough to eliminate the breakdown. However, the remaining parts that make up this element of the chainsaw should be carefully inspected.

READ How to install a spring on a STIHL trimmer starter

When inspecting the starter components, the following malfunctions may be identified:

Most often, damage to the soft start spring occurs at the end where it is visible when disassembling the housing.

- The pulley may be damaged. There may be cracks or tears, or damage to the back. As a result of these problems, the tool cannot perform the job.

- Damage to the soft start spring. In this case, either the spring itself may be mechanically faulty or there may be defects in the place where it is attached. The weakest point of this element is precisely the fastening point and the tip of the spring that is inserted into it.

If faulty or partially damaged starter parts are found, they must be replaced with new ones. In this case, the new elements must correspond to the saw model being repaired.

After completing the repair, you need to properly reassemble the starter.

The pulley is installed on top of the spring. In this case, it is necessary to check how much they adhere to each other. To continue the repair, it is necessary to wind the pulley. This must be done in such a way that when it rotates, it pulls the cord into the starter. It is enough to make 3-4 turns to give the required voltage. First, the rope is threaded through the hole in the lid of the chainsaw.

READ Carburetor Adjustment for Stihl MS 180 Chainsaw

Practical recommendations

You may need to make a few more turns to line up the cord securing holes in the pulley and housing. The new rope is threaded through the technological hole and a loop or knot is made: this will allow it to slip out of the pulley. The rope is moved to the side so that it does not interfere with further work. Next you need to fix the pulley.

First you need to install the soft start spring in place. This is how we repaired the starter of the forester 3816 chainsaw. The breakdown is that the spring of the starter rope winding mechanism. It can be used as before if no damage is found in it. or a new one if replacement is necessary. A starter clamp is installed on top of the spring, which is secured with a special screw. It securely fixes the clamp for a long time, preventing it from skewing and swinging. After this, you need to make several turns of the rope and run it inside. The cover with the assembled starter is installed in place. It is secured using screws.

After completing the repair and assembly, you can begin to work. Repairing the starter yourself does not take much time and does not require complex skills, but it saves time and money if such work is performed in a service center.

It is necessary to approach chainsaw repair responsibly and carry out timely preventive inspections, monitor the quality of the fuel and oil used. These simple manipulations will increase the duration of the tool in working condition.

Source

Specifications

The manufacturer does not skimp on materials and mechanisms for electrical equipment. The chainsaw will become a reliable assistant in the garden, for wood harvesting and processing, for felling trunks with diameters up to 30 cm and in the construction of small private buildings. The device has the following features:

- Area of use: harvesting firewood, forming tree crowns, cutting timber for private construction.

- Short and comfortable tires allow you to work in places that are difficult for professional saws to reach.

- The employee does not require special skills. After studying the instructions, you can start sawing.

Design features of the Husqvarna chainsaw:

- Economical oil and fuel consumption due to stable traction characteristics of the unit.

- Convenient configuration of controls and switching, comfortable work with the tool. Uniform distribution of the weight of the device between the main components of the structure.

- Easy starting is ensured by a manual starter, booster pump and electronic ignition. The device operates in extreme temperatures.

- Effective local vibration damping system.

- Availability of settings for components and assemblies.

- Possibility of using an alternative working headset.

- Forged steel crankshaft. The cylinder liner has a wear-resistant chrome coating.

- 2 compression rings in the piston group, increasing the working life up to 5 years.

- Simplified access to the air filter.

- Reliable Japanese carburetor and durable ignition system.

- An undemanding saw when it comes to gasoline quality.

Technical characteristics of the Husqvarna 142 chainsaw:

- weight - 4.6 kg;

- power - 1.9 kW;

- two-stroke engine with a volume of 40.2 cm³;

- The chainsaw chain has a pitch of 0.325″;

- fuel system tank volume - 0.41 l;

- lubrication system with 0.2 l oil tank.

The model is characterized by a dense layout, convenient access to filling tanks and adjustment units. When performing complex work, the ergonomic shape of the handles provides a secure grip.

Controls are presented to a minimum. These are the switch, the choke position lever and the combination throttle control lever with stopper. Simplicity and minimalism in management are the key to fewer malfunctions.

How to adjust the carburetor of a Husqvarna 142 chainsaw?

If the Husqvarna 142 chainsaw does not start at all, or starts and stalls, then most likely it needs carburetor adjustment. This procedure is performed in the same order as with other chainsaws. However, it should be remembered that due to the design features of the Husqvarna 142 chainsaw, changes in the operation of its motor will not be noticeable immediately, but 5–10 seconds after turning the adjusting screws. Immediately before setting up the carburetor with your own hands, you need to remove the air filter and check it for blockages. If the filter is completely clean, then you need to proceed to adjusting the saw. Setting up the carburetor of the Husqvarna 142 chainsaw is as follows:

- Set the chainsaw to factory settings with the engine turned off - they are indicated in the operating instructions for the tool;

- Start the engine and wait a few minutes;

- Rotate screw “L” clockwise to find the position at which the engine reaches maximum speed. Then turn the screw ¼ turn counterclockwise. If after this the saw chain begins to rotate, then slowly turn the screw “T” until the chain stops moving;

- Next, the engine operation is adjusted at maximum speed. To do this, connect a tachometer to the running saw and squeeze the gas trigger all the way. Look at the tachometer scale - if the device shows more revolutions than the manufacturer recommends, then start turning the “H” screw counterclockwise until the tachometer shows the normal number of revolutions.

Adjusting the carburetor of the Husqvarna 142 chainsaw with your own hands

In order for the 142nd model of the Husqvarna brand to work properly, its owner must promptly adjust the chainsaw carburetor.

This should be done in the following cases:

- if the Husqvarna 142 chainsaw does not start;

- if the engine starts but runs intermittently;

- if the engine starts and stalls when you press the gas trigger;

- if fuel consumption increases sharply.

All these malfunctions threaten more serious breakdowns, which will be quite difficult to cope with on your own and without the necessary experience. To prevent this, you need to adjust the element responsible for enriching the fuel mixture with air. Setting up the carburetor of the Husqvarna 142 chainsaw should be done in the following sequence:

- First you need to set the Husqvarna chainsaw carburetor to factory settings. To do this, with a cold engine, you need to turn the adjusting screws as indicated in the model’s operating manual;

- After this, you need to start the saw motor and give it 5 minutes to warm up completely. After this, you need to slowly turn the screw “L” until the engine starts to operate at maximum idle speed. Immediately after this, screw “L” must be turned out 1/4 turn in the opposite direction;

- If the chain on the bar then rotates, the operator will need to begin turning the "T" bolt one at a time until the chain stops;

- Next you need to find the maximum engine speed. To do this, you need to hold the gas trigger and start turning the “H” bolt until the engine begins to operate stably at high speeds. After this, screw “H” must be turned out 1/4 turn in the opposite direction.

After adjusting the carburetor, you need to turn off the Husqvarna chainsaw engine and start it again. To check engine operation, the operator must press the throttle trigger sharply several times. If, when the trigger is pressed, the engine quickly gains speed and loses it when the trigger is released, then the adjustment of the standard carburetor was carried out successfully by the operator.

Adjustment options

For the Husqvarna 142 chainsaw, fuel adjustment and chain tension adjustment are available. As with most chainsaws, tension is achieved using an adjustment screw; The end criterion is that the chain does not sag and, at the same time, moves easily along the tire. Carburetor adjustment is required when weather conditions and fuel quality change. The symptoms for which it is necessary are the following: the chain spins at idle, the chainsaw stalls when you press the gas, does not develop speed, and greatly slows down when cutting. If you need to adjust a chainsaw, we recommend reading our article on how to adjust a Husqvarna carburetor, which details all the nuances of adjusting Husqvarna saws, and also check out this

How to fix a chainsaw

The measures necessary to restore proper operation of the saw, no matter whether you have a Ural or any other model, depend on the location of the problem.

Please note that not everything you can fix with your own hands - if the breakdown is serious, you will have to take the saw to a specialist.

If you have done the first step - checked and corrected the quality of the oil, but the device still does not work, then you can move on.

If the problem is in the candle, then it is also quite simple to solve - you need to unscrew and dry the candle, but do not pierce it, because... this will render the candle unusable.

Excess fuel that is inside should be drained through the hole. You need to dry the candle for at least half an hour, then insert it back and try to start the tool again.

In addition to filling, it may be that the candle has simply become unusable.

In this case, it’s a good idea to have a spare part (or better yet, a set) to replace this element and eliminate it from the possible causes of device failure.

In addition to the spark plug itself, the reason why the chainsaw is difficult to start when hot or stalls may be poor contact connecting the end of the spark plug and the high-voltage wire.

If there is nothing wrong with this area, but there is still no spark, the ignition unit may be broken. It cannot be fixed - you will have to replace it with a new one.

From time to time you have to clean the air filters in chainsaws. If you have never done this before, then the reason for the tool failure may be that it is clogged with dust.

If you have a Shtil 180, Partner 350 or Ural chainsaw, check the saloon first. A common reason for the incorrect operation of these models is its clogging.

You can clean the saloon using a sewing needle - there is nothing complicated about it.

Another point that sometimes worries owners of Shtil 180 chainsaws is frequent idling after the first tanks of gasoline are used up. However, according to experts, this is not a problem at all.

But if the phenomenon still bothers you, then you can use the carburetor screw to reduce the engine speed.

The video below shows how a Shtil chainsaw is repaired.

You can also clean the muffler yourself - this is a problem not only for Shtil 180 or Husqvarna 142 chainsaws. Domestic Druzhba and Ural can also stall due to this problem.

The problem with poor performance of chainsaws often lies in the carburetor, but it may not be possible to repair it yourself without experience in this matter.

Therefore, if you have not done this before, take your saw to the specialists. Trying to save now, you may end up paying many times more if you accidentally damage some important part.

If you have done all of the above and the problem is still not resolved and your chainsaw stalls or does not start, then the problem may lie in the cylinder group.

If chips and damage are found on the cylinder or piston assemblies, then these elements will have to be replaced or the cylinder will have to be bored out for a new piston of a suitable size.

If you inspect the chainsaw tubes and see that they are leaking, this means that the problem with your chainsaw is insufficient lubrication of the chain.

To fix this problem, you need to replace the tubes and carefully seal the places where they connect with sealant.

It may also be that the parts with which your saw is equipped have expired. In this case, you will have to replace them with new ones.

You can see the service life of the components in the instructions.

Shtil 180 is one of the most common models of chainsaws, so let’s talk about its problems in more detail.

The most common reason why a Shtil 180 model saw does not start or stalls is that the carburetor is clogged. In this case, it will have to be cleaned. The second most common problem is a clogged fuel filter.

If it malfunctions, it will have to be replaced.

Replacing the spark plug is also a common solution to problems with the 180.

Also look at the condition of the pistons - perhaps they, as well as the cylinder and seals, need to be replaced.

In general, the Shtil 180 model is quite durable and, most likely, if it does not start or stalls, then the problems with it are not too serious and you can fix them yourself.

The video below shows the repair of a Ural chainsaw carburetor.

Almost the same can be advised regarding the Partner 350 and Husqvarna 142, Ural, Makita models.

First of all, check the air filter - it could be clogged with sawdust and other debris. Then inspect the carburetor (in the Partner 350 it is located in the same place as the spark plug).

The main advice in repairing a chainsaw with your own hands is not to do what you don’t know how to do, because... this can only make the situation worse.

If the chainsaw does not start, stalls or does not work well, then first check the simplest and most easily accessible elements: perhaps the oil was chosen incorrectly, or it is flooding the spark plug, the filter is clogged, or the pipes have begun to leak.

All these problems can be easily fixed with your own hands.

In case of serious damage, if you do not have the necessary qualifications, it is better not to try to repair it yourself and entrust the work to a specialist.

In any case, fixing the breakdown, even with someone else’s hands, will cost you less than a new model.

Don’t forget to also check the instructions for the tool and promptly replace all the parts responsible for its operation.

This will help you not to rack your brains over why the tool stopped working and not waste time disassembling and checking it.

If you still cannot do without repairs, then before starting work, watch a video on how to disassemble and repair a chainsaw - it will help you.